crystalline - stangl.de

crystalline - stangl.de

crystalline - stangl.de

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

[news]<br />

NEWS MAGAZINE FOR OUR BUSINESS FRIENDS<br />

ISSUE 34 MAY 2007<br />

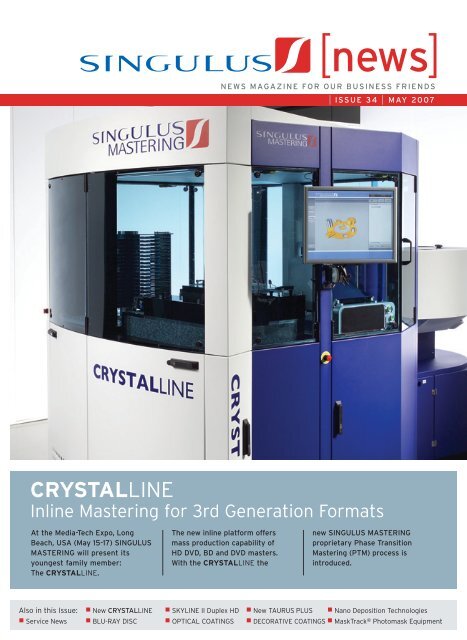

CRYSTALLINE<br />

Inline Mastering for 3rd Generation Formats<br />

At the Media-Tech Expo, Long<br />

Beach, USA (May 15-17) SINGULUS<br />

MASTERING will present its<br />

youngest family member:<br />

The CRYSTALLINE.<br />

The new inline platform offers<br />

mass production capability of<br />

HD DVD, BD and DVD masters.<br />

With the CRYSTALLINE the<br />

new SINGULUS MASTERING<br />

proprietary Phase Transition<br />

Mastering (PTM) process is<br />

introduced.<br />

Also in this Issue: � New CRYSTALLINE � SKYLINE II Duplex HD � New TAURUS PLUS � Nano Deposition Technologies<br />

� Service News � BLU-RAY DISC � OPTICAL COATINGS � DECORATIVE COATINGS � MaskTrack ® Photomask Equipment

page 2<br />

[News Optical Disc] | ISSUE 34 | MAY 2007<br />

CRYSTALLINE: Inline<br />

The CRYSTALLINE system is a fully<br />

automated inline mastering platform, based<br />

on the “fresh glass substrate in – finished<br />

master out” principle. The system is a Class<br />

100 cleanroom in itself in with all process<br />

stations integrated, thereby avoiding<br />

the construction of a real and expensive<br />

clean room.<br />

The robot disc handler at the center of the<br />

system has proven its speed, flexibility and<br />

reliability in the semiconductor industry.<br />

Running the system in unatten<strong>de</strong>d mo<strong>de</strong> and<br />

also anticipating higher recording speeds,<br />

the CRYSTALLINE is equipped with a<br />

substrate warehouse.<br />

Dynamic mo<strong>de</strong>ling and simulation have been<br />

applied for the mechanical <strong>de</strong>sign of the new<br />

Laser Beam Recor<strong>de</strong>r (LBR). Fundamental<br />

new principles inclu<strong>de</strong> the implementation<br />

of a new ultra-precise translation system,<br />

consisting of a linear motor, an optical scale<br />

(1 nm resolution) and servo-control, and the<br />

Learning Feed Forward Focus control.

CRYSTALLINE: PTM<br />

Phase Transition Mastering<br />

Essentially new in the recording of a PTM<br />

layer is that heat is induced to the sensitive<br />

layer of the substrate. In the photoresist<br />

process the sensitive layer is only exposed<br />

by the laser. Heating of the PTM layer is done<br />

with the same 405 nm dio<strong>de</strong> laser dio<strong>de</strong> that<br />

has been successfully used for many years<br />

for CD / DVD mastering with photoresist.<br />

The CRYSTALLINE platform contains a<br />

“single chamber – three target” sputtering<br />

unit <strong>de</strong>veloped by SINGULUS TECHNOLOGIES,<br />

known as the specialist in the <strong>de</strong>velopment<br />

of sputtering technologies. The PTM<br />

sputtering module applies the SINGULUS’<br />

SmartCatho<strong>de</strong> ® principle to obtain maximum<br />

layer thickness uniformity.<br />

CRYSTALLINE: Multi-format:<br />

HD DVD, BD & DVD<br />

The CRYSTALLINE is primarily <strong>de</strong>signed<br />

for HD DVD and BD mastering, offering maximum<br />

flexibility in<strong>de</strong>pen<strong>de</strong>nt of which format<br />

is required to serve the market. The DVD format<br />

can be mastered as well enabling a<br />

smooth transition into the new generation<br />

formats with a ramping up <strong>de</strong>mand.<br />

The CRYSTALLINE will be officially<br />

unveiled on Monday, May 14, 5.00 pm at the<br />

Long Beach Convention Center.<br />

DVD<br />

0.5<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

µm<br />

x: 0.500 µm/div<br />

z: 250.000 nm/div<br />

HD DVD<br />

0.5<br />

1.0<br />

1.5<br />

2.0<br />

2.5<br />

µm<br />

Contact:<br />

SINGULUS MASTERING B.V.<br />

Marinus v. Meelweg 2<br />

5657 EN Eindhoven, The Netherlands<br />

Phone: +31-40 7501-400<br />

Fax: +31-40 7501-409<br />

E-Mail: info@singulus.nl<br />

www.singulus.nl<br />

x: 0.500 µm/div<br />

z: 250.000 nm/div<br />

[News Optical Disc]<br />

BD<br />

0.5<br />

1.0<br />

1.5<br />

2.0<br />

µm<br />

x: 0.500 µm/div<br />

z: 250.000 nm/div<br />

page 3

page 4 [News Optical Disc] | ISSUE 34 | MAY 2007<br />

Blu-ray Disc<br />

Dual layer Technology<br />

To give the Blu-ray Disc a large capacity<br />

capability, SINGULUS cooperates with Sony<br />

DADC, Salzburg, in further <strong>de</strong>veloping the<br />

production technology for the mass production<br />

of Blu-ray dual layer Discs with a storage<br />

capacity of 50 GB. The good cooperation with<br />

Sony DADC offers SINGULUS a big opportunity<br />

to establish itself even faster in the market<br />

for the new disc formats as the leading partner<br />

of the Hollywood studios <strong>de</strong>mand and to<br />

gain enormous competitive advantages.<br />

SINGULUS will launch the wet-embossing<br />

based dual layer module later this year and<br />

give all customers the option to upgra<strong>de</strong><br />

their installed BLU-LINE to dual layer media.<br />

SINGULUS BLU-LINE<br />

The Solution for BD 50<br />

The BLU-LINE from SINGULUS with a flexible<br />

machine size and modular arrangement of<br />

process modules allows the media manufacturer<br />

to customize the system for the inhouse<br />

process requirements. The procedure<br />

for upgrading a single layer BLU-LINE into a<br />

dual layer production line is easy and fast.<br />

SINGULUS TECHNOLOGIES has prepared a<br />

system which inclu<strong>de</strong>s substrate molding,<br />

layer 0 metallization, high accurate spacerlayer<br />

application, layer 1 wet-embossing,<br />

layer 1 metallization, cover-layer application,<br />

hard-coating, label-si<strong>de</strong>-coating and final<br />

inspection. The arrangement of the dual<br />

layer module is specially adjusted for the<br />

best and most cost efficient process to<br />

manufacture a dual layer disc. The BLU-LINE<br />

does inclu<strong>de</strong> 2 different size systems from<br />

a 25GB single layer to a 50GB dual layer<br />

process. With this broad program we handle<br />

any Blu-ray Disc <strong>de</strong>mand, starting from<br />

process <strong>de</strong>velopment up to robust and high<br />

pace production of all Blu-ray media.<br />

Embossing Processes – L1 stamper Embossing Processes – L1 replicated<br />

Cover-Layer uniformity 75µm < ± 2µm<br />

Spacer-Layer uniformity 2µm + 23µm < ± 1µm

TAURUS PLUS Production Line for all Recordable<br />

Formats<br />

The HamaTech TAURUS PLUS is a new<br />

generation disc replication system for the<br />

production of recordable CD and DVD (CD-R<br />

and DVDR) as well as HD DVD-R discs.<br />

The <strong>de</strong>sign is based on thirteen years of<br />

experience with HamaTech’s CD-R and DVDR<br />

programs. The TAURUS family of products<br />

continues this successful story.<br />

TAURUS PLUS<br />

The HamaTech TAURUS PLUS is an innovative<br />

replication line, <strong>de</strong>dicated for mass<br />

production of CD-R and DVDR on the same<br />

production platform. The key features are:<br />

� High quality CD-R and DVDR production<br />

on the same line<br />

� CD-R production at 1.6 sec cycle time<br />

� DVDR production at 1.8 sec cycle time<br />

� Standard 2 IMM interface, 3rd IMM Interface<br />

optionally available<br />

� Easy CD-R to DVDR line conversion<br />

� OEM customer proven high quality system<br />

and components<br />

With all options and following the optimized<br />

setup, the TAURUS PLUS allows for:<br />

CDR production with up to three injection<br />

molding machines that results in typical<br />

output values of:<br />

� more than 45.000 good CD-R/24hrs<br />

(OEM quality level) and<br />

HamaTech Service<br />

The major project for SINGULUS Service<br />

this year has been the integration of the<br />

HamaTech customer support into the<br />

SINGULUS Business Unit Customer Service.<br />

The incorporation of HamaTech spare parts<br />

into SINGULUS headquarters’ stock and data<br />

system is 90 % accomplished. A systematic<br />

approach was necessary to integrate 12,000<br />

HamaTech parts into an existing stock<br />

volume of 30,000 parts at SINGULUS.<br />

� more than 50.000 sellable CD-R/24hrs.<br />

DVDR manufacturing with up to two injection<br />

molding machines that result in typical<br />

output values of:<br />

� more than 28.000 good DVDR/24hrs<br />

(OEM quality level) and<br />

� more than 30.000 sellable DVDR/24hrs.<br />

The TAURUS PLUS machine is a “future-proof”<br />

system for recordable markets who <strong>de</strong>mand<br />

the flexibility of swapping production capacity<br />

from CD-R to DVDR without compromising<br />

the OEM quality level of each product.<br />

Roberto Calleja, Head of Business Unit<br />

Customer Service, said: "This was and still is<br />

a real challenge which the entire Service<br />

staff has embraced with great enthusiasm.<br />

We are pleased to be able to offer Service out<br />

of one central location." SINGULUS Service is<br />

able to provi<strong>de</strong> technical and hotline service<br />

to SINGULUS and HamaTech customers!<br />

[News Optical Disc]<br />

With its high level of process stability, the<br />

TAURUS platform is the leading system for<br />

recordable manufacturing.<br />

Contact:<br />

HamaTech AG<br />

c/o: SINGULUS TECHNOLOGIES AG<br />

Hanauer Landstrasse 103<br />

63796 Kahl am Main, Germany<br />

Phone: +49 61 88/4 40-0<br />

Fax: +49 61 88/4 40-110<br />

E-mail: sales@singulus.<strong>de</strong><br />

As a special service, SINGULUS now offers its<br />

customers a 24 hours, 7 days Help Desk for<br />

all technical related questions.<br />

24/7 HAMATECH<br />

HELP DESK<br />

+49 7045 41 911<br />

Open 24 hours!<br />

page 5

page 6<br />

[News Optical Disc] | ISSUE 34 | MAY 2007<br />

SKYLINE II Duplex HD<br />

Now ready for Single Layer HD DVD Production<br />

Together with SPACELINE II a Complete Family<br />

of Production Lines for All Single and Dual Layer<br />

DVD & HD DVD Formats<br />

As the leading equipment supplier for CD and<br />

DVD formats with a global market share of<br />

more than 65 % the Kahl am Main-based<br />

SINGULUS TECHNOLOGIES is proud to<br />

present a further enlargement of its product<br />

portfolio.<br />

The new SKYLINE II Duplex HD – originally<br />

<strong>de</strong>signed for CD and DVD 5 media replication<br />

- is now able to manufacture in addition HD<br />

DVD single layer formats. In combination with<br />

the SPACELINE II – the benchmark in Dual<br />

Layer DVD and HD DVD production – and the<br />

SINGULUS injection molding machines of type<br />

MOLDPRO and EMOULD, a complete family of<br />

HD DVD production equipment is available.<br />

The benchmark SKYLINE II<br />

Since the presentation of the SKYLINE II to<br />

the public in 2003, this production tool was<br />

able to tie up seamless to the track record of<br />

its successor SKYLINE I. Out of more than<br />

1900 worldwi<strong>de</strong> installed SKYLINE systems,<br />

more than 500 lines are of type SKYLINE II.<br />

Being recognized as the working horse within<br />

the replication industry, the market share<br />

of the SKYLINE II surpassed the above mentioned<br />

benchmark like SPACELINE II also did.<br />

Differences to SPACELINE II<br />

Whereas SPACELINE II is <strong>de</strong>signed to manufacture<br />

DVD 5, DVD 9, DVD 10 and HD DVD<br />

(single and dual layer formats), the SKYLINE II

Duplex HD is prepared for CD, DVD5 and HD<br />

DVD single layer production. Besi<strong>de</strong>s that<br />

SPACELINE II is equipped with additional<br />

<strong>de</strong>vices to enable the manufacturing of<br />

dual layer formats, SKYLINE II can easily be<br />

i<strong>de</strong>ntified as a member of the SINGULUS<br />

family of replication equipment.<br />

Consistency facts<br />

As most SINGULUS customers are using<br />

SKYLINE II and SPACELINE II equipment in<br />

parallel, one of the main objectives for<br />

SINGULUS´ engineers has been, to consi<strong>de</strong>r<br />

the implementation of non-variable parts on<br />

both type of lines. Therefore these customers<br />

do benefit from a remarkable reduction on<br />

the amount and costs of spare parts within<br />

their stocks, generally increasing their<br />

availability in parallel.<br />

Also the visualization was <strong>de</strong>signed i<strong>de</strong>ntically<br />

on both lines, allowing a fast transfer and<br />

reduced training for operating personnel.<br />

This inclu<strong>de</strong>s a single-push-button solution<br />

enabling a quick switch between the formats<br />

to be manufactured. Therefore in most cases<br />

only a stamper change is necessary. Freely<br />

configurable parameter sets do provi<strong>de</strong> best<br />

support to prepare a format exchange,<br />

reduce the conversion time and increase the<br />

uptime.<br />

Outlook<br />

Of course both SKYLINE II and SPACELINE II<br />

do achieve the most cost-efficient disc<br />

production, highest product quality and<br />

yield available in the market. Based on this<br />

measures and paired with its capabilities<br />

in manufacturing HD DVD formats, it is<br />

predicted that both replication lines will<br />

remain the benchmark within the industry.<br />

[News Optical Disc]<br />

page 7

page 8 [News Nano Deposition Technologies] | ISSUE 34 | MAY 2007<br />

SINGULUS Nano Deposition Technologies<br />

Since the <strong>de</strong>cision in 2002 to enter the new<br />

business area of thin film <strong>de</strong>position tools for<br />

magneto – electronic applications, SINGULUS<br />

has manufactured six of their TIMARIS PVD<br />

bridge tools (wafer size up to 300mm diameter).<br />

Besi<strong>de</strong>s MRAM technology SINGULUS has<br />

qualified the TIMARIS for other applications,<br />

especially as a production tool for Thin Film<br />

Heads (TFHs) required in Hard Disk Drives<br />

(HDD). SINGULUS is also cooperating with<br />

Qimonda to qualify the TIMARIS for a standard<br />

semiconductor application in the frame of the<br />

SEA-NET project, a European-fun<strong>de</strong>d integrated<br />

project including 27 industrial and institutional<br />

partners. All applications require the <strong>de</strong>posit<br />

of ultra–thin metallic and insulating films and<br />

film stacks down to nanometer thickness and<br />

below with extremely high requirements<br />

regarding thickness and material uniformities.<br />

The special capabilities of the TIMARIS and the<br />

addressed market for this type of machine<br />

have led to the <strong>de</strong>cision to give the respective<br />

business unit insi<strong>de</strong> of SINGULUS the name<br />

“Nano – Deposition – Technologies” (NDT).<br />

The Multi–Target–Module (MTM) as key<br />

component of the TIMARIS PVD tool incorporates<br />

Linear Dynamic Deposition (LDD)<br />

technology in combination with ten (10)<br />

sputter targets in one vacuum chamber. This<br />

technology is especially <strong>de</strong>signed for<br />

<strong>de</strong>position of ultra–thin films, magnetic films,<br />

high–quality metallic, conductive and insulating<br />

films and multiple film stack <strong>de</strong>position<br />

comprising these materials without needing to<br />

break the ultra-high vacuum. The LDD technology<br />

is the key to <strong>de</strong>liver world class material<br />

uniformity across large wafers and exceptional<br />

precise control of ultra thin layer thickness<br />

down to 1% of a nanometer. SINGULUS’ TIMARIS<br />

system is <strong>de</strong>signed as a flexible cluster tool.<br />

Additional modules to the MTM are available<br />

to configure a complete machine according to<br />

the customers specifications. These modules<br />

are the Oxidation module, Soft–Etch module,<br />

Combi–module, and Static PVD module. Further<br />

modules are un<strong>de</strong>r <strong>de</strong>velopment. The<br />

latest version of the MTM incorporates<br />

the full scope of sputtering techniques: DC<br />

magnetron sputtering, pulsed DC magnetron<br />

sputtering, RF magnetron and dio<strong>de</strong><br />

sputtering as well as combinations of it are<br />

selectable by recipe. Substrate bias is offered<br />

as an option.<br />

In 2006, SINGULUS announced the sale of four<br />

TIMARIS thin-film <strong>de</strong>position system for MRAM<br />

wafer production & Thin Film Head Applications.<br />

Two of these TIMARIS systems have<br />

passed their technical acceptance in Q1 of this<br />

year. Another TIMARIS system has been sold<br />

and is now <strong>de</strong>livered to GRANDIS in Silicon<br />

Valley/USA for the MRAM application. As part<br />

of the purchase contract, Grandis & SINGULUS<br />

signed an agreement to jointly <strong>de</strong>velop<br />

advanced TMR films for MRAM based on the<br />

Spin–Torque – Transfer technology (STT).<br />

Grandis is one of the leading groups <strong>de</strong>veloping<br />

this technique. MRAM is a non-volatile<br />

memory technology that also provi<strong>de</strong>s highspeed<br />

read and write operation as well as<br />

unlimited rewriting capability. Whereas<br />

the originally pursued “classical” MRAM<br />

technology could not fulfill all the scaling<br />

requirements according to the semiconductor<br />

ITRS roadmap (which led to the withdrawal of<br />

several tier-one semiconductor manufacturers<br />

from MRAM <strong>de</strong>velopment), the STT technology<br />

is now promising to be scaled down according<br />

to the requirements. As a result, a number of<br />

big semiconductor companies (e.g. Samsung,<br />

TSMC, Toshiba, Sony and others) are again<br />

working to <strong>de</strong>velop the MRAM technology. The<br />

goal is to replace the volatile DRAM by MRAM<br />

and to use MRAM as embed<strong>de</strong>d memory in several<br />

applications. The cooperation with Grandis<br />

will ensure that Singulus NDT is involved in the<br />

very promising STT technology <strong>de</strong>velopment.<br />

Thin Film Heads (TFH)<br />

� High Moment Material (Writer–Material)<br />

� TMR (Rea<strong>de</strong>r Material)<br />

� GMR (Rea<strong>de</strong>r Material)<br />

� Deposition of seed and gap layers<br />

Semiconductor<br />

� MRAM<br />

� HK Dielectrics<br />

� Metal Gates<br />

� Phase Change material <strong>de</strong>position<br />

� Seposition of EUV mirrors<br />

(Extreme Ultra - Violet) for next<br />

generation of lithography<br />

� SAW/BAW film <strong>de</strong>position<br />

At Semicon West, the largest capital<br />

equipment exhibition show worldwi<strong>de</strong> (in<br />

San Francisco from July 16-20, 2007), the<br />

SINGULUS Nano Deposition Technologies<br />

Group will display its activities to its<br />

customers.

MaskTrack ® Photomask Equipment<br />

HamaTech’s Advanced Process Equipment<br />

(APE) division provi<strong>de</strong>s photomask and wafer<br />

processing equipment & solutions for the<br />

worldwi<strong>de</strong> semiconductor industry. The<br />

business activities of this division were<br />

transferred to an in<strong>de</strong>pen<strong>de</strong>nt legal entity.<br />

As a member of the SINGULUS Group,<br />

HamaTech APE will look into potential synergies<br />

and benefits of the overall company’s<br />

network, especially with SINGULUS’ Nano<br />

Deposition Technologies (NDT) division.<br />

HamaTech APE has expan<strong>de</strong>d its leading role<br />

for equipment for the cleaning and processing<br />

of photo masks; its global market share<br />

in these sub-segments is to more than 30 %.<br />

As technology of integrated circuits (ICs)<br />

evolves to ever shrinking dimensions, the<br />

manufacturing of photomasks becomes more<br />

and more challenging. For HamaTech APE<br />

with its expertise in photomask cleaning,<br />

<strong>de</strong>veloping and baking these increasing<br />

Contact:<br />

HamaTech APE GmbH & Co. KG<br />

Ferdinand-von-Steinbeis Ring 10<br />

D-75447 Sternenfels, Germany<br />

Phone: +49 (0) 70 45 / 41 - 8<br />

Fax: +49 (0) 70 45 / 41 - 239<br />

www.hamatech-ape.<strong>de</strong><br />

[News HamaTech APE’s MaskTrack® Equipment]<br />

<strong>de</strong>mands provi<strong>de</strong> the opportunity to<br />

differentiate itself from its competitors by<br />

offering leading solutions for its customers.<br />

Six out of the top ten semiconductor<br />

companies, and all three major merchant<br />

mask manufacturers are customers of<br />

HamaTech APE, giving it access to <strong>de</strong>velop<br />

leading technologies with them. A Joint<br />

Development Program on EUV and optical<br />

blank and mask cleaning with SEMATECH, a<br />

semiconductor consortium of renowned chip<br />

producers like Intel, IBM, TI, Freescale,<br />

Samsung, and others, is of high strategic<br />

importance. This cooperation enables<br />

HamaTech APE to address already today the<br />

future requirements of cleaning, leading to<br />

an excellent competitive position for<br />

HamaTech APE´s most advanced MaskTrack ®<br />

cleaners.<br />

Overall, well over 10 MaskTrack ® systems as<br />

well as several other equipments were <strong>de</strong>livered<br />

to leading customers in the business<br />

year 2006, and well over 20 systems have<br />

been or<strong>de</strong>red by customers by Q1/2007.<br />

Combined with the exclusive customer portfolio<br />

this proves the great success of the<br />

MaskTrack ® product introduced only in 2005.<br />

The majority of these equipments are used in<br />

mask cleaning, where today the most severe<br />

challenges exist for the <strong>de</strong>mands of 65 and<br />

45nm chip technologies: Such cleaning has to<br />

be accomplished without leaving a single<br />

particle of a critical size (e.g. 60 nm) on the<br />

mask surface, while at the same time the<br />

structure of similar size must not be damaged,<br />

optical properties may not be altered,<br />

and any chemical traces on the mask surface<br />

must be avoi<strong>de</strong>d.<br />

page 9

page<br />

10<br />

[News Optical Coatings] | ISSUE 34 | MAY 2007<br />

OPTICUS - For Coating of Eyeglass Lenses<br />

First Time at the MIDO in Milan<br />

SINGULUS presented its innovative inline ophthalmic<br />

lens coating machine OPTICUS at the<br />

MIDO in Milan from May 4 to May 7. This was<br />

the first time that the machine was operating<br />

on display at a show. Visitors were able to<br />

view the machine that will revolutionize<br />

traditional eye lens production. SINGULUS’<br />

proven Inline coating process stems from the<br />

inline production of CDs and DVDs and automates<br />

the production process, consi<strong>de</strong>rably<br />

reducing personnel and logistics requirements<br />

as well as other expenses.<br />

Dr. Steffen Runkel, Technical Director Optical<br />

Coatings, comments: “We are happy to<br />

present our OPTICUS coating machine for the<br />

first time to the tra<strong>de</strong>show in Milan. This<br />

marks another milestone in the introduction<br />

of this new machine concept to the market.”<br />

SINGULUS achieved an important<br />

breakthrough with this machine concept last<br />

December, when the first OPTICUS coating<br />

machine for plastic ophthalmic lenses was<br />

qualified for production and technically<br />

accepted by a customer. In total, three<br />

machines were <strong>de</strong>livered in 2006, which are<br />

employed in pilot production and daily mass<br />

production of eyeglass lenses.<br />

Dr. Runkel adds: “The fruitful cooperation<br />

with several renowned eyeglass producers<br />

and the resulting exchange of know-how<br />

was a great help to the <strong>de</strong>velopment of the<br />

machine, and strengthens our position in the<br />

eyeglass market."

In November 2005, SINGULUS had introduced<br />

the metallization system SINGULUS 3DS, an<br />

innovative machine for <strong>de</strong>corative vacuum<br />

coating of plastic parts. This machine is a<br />

revolutionary new <strong>de</strong>velopment in the segment<br />

of metallisation for complex plastic surfaces.<br />

With the sputtering process used in the<br />

SINGULUS 3DS, three-dimensional plastic<br />

parts can be handled and coated in vacuum<br />

with <strong>de</strong>corative metallic layers.<br />

On the basis of the SINGULUS 3DS metallizer,<br />

a new system which integrates all necessary<br />

production steps from the injection molding<br />

machines to the metallization and the application<br />

of anti-scratch finishes was <strong>de</strong>veloped:<br />

the DECOLINE. All production processes are<br />

completely automated.<br />

The DECOLINE was <strong>de</strong>veloped in cooperation<br />

with Balda AG, Bad Oeynhausen in<br />

October 2006. In January, SINGULUS<br />

TECHNOLOGIES announced this cooperation<br />

to the public. The new production line for<br />

the processing of plastic covers for mobile<br />

phones, handheld game <strong>de</strong>vices and other<br />

plastic parts will be marketed un<strong>de</strong>r the<br />

brand DECOLINE. Amongst electronic <strong>de</strong>vices,<br />

the line provi<strong>de</strong>s many advantages in<br />

[News Decorative Coatings]<br />

DECOLINE<br />

A New Production Line for Surface Processing of<br />

Plastic Parts<br />

applications like packaging for cosmetics<br />

& personal care, toys, automobile industries,<br />

household appliances and many other<br />

applications.<br />

The <strong>de</strong>livery to the key customer Balda will<br />

take place in May 2007.<br />

The new DECOLINE will also be shown on the<br />

K show in Duesseldorf/Germany from October<br />

24-31, 2007.<br />

page 11

Headquarters<br />

SINGULUS TECHNOLOGIES AG<br />

Hanauer Landstrasse 103,<br />

D-63796 Kahl, Germany<br />

Phone: +49 - 61 88 - 440 - 0<br />

Fax: +49 - 61 88 - 440 - 110<br />

E-mail: sales@singulus.<strong>de</strong><br />

Internet: www.singulus.<strong>de</strong><br />

Associated Companies<br />

Germany:<br />

SINGULUS EMOULD GmbH<br />

St.-Jobser-Strasse 52<br />

D-52146 Würselen<br />

Phone: +49-24 05-60 19-13<br />

Fax: +49-24 05-60 19-25<br />

E-Mail: info@emould.<strong>de</strong><br />

www.emould.<strong>de</strong><br />

Netherlands:<br />

SINGULUS MASTERING B.V.<br />

Marinus v. Meelweg 2<br />

5657 EN Eindhoven<br />

Phone: +31-40 7501-400<br />

Fax: +31-40 7501-409<br />

E-Mail: info@singulus.nl<br />

www.singulus.nl<br />

Switzerland:<br />

SINGULUS MOLDING AG<br />

Schlachthofstrasse 35<br />

CH-8200 Schaffhausen<br />

Phone: +41-52 632-62 22<br />

Fax: +41-52 632-62 61<br />

E-Mail: sales@singulus-molding.ch<br />

www.singulus-molding.ch<br />

NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS NEWS<br />

SINGULUS TRAINING<br />

10 Years of Training Classes<br />

During the last ten years, we have provi<strong>de</strong>d<br />

training to 7,235 participants in our training<br />

centers worldwi<strong>de</strong>. With your continued<br />

feedback, we have <strong>de</strong>signed programs that<br />

are presented on-site, incorporating intensive<br />

hands-on, practical experience. We have also<br />

tailored our instruction to the specific skill<br />

levels of your personnel.<br />

In short, we have listened and improved our<br />

training strategy to better suit your needs<br />

and production schedules. Our specially<br />

structured and customized training courses<br />

will provi<strong>de</strong> the content to meet your<br />

requirements.<br />

We have experienced training instructors in<br />

the U.S., Asia, the Netherlands and Germany.<br />

Learn from the experts – in one of our<br />

in-house training classrooms or in your<br />

own facility – how best to improve the<br />

performance and uptime of your equipment<br />

and get ready for the high production<br />

<strong>de</strong>mands of the season.<br />

Please contact:<br />

Headquarters worldwi<strong>de</strong>:<br />

training@singulus.<strong>de</strong><br />

North America:<br />

training@singulus.com<br />

Asia Pacific/Australia:<br />

training@singulus.com.sg<br />

SINGULUS Mastering:<br />

training@singulus.nl<br />

Let us know your needs and we are pleased<br />

to prepare an offer for you.<br />

Use the opportunity... be good - become<br />

better!<br />

SINGULUS TECHNOLOGIES AG Subsidiaries<br />

Brazil SINGULUS TECHNOLOGIES LATIN AMERICA LTDA.<br />

Tel.: +55-11-3641-0113, Fax: +55-11-3641-0110<br />

E-mail: latinamerica@singulus.com.br<br />

France SINGULUS TECHNOLOGIES France S.A.R.L.<br />

Tel.: +33-3893-11129, Fax: +33-3896-17264<br />

E-mail: singulus@club-internet.fr<br />

Great Britain/ SINGULUS TECHNOLOGIES UK LTD.<br />

Ireland Tel.: +44-1793-7842-00, Fax: +44-17 93-784-222<br />

E-mail: singulus@singulusuk.com<br />

Italy SINGULUS TECHNOLOGIES ITALIA S.R.L.<br />

Tel.: +39-071-7930-312, Fax: +39-071-7930-821<br />

E-mail: singulus.italia@singulus.it<br />

Singapore SINGULUS TECHNOLOGIES Asia Pacific<br />

Tel.: +65-67 41 19 12, Fax: +65-67 41 12 13<br />

E-mail: singulus@singnet.com.sg<br />

Spain SINGULUS TECHNOLOGIES IBERICA S.L.<br />

Tel.: +34-936-750-025, Fax: +34-935-906-426<br />

E-mail: singulus@singulusib.com<br />

Taiwan SINGULUS TECHNOLOGIES TAIWAN LTD.<br />

Tel.: +886-2-2748-3366, Fax: +886-2-2748-6565<br />

E-mail: sales@singulus.com.tw<br />

USA/Canada SINGULUS TECHNOLOGIES INC.<br />

Tel.: +1-860-683-8000, Fax: +1-860-683-8010<br />

E-mail: sales@singulus.com<br />

USA/ SINGULUS TECHNOLOGIES INC.<br />

West-Coast Tel.: +1-805-373-6216, Fax: +1-805-371-7433<br />

Office E-mail: sales@singulus.com<br />

3.0/05-2007-MetaCom Printed in Germany, Technical alterations reserved

![[news] - Singulus Technologies AG](https://img.yumpu.com/5163079/1/190x260/news-singulus-technologies-ag.jpg?quality=85)