mep drawings

mep drawings

mep drawings

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

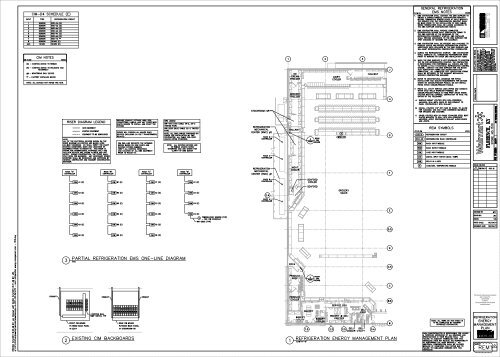

SUITE 5268 479-636-50041805 N 2ND STJOB NO.:JRC14140800-321-8721INPUT1234568AUXCIM-D4 SCHEDULE (E)TYPESENSORSENSORSENSORSENSORSENSORSENSORSENSORSENSORSPARECIM NOTESREFRIGERATION CIRCUITMTD-3a (E)MTD-3b (E)MTD-4a (E)MTD-4b (E)MTD-4c (E)MTD-4d (E)MTD-13 **SPARE (E)SPARE (E)06.15.09 REMC(E) - EXISTING DEVICE TO REMAIN(R) - EXISTING DEVICE TO RELOCATE AND## - MONITORING ONLY DEVICE** - FACTORY INSTALLED DEVICENOTE: ALL DEVICES NOT NOTED ARE NEW.RECONNECT1ICECREAMFREEZERGROCERYFREEZER2 3DAIRY COOLERHALLWAYJHGENERAL REFRIGERATION EMS NOTES11.19.10 EN051. EMS CONTRACTOR SHALL CONTACT THE EMS SUPPLIERTO OBTAIN A CURRENT MODULE CONFIGURATION PRINTOUTBEFORE TERMINATING SENSOR LEADS AT INPUT MODULES.THE REQUEST FOR THE CONFIGURATION PRINTOUT SHALLBE MADE PRIOR TO THE INSTALLATION OF EMS CABLES.WIRING TERMINATIONS SHALL BE LANDED ACCORDING TOTHE EMS SUPPLIER CONFIGURATION SHEETS.2. EMS CONTRACTOR SHALL PROVIDE COMPLETEDREFRIGERATION SENSOR INPUT VERIFICATION FORMS TOTHE EMS SUPPLIER AT THE BEGINNING OF THEREFRIGERATION EQUIPMENT STARTUP. EMS INSTALLERSHALL PROVIDE ASSISTANCE TO THE EMS SUPPLIER FORSPOT CHECKING OF SENSORS FOR ACCURACY.3. EMS CONTRACTOR SHALL BE PRESENT AND AVAILABLETO RESOLVE ISSUES AND PROVIDE REFRIGERATIONSTARTUP ASSISTANCE UNTIL RELEASED BY THE EMSSUPPLIER AND WAL-MART REFRIGERATION CONSTRUCTIONCOORDINATOR.4. DURING THE REFRIGERATION STARTUP, EMSCONTRACTOR SHALL COMPLETE ALL UNRESOLVEDREFRIGERATION WORK PRIOR TO WORKING ON OTHER EMSINSTALLATION ITEMS.5. WHEN THE EMS SUPPLIER IS NOT SCHEDULED TOPERFORM THE ON SITE REFRIGERATION STARTUP, THECONTRACTOR IS RESPONSIBLE FOR PERFORMING ALLCHECKS AND TEST TO ENSURE A FULLY FUNCTIONALREFRIGERATION CONTROL SYSTEM. CONTACT THE EMSSUPPLIER FOR THE BLANK TEST VERIFICATION FORMS ANDINSTRUCTIONS FOR COMPLETING. ALL COMPLETED TESTVERIFICATION FORMS SHALL BE RETURNED TO THEWALMART MECHANICAL SERVICES CONSTRUCTIONMANAGER.6. REFER TO ARCHITECTURAL DRAWINGS FOR PIPINGINSTALLATION AND SEALING REQUIREMENTS FOR DEVICESSHOWN ON COOLER/FREEZER PANELS. DO NOT INSTALLPIPING WITHIN COOLER/FREEZER PANELS.7. ROUTE ALL UTILITY SERVICE LINES (PIPES AND CONDUIT)WITHIN STUD WALLS WHEREVER POSSIBLE. ONCOOLER/FREEZER PANELS IN FOOD PREP AREAS WHEREUTILITIES MUST BE EXPOSED, CONTRACTOR TO HAVE THEOPTION OF THE FOLLOWING:STIPULATION FOR REUSECONSULTANTSROGERS, AR 72756 DESIGNED BY:RISER DIAGRAM LEGENDNEW EQUIPMENTEXISTING EQUIPMENTEQUIPMENT TO BE DEMOLISHEDNOTE:ALL OF THE ELECTRICAL DEVICES SHOWN ON THERISER DIAGRAM AS EXISTING ARE BASED UPONAS-BUILT DRAWINGS. EC SHALL VERIFY THE EXACTEXISTING CONDITIONS, SIZES AND LOCATIONS OFEQUIPMENT PRIOR TO ROUGH-IN. THIS RISER ISSHOWN FOR INFORMATIONAL PURPOSES ONLY ANDANY NEW DEVICES ARE SHOWN IN BOLD AND ARENOTED. DURING CONSTRUCTION, THE STORESHALL STAY OPEN FOR BUSINESS. ANYNECESSARY POWER DOWNTIME SHALL BESCHEDULED AND APPROVED BY GENERALCONTRACTOR AND WALMART CONSTRUCTIONPROVIDE CONDUIT, FITTINGS, WIRE-TIES, CONNECTORS, LABELS, AND ANY OTHER MISC. PARTS NEEDED TO INSTALL AND START THE SYSTEM.OWNER WILL FURNISH ALL MAJOR E.M.S. DEVICES (INCLUDING 24 VOLT TRANSFORMERS, RELAYS).CIM ONE-LINE REFLECTS THE INTENDEDDESIGN BASED ON NEW CASES ANDEXISTING SYSTEM NUMBERS.VERIFY ALL EXISTING CONDITIONSAND LOCATION OF ALL EMS EQUIPMENTPRIOR TO ROUGH-IN.WIRE LEGENDWIR-1010 (TAN CABLE 18-2, 20-2 TWISTED PAIR)WIR-2020 (BLUE CABLE 22-2 TWISTED PAIR)NOTE: ALL EMS CABLES FURNISHED BY OWNER FOR INSTALLATION BY EMS CONTRACTOR. ALL CABLE WIR-2020 UNLESS NOTED OTHERWISE.NOTE: ALL EXISTING DEVICES ARE TO REMAIN UNLESS NOTED OTHERWISE AND ARE SHOWN FOR CLARITY OF EMS DESIGNSTOCKROOM-GRREFRIGERATION MECHANICAL CENTER (RMC) #2RACK D CONTROLLERRACK C CONTROLLERHALLWAY2REM1REARCIMBOARDSMTD-13GA. SURFACE MOUNT UTILITIES WITH NON-CORROSIVEANCHORS; SEAL BOTH SIDES OF PIPE/CONDUIT TO PANELCONTINUOUSLY WITH SEALANT.B. INSTALL UTILITIES 1/2" OFF FACE OF PANEL TO ALLOWFOR CLEANING; USE ONLY NON-CORROSIVE MATERIALS FORSPACERS AND ANCHORS.C. COVER UTILITIES WITH 20 GAUGE STAINLESS STEELBENT PLATES MOUNTED TO WALL WITH NON-CORROSIVEANCHORS; APPLY CONTINUOUS SEALANT ALONG EDGES07.31.09 ES10LTA-XRC2-XERIMROMCIMDISRIBREM SYMBOLSREFRIGERATION CIRCUITREFRIGERATION RACK CONTROLLERRACK INPUT MODULERACK OUTPUT MODULECASE INPUT MODULEDIGITAL INPUT SWITCH (DUAL-TEMP)RELAY IN A BOXFLORENCE, KYSTORE NO. 1510195 GENERAL REMODEL14140JOB NUMBER:RACK "A"CONTROLLERRACK "B"CONTROLLERRACK "C"CONTROLLERRACK "D"CONTROLLERREFRIGERATION MECHANICAL CENTER (RMC) #1MEAT COOLERFSCASE/COIL TEMPERATURE MODULEISSUE BLOCK1 08/04/11 ADD #1CIMA1 (E)CIMB1 (E)CIMC1 (E)CIMD1 (E)RACK B CONTROLLERSEAFOODCOOLERSEAFOODCIMA2 (E)CIMB2 (E)CIMC2 (E)CIMD2 (E)E.4GROCERYSALESRACK A CONTROLLERCIMA3 (E)CIMB3 (E)CIMC3 (E)CIMD3 (E)CIMA4 (E)CIMB4 (E)CIMC4 (E)CIMD4 (E)STEMPERATURE SENSOR (TYP)- SEE CIM SCHEDULEECHECKED BY:DRAWN BY:PROTO:XXXXXXX195CIMA5 (E)CIMB5 (E)CIMC5 (E)WIR-2020 (TYP)PROTO CYCLE:DOCUMENT DATE:06/24/1108/04/11D.5CIMA6 (E)CIMB6 (E)CIMC6 (E)D3%PARTIAL REFRIGERATION EMS ONE-LINE DIAGRAMNTSEDC4C.5PRODUCEPREP2REM1FRONTCIMBOARDCPRINTED: 8/4/2011 8:38 AM BY: Jon Channell LAST SAVED: 8/4/2011 8:37 AM BY: JRCg:\141\14140\engineering\remodel\sheetstempjrc-ai-2011-08-04\4751 - rem1 refrigeration energy management plan - 1510.dwgCONDUITCIM-A1CIM-A2CIM-B6CIM-C1CIM-C2CIM-C3CIM-C4CIM-C6CIM-D1CONDUITEXISTING DUAL TEMP SWITCH, TYPCIM-A3CIM-A4CIM-A5CIM-A6CIM-B1CIM-B2CIM-B3CIM-B4CIM-B5CIM-C5CIM-D2CIM-D3CIM-D4FRONT CIM BOARDREAR CIM BOARDPLYWOOD BACK PANELPLYWOOD BACK PANELIN EDC4IN STOCKROOM-GR2%EXISTING CIM BACKBOARDSCONDUITPRODUCECOOLERBAKERYUTILITYBAKERYBAKERYCOOLER1.5 2.2SERVICE DELIBAKERY & DELIFREEZERDELI DELI2.5COOLER UTILITY3.41%REFRIGERATION ENERGY MANAGEMENT PLAN1/16"=1'-0"DELIPREPB.6BNOTE: ALL WORK ON THIS SHEET IS TO BE COMPLETED BY WALMART APPROVED CONTRACTOR.EACH SUBCONTRACTOR IS RESPONSIBLE FOR HAVING A THOROUGH KNOWLEDGE OF ALL DRAWINGS AND SPECIFICATIONS IN THEIR RELATED FIELD. THE FAILURE TO ACQUAINT THEMSELVES WITH THIS KNOWLEDGE DOES NOT RELIEVE THE RESPONSIBILITY OF PERFORMING THE WORK PROPERLY. NO ADDITIONAL COMPENSATION SHALL BE ALLOWED BECAUSE OF CONDITIONS THAT OCCUR DUE TO FAILURE TO FAMILIARIZE WORKERS WITH THIS KNOWLEDGE.This document originally issued and sealed byJason C. Adams, P.E.,License #27288on 08/04/11.This document should not be considereda certified document.XXXXXXSHEET:XX1