Type S Addresses - Stöbich Brandschutz

Type S Addresses - Stöbich Brandschutz

Type S Addresses - Stöbich Brandschutz

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

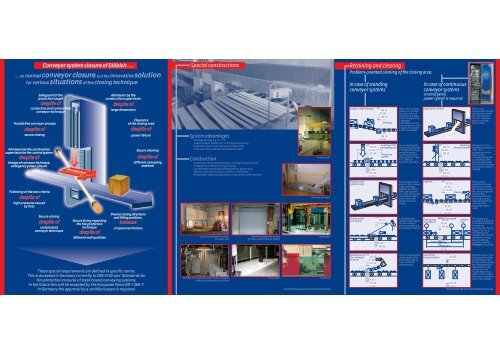

Conveyor system closure of <strong>Stöbich</strong> . . .<br />

… no normal conveyor closure, but the innovative solution<br />

for various situations of the closing technique<br />

Safeguard of the<br />

protection target<br />

despite of<br />

conductive and combustible<br />

conveyor technique<br />

Troublefree conveyor process<br />

despite of<br />

secure closing<br />

Admission by the construction<br />

supervision for the control system<br />

despite of<br />

linkage of conveyor technique,<br />

emergency power, closure<br />

Following of the test criteria<br />

despite of<br />

high pressures caused<br />

by fires<br />

despite of<br />

Secure closing<br />

complicated<br />

conveyor technique<br />

Secure fixing regarding<br />

the fire protection<br />

technique<br />

despite of<br />

different wall qualities<br />

Admission by the<br />

construction supervision<br />

despite of<br />

large dimensions<br />

Clearance<br />

of the closing area<br />

because<br />

despite of<br />

power failure<br />

Diverse closing directions<br />

and fitting positions,<br />

of space restrictions<br />

These special requirements are defined in specific norms.<br />

This is accepted in Germany currently to DIN 4102 and Standards for<br />

fire protection closures of track bound conveying systems.<br />

In the future this will be accepted by the European Norm EN-1366-7.<br />

In Germany the approval by a certified expert is required.<br />

Secure clearing<br />

despite of<br />

different conveying<br />

material<br />

Special constructions<br />

System advantages<br />

· Very large opening, e.g. 15 x 1 m<br />

· Several conveyor systems can run through one opening<br />

· Fixed deep closures with intumescent components<br />

· Crane way closure (slide door and butterfly valve)<br />

Construction<br />

· Combination of the different designs of conveyor system closures<br />

· Combination of different closing directions,<br />

e.g. from below horizontally pushing and from above tilting<br />

· Various constructions based on more than 100 fire tests<br />

· Re-opening is made manually, electric motor driven or pneumatically<br />

Continuous ground conveyor<br />

for paper rolls<br />

Movable closure plane at the circular conveyor<br />

with textile fire protection closure<br />

Textile fire protection closure<br />

for interrupted conveyor system<br />

Storey lifter<br />

Tilt tray sorter<br />

Nap tape conveyor<br />

Storey lifter<br />

Craneway<br />

You will find the approval in www.stoebich.de/zulassung.<br />

Retaining and clearing<br />

Problem-oriented clearing of the closing area.<br />

In case of standing<br />

conveyor systems<br />

Gravity roller conveyor<br />

Stop M<br />

Pulling out of<br />

general cargo<br />

Pulling out of<br />

bulk goods<br />

Blowing out of<br />

the conveyed<br />

material<br />

Clearing<br />

Crushing of the<br />

conveyed goods<br />

Protective<br />

screen<br />

When roller conveyor<br />

systems run through<br />

the closure with an<br />

inclination, the delay<br />

of the closing process<br />

is adequate.<br />

Precondition is that it<br />

may not lead to a back<br />

draught of the goods<br />

to the closure level.<br />

For conveyed goods,<br />

which can be crushed<br />

or displaced by kinetic<br />

energy because of<br />

their properties, the<br />

clearing system “<strong>Type</strong><br />

A-Y1” offers an<br />

economic possibility.<br />

General cargo, which<br />

move on the conveyor<br />

system with gaps<br />

between one to the<br />

other, can be pulled<br />

out of the closing area<br />

via swivelling return<br />

motion lever with<br />

stored pneumatic<br />

energy.<br />

A rake, driven by<br />

stored energy, swivels<br />

into the conveyor<br />

process and pulls out<br />

the conveyed material.<br />

Light conveyed goods<br />

can be blown out of<br />

the closing range by<br />

means of stored<br />

compressed air.<br />

In case of continuous<br />

conveyor systems<br />

an emergency<br />

power system is required.<br />

Light barrier control<br />

Logistics<br />

Stop M M<br />

Closing area<br />

surveillance<br />

Scan of the<br />

hanger position<br />

Initiator occupied<br />

Clearing<br />

Initiator<br />

free<br />

I II III<br />

Passage safeguard Parking space<br />

Security area<br />

One or more<br />

transversally arranged<br />

light barriers control<br />

the closing level. In<br />

case of a detected<br />

gap the conveyor<br />

system stops.<br />

Retaining Bulk goods can be<br />

of bulk material retained by means of a<br />

slider . The<br />

arrangement of the<br />

slider can be<br />

rectangular, diagonal<br />

or according to the<br />

snow plow principle.<br />

Only after the clearing<br />

the conveyor system is<br />

stopped.<br />

When several<br />

separated conveyor<br />

systems are used for<br />

the conveyor process,<br />

the closing range can<br />

be cleared by<br />

switching-off of the<br />

incoming conveyor<br />

route and continued<br />

running of the<br />

outgoing conveyor<br />

route.<br />

The closing area<br />

surveillance is defined<br />

for the distance that is<br />

necessary to<br />

guarantee the closing<br />

range to be free of<br />

conveyed goods.<br />

Usually in front of and<br />

behind this closing<br />

area surveillance,<br />

proximity switches<br />

(initiators) are placed.<br />

With this system it has<br />

to be guaranteed that<br />

all openings are free<br />

simultaneously during<br />

the closing period. In<br />

dependence on the<br />

uniformity of the<br />

hanger distances as<br />

well as of the hangers<br />

itself, control elements<br />

have to be installed.<br />

You will find the approval in www.stoebich.de/zulassung.