Svetsaren nr 2. 2000 - Esab

Svetsaren nr 2. 2000 - Esab

Svetsaren nr 2. 2000 - Esab

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

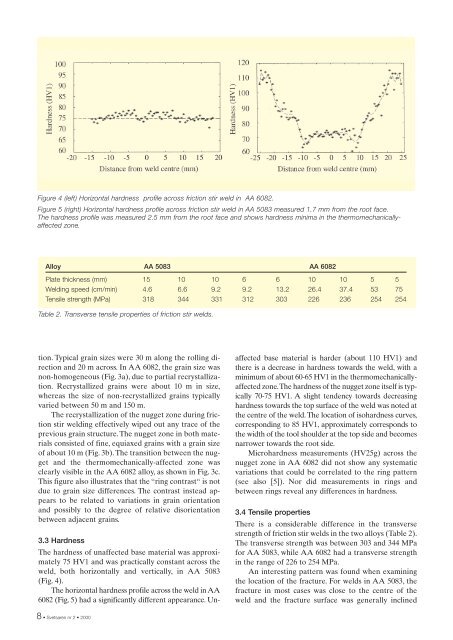

Figure 4 (left) Horizontal hardness profile across friction stir weld in AA 608<strong>2.</strong>Figure 5 (right) Horizontal hardness profile across friction stir weld in AA 5083 measured 1.7 mm from the root face.The hardness profile was measured <strong>2.</strong>5 mm from the root face and shows hardness minima in the thermomechanicallyaffectedzone.Alloy AA 5083 AA 6082Plate thickness (mm) 15 10 10 6 6 10 10 5 5Welding speed (cm/min) 4.6 6.6 9.2 9.2 13.2 26.4 37.4 53 75Tensile strength (MPa) 318 344 331 312 303 226 236 254 254Table <strong>2.</strong> Transverse tensile properties of friction stir welds.tion. Typical grain sizes were 30 m along the rolling directionand 20 m across. In AA 6082, the grain size wasnon-homogeneous (Fig. 3a), due to partial recrystallization.Recrystallized grains were about 10 m in size,whereas the size of non-recrystallized grains typicallyvaried between 50 m and 150 m.The recrystallization of the nugget zone during frictionstir welding effectively wiped out any trace of theprevious grain structure. The nugget zone in both materialsconsisted of fine, equiaxed grains with a grain sizeof about 10 m (Fig. 3b).The transition between the nuggetand the thermomechanically-affected zone wasclearly visible in the AA 6082 alloy, as shown in Fig. 3c.This figure also illustrates that the “ring contrast“ is notdue to grain size differences. The contrast instead appearsto be related to variations in grain orientationand possibly to the degree of relative disorientationbetween adjacent grains.3.3 HardnessThe hardness of unaffected base material was approximately75 HV1 and was practically constant across theweld, both horizontally and vertically, in AA 5083(Fig. 4).The horizontal hardness profile across the weld in AA6082 (Fig. 5) had a significantly different appearance. Unaffectedbase material is harder (about 110 HV1) andthere is a decrease in hardness towards the weld, with aminimum of about 60-65 HV1 in the thermomechanicallyaffectedzone.The hardness of the nugget zone itself is typically70-75 HV1. A slight tendency towards decreasinghardness towards the top surface of the weld was noted atthe centre of the weld. The location of isohardness curves,corresponding to 85 HV1, approximately corresponds tothe width of the tool shoulder at the top side and becomesnarrower towards the root side.Microhardness measurements (HV25g) across thenugget zone in AA 6082 did not show any systematicvariations that could be correlated to the ring pattern(see also [5]). Nor did measurements in rings andbetween rings reveal any differences in hardness.3.4 Tensile propertiesThere is a considerable difference in the transversestrength of friction stir welds in the two alloys (Table 2).The transverse strength was between 303 and 344 MPafor AA 5083, while AA 6082 had a transverse strengthin the range of 226 to 254 MPa.An interesting pattern was found when examiningthe location of the fracture. For welds in AA 5083, thefracture in most cases was close to the centre of theweld and the fracture surface was generally inclined8 • <strong>Svetsaren</strong> <strong>nr</strong> 2 • <strong>2000</strong>