ENGINEERING/TECHNICAL - Dodge-pt.com

ENGINEERING/TECHNICAL - Dodge-pt.com

ENGINEERING/TECHNICAL - Dodge-pt.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Gearing Reference Guide<br />

TORQUE-ARM II<br />

TORQUE-ARM<br />

MAXUM Concentric Reducer<br />

TIGEAR-2<br />

<strong>ENGINEERING</strong>/<strong>TECHNICAL</strong><br />

MAXUM Concentric Reducer<br />

GENERAL GUIDELINES FOR MOUNTING VARIABLE SPEED AC OR DC MOTORS<br />

SCOOP MOUNT ACCESSORY<br />

1. This is a soft mounting of the motor.<br />

2. The benefits obtained by using this accessory are low<br />

cost and isolation of the reducer support structure<br />

from the motor vibration.<br />

3. This motor mount was designed for use with a<br />

constant speed motor at 1750 RPM. Use of motors<br />

with lower base speeds increases the chance of<br />

producing resonance.Stiffening techniques within the<br />

scoop structure can increase the fundamental natural<br />

frequency about 20% which is generally enough to<br />

eliminate resonance should it occur.<br />

4. This accessory is NOT re<strong>com</strong>mended for variable<br />

speed DC or AC applications.<br />

5. Customers who prefer to use the scoop mount<br />

accessory to mount variable speed AC or DC motors<br />

must state on the face of the purchase order that they<br />

plan to support scoop and assume full responsibility<br />

for any vibratory or transient load induced by the<br />

motor. For re<strong>com</strong>mended scoop support, contact<br />

Reliance Electric and reference drawing #A31512.<br />

NOTE: For more information on DODGE MAXUM<br />

Concentric Reducer Scoop Mount Reducers,<br />

refer to page G3-41.<br />

TOP MOUNT ACCESSORY<br />

1. This may be a soft or hard mounting of the motor<br />

depending on the size of the motor and the distance<br />

that the adjusting screws are extended.<br />

FEATURES/BENEFITS<br />

PAGE G3-3<br />

NOMENCLATURE<br />

PAGE G3-6<br />

G3-82<br />

2. The benefits obtained by using this accessory are low<br />

cost, minimum floor space used for the motor/reducer<br />

assembly, and greater flexibility to obtain the required<br />

output RPM of the reducer than concentric coupling.<br />

3. This motor mount was designed for use with a<br />

constant speed motor at 1750 RPM.<br />

4. This accessory is NOT re<strong>com</strong>mended for variable<br />

speed DC or AC applications. Consult Reliance.<br />

NOTE: For more information on DODGE MAXUM<br />

Concentric Reducer Motor Mounts, refer to<br />

pages G3-51 throughG3-52.<br />

HD BASEPLATE ACCESSORY<br />

1. This is a hard mounting of the motor.<br />

2. The benefits obtained by using this accessory are:<br />

a. resonance problems are minimized<br />

b. accurate assembly of motor/coupling/reducer<br />

can be done at the factory instead of the job site.<br />

Note: Alignment must always be rechecked at<br />

job site prior to start-up.<br />

c. large motors can be rigidly mounted to keep<br />

deflection under control and provide longer<br />

service life.<br />

3. This accessory is re<strong>com</strong>mended for large motors<br />

where the motor weight exceeds the reducer weight or<br />

700 lbs., and for variable speed DC or AC applications<br />

regardless of the motor weight. For mounting<br />

dimensions see page G3-39.<br />

NOTE: For more information on DODGE MAXUM<br />

Concentric Reducer HD Baseplates, refer to<br />

pages G3-38.<br />

EASY SELECTION<br />

PAGE G3-7<br />

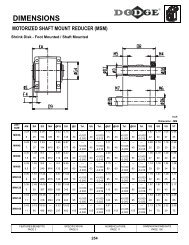

SELECTION/DIMENSIONS<br />

PAGE G3-23