mep drawings

mep drawings

mep drawings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

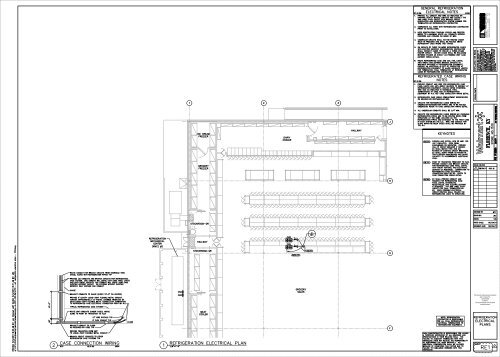

SUITE 5268 479-636-50041805 N 2ND STJOB NO.:JRC14140800-321-872107.31.09GENERAL REFRIGERATION ELECTRICAL NOTESEN061. PROVIDE ALL CONDUIT AND WIRE AS INDICATED ON DRAWING. NEATLY BUNDLE CIRCUITSAND CLEARLY TAG AND LABEL EACH CIRCUIT WITH BRANCH CIRCUIT DESIGNATION ANDREFRIGERATION SYSTEM NUMBER FOR TERMINATION BY REFRIGERATION CONTRACTOR.2. COORDINATE ALL WORK WITH REFRIGERATION CONTRACTOR PRIOR TO INSTALLATION.3. KEEP PENETRATIONS THROUGH COOLER AND FREEZER BOXES TO A MINIMUM. ROUTEALL CONDUITS SERVING FREEZERS AND COOLERS ON INSIDE OF BOX.4. UNDERSLAB CIRCUITS SHALL NOT BE ROUTED UNDER WALK-IN FREEZERS AND SHALL BEROUTED ABOVE REFRIGERANT LINES WHERE THEY CROSS.5. ON GROUPS OF THREE OR MORE REFRIGERATED CASES WITH ELECTRIC DEFROST,REFRIGERATION CONTRACTOR SHALL CONNECT CASES TO CREATE A THREE-PHASEHEATER CIRCUIT. HEATER LOADS SHALL BE BALANCED BETWEEN PHASES AS EVENLY ASPOSSIBLE (REF CASE DEFROST WIRING DETAIL).6. ROUTE REFRIGERATED CASE AND COIL FAN, LIGHTS, ANTI-SWEAT AND DEFROST BRANCHCIRCUITS TO WIREWAYS PROVIDED AT REFRIGERATION EQUIPMENT. PROVIDE ANADDITIONAL 6 FEET OF CONDUCTOR AT REFRIGERATION EQUIPMENT TO ALLOW ADEQUATELENGTH FOR TERMINATION. FINAL TERMINATION AT REFRIGERATED CASES BYREFRIGERATION CONTRACTOR.ROGERS, AR 72756 DESIGNED BY:STIPULATION FOR REUSE1 2 3REFRIGERATED CASE WIRING NOTES07.31.091. PROVIDE CONDUIT AND WIRE FOR REFRIGERATED CASE FANS, LIGHTS AND ANTI-SWEATHEATERS TO WIREWAY AT REFRIGERATION EQUIPMENT, UNLESS NOTED OTHERWISE. WIRE SIZEAS INDICATED IN SCHEDULE. FINAL TERMINATIONS AT CASE AND AT REFRIGERATIONEQUIPMENT BY R.C. REF CASE CONNECTION WIRING DETAIL.2. REFRIGERATED CASE WIRING COMPARTMENT REPRESENTED ON DRAWING BYRECTANGULAR BOX.3. CIRCUITS FOR REFRIGERATED CASES SERVED BY UNDERSLAB REFRIGERATION PIPING ARETO BE ROUTED UNDERSLAB. REFER TO CASE CONNECTION WIRING DETAIL.4. ALL UNDERSLAB CONDUITS SHALL BE 3/4" MIN.5. CIRCUITS FOR REFRIGERATED CASES SERVED BY OVERHEAD REFRIGERATION PIPING ARETO BE ROUTED DOWN FROM STRUCTURE AT THE SAME LOCATION AS THE REFRIGERATIONPIPING AND EXTENDED TO THE FIRST CASE IN EACH SYSTEM BY THE E.C. WIRE AND CONDUITFOR SLAVE WIRING BETWEEN CASES SHALL BE PROVIDED BY THE R.C.CONSULTANTSICE CREAMFREEZERDAIRYCOOLERHALLWAYJ16.470KEYNOTESFURNISH AND INSTALL NEW 20 AMP, 120 VOLT CIRCUIT(S). FEED FROM PANELBOARD AS INDICATED. PROVIDE 20A-1P CIRCUIT BREAKER IF NEEDED. EC SHALL MATCH TYPE AND AIC RATINGS OF EXISTING CIRCUIT BREAKERS. EC SHALL VERIFY PRIOR TO ROUGH-IN THAT EXISTING PANELBOARD HAS SPARE CAPACITY TO ACCOMMODATE ADDITIONAL LOAD.FLORENCE, KY1510STORE NO.195 GENERAL REMODEL14140JOB NUMBER:GROCERYFREEZER16.711POINT OF TRANSITION FROM EMT TO FLEX. PROVIDE CONDUIT ANDBRANCH CIRCUITS FOR REFRIGERATED CASE FANS, LIGHTS, ANTI-SWEATHEATERS, AND ELECTRICAL DEFROST (IF REQUIRED). TERMINATION TOREFRIGERATED CASE ELECTRICAL CONNECTION POINT BY RC. REFER TOCASE CONNECTION WIRING DETAIL.ISSUE BLOCK1 08/04/11 ADD #1H16.765EC SHALL PROVIDE CONDUIT AND FEEDERS FOR REFRIGERATED CASE FANS, LIGHTS, ANTISWEATS, RECEPTACLES, AND ELECTRIC DEFROST IF REQUIRED. TAG AND LABEL EACH CIRCUIT FOR FINAL TERMINATION BY RC. WHEN POSSIBLE ELECTRICAL CIRCUIT ROUTING SHALL FOLLOW THE REFRIGERATION LINES TO STRUCTURE.CHECKED BY:XXXXDRAWN BY:XXXPROTO:195STOCKROOM-GRPROTO CYCLE:DOCUMENT DATE:06/24/1108/04/112RE1REFRIGERATIONMECHANICAL CENTER(RMC) #2HALLWAYCH2F16.47016.765FCH2L16.470J16.765STOCKROOM-GR16.711GMTD-13ROUTE CONDUIT FOR BRANCH CIRCUITS FROM OVERHEAD THRUCHASE, ALONG WITH REFRIGERATION PIPING TYPPROVIDE (2) CONDUITS AND BRANCH CIRCUITS PER REFRIGERATEDCASE SYSTEM. ONE CONDUIT WILL SERVE 120V CASE FANS, LIGHTSAND ANTI-SWEAT CIRCUITS; ONE CONDUIT WILL SERVE 208V CASEELECTRIC DEFROST CIRCUIT. ON SYSTEMS WITHOUT ELECTRICDEFROST, ONLY PROVIDE ONE CONDUITCHASECH2LGROCERYSALESPRINTED: 8/4/2011 8:38 AM BY: Jon Channell LAST SAVED: 8/4/2011 8:37 AM BY: JRCg:\141\14140\engineering\remodel\sheetstempjrc-ai-2011-08-04\4710 - re1 refrigeration electrical plans - 1510.dwg10'-0"18"BRACKET CONDUITS TO CHASE (EVERY 10'-0" ON CENTER)PROVIDE 5' LENGTH LIQUID-TIGHT FLEXIBLE METAL CONDUIT.FURNISH APPROXIMATELY 12" PIGTAIL STUBBED FROM END OFEACH LIQUID-TIGHT FLEXIBLE METAL CONDUIT FOR TERMINATIONTO REFRIGERATED CASE ELECTRICAL CONNECTION POINT BY R.C.TYPICAL REFRIGERATED CASE SYSTEMROUTE EMT CONDUITS (UNDER CASES, ABOVESLAB) TO POINT OF TRANSITION TO FLEXBRACKET CONDUIT TO FLOORAS REQUIRED BY CODE TYPPROVIDE TRANSITION FROM EMTTO LIQUID-TIGHT FLEXIBLE METAL CONDUITBRANCH CIRCUIT CONDUITS TO OTHERREFRIGERATED CASE SYSTEMS TYP12" WIRE PIGTAILS TYP5' FLEX CONDUIT TYP2CASE CONNECTION WIRINGNTS 10.31.03 ER04FLOORCH2FMEATCOOLER1%REFRIGERATION ELECTRICAL PLAN1/8"=1'-0"FNOTE: REFRIGERATION CONTRACTOR IS RESPONSIBLE FOR ALL FINAL REFRIGERATION ELECTRICAL TERMINATIONS TO REFRIGERATION EQUIPMENT.EACH SUBCONTRACTOR IS RESPONSIBLE FOR HAVING A THOROUGH KNOWLEDGE OF ALL DRAWINGS AND SPECIFICATIONS IN THEIR RELATED FIELD. THE FAILURE TO ACQUAINT THEMSELVES WITH THIS KNOWLEDGE DOES NOT RELIEVE THE RESPONSIBILITY OF PERFORMING THE WORK PROPERLY. NO ADDITIONAL COMPENSATION SHALL BE ALLOWED BECAUSE OF CONDITIONS THAT OCCUR DUE TO FAILURE TO FAMILIARIZE WORKERS WITH THIS KNOWLEDGE.This document originally issued and sealed byJason C. Adams, P.E.,License #27288on 08/04/11.This document should not be considereda certified document.XXXXXXSHEET:XX1