Barrick Beyond Borders - May 2012 - Barrick Gold Corporation

Barrick Beyond Borders - May 2012 - Barrick Gold Corporation

Barrick Beyond Borders - May 2012 - Barrick Gold Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

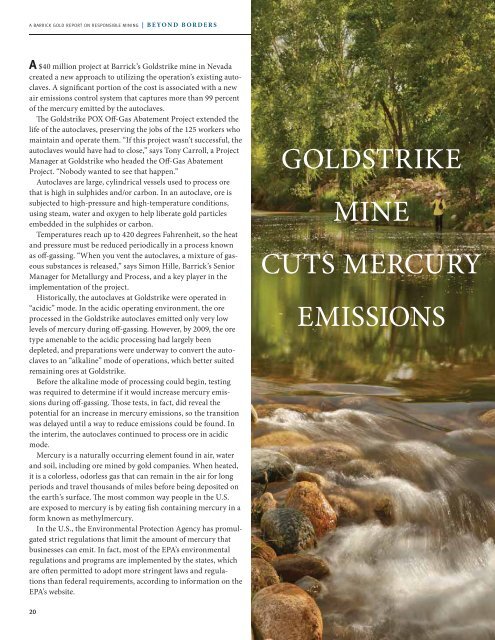

A BARRICK GOLD REPORT ON RESPONSIBLE MINING | BEYOND BORDERSA $40 million project at <strong>Barrick</strong>’s <strong>Gold</strong>strike mine in Nevadacreated a new approach to utilizing the operation’s existing autoclaves.A significant portion of the cost is associated with a newair emissions control system that captures more than 99 percentof the mercury emitted by the autoclaves.The <strong>Gold</strong>strike POX Off-Gas Abatement Project extended thelife of the autoclaves, preserving the jobs of the 125 workers whomaintain and operate them. “If this project wasn’t successful, theautoclaves would have had to close,” says Tony Carroll, a ProjectManager at <strong>Gold</strong>strike who headed the Off-Gas AbatementProject. “Nobody wanted to see that happen.”Autoclaves are large, cylindrical vessels used to process orethat is high in sulphides and/or carbon. In an autoclave, ore issubjected to high-pressure and high-temperature conditions,using steam, water and oxygen to help liberate gold particlesembedded in the sulphides or carbon.Temperatures reach up to 420 degrees Fahrenheit, so the heatand pressure must be reduced periodically in a process knownas off-gassing. “When you vent the autoclaves, a mixture of gaseoussubstances is released,” says Simon Hille, <strong>Barrick</strong>’s SeniorManager for Metallurgy and Process, and a key player in theimplementation of the project.Historically, the autoclaves at <strong>Gold</strong>strike were operated in“acidic” mode. In the acidic operating environment, the oreprocessed in the <strong>Gold</strong>strike autoclaves emitted only very lowlevels of mercury during off-gassing. However, by 2009, the oretype amenable to the acidic processing had largely beendepleted, and preparations were underway to convert the autoclavesto an “alkaline” mode of operations, which better suitedremaining ores at <strong>Gold</strong>strike.Before the alkaline mode of processing could begin, testingwas required to determine if it would increase mercury emissionsduring off-gassing. Those tests, in fact, did reveal thepotential for an increase in mercury emissions, so the transitionwas delayed until a way to reduce emissions could be found. Inthe interim, the autoclaves continued to process ore in acidicmode.Mercury is a naturally occurring element found in air, waterand soil, including ore mined by gold companies. When heated,it is a colorless, odorless gas that can remain in the air for longperiods and travel thousands of miles before being deposited onthe earth’s surface. The most common way people in the U.S.are exposed to mercury is by eating fish containing mercury in aform known as methylmercury.In the U.S., the Environmental Protection Agency has promulgatedstrict regulations that limit the amount of mercury thatbusinesses can emit. In fact, most of the EPA’s environmentalregulations and programs are implemented by the states, whichare often permitted to adopt more stringent laws and regulationsthan federal requirements, according to information on theEPA’s website.GOLDSTRIKEMINECUTS MERCURYEMISSIONS20