Submersible Sewage Pumps Wilo FA Series

Submersible Sewage Pumps Wilo FA Series

Submersible Sewage Pumps Wilo FA Series

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

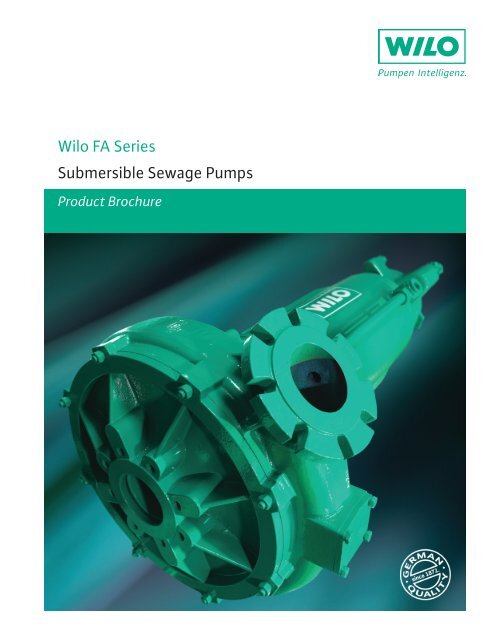

<strong>Wilo</strong> <strong>FA</strong> <strong>Series</strong><strong>Submersible</strong> <strong>Sewage</strong> <strong>Pumps</strong>Product BrochureProduct Brochure

<strong>Wilo</strong> MotorsFK, HC, FKT, & T MotorsFK MotorsWet Sump Installation»»Low costs for lift station and assembly»»Low space requirement for the pumps»» Service-friendly installation and removalthanks to suspension device»»Motor is cooled by the pumped mediaFK motors feature an oil-filled motor chamber. Bymeans of an internal oil circulation cooling system,the heat produced by the motor is dissipated to thepumped media via a heat exchanger. The type FK 17.1of this series is available in explosion-proof design.Advantages:»»Continuous operation in wet and dry sumpinstallation»»Draining wet well to very low level is possible»»Cooling independent of the type of pumpedmedia»»Room ventilation not necessary in the event ofdry sump installation»»Sump volume can be reduced, resulting in lowerconstruction costsHC MotorsDry Sump Installation»»Accessible pump chamber»»»»» Pump can be monitored during operation» Quick repairs under hygienic conditions» Pump remains in operation in case of flooding» Internal cooling system, external cooling notrequiredHC motors are air filled with a closed loop water/glycol cooling system. The heat of the motor isdissipated to the pumped liquid by the coolingliquid - driven by a magnetic coupling – by meansof a highly efficient heat exchanger. This series isavailable in explosion-proof design.Advantages:»»2-chamber system – therefore control of bothmechanical shaft seals possible»»Separate leakage chamber, high processsecurity»»Cooling system hermetically sealed, nopenetration and leakage of liquid possible»»Same advantages as the FK-motorFKT MotorsFKT motors are air filled with a closed loop water/glycolor oil cooling system. The motor heat is dissipated tothe pumped media via a heat exchanger.Advantages:»»Continuous operation in wet and dry sumpinstallation»»Draining pump sump to very low level is possible»»Cooling independent of the type of pumpedmedia»»Room ventilation not required in the event of drysump installation»»Sump volume can be reduced, resulting in lowerconstruction costs»»Most available in explosion proof designT MotorsTransportable Installation»»Deep, narrow shafts»»Shallow basins»»»»Sewer renewal» Dewatering on construction sites» Industrial and municipal sewage disposalAir filled T motors are cooled when submerged inthe surrounding pumped media. Here, the motorwaste heat is emitted directly via the casing, tothe pumped medium. The types of this series areavailable in explosion-proof design.Advantages:»»Competitive solution»»Separate cooling system not required*More details available upon request

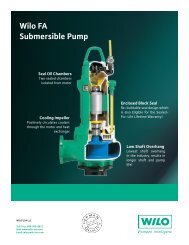

<strong>Wilo</strong> ImpellersModular system impellersModular System»»Multiple combinations of pump ends and motorsto fulfill the requirements of each project.<strong>Wilo</strong> Block SealSingle-Channel Impeller»»Low to medium capacity at medium to high heads»»Raw unscreened sewage and dewateringapplications»»Return and Waste Activated Sludges and recycledsludge with up to 8% solidsMechanical shaft seals of high wear-resistant siliconcarbideat the motor and pumpside integrated in a stainlesssteel cartridgeHigh wear and corrosion resistanceHigh operation safetyLong working life»»Operation not dependent on the direction of rotationMulti-Channel Impeller»»Raw unscreened sewage of larger pumps»»Screened wastewater and sludges, storm waterand drainage applications.Special MaterialsVortex-Type System»»Raw unscreened sewage and dewateringapplications»»Raw and digested sludges with up to 8% solids»»Best in solids passage and abrasive duty»»Wear-resistant materials andcoatings»»Corrosion-resistant materials andcoatings»»Ceram coatingsPropeller-Type System»»High capacity at low heads»»Storm water, irrigation and well screenedwastewater»»Return sludge and recycle of activated sludge inwastewater treatment plantsSpecial Designs»»Mechanical mixing head»»Grinder pumps»»Cast stainless steel

<strong>Wilo</strong> <strong>FA</strong> <strong>Series</strong>Sumbersible <strong>Sewage</strong> <strong>Pumps</strong>Applications Include:»»<strong>Sewage</strong> Collection »»Storm Water »»Raw Water»»<strong>Sewage</strong> Treatment »»Dewatering »»Industry<strong>Wilo</strong> <strong>FA</strong> <strong>Series</strong>500400Range of <strong>Sewage</strong>pumps 60 Hz30012“2004“H(feet)1003“6“14“20“24“5010“16“402“308“201020 40 60 80 100 200 400 600 800 100010 Q (US-GPM) 2000 4000 6000 8000 10000 20000 30000All <strong>FA</strong> pumps are shippedfrom our manufacturingfacility in Thomasville, GA.WILO USA LLCToll-Free: 888-945-6872Web: www.wilo-usa.comEmail: info@wilo-usa.comWILO Canada Inc.Toll-Free: 888-945-6236Web: www.wilo-canada.comEmail: info@wilo-canada.com10-27-001-1111