Pit Jacks, Support Systems and Accessories - Tecalemit AS

Pit Jacks, Support Systems and Accessories - Tecalemit AS

Pit Jacks, Support Systems and Accessories - Tecalemit AS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

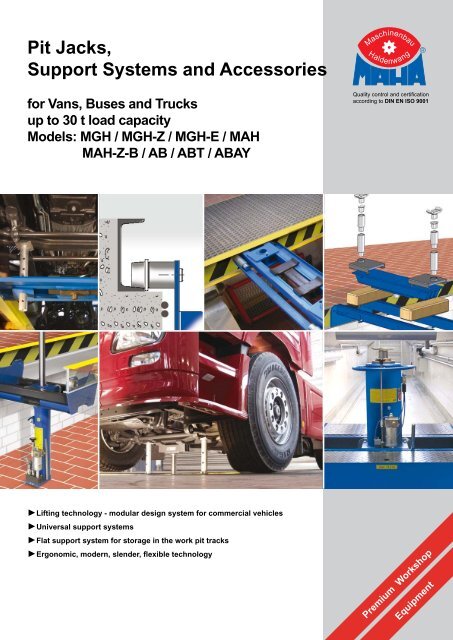

<strong>Pit</strong> <strong>Jacks</strong>,<strong>Support</strong> <strong>Systems</strong> <strong>and</strong> <strong>Accessories</strong>for Vans, Buses <strong>and</strong> Trucksup to 30 t load capacityModels: MGH / MGH-Z / MGH-E / MAHMAH-Z-B / AB / ABT / ABAYQuality control <strong>and</strong> certificationaccording to DIN EN ISO 9001►Lifting technology - modular design system for commercial vehicles►Universal support systems►Flat support system for storage in the work pit tracks►Ergonomic, modern, slender, flexible technology

<strong>Pit</strong> <strong>Jacks</strong>MAHA <strong>Pit</strong> <strong>Jacks</strong> & <strong>Accessories</strong>Table of Contents:PageSelection Criteria for <strong>Pit</strong> <strong>Jacks</strong>Hanging Hydraulic/Pneumatic <strong>Pit</strong> JackHanging Electro-Hydraulic <strong>Pit</strong> JackTest St<strong>and</strong> <strong>and</strong> Transmission Jack Floor-runningUniversal Jack Floor-runningJack Adaption to existing Working <strong>Pit</strong>Ideal <strong>Pit</strong> Working Area<strong>Support</strong> Bridge AB<strong>Support</strong> System ABT<strong>Support</strong> System ABAYAxle Traverses<strong>Pit</strong> Edge Design<strong>Support</strong> <strong>and</strong> Lift matrixSt<strong>and</strong>ard Program Hanging <strong>Pit</strong> <strong>Jacks</strong>St<strong>and</strong>ard Program Floor-running <strong>Pit</strong> <strong>Jacks</strong>St<strong>and</strong>ard Program Axle Traverse <strong>and</strong> <strong>Accessories</strong>St<strong>and</strong>ard Program <strong>Support</strong> <strong>Systems</strong>345678910111213141516171819What ever jack you need, we have it!Manual-hydraulic – Hydraulic/Pneumatic - Electro-hydraulicA jack without a support system is incomplete!2

<strong>Pit</strong> <strong>Jacks</strong>MAHA <strong>Pit</strong> Jack & <strong>Accessories</strong>Selection Criteria for <strong>Pit</strong> <strong>Jacks</strong>:Load capacity:0.5 / 2.0 / 4.0 / 4.5 / 6.5 / 11.0 / 14.5 / 16.5 / 20.0 / 30.0 tAllow for generous load capacity. Pay attention to loaded vehicles:When lifting a rear axle, the entire flatbed axle <strong>and</strong> the third axle are lifted.Stroke:450 / 600 / 750 / 1.050 / 1.200 mm450 mm is suffi cient for all st<strong>and</strong>ard jobs on trucks. If necessary, extenders can be used toreach high lifting points. 600 mm is an intermediate solution. 750 mm is required for transmissionremoval or for jobs on elevated units or trailers. For frequent work on units, a telescopic universal jackwith 1.200 mm is the right choice.Carriage:„S-Carriage“, „P-Carriage“ or „B-Carriage“The st<strong>and</strong>ard jack is supplied with „S-Carriage“ with a stroke of 450 und 600 mm. We supply„P-Carriages“ with a stroke of 750 mm for professional application of support bridgeswith axle traverses. Testing pits are equipped with fl oor running „B-Carriages“ jacks with750 mm stroke.Our „fl oor running“ universal jack with a „B-Carriage“ is supplied with a stroke of 1.200mm. Due to its low height it is optimally suited for transmission <strong>and</strong> unit work. This jackcan be used outside of the pit for mobile lift systems, four cylinder lifts or truck lift units.Working speed/Operation/ControlManual-hydraulic, pneumatic, hydraulic-pneumaticManual-hydraulic jacks (MGH) are offered for infrequent tasks in work pits.A jack variation with faster working speed, the MGH-Z has been developed with pneumaticcontrol. This is equipped with a compressed air high-speed control up to load point <strong>and</strong>compressed air feedback control from load point in rest position.The hydraulic-pneumatic control (MGH-Z-LM) is optimum. This is additionally equippedwith an air motor for automatic lifting with load.Lifting platforms:Lifting platforms are needed to lift vehicles properly <strong>and</strong> securely. These are divided intoaxle traverses for vehicles which cannot be lifted in the middle, pads for different liftingpoints <strong>and</strong> in unit <strong>and</strong> transmission plates for safe removal <strong>and</strong> installation of assemblies.<strong>Support</strong> systems:Two systems are available. In one system (AB) the vehicle is lifted in the middle <strong>and</strong> supportedat two points. The other system (ABT) lifts the vehicle with an axle traverse <strong>and</strong> issupported by it.The support bridge ABAY is a mixture of both systems.The supports systems are compatible with the lifting platforms <strong>and</strong> can be used variably ina modular system.3

<strong>Pit</strong> <strong>Jacks</strong>Hydraulic/Pneumatic-operated Jack as Hanging VersionModel: MGH / MGH-Z with Air MotorFlexibleThe adjustable carriage can be used in variousworking pits.FastThe MGH-Z is equipped with a high speed controlfunction to move quickly to the lifting point. The airmotor (optional) supports fast <strong>and</strong> effective load lifting.AccuracyThe jack control has a very sensitive setting.ErgonomicThe high speed function is attached to the side of thejack so that it can be operated from either side of thepit.Smooth maneuverability in pitRunning rollers with needle bearings for fast <strong>and</strong> easymovement in the working pit.Long-lifeThe guidance pipe is covered with hydraulic oil at eachcomplete lifting stroke to prevent rust build up.MGH-Z 14.5/75 with airMGH <strong>Pit</strong> Jackis manually pumped up from the rest position. Experienceshows that more time is needed to pump up to the lifting pointthan the actually lifting itself. This jack is only recommended forpits without compressed air supply or special cases!MGH-Z <strong>Pit</strong> Jackis an ideal combination between hydraulic <strong>and</strong> pneumatic. Thejack is at the lifting point in a matter of seconds <strong>and</strong> the vehicle israised with a few pump strokes. The retraction of the cylinder issupported by compressed air.Ø 60450570 650Ø 60Ø 1437501150 700All dimensions in mm!4MGH 14.5/45 All dimensions in mm!MGH-Z 14.5/75

<strong>Pit</strong> <strong>Jacks</strong>Electro-hydraulic <strong>Pit</strong> Jack as Hanging VersionModel: MGH-EFlexibleA uniform modular plug-in system for using a widerangeof accessories. The lifting platform has a uniformdiameter of 45 mm starting at 6.5 t.This pit jack are well suited for professional operationsor for working pits without compressed air connection.FastThe high speed lifting action under load is 35 sec. for750 mm.The jack‘s working speed can be precisely adjustedusing fi ne control. This function controls the up <strong>and</strong>down movement.ErgonomicThe shock resistant cover hood has been developedfor use in working pits.Control knobs <strong>and</strong> a low noise submerged oil unitmake for easy h<strong>and</strong>ling in the pit.Long-lifeThe sturdy piston rods are hard-chrome plated <strong>and</strong>designed for use in extreme workshop pit operation.MGH-E 14.5/75The sturdy Electro-Hydraulic pit jack MGH-E is designedfor frequently used working pits.A mixture of hydraulic, submerged oil unit <strong>and</strong> electroniccontrol guarantees for a sensitive, quick, quiet <strong>and</strong> smoothtotal operation.Our electrical or hydro-pneumatic jacks have a very slenderdesign to allow for generous passage through the work area.For this reason, lateral jack movement is of great importance.Ø 907501160 700All dimensions in mm!MGH-E 14.5/755

<strong>Pit</strong> <strong>Jacks</strong>Manual hydraulic/pneumatic Test St<strong>and</strong> <strong>and</strong> Transmission Jackas Floor-running VersionVersatileThe slender carriage (750 x 1.000 mm) makes it easyto use the jack in test pits, mobile lift systems or inconnection with rail lifts.FastThis jack is equipped with a high speed control function.Optionally it can be equipped with an air motor.SafeAt a load of 800 - 1,000 kg the jack sits securely on thefl oor.Smooth maneuverability in pitEasy jack movement with spring loaded bearings foreasy-run poly rollers 360° rotatable.ErgonomicThis jack type can be adapted to the pit depth. Theoverall height can vary between 1.180 - 1.580 mm.With a lift stroke of 750 mm the total height is 1.930- 2.330 mm.This jack also has all product advantages of ourmodular system.MAH-Z-B 14.5/75 with air motorThe fl oor-running Telescopic-Transmission Jack MAH 4with its freely movable carriage is well-suited for motor <strong>and</strong>transmission work in connection with a mobile lift system.The test st<strong>and</strong> jack MAH-Z-B is suitable for test pits whichdo not have a continuous pit edge fi tting for hanging jacks.Ø 60Ø 90835 120010001930-2330Ø 70160750All dimensions in mm! MAH-4.0/120 All dimensions in mm! MAH-Z-B 14.5/75 with air motor6850 850750

<strong>Pit</strong> <strong>Jacks</strong>Hydraulic/Pneumatic Universal Jackin Floor-Running Version as Repair JackLow Overall HeightThe low overall height of the jack means that a transmissionclamped on the jack can be moved underneaththe vehicle axle <strong>and</strong> then, behind the vehicle,removed from the jack.Thanks to the generous lifting height, the removal <strong>and</strong>mounting of vehicle components can even be done onoff-road vehicles with large ground clearance.FastThe piston stroke to the load point is done with a highspeed lift. To adjust the axle traverse or to do transmission/ component work, the slow load stroke isregulated with the foot control. In this way, both h<strong>and</strong>sare free to do adjustment work.VersatileTo easliy reach <strong>and</strong> work in the upper areas of the vehicle,this jack has two steps installed. Working undervehicle is easy with the free-st<strong>and</strong>ing lifting cylinder.ErgonomicThe sturdy cover hood safely covers a variety ofconstruction elements such as compressed air maintenanceunit, air motor <strong>and</strong> control elements.MAH-Z 14.5/120SafeVehicles must be securely lifted <strong>and</strong> supported.These accessories can be found on the followingpages.The fl oor-running Telescopic-Transmission Jack MAH 0.5with a load capacity of 0.5 t is extremely fl exible with a sturdydesign suitable for removal <strong>and</strong> installation of motors <strong>and</strong>transmissions.The telescopic-universal jack MAH-Z is ideal fortransmission <strong>and</strong> other unit work. Suitable for vehicle liftingup to 1 6.5 t axle load. It can be used in working pits but alsoas supplement for mobile lift systems, track lifts or truck lifts.Ø 70Ø 45720 10502090890Ø 115Ø 701200800 800750All dimensions in mm! MAH 0,5 All dimensions in mm!1000MAH-Z7

<strong>Pit</strong> <strong>Jacks</strong>Adaption Jack Carriage for existing Working <strong>Pit</strong>sSelection CriteriaWhen selecting the jack carriage, pay attention to theexisting pit protrusion.Pay close attention to any lighting that is installed inthe pit when using hanging carriages.FlexibleBy moving the side plates,the jack carriage is adjustedto the pit dimensions.Serial rollers have a slightangle <strong>and</strong> fi t most profi les.The serial rollers must be adaptedfor profi les with pronounced angle.(optional).The adjustment range iscalculated in steps so thatthe jack installation canbe done in a closed pitprofi le U 220. Only weldedcarriages are supplied witha load capacity of 15 t ormore. Custom made carriagesare offered for lowerload capacities.Protruding cement, lamps or linesetc. require that elongated rollers beused (optional).Our pit jacks are made to fit your pit dimensions. Pleasemake use of our dimension sheet when placing your order!S-CarriageWith this carriage, the upper end of the retracted piston rodis at the same level as the jack‘s total height. This meansjacks with low lift can be used.P-CarriageProfessional use of support bridges with axle traverses in thisversion. The smooth, deeply drawn carriage side plates meansaxle traverses <strong>and</strong> other platforms can be moved underneaththe support bridges.Our jack systems are designedfor a pit edge width upto 1.080 mm. Special solutionsare possible. (optional).8

<strong>Pit</strong> <strong>Jacks</strong>Ideal <strong>Pit</strong> Working PlaceOptimum <strong>Pit</strong> Working Place recommended for new installations.Workplace-Friendly:This pit variation offersgenerous space forworking <strong>and</strong> has versatileusage.Parking:The jack can be parked in pitpockets.<strong>Pit</strong> Width:The closed U-designprovides a very wide pitopening for optimumworking conditions.These details are describedon page 14.Workplace Utility:The pit pockets can be usedfor storage of oil hoses <strong>and</strong>drums, used oil collector,grease presses, specialtools <strong>and</strong> tool carts.Our jack carriage variety with a 1.200 mm liftThis universal jack runs in a lengthwise direction on angleor U-tracks. The sideways movement in the carriage is easy<strong>and</strong> smooth. The pit cross cut determines how far the it canbe moved.Carriage version for free movement in or outside of the workingpit. The parking position is in a pit pocket area.9

<strong>Pit</strong> <strong>Jacks</strong><strong>Support</strong> Bridges ABThe use of a support bridge is the only safe method of vehicle support in order to work on it. Once the vehicle sitssecurely on the support bridge, the jack is freed up for other uses.VersatileThanks to the continuous opening in the middle areaof the support bridge the jack can be fully slided to oneside.Our support bridges are specially manufactured for theexisting pit design.The maximum height of the support bridge is 185 mm,so that is fi ts well into the pit design. See Version C.Highly placed parts such as frames can be supportedwith this support bridge <strong>and</strong> pipe extender set.The support bridge can be supplied up to 14.5 t, adjustablein steps. It can then be used in various workingpits.The pipe extenders of support bridges may only be extended by onestep.ErgonomicThe light design makes it easy to move the supportbridge in the working pit.Ideal VersionVersion A Version B Version C Version D Version EThe vehicle is lifted at the front axle yoke <strong>and</strong> supported withthe support bridge via the support pipes.The jack is freed to be used at other positions.The vehicle is securely supported.10

<strong>Pit</strong> <strong>Jacks</strong><strong>Support</strong> System ABTFor lifting of vehicles at two lifting points.Traverses with their support systems are necessary with offset differentials <strong>and</strong> many air-cushioned buses.VersatileThe support bridge is adjustable in steps <strong>and</strong> has ast<strong>and</strong>ard height of 185 mm. It fi ts into various workingpits <strong>and</strong> in pit edge design C (picture page 10).Optimum lifting of offset lifting points thanks to continuoussupport bridge opening. Especially helpful inconnection with an axle traverse, movable sideways,for low-platform buses.User-friendlyUnder load, the axle traverse is settled on thewooden blocks, as shown. This is one of the fastest<strong>and</strong> quickest ways to support vehicles.ErgonomicWhen the support system is not used it remains in thepit. The axle traverse is laid in the support bridge.The advantages of this support bridge:Lift vehicle, support it <strong>and</strong> free up the jack forother tasks.The axle traverses may only be extended by one step(max. 150 mm) ! <strong>Support</strong> system rests in the pit. Traverse lifts the vehicle up. Jack is freed up for other tasks.11

<strong>Pit</strong> <strong>Jacks</strong><strong>Support</strong> Bridge ABAYThe fl exible ABAY system for vehicle support with <strong>and</strong> without axle traverse.ErgonomicThe transport of the support system can be done withthe pit jack <strong>and</strong> a transport device (optional) in the pit.ProtectionThe middle recess of the support bridge is lined withsponge rubber as protection for the piston rod.FlexibleExtension pipes can be used to reach uppermost supportpoints.Vehicle support is independent of the location of the pitjack.The axle traverse (see diagram below) can be securelystored in the special mount.The axle traverse can be used with various supportbridges.MAHA pit jack accessories can also be used with thissupport bridge system.The pipe extensions of support bridges may only be extended by onestep.Easy support with single pipes <strong>and</strong> placement of axletraverse in the support bridge.Using the system with axle traverse. Axle traverse supportedon the support bridge.12

<strong>Pit</strong> <strong>Jacks</strong>Axle traversesThe axle traverses in the MAHA program are very fl at <strong>and</strong> can remain in the pit when not being used <strong>and</strong> are not ahindrance for drive over82-1018214The movable platform bolts of the AT-NB axle traversecan lift vehicles with offset load points.To reach the lifting points of the low-platform buses,the axle traverse height was limited to 126 mm.17590017582-1018214The fl at, slim design of the st<strong>and</strong>ard support bridgeAT 15 is suitable for storage in the ABT 15 bridge.9001581318140318The ATY axle traverse is suitable for alarge lifting area.This is needed for buses, municipal or militaryvehicles.9001941262080-622-1520The universal traverse is designed for a load capacityof 1.5 t in its extended form.Vehicles with a load up to 15 t can lifted using the plugonwooden pad in the middle.727All dimensions in mm!5813

<strong>Pit</strong> <strong>Jacks</strong><strong>Pit</strong> Edge DesignThe choice of pit edge design determines whether the working pit is to be used as a repair pit, test st<strong>and</strong> pit orcovered emergency pit.Our pit edges are designed with width <strong>and</strong> length dimensions. Re-closable openings are part of the pit edging tohang in the pit jacks <strong>and</strong> support systems.Ideal <strong>Pit</strong> Edging SystemThe working area isthe same as the trackwidth.The track width isca. 130 mm wider thanthe working area.The track width isca. 180 mm wider thanthe working area._ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ __________________ _ _ _ __ _ _ _ _Track widthWorking areaTrack widthTrack width_ _ _ _ __ _ _ _ __ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _________________<strong>Pit</strong> profi le U 220 withoutwheel defl ector is the optimumworking pit! The trackwidth equals the workingwidth <strong>and</strong> there is no wheeldefl ector to get in the way.<strong>Pit</strong> Edging with CoverThe pit profi le U 220 is setdeeper for placement of covergrids. The dimensions for thedeeper setting are determinedby the drive over load <strong>and</strong>cover grid thickness.A pit head can be used todrive safely in the test area.<strong>Pit</strong> Edging Systemwith Wheel DeflectorThe pit profi le L 180 withwheel defl ector is suitablefor test pits.14

<strong>Support</strong> <strong>and</strong> Jack Matrix<strong>Support</strong> system AT-NB <strong>Support</strong> system ABT Extender set <strong>Support</strong> system ABAY <strong>Support</strong> system ABApplication for:<strong>Support</strong> ofFront Axles which can be lifted in themiddle:consisting of:1 x support bridge2 x st<strong>and</strong>ard pads2 x support pipe 400 mm2 x plug<strong>Support</strong> of drive axles which mustbe lifted with an axle traverse, <strong>and</strong> forfront axles,which can be lifted in the middle:consisting of:1 x support bridge2 x st<strong>and</strong>ard pads2 x support pipes 400 mm2 x plugExtender set to extend support pipesfor AB- <strong>and</strong> ABAYsupportsystems:consisting of:2 x mushrooms2 x intermediate piece 150 mm2 x support pipes 300 mm2 x connection pegs2 x support pipe 600 mm<strong>Support</strong> <strong>and</strong> lifting of rear axles(e.g. with differential). These must belifted via Two point platform with axletraverseconsisting of:1 x support bridge1 x traverse2 x slim pads2 x mushrooms2 x intermediate pieces 100 mm2 x intermediate pieces 150 mm2 x wooden blocks<strong>Support</strong> <strong>and</strong> lifting of Rear axles whichmust be lifted with an axle traverse.Necessary if the bottom clearance ofthe vehicle is very small <strong>and</strong> the vehiclecannot be lifted with offset axle.consisting of:1 x support bridge1 x traverse for low-platform buses2 x large pads2 x wooden blocks2-Axle commercial vehicleXX O O X X X X O O OO X X X O X X O O OO O O O O X X X OX O O XX X X XX X XX X XX X X XO O O O3-Axle commercial vehicle4-Axle commercialBusBus-low plat. technologyBuild.mach./Wheel loaderMunicipal vehiclesAuto craneUnimogVansX X O X OX X X O OX X O OX X X OX XX X O OX X X OO O O X X O O O O OO O O X O O O O O OXmax. loadcapacity4.0 t13.0 t15.0 t20,0 t13.0 t15.0 t15.0 t20.0 t6.0 t15.0 t20.0 t11.0 t15.0 tModelAB 4AB 13AB 15AB 20ABAY 13ABAY 15EG 15EG 20ABT 6ABT 15ABT 20AT-NB 11AT-NB 15Article No.VZ 975381VZ 975325VZ 975326VZ 975526VZ 975264VZ 975266VZ 975268VZ 975529VZ 975382VZ 975269VZ 975271VZ 975273VZ 975274X IdealO Possible15

<strong>Pit</strong> <strong>Jacks</strong>Delivery Program Hanging <strong>Pit</strong> <strong>Jacks</strong>16Model Lift Load Drive Hole Carriage Article No. Picture DescriptioncapacitydiameterModel: MAH-Z Model: MGH-E LM Model: MGH-Z Model: MGHLift 1200 Lift 1200 Lift 750 Lift 750 Lift 600 Lift 450 Lift 750 Lift 600 Lift 4502 t4.5 t6.5 t11 t14.5 t16.5 t20 t6.5 t11 t14.5 t2 t4.5 t6.5 t11 t14.5 t16.5 t20 t2 t4.5 t6.5 t11 t14.5 t16.5 t20 t6.5 t11 t14.5 t2 t4.5 t6.5 t11 t14.5 t16.5 t20 t6.5 t11 t14.5 t16.5 t20 t14.5 t16.5 t14.5 t8 bar8 bar8 bar8 bar8 bar8 bar8 bar8 bar8 bar8 bar8 bar8 bar8 bar8 bar8 bar8 bar8 bar8-10 bar400 V400 V400 V400 V400 V8 bar8 bar8 bar30 mm30 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm30 mm30 mm45 mm45 mm45 mm45 mm45 mm30 mm30 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm30 mm30 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mmS-carriageS-carriageS-carriageS-carriageS-carriageS-carriageS-carriageS-carriageS-carriageS-carriageP-carriageP-carriageP-carriageP-carriageP-carriageP-carriageP-carriageS-carriageS-carriageS-carriageS-carriageS-carriageS-carriageS-carriageS-carriageS-carriageS-carriageP-carriageP-carriageP-carriageP-carriageP-carriageP-carriageP-carriageP-carriageP-carriageP-carriageP-carriageP-carriagehanginghanginghangingVP 254001VP 254003VP 454001VP 454002VP 454003VP 454004VP 454005VP 454011VP 454013VP 454015VP 254002VP 254004VP 454012VP 454014VP 454016VP 454017VP 454018VP 254005VP 254007VP 454006VP 454007VP 454008VP 454009VP 454010VP 454019VP 454021VP 454023VP 254006VP 254008VP 454020VP 454022VP 454024VP 454025VP 454026VZ 975261VP 454061VP 454062VP 454063VP 454064VP 454065VP 454202 +VZ 975521VP 454203 +VZ 975521VP 454206 +VZ 975521<strong>Pit</strong> Jack, Model: MGH450 mm lifting heightManual hydraulic operation withmanual pumps for high-speed <strong>and</strong>load lifthard-chromed plated piston rod<strong>Pit</strong> Jack, Model: MGH600 mm lifting heightManual hydraulic operation withmanual pumps for high-speed <strong>and</strong>load lifthard-chromed plated piston rod<strong>Pit</strong> Jack, Model: MGH750 mm lifting heightManual hydraulic operation withmanual pumps for high-speed <strong>and</strong>load lifthard-chromed piston rod<strong>Pit</strong> Jack, Model: MGH-Z450 mm lifting heightManual hydraulic load lift with manualpump, pneumatic high-speed lift,pneumatic forced retraction of cylinder,hard-chromed piston rod<strong>Pit</strong> Jack, Model: MGH-Z600 mm lifting heightManual hydraulic load lift with amanual pump, pneumatic high-speedlift, pneumatic forced retraction of thecylinder, hard-chromed piston rod.<strong>Pit</strong> Jack, Model: MGH-Z750 mm lifting heightManual hydraulic load lift with manualpump, pneumatic high-speed lift,pneumatic forced retraction of cylinder,hard-chromed piston rodAir Motor for automaticload lift, air volume 350 l/min with anoperating pressure of 10 bar<strong>Pit</strong> Jack, Model: MGH-E750 mm lifting heightElectro-hydraulic high speed <strong>and</strong>load liftPower: 2.5 kW/380 VVery sensitive or very fast control ofthe jackTelescopic <strong>Pit</strong> Jack,Model: MAH-Z-T1.200 mm lifting heightPneumatic high-speed lift, automaticload lift with air motor, pneumaticforced retraction of the cylinder, hardchromedpiston rodTelescope <strong>Pit</strong> Jack,Model: MAH-Z-B-TEquipped like MAH-Z-T, butwithout protective covering,foot controlSt<strong>and</strong>ard delivery includes st<strong>and</strong>ard carriages either welded fi x to the dimensions of the pit or with adjustable carriages with 6.5 to 14.5 t. Please fi llout the pit dimension measurement sheet carefully. Special carriages may be needed due to local conditions, e.g. due to extra wide pits or protrusionson the pits. This will have additional charges. (Order number VZ 975519). This extra charge can also occur subsequently after checking thedimension sheet.

<strong>Pit</strong> <strong>Jacks</strong>Delivery Program Floor-Running <strong>Pit</strong> <strong>Jacks</strong>Carriage U or F MAH-Z MAH-Z LM MAH-Z-B MAH MAHModel Lift Load Drive Hole Carriage Article No. Picture DescriptioncapacitydiameterLift 1200 Lift 1200 Lift 1200 Lift 750 Lift 1200 Lift 10500.5 t0.5 t2 t2 t4 t11 t14.5 t16.5 t20 t14.5 t16.5 t14.5 t14.5 t16.5 t14.5 t8 bar8-10 bar8 bar8 bar8 bar8 bar8 bar8 bar30 mm30 mm30 mm30 mm30 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mm45 mmfl oor-runningfl oor-runningfl oor-runningfl oor-runningfl oor-runningfl oor-runningfl oor-runningfl oor-runningfl oor-runningfl oor-runningfl oor-runningfl oor-runningfl oor-running, ontracksup to 1.200 mm(1.400 mm optional)fl oor running, ontracksup to 1.200 mm(1.400 mm optional)floor running, ontracksup to 1.200 mm(1.400 mm optional)VP 245205VP 245208VP 245206VP 245200VP 245201VP 454204VP 454205VP 454207VP 454208VZ 975261VP 454202VP 454203VP 456206VP 454202 +VZ 975314VP 454203 +VZ 975314VP 454206 +VZ 975314Transmission Jack, Model: MAH1.050 mm lifting height,St<strong>and</strong>ard overall height 720 mmFoot hydraulic load liftHard-chromed plated piston rodTransmission Jack, Model: MAH1.200 mm lifting height,St<strong>and</strong>ard overall height 835 mmManual-hydraulic load lift with amanual pump, pneumatic high-speed,pneumatic forced retraction of cylinder,hard-chromed piston rodAxle Jack, Model: MAH-Z-B750 mm lifting height,St<strong>and</strong>ard overall height 1.180-1.580mmManual-hydraulic load lift with a manualpump, pneumatic high-speed,pneumatic forced retraction of cylinder,hard-chromed piston rodAir Motor for automaticload lift, air volume 350 l/min with anoperating pressure of 10 barTelescopic <strong>Pit</strong> Jack, Model: MAH-Z1.200 mm lifting height,Pneumatic high-speed liftAutomatic load lift with air motorPneumatic forced retraction of cylinder,hard-chromed plated cylinderTelescopic <strong>Pit</strong> Jack,Model: MAH-Z-BEquipped like MAH-Z, but without protectivecover, foot control.Telescopic <strong>Pit</strong> Jack, Model: MAH-Z1.200 mm lifting height,Pneumatic high-speed liftAutomatic load lift with air motorPneumatic forced retraction of cylinder,hard-chromed plated cylinderTelescopic <strong>Pit</strong> Jack,Model: MAH-Z-BEquipped like MAH-Z, but withoutprotective covering, foot control.17

<strong>Pit</strong> <strong>Jacks</strong><strong>Accessories</strong> for <strong>Pit</strong> <strong>Jacks</strong>St<strong>and</strong>ard Pads4.5 t, 30 mm, VZ 97536516.5 t, 45 mm, VZ 97527720.0 t, 45 mm, VZ 975278Narrow pad 100 mm surface4.5 t, 30 mm, VZ 97536616.5 t, 45 mm, VZ 97527920.0 t, 45 mm, VZ 975280Large Pad 145 mm surface16.5 t, 45 mm, VZ 97528120.0 t, 45 mm, VZ 975284Large Pad 175 mm surface16.5 t, 45 mm, VZ 97528220.0 t, 45 mm, VZ 975285Large Pad 220 mm surface16.5 t, 45 mm, VZ 975283Wooden pad4.5 t, 30 mm, VZ 97536716.5 t, 45 mm, VZ 975409Wooden pad MB2.0 t, 30 mm, VZ 975368Pad with rubber surface4.5 t, 30 mm, VZ 975369 D:12010.0 t, 45 mm, VZ 975287 D:165Mushrooms4.0 t, 30 mm, VZ 97539320.0 t, 45 mm, VZ 975515Adapter45 mm to 30 mm, VZ 975514Lift extenders 100 mm4.5 t, 30 mm, VZ 97537216.5 t, 45 mm, VZ 975289Lift extenders 150 mm4.5 t, 30 mm, VZ 97537316.5 t, 45 mm, VZ 975290Lift extenders 200 mm16.5 t, 45 mm, VZ 975410<strong>Support</strong> pipe 300 mm4.5 t, 30 mm, VZ 97539016.5 t, 45 mm, VZ 97541120.0 t, 45 mm, VZ 975412<strong>Support</strong> pipe 400 mm4.5 t, 30 mm, VZ 97539116.5 t, 45 mm, VZ 97533020.0 t, 45 mm, VZ 975413<strong>Support</strong> pipe 600 mm4.5 t, 30 mm, VZ 97539216.5 t, 45 mm, VZ 975331Front Axle Forkfor MB-Sprintersynthetic coated4.0 t, 30 mm, VZ 9753702-point surface20.0 t, 45 mm, VZ 975288Wooden blockfor support system ABT, VZ 975414Transmission plate rigidPlatform surface 300 x 200 mm0.8 t, 30 mm, VZ 9753710.8 t, 45 mm, VZ 975415Transmission plate swivable1 x 45° <strong>and</strong> 2 x 15° swivablePlatform surface 536 x 366 mm0.8 t, 45 mm, VZ 975315Transmission plate swivable1 x 45° swivable <strong>and</strong>2 x 10° inclinable via spindle,incl. tightening strap with quick lashingPlatform surface 536 x 366 mm0.8 t, 45 mm, VZ 975416Axle traverse 1.2Adjustable from 640 – 870 mm1.2 t, 30 mm, VZ 975374Axle traverse 1.5Adjustable from 800 – 1.550 mm1.5 t, 30 mm, VZ 975507Axle traverse 6.0Adjustable from 82 – 1.018 mm6.0 t, 45 mm, VZ 975262Axle traverse 15.0Adjustable from 82 – 1.018 mm15.0 t, 45 mm, VZ 975263Axle traverse for low-platformbusesAdjustable from 82 – 1.018 mm11.0 t, 45 mm, VZ 975395,126 high15.0 t, 45 mm, VZ 975396,Axle traverse for NeoplanAdjustable from 818 – 1.318 mm10.0 t, 45 mm, VZ 975517194 highAxle traverse for municipal vehiclesAdjustable from 318 – 1.318 mm10.0 t, 45 mm, VZ 975518 ,194 highMaintenance unit ¼“VZ 975320 at jackVZ 575364 in wiring system18

<strong>Pit</strong> <strong>Jacks</strong><strong>Support</strong> <strong>Systems</strong><strong>Support</strong> system ABwithout middle recessInclusive:2 x St<strong>and</strong>ard pads2 x <strong>Support</strong> pipe L = 400 mm2 x Insert bolts<strong>Pit</strong> width B up to 1.080 mm13.0 t, VZ 97532515.0 t, VZ 975326<strong>Pit</strong> width B from 1.080 mm up to1.200 mm at extra charge<strong>Support</strong> system ABTwithout middle recessInclusive:1 x <strong>Support</strong> bridge ABT1 x Axle traverse2 x slim pads2 x mushrooms2 x intermediate piece L=100 mm2 x intermediate piece L=150 mm2 x wooden block<strong>Pit</strong> width B up to 1.080 mm15.0 t, VZ 97526920.0 t, VZ 975271<strong>Pit</strong> width B from 1.080 mm up to1.280 mm at extra charge<strong>Support</strong> system ABAYwith middle recessInclusive:2 x St<strong>and</strong>ard pads2 x <strong>Support</strong> pipe L = 400 mm2 x Insert bolts<strong>Pit</strong> width B up to 1.080 mm13.0 t, VZ 97526415.0 t, VZ 975266<strong>Pit</strong> width B from 1.080 mm up to1.200 mm at extra charge<strong>Support</strong> system ABTAwith middle recessInclusive:1 x <strong>Support</strong> bridge ABY1 x Axle traverse AT2 x <strong>Support</strong> pipe L = 400 mm2 x Insert bolts2 x Slim pads2 x Mushrooms2 x Intermediate pieces L=100 mm2 x Intermediate pieces L=150 mm2 x Wooden blocks<strong>Pit</strong> width B up to 1.080 mm15.0 t, VZ 975275<strong>Pit</strong> width B from 1.080 mm up to1.200 mm at extra charge<strong>Support</strong> system ABT-NBFor MB-/MAN-low-platform buses11 t load capacityInclusive:1 x <strong>Support</strong> bridge ABT-NB1 x Axle traverse forlow-platform buses2 x Wooden blocks2 x Large pads<strong>Pit</strong> width B up to 1.080 mm11.0 t, VZ 975273<strong>Pit</strong> width B from 1.080 mm up to1.200 mm at extra charge<strong>Accessories</strong> set EVOInclusive:2 x Slim pads 145 mm2 x Slim pads 175 mm2 x Slim pads 245 mmVZ 975327<strong>Accessories</strong> Set MBInclusive:2 x Mushrooms MB2 x Slim pads 175 mm2 x Slim pads 100 mmVZ 975328<strong>Support</strong> system ABTYwith middle recessProduction dimensions up to1.080 mmInclusive:1 x <strong>Support</strong> bridge ABY1 x Axle traverse ATY2 x <strong>Support</strong> pipe L = 400 mm2 x Insert bolts2 x Intermediate pieces L=100 mm2 x St<strong>and</strong>ard pads10.0 t, VZ 975520<strong>Pit</strong> width B from 1.080 mm up to1.200 mm at extra chargeExtender setInclusive:2 x Mushrooms2 x Intermediate pieces L=150 mm2 x <strong>Support</strong> pipes L = 300 mm2 x <strong>Support</strong> pipes L = 600 mm15.0 t, VZ 97526820.0 t, VZ 975529<strong>Accessories</strong> Set SETRAInclusive:2 x Slim pads 220 mm2 x Slim pads 100 mm1 x Front axle forkVZ 997532919

<strong>Pit</strong> <strong>Jacks</strong>Production Program:Testing Technology for Cars, Trucks, Motorcycles, Tractors, Forklifts, Aircraft · Roller Brake Testers · Platform Brake Testers · Shock Absorber<strong>and</strong> Suspension Testers · Side-Slip Testers · Play Detectors · Roller Dynamometers for Performance <strong>and</strong> Function Testing · SpeedometerTesters · Tachograph <strong>and</strong> Taximeter Testers · Axle <strong>and</strong> Wheel Load Scales · Scissors Lifts · Two- <strong>and</strong> Four-Post Lifts · In-Ground Lifts· <strong>Pit</strong> <strong>Jacks</strong> · Axle <strong>and</strong> Transmission <strong>Jacks</strong> · Mobile Column Lifts · Headlight Testers · Diesel Smoke Meters · Emission Testers for Petrol <strong>and</strong>Gas Engines · Sound Level Meters · Air Conditioning Service Equipment · Decelerometers · Closing Force Meters · Brake Fluid Testers· Complete Test Lanes for Cars <strong>and</strong> Trucks · Mobile Test Containers · Wheel Alignment Analysers · Wheel Balancers · Tyre Changers.Additional Services: Workshop Design <strong>and</strong> Planning · Training Seminars for Users <strong>and</strong> Service TechniciansMAHA Maschinenbau Haldenwang GmbH & Co. KG.Hoyen 20 · 87490 Haldenwang · GermanyTel.: +49 (0)8374-585-0 · Fax: +49 (0)8374-585-497Internet: www.maha.de · eMail: sales@maha.de►MAHA USA • Charleston SC • USA►MAHA U.K. Ltd. • Wisbech • Great Britain►MAHA Irel<strong>and</strong> Ltd. • Dublin • Irel<strong>and</strong>►MAHA Italy SRL • Parma • Italy►MAHA España • Girona • Spain►MAHA Polska • Gliwice • Pol<strong>and</strong>►MAHA Russia • St. Petersburg • Russian Fed.►MAHA LITA Bj. • Vilnius • Lithuania►MAHA China • Peking • China►MAHA Japan • Kitakyushu • Japan►MAHA Consulting s.r.o. • Prague • Czech RepublicMAHA►Nederl<strong>and</strong> B.V. • Vianen • The Netherl<strong>and</strong>s►MAHA France Distrib. • Strasbourg • France►MAHA South Africa • Northcliff • Republic of South AfricaD1 5500BR0-GB03 · Subject to change without notice! The illustrations also show options which are not st<strong>and</strong>ard equipment.