PowerCut® - ESAB Welding & Cutting Products

PowerCut® - ESAB Welding & Cutting Products

PowerCut® - ESAB Welding & Cutting Products

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

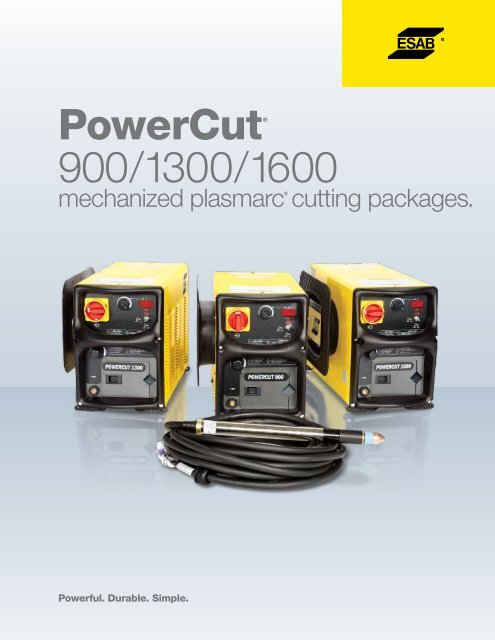

PowerCut®900/1300/1600®mechanized plasmarccutting packages.Powerful. Durable. Simple.

Powerful,durable,simple.The PowerCut plasma cutting package willtake whatever you throw at it, and ask formore. Designed with <strong>ESAB</strong> Plasmarc technology,PowerCut machines are more powerful anddurable than any other machine in their class.They also make plasma cutting easier andmore economical – delivering reliability, highproduction, and a wide variety of performancefeatures. With design features that simplifyoperation, reduce set-up time, and enhanceconsumable life, PowerCut packages let youspend less time troubleshooting and more timecutting. And with the addition of the PowerCut900 to the family, the most rugged machines inthe industry are more versatile and accessiblethan ever.PowerCut gives you:n Powerful performance – PowerCut offers the highestspeeds and thickness capabilities in its price class,as well as high duty cycle ratings, for outstandingproductivity and performancen Powerful economy – through a combination of longpart life, high speeds, and simple torch design, thePowerCut series offers the lowest cost per foot of cutof any machine in its price classn Powerful durability – these robust cutters stand upto rugged treatment and outdoor use, plus cut up to1 1 ⁄2 inch metal with easen Powerful ease of operation – with features suchas the tool-less quick disconnect torch and a digitalreadout display, the PowerCut family is easy to setup and operate, increasing productivity andreducing downtimePowerCut Features:n Rugged design – PowerCut’s external housingdesign is durable, damage-resistant, corrosionresistant,and weather-resistant, while remaininglightweight for portability n Tool-less quick disconnect torch – disconnects fromthe machine without the use of wrenches or specialtools. Now you can easily disconnect your PT-38 torchfor storage, repairs, or replacement, or to attach a PT-37mechanized torch for mechanized applications.n Digital readout display – easy to read and shows theexact pressure or amperage, so you can operate withconfidence. The display also shows help codes toassist in troubleshooting minor errors, reducing downtime.n Input voltage selector switch – conveniently locatedon the back of the machine, lets you easily changeinput voltage from 208-460 (1300 and 1600 models only)n Blowback technology – eliminates high-frequencystartups that can disrupt CNC controls and nearbycomputer systemsn Auto-modes (gouge, grate, and normal modes) –switch between modes automatically, tailoring yourapplication without manually changing settings onthe consolen Isolated electronics – sensitive internal electronics areisolated from the cooling air flow diminishing exposureto airborne particulate

Rugged steel caseLED readoutStandard torchwrap and spareparts kit holderHelp codesGlass-reinforcednylonhandles/guardsTool-less quickdisconnectHeavy-dutyrubber feetFront-mountedpressure-adjustingknobPT-37 Mechanized cut speedsCarbon SteelPT-37 Cut Speeds (Minimum)Mild SteelPT-37 Mechanized cut speedsStainless SteelPT-37 Cut Speeds (Minimum)Stainless SteelPT-37 Mechanized cut speedsAluminumPT-37 Cut Speeds (Minimum)AluminumCut speed in inches (Millimeters)600(15240)PowerCut 1600500(12700)PowerCut 1300PowerCut 900400(10160)Cut Speed in inches (Millimeters)300(7620)200(3810)100(2540)00.00 0.25 0.50 0.75 1.00 1.25 1.50 1.75(6.4) (12.7) (19.1) (25.4) (31.8) (38.1)Thickness in inches (Millimeters)Cut speed (in inches (Millimeters)Cut Speed in inches (Millimeters)450(11430)400PowerCut 1600(10160)PowerCut 1300350(8890)PowerCut 900300(7620)250(6350)200(5080)150(3810)100(2540)50(1270)00.00 0.25 0.50 0.75 1.00 1.25 1.50 1.75(6.4) (12.7) (19.1) (25.4) (31.8) (38.1)Thickness in inches (Millimeters)Cut speed in inches (Millimeters)450(11430)400(10160)PowerCut 1600350(8890)PowerCut 1300Cut Speed in inches (Millimeters)300PowerCut 900(7620)250(6350)200(5080)150(3810)100(2540)50(1270)00.00 0.25 0.50 0.75 1.00 1.25 1.50 1.75(6.4) (12.7) (19.1) (25.4) (31.8) (38.1)Thickness in inches (Millimeters)Thickness in inches (Millimeters)Data collected using standardconsumables and 80 psi AirThickness in inches (Millimeters)Data collected using standardconsumables and 80 psi AirThickness in inches (Millimeters)Data collected using standardconsumables and 80 psi Air+ + nSealed switches – silicone-sealed switches areimmune to corrosion, as well as dust and dirt infiltration+ + nGouging capability – PowerCut delivers the extraoutput voltage needed for superior plasma gougingcapability+ + n Automatic fan control – the cooling fan is automaticallycontrolled to run only when necessary, to conserveenergy and reduce ingested dust and dirt+ + n Built-in power line conditioner – protects againstdamage from power line noise and spikes, evenwith poor-quality power+ ++ + n Torch wrap and spare parts kit holder – now standardon all packages, the holder lets you neatly fold upexcess torch cables for convenient storage in yourconsumable box+ + n Plug-n-play mechanized option – lets you easilytransform your manual cutting system into a powerfulmechanized system for your gantry machine+ + n Optional five-year warranty – PowerCut packagescome with a three-year warranty and an option topurchase an extended warranty for a total of five years

Plasma offers Precision,Versatility and Value<strong>ESAB</strong> invented plasma cutting in 1955, and since thenwe’ve never stopped supplying our customers with theindustry’s most advanced plasma cutting solutions.Plasma efficiently cuts both ferrous and non-ferrousmetals quickly and accurately, offering a customerhigher production and quality cutting solutions whencompared to it’s oxyfuel counterpart. With just shopair, plasma’s more versatile cutting capability offers afabricator maximum flexibility at minimal costs.Advantages of PlasmaBetter Cut Quality and Speedn Excellent cut edge quality with low angularityn Smaller heat effected zonenEasier process to control to maintain cut consistencyLower Cost per PartnVirtually dross free cuts requiring minimal clean upnNo preheat time provides very fast piercingnMuch faster cutting speedsnUses only compressed air vs. oxygen and fuel gasnSafer processnLong consumable life further provides lowerproduction costsHigh VersatilitynCuts any material that conducts electricity (stainlesssteel, aluminum, carbon steel and other alloys)nFine feature cutting capability eliminates somework-in-process stepsPlasma can be defined as an electrically heated gas stream.The gas stream is heated to such high temperature that itbecomes ionized. The ionized gas by definition can then freelyexchange electrons between atoms. This electron movement iswhat allows the gas to carry the cutting amperage and providetremendous cutting potential.Lower Costs Across the BoardWith over 50 years of experience producing manualand mechanized plasma cutting systems, <strong>ESAB</strong> isunsurpassed when it comes to reducing operationcosts. In addition to attractive pricing, plasma nozzlesand electrodes are designed for long life. Also, <strong>ESAB</strong>offers simplified torch designs that significantlyreduces wear on the other parts as well as the quantityof other parts that need replacing.Air Plasma vs. OxyfuelCut SpeedsAir Plasma vs. OxyfuelCut Costs / Meter400(10,160)350(8,890)300(7,620)OxyfuelAir PlasmaO 2Plasma7.006.005.0040 Amps50 Amps70 Amps100 AmpsOxyfuel250(6,350)4.00Cut Speed in Inches (Millimeters)200(5,080)150(3,810)100(2,540)50(1,270)0 0 .25 .5 .75 1 1.25 1.5(6.4) (12.7) (19.1) (25.4) (31.8) (38.1)Relative Cost / Meter3.002.001.000.00Thickness in inches (Millimeters)Costs associated with cutting .25” Carbon Steel

PowerCut family line.PowerCut 900Manual cut capacityn Cuts 7/8 in (22 mm)n Severs 1¼ in (32 mm)Mechanized pierce capacityn Maximum 1/2 in (13 mm)PowerCut 1300Manual cut capacityn Cuts 1¼ in (32 mm)n Severs 1½ in (38 mm)Mechanized pierce capacityn Maximum 5/8 in (16 mm)PowerCut 1600Manual cut capacityn Cuts 1½ in (38 mm)n Severs 1¾ in (44 mm)Mechanized pierce capacityn Maximum 3/4 in (19 mm)

PT-38 Assembly.Big facetorch triggerErgonomichandlePatented designelectrode0558005220Molded strainreliefUnbreakablestandard heat shield0558007549PT-38 blowback torchPointed nozzle60A – 055800841770A – 055800521990A – 0558007680Insulator30-70A – 055800521790A – 0558004870Torch Features:n Ergonomic handle for operator comfortn Big face switch maximizes convenience whenwearing welder’s gloves. New blowback technologyn Easily repairable in the fieldn Minimum part configurationsn Molded strain relief for secure torch leadsPT-37 Assembly.Torch Features:n 100% duty cycle for enhanced productivityand continuous operationn Machined torch body with 1 in (34.9 mm)metal handlen Copper shield for optimum longevityPointed nozzle30A – 055800521850A – 055800487860A - 055800841770A – 055800521990A – 0558007680100A – 0558004879Nozzle retainer0558006600Copper shield30-40A – 055800660350-90A – 0558006602100A – 0558006601Insulator30-70A – 055800521790-100A – 0558004870Patented design electrodeextended life – 0558004875standard – 0558005220

Accessories.The PowerCut cart (0558007898)This convenient cart features large rear wheels to easily transport your PowerCutaround the shop. Its tilted configuration allows for easy viewing of the front display.The cart also provides extra cable wraps for your ground clamp and input cable.Heavy-duty water separator (0558007897)The heavy-duty water separator protects your machine by filtering dirt and moisturefrom severely contaminated lines. The separator comes ready to install on the backof your PowerCut.Remote hand switch (25’ – 0558008349, 50’ – 0558009277)This convenient remote switch allows you to easily start and stop your cuttingprocess in a mechanized application. This switch is for use only on non-CNCcontrolled cutting applications.Plug-n-play mechanized kit (900 – 0558008284, 1300/1600 – 0558007885)Connect your PowerCut machine directly to a CNC controlled cutting table formechanized applications. This easy-to-use kit allows you to convert your manualsystem to a fully operable CNC cutting system.Spare parts kit (60A – 0558008418, 70A – 0558007641, 90A – 0558007639)Available for the PowerCut 900, 1300, and 1600, spare parts kits provideeverything you need to keep your torch running. The package is less expensivethan buying each part individually.Gas flow measuring kit (19765, CE – 0558000739)Allows measurement of actual plasma gas flow through torch.Torch holder assembly (0558005926)Manually adjustable torch holder with hand wheel. Handles 1 3/8” diameter torchbarrels with a 32 pitch rack.