Material Properties_V127 AMS3353 (FKM)x - Simrit

Material Properties_V127 AMS3353 (FKM)x - Simrit

Material Properties_V127 AMS3353 (FKM)x - Simrit

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

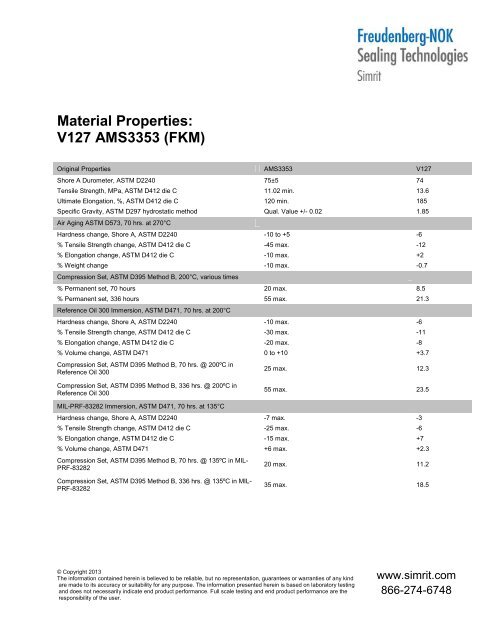

<strong>Material</strong> <strong>Properties</strong>:<strong>V127</strong> <strong>AMS3353</strong> (<strong>FKM</strong>)Original <strong>Properties</strong> <strong>AMS3353</strong> <strong>V127</strong>Shore A Durometer, ASTM D2240 75±5 74Tensile Strength, MPa, ASTM D412 die C 11.02 min. 13.6Ultimate Elongation, %, ASTM D412 die C 120 min. 185Specific Gravity, ASTM D297 hydrostatic method Qual. Value +/- 0.02 1.85Air Aging ASTM D573, 70 hrs. at 270°CHardness change, Shore A, ASTM D2240 -10 to +5 -6% Tensile Strength change, ASTM D412 die C -45 max. -12% Elongation change, ASTM D412 die C -10 max. +2% Weight change -10 max. -0.7Compression Set, ASTM D395 Method B, 200°C, various times% Permanent set, 70 hours 20 max. 8.5% Permanent set, 336 hours 55 max. 21.3Reference Oil 300 Immersion, ASTM D471, 70 hrs. at 200°CHardness change, Shore A, ASTM D2240 -10 max. -6% Tensile Strength change, ASTM D412 die C -30 max. -11% Elongation change, ASTM D412 die C -20 max. -8% Volume change, ASTM D471 0 to +10 +3.7Compression Set, ASTM D395 Method B, 70 hrs. @ 200ºC inReference Oil 30025 max. 12.3Compression Set, ASTM D395 Method B, 336 hrs. @ 200ºC inReference Oil 30055 max. 23.5MIL-PRF-83282 Immersion, ASTM D471, 70 hrs. at 135°CHardness change, Shore A, ASTM D2240 -7 max. -3% Tensile Strength change, ASTM D412 die C -25 max. -6% Elongation change, ASTM D412 die C -15 max. +7% Volume change, ASTM D471 +6 max. +2.3Compression Set, ASTM D395 Method B, 70 hrs. @ 135ºC in MIL-PRF-8328220 max. 11.2Compression Set, ASTM D395 Method B, 336 hrs. @ 135ºC in MIL-PRF-8328235 max. 18.5© Copyright 2013The information contained herein is believed to be reliable, but no representation, guarantees or warranties of any kindare made to its accuracy or suitability for any purpose. The information presented herein is based on laboratory testingand does not necessarily indicate end product performance. Full scale testing and end product performance are theresponsibility of the user.www.simrit.com866-274-6748

ASTM Fuel B Immersion, ASTM D471 and ASTM D1414, 70 hrs. at 25°CHardness change, Shore A, ASTM D2240 -10 max. -4% Tensile Strength change, ASTM D412 die C -35 max. -15% Elongation change, ASTM D412 die C -20 max. -8% Volume change, ASTM D471 +1 to +10 +4.1Low Temperature Glass Transition Temperature, ASTM D3418DSC Tg, C, midpoint -40 or colder -42Low Temperature Retraction, ASTM D1329TR-10, degrees C -38.3 or colder -40© Copyright 2013The information contained herein is believed to be reliable, but no representation, guarantees or warranties of any kindare made to its accuracy or suitability for any purpose. The information presented herein is based on laboratory testingand does not necessarily indicate end product performance. Full scale testing and end product performance are theresponsibility of the user.www.simrit.com866-274-6748