VRIJE UNIVERSITEIT BRUSSEL Acoustics - the Dept. of ...

VRIJE UNIVERSITEIT BRUSSEL Acoustics - the Dept. of ...

VRIJE UNIVERSITEIT BRUSSEL Acoustics - the Dept. of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>VRIJE</strong> <strong>UNIVERSITEIT</strong><strong>BRUSSEL</strong><strong>Acoustics</strong>Bruface Master 1 Electromechanical EngineeringPr<strong>of</strong>. S. Vanlanduit

PrefaceSound is caused by <strong>the</strong> vibration <strong>of</strong> air particles. Sound can also be representedas a wave, propagating in a certain media (air, steel, et cetera... ).Soundisaperfectmeans<strong>of</strong>communication. Spokenlanguageisanecessity inour contemporary society. It is difficult to imagine our world without sound.A total absence <strong>of</strong> sound (like in an anechoic room) feels weird although itcould be a blessing sometimes. Sound has many pleasurable aspects: listeningto your favourite music, a phone call from your friend, an aria <strong>of</strong> LucianoPavarotti, <strong>the</strong> growling <strong>of</strong> <strong>the</strong> engine <strong>of</strong> a sports car. It is clear that <strong>the</strong>notion <strong>of</strong> a sound being pleasurable or not is subjective. The sounds emittedduring an activity will in most cases not hinder <strong>the</strong> executor. This samesound however, can hinder a person in <strong>the</strong> proximity. The interpretation <strong>of</strong>sound is highly individual, meaning that it is a factor that is hard to takeinto account. For example; listening to modern music, played extremely loudcan be a lust for daughter or son; whereas it causes annoyance for fa<strong>the</strong>r andmo<strong>the</strong>r. The lawnmower <strong>of</strong> your neighbour can irritate you while <strong>the</strong> sound<strong>of</strong> your own one doesn’t bo<strong>the</strong>r you. There is a thin line between sound andsound pollution. In o<strong>the</strong>r cases (like noise pollution on <strong>the</strong> shop floor) itis quite obvious. One could think <strong>of</strong> a distinction between sound and noisepollution on basis <strong>of</strong> <strong>the</strong> sound level. This is <strong>the</strong> way <strong>the</strong> difference is definedin current legislation. It is clear however that not only <strong>the</strong> sound level determinesif we are dealing with sound pollution. The time <strong>of</strong> day, <strong>the</strong> activity<strong>of</strong> a person and his/her mood play a role as well. A leaking tap can cause alarge irritation during <strong>the</strong> night, and no irritation at all during <strong>the</strong> day.i

iiWhen sound becomes noise, it will hinder us and start to annoy. At thispoint we call it sound pollution (or noise pollution). Sound pollution notonly occurs on <strong>the</strong> shop floor but in our daily lives as well. There existmultiple causes <strong>of</strong> sound pollution: industry, traffic, trains, airplanes, disco’set cetera. Noise is sound that:causes hinder, disturbs or is uncomfortablecauses harmor has both consequencesNoise must always be contested because it poses some risks for man.The most notable being hearing impairment. When someone is exposed tocertain noises for a to long period <strong>of</strong> time, <strong>the</strong>ir hearing capabilities will degrade.In some cases it is only temporary; after some rest <strong>the</strong> hearing willrecover. In o<strong>the</strong>r cases irreversible damage is caused, because no or insufficientprecautions were taken to reduce <strong>the</strong> noise or to protect <strong>the</strong> hearing.The occupational hearing impairment or deafness is included on <strong>the</strong> list <strong>of</strong>occupational disabilities. Noise or unwanted sounds can lead to: stomachulcers; high blood pressure; headache; infection <strong>of</strong> <strong>the</strong> large intestine; raisedpulsation; dilatation <strong>of</strong> <strong>the</strong> eye pupil; palpitations; reaction <strong>of</strong> <strong>the</strong> Skeletalstriated muscle; vasoconstriction. Noise has an indirect negative influence on<strong>the</strong> general health, because it causes feelings <strong>of</strong> hinder, anger, tension, andanxiety. Noise is probably a far greater risk for <strong>the</strong> general health than wasassumed in <strong>the</strong> past.One could think that noise pollution only occurs in our time. This is nottrue however, as is indicated in <strong>the</strong> following chronicle: At <strong>the</strong> time <strong>of</strong> <strong>the</strong>reign <strong>of</strong> Queen Elisabeth II (1533 - 1603) a law was enforced that forbademale nationals from beating <strong>the</strong>ir wives after 10 pm. The screaming <strong>of</strong> <strong>the</strong>victims was said to disrupt <strong>the</strong> good nights sleep <strong>of</strong> <strong>the</strong> neighbours. Eveno<strong>the</strong>r writings (incl. Horatius, 65-8 BC) complained about <strong>the</strong> increasingnoise in <strong>the</strong> cities. It is clear for everyone that sound pollution increasesdaily due to <strong>the</strong> ever increasing contribution <strong>of</strong> traffic, industry, and hobbies.In <strong>the</strong> following modules we will discuss how we can deal with this problempractically and scientifically sound.The permissible noise level for different application areas is regulatedextensively in legislation. In this course we will focus on three recent Europeandirectives regulating <strong>the</strong> noise pollution in <strong>the</strong> environment and on <strong>the</strong>workfloor. The main objectives and actions <strong>of</strong> <strong>the</strong>se European directives aredescribed in Part III <strong>of</strong> <strong>the</strong> course.In each <strong>of</strong> <strong>the</strong>se directives <strong>the</strong> primary objective is to limit <strong>the</strong> noise a <strong>the</strong>level <strong>of</strong> <strong>the</strong> sound source as much as possible. In Chapter 6 some practical

measures that can be used to reduce <strong>the</strong> sound production in an industrialenvironment are outlined. In practice, it is not always possible to modify<strong>the</strong> sound source itself because <strong>of</strong> financial implications. In that case onecan consider reducing <strong>the</strong> transfer <strong>of</strong> sound to <strong>the</strong> receiver. In Chapter 5<strong>the</strong> transmission <strong>of</strong> sound through a wall is studied. A simple calculationmethod is introduced to calculate <strong>the</strong> transmission loss based on materialproperties <strong>of</strong> <strong>the</strong> wall. This so called mass-frequency law formula <strong>the</strong>n allowsone to calculate <strong>the</strong> required thickness <strong>of</strong> an enclosure to reduce <strong>the</strong> noiselevel to acceptable level. In order to significantly reduce <strong>the</strong> noise level <strong>of</strong>a source, acoustic absorption should also be applied in addition to soundinsulation. The latter means that <strong>the</strong> walls <strong>of</strong> an enclosure are treated toeliminate reflections at <strong>the</strong> wall possibly leading to an amplification <strong>of</strong> <strong>the</strong>sound (giving rise to an acoustic resonance). This is described in Chapter 4.Before <strong>the</strong> elements <strong>of</strong> noise control are outlined, <strong>the</strong> fundamental concepts<strong>of</strong> acoustics are given in Chapter 1.iii

ContentsI Introduction to acoustics 11 Fundamental Concepts <strong>of</strong> <strong>Acoustics</strong> 31.1 Definition and origin <strong>of</strong> sound . . . . . . . . . . . . . . . . . . 31.2 Plane sound waves . . . . . . . . . . . . . . . . . . . . . . . . 41.2.1 Definition . . . . . . . . . . . . . . . . . . . . . . . . . 41.2.2 The speed <strong>of</strong> sound . . . . . . . . . . . . . . . . . . . . 61.2.3 The one-dimensional wave equation . . . . . . . . . . . 81.2.4 Acoustic impedance <strong>of</strong> a medium . . . . . . . . . . . . 111.3 Spherical sound waves . . . . . . . . . . . . . . . . . . . . . . 111.4 Cylindrical sound waves . . . . . . . . . . . . . . . . . . . . . 121.5 Sound levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131.5.1 The effective sound pressure . . . . . . . . . . . . . . . 131.5.2 The dB-scale . . . . . . . . . . . . . . . . . . . . . . . 141.5.3 Superposition <strong>of</strong> two sounds . . . . . . . . . . . . . . . 161.5.4 Types <strong>of</strong> sound . . . . . . . . . . . . . . . . . . . . . . 181.6 The acoustic intensity . . . . . . . . . . . . . . . . . . . . . . 181.6.1 Definition . . . . . . . . . . . . . . . . . . . . . . . . . 181.6.2 The sound intensity level . . . . . . . . . . . . . . . . . 201.7 Source power . . . . . . . . . . . . . . . . . . . . . . . . . . . 201.7.1 Definition . . . . . . . . . . . . . . . . . . . . . . . . . 201.7.2 The sound field produced by a point source . . . . . . 212 The human hearing system 232.1 Anatomy <strong>of</strong> <strong>the</strong> ear . . . . . . . . . . . . . . . . . . . . . . . . 232.1.1 The external ear . . . . . . . . . . . . . . . . . . . . . 232.1.2 The middle ear . . . . . . . . . . . . . . . . . . . . . . 232.1.3 The internal ear . . . . . . . . . . . . . . . . . . . . . . 242.2 Physiology <strong>of</strong> <strong>the</strong> ear . . . . . . . . . . . . . . . . . . . . . . . 252.2.1 The auditory field . . . . . . . . . . . . . . . . . . . . . 252.2.2 Amplification <strong>of</strong> signals in hearing . . . . . . . . . . . . 262.3 Pathology <strong>of</strong> <strong>the</strong> ear . . . . . . . . . . . . . . . . . . . . . . . 30v

viCONTENTS2.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . 302.3.2 Development <strong>of</strong> <strong>the</strong> ear with age . . . . . . . . . . . . . 302.4 The human perception <strong>of</strong> sound . . . . . . . . . . . . . . . . . 312.4.1 The phon . . . . . . . . . . . . . . . . . . . . . . . . . 312.4.2 The sone as measure <strong>of</strong> loudness . . . . . . . . . . . . . 313 Measuring sound 333.1 Introduction: why measure sound . . . . . . . . . . . . . . . . 333.2 The measurement microphone . . . . . . . . . . . . . . . . . . 333.2.1 Size <strong>of</strong> <strong>the</strong> microphone . . . . . . . . . . . . . . . . . . 353.2.2 The sound field where measurements take place . . . . 363.2.3 Influence <strong>of</strong> <strong>the</strong> wind speed . . . . . . . . . . . . . . . 373.2.4 Division <strong>of</strong> sound in frequency bands . . . . . . . . . . 393.3 Frequency weighting <strong>of</strong> microphone signals . . . . . . . . . . . 413.4 The sonometer . . . . . . . . . . . . . . . . . . . . . . . . . . 423.5 Calibration <strong>of</strong> measurement systems . . . . . . . . . . . . . . . 443.6 Presence <strong>of</strong> <strong>the</strong> observer . . . . . . . . . . . . . . . . . . . . . 443.7 Background noise . . . . . . . . . . . . . . . . . . . . . . . . . 453.8 Quantitative parameters . . . . . . . . . . . . . . . . . . . . . 463.8.1 The equivalent sound pressure level . . . . . . . . . . . 463.8.2 Sound Exposure Level . . . . . . . . . . . . . . . . . . 473.8.3 Statistic sound levels . . . . . . . . . . . . . . . . . . . 473.8.4 The Noise Rating value . . . . . . . . . . . . . . . . . . 483.8.5 The nuisance <strong>of</strong> fluctuating sound . . . . . . . . . . . . 493.9 The intensity meter . . . . . . . . . . . . . . . . . . . . . . . . 503.10 Measuring sound sources . . . . . . . . . . . . . . . . . . . . . 523.10.1 Measurements in an anechoic half-space . . . . . . . . 523.10.2 Measurements in a full anechoic room . . . . . . . . . . 543.10.3 The comparison method . . . . . . . . . . . . . . . . . 553.10.4 Power measurement with an intensity meter . . . . . . 55II Noise control 574 Sound Absorption 594.1 Acoustic transmission between two media . . . . . . . . . . . . 594.1.1 Normal incidence . . . . . . . . . . . . . . . . . . . . . 604.2 Realization <strong>of</strong> acoustic absorption . . . . . . . . . . . . . . . . 644.2.1 Plate on an air layer . . . . . . . . . . . . . . . . . . . 644.2.2 Helmholtz resonator . . . . . . . . . . . . . . . . . . . 654.2.3 Porous acoustic absorbing materials . . . . . . . . . . . 67

CONTENTSvii4.3 Measuring <strong>the</strong> acoustic absorption . . . . . . . . . . . . . . . . 704.3.1 Reverberation time . . . . . . . . . . . . . . . . . . . . 704.3.2 Measuring <strong>the</strong> absorption in a reverberation room . . . 754.3.3 Measuring <strong>the</strong> absorption in <strong>the</strong> Kundt tube . . . . . . 754.4 The direct and diffuse sound field . . . . . . . . . . . . . . . . 775 Sound Insulation 815.1 Measuring sound insulation . . . . . . . . . . . . . . . . . . . 815.1.1 Measuring airborne sound insulation . . . . . . . . . . 815.1.2 Measurement <strong>of</strong> impact sound . . . . . . . . . . . . . . 845.1.3 Single number rating . . . . . . . . . . . . . . . . . . . 855.2 Airborne sound insulation <strong>of</strong> a wall . . . . . . . . . . . . . . . 865.2.1 Simple law . . . . . . . . . . . . . . . . . . . . . . . . . 865.2.2 Effect <strong>of</strong> <strong>the</strong> wall stiffness . . . . . . . . . . . . . . . . 885.2.3 The coincidence effect . . . . . . . . . . . . . . . . . . 905.2.4 Insulation <strong>of</strong> double wall constructions . . . . . . . . . 925.2.5 Insulation <strong>of</strong> a composite wall . . . . . . . . . . . . . . 945.3 The acoustical barrier . . . . . . . . . . . . . . . . . . . . . . 956 Noise control 996.1 Origin <strong>of</strong> noise . . . . . . . . . . . . . . . . . . . . . . . . . . . 996.2 Reducing noise at <strong>the</strong> level <strong>of</strong> <strong>the</strong> sound source . . . . . . . . . 1026.2.1 Aerodynamic noise sources . . . . . . . . . . . . . . . . 1026.2.2 Sources <strong>of</strong> hydrodynamic noise . . . . . . . . . . . . . . 1056.2.3 Sources <strong>of</strong> structure-borne noise . . . . . . . . . . . . . 1086.3 Tackling noise transmission . . . . . . . . . . . . . . . . . . . 1106.3.1 Transmission <strong>of</strong> aerodynamic noise . . . . . . . . . . . 1106.3.2 Hydrodynamic noise transmission . . . . . . . . . . . . 1126.3.3 Structure-borne noise transmission . . . . . . . . . . . 1136.4 Radiation noise . . . . . . . . . . . . . . . . . . . . . . . . . . 115III Noise directives 1197 Directive 2000/14/EG : ’Machines in open air’ 1238 Noise on <strong>the</strong> work floor 1278.1 Previous guideline . . . . . . . . . . . . . . . . . . . . . . . . . 1278.2 Present guideline: directive 2003/10/EG . . . . . . . . . . . . 1298.3 Risk <strong>of</strong> hearing damage . . . . . . . . . . . . . . . . . . . . . . 1328.4 The audiometric examination . . . . . . . . . . . . . . . . . . 135

viiiCONTENTS8.4.1 Personal hearing protection . . . . . . . . . . . . . . . 1379 Community noise 1399.1 EC directive 2002/49/EC . . . . . . . . . . . . . . . . . . . . 139A Material properties 143

Part IIntroduction to acoustics1

Chapter 1Fundamental Concepts <strong>of</strong><strong>Acoustics</strong>1.1 Definition and origin <strong>of</strong> soundWhen an external mechanical excitation is applied on a material, a liquid ora gas, vibrations are induced in it. The molecules <strong>of</strong> <strong>the</strong> medium vibratesaround an equilibrium position. If this phenomenon occurs in a solid or aliquid, we talk about vibrations. The term sound is used if air is <strong>the</strong> medium,as long as it can be perceived by <strong>the</strong> human ear. This latter concept can beexplained by means <strong>of</strong> a simple example (Figure 1.1): a tuning fork is struckand produces sound. The reason for this sound production is <strong>the</strong> vibration <strong>of</strong><strong>the</strong> instrument which creates over – and underpressures in <strong>the</strong> surroundingmedium, <strong>the</strong> air. Note that <strong>the</strong> order <strong>of</strong> magnitude is really small comparedto <strong>the</strong> atmospheric pressure (10 5 Pa).Seen in <strong>the</strong> space this phenomenon is comparable to a wave, like a stonefallingintoapuddle. Soundwillthuspropagateasawavethroughitsmediumand can consequently be characterized by an amplitude, a frequency and awave velocity.Like mentioned above sound waves are induced by a disturbance <strong>of</strong> <strong>the</strong> equilibriumin a given point <strong>of</strong> <strong>the</strong> elastic medium. They propagate to ano<strong>the</strong>rpoint, in a predictable manner, depending on <strong>the</strong> physical properties <strong>of</strong> <strong>the</strong>elastic medium. Between 20 Hz and 20.000 Hz one speaks <strong>of</strong> sound. Under<strong>the</strong> first value and above <strong>the</strong> second one a human can not hear it, but itsbody is not completely insensitive to <strong>the</strong>se pressure changes.Different wave types can be distinguished. Sound waves are longitudinalwaves: <strong>the</strong> particle displacement is parallel to <strong>the</strong> direction <strong>of</strong> wave propagation.3

4 CHAPTER 1. FUNDAMENTAL CONCEPTS OF ACOUSTICSFigure 1.1: Sound production by tuning fork. Source: Bruël&Kjær.The wave type produced by e.g. <strong>the</strong> stone falling into a puddle is calledtransverse wave: <strong>the</strong> particle displacement is perpendicular to <strong>the</strong> direction<strong>of</strong> wave propagation.1.2 Plane sound waves1.2.1 DefinitionBecause <strong>of</strong> <strong>the</strong> more simplistic ma<strong>the</strong>matical description with respect tospherical waves, plane waves will first be discussed. However, <strong>the</strong> physicalrealization is more difficult: an infinite large flat plate must be broughtinto a vibratory motion perpendicular to <strong>the</strong> plane <strong>of</strong> that plate. In thisway, it results in a oscillating system <strong>of</strong> plane regions with alternating over– and under-pressure. The wave fronts (surfaces <strong>of</strong> constant phase) propagateindeed in a direction normal to <strong>the</strong> flat pane. The air particles in <strong>the</strong>direct surrounding <strong>of</strong> <strong>the</strong> plate, and some time later, also fur<strong>the</strong>r away, movearound <strong>the</strong>ir equilibrium in <strong>the</strong> same direction (normal to <strong>the</strong> plate). In agiven point <strong>the</strong> air density ρ is a function <strong>of</strong> time t, and on a given time als<strong>of</strong>unction <strong>of</strong> <strong>the</strong> position x: ρ(x,t). The pressure disturbances propagate witha velocity c (<strong>the</strong> wave velocity, or speed <strong>of</strong> sound, or also known as phasevelocity).Different parameters are associated to a plane wave:p <strong>the</strong>pressure fluctuationwithrespect to<strong>the</strong>atmosphericpressureP 0 causedby sound. Generally, p ≪ P 0 with p = p(x,t).

1.2. PLANE SOUND WAVES 5u <strong>the</strong> air particle displacement from equilibrium position caused by soundwith u = u(x,t). (A ‘particle’ is a volume that is small enough so thatwithin it , u and v can be considered to be constant).v <strong>the</strong> particle velocity given by v = ∂u∂tand must not be confused with c.The speed <strong>of</strong> sound is <strong>the</strong> propagation speed <strong>of</strong> <strong>the</strong> wave, constant for<strong>the</strong> continuous medium, for a given pressure and temperature. Theparticle velocity v is variable because <strong>the</strong> particle (e.g. air) vibratesaround an equilibrium position. On average <strong>the</strong>se particles have a zerovelocity, while <strong>the</strong> wave phenomenon propagates. The direction <strong>of</strong> vand c is equal and this explains why sound waves are considered to belongitudinal.Consider a plane wave: along x-axis and independent <strong>of</strong> y- and z coordinates.In point x = 0 <strong>the</strong> harmonic motion <strong>of</strong> a random point can bedescribed by :u(t,0) = U exp(iωt) (1.1)We call this a wave if on position x <strong>the</strong> same vibrational state holds as inx = 0, but with <strong>the</strong> proviso that <strong>the</strong>re is a phase difference, caused by <strong>the</strong>finite propagation speed <strong>of</strong> <strong>the</strong> wave phenomenon. This means that at timet and on position x we have <strong>the</strong> same vibrations as at time t− x on positioncx = 0.By solving <strong>the</strong> 1–D wave equation [19] :∂ 2 u∂x 2 = 1 c 2 ∂ 2 u∂t 2 (1.2)one obtains <strong>the</strong> harmonic solution describing <strong>the</strong> wave propagation :(u(t,x) = U exp(iωt−i ω )c x = U exp(iωt−ikx) (1.3)withk <strong>the</strong>wave number ormorespecifically <strong>the</strong>angularwavenumber definedas k = ω (radians per unit distance).cThe amplitude U is considered independent <strong>of</strong> x and t, and consequently<strong>the</strong>se equations are only valid for undamped propagation. Moreover, <strong>the</strong>wave equation is only valid for small variations around <strong>the</strong> equilibrium,which is always <strong>the</strong> case in acoustics and noise unless so called aerodynamicshock-waves are considered. It can easily be shown that <strong>the</strong> planewave u(t,x) = U exp(iωt−ikx) is a possible solution <strong>of</strong> <strong>the</strong> PDE known as

6 CHAPTER 1. FUNDAMENTAL CONCEPTS OF ACOUSTICS<strong>the</strong> wave equation by differentiating two times with respect to <strong>the</strong> time andrepeating <strong>the</strong> same with respect to <strong>the</strong> position x :∂ 2 u= −ω 2 u(t,x)∂t 2∂ 2 u= − ω2∂x 2 c2u(t,x) (1.4)and filling <strong>the</strong>se expressions in <strong>the</strong> wave equation.If damping is present due to absorption <strong>of</strong> <strong>the</strong> medium, <strong>the</strong> solution has<strong>the</strong> following form:U = U 0 exp(−αu) (1.5)Note that <strong>the</strong> wave can be considered undamped if propagation <strong>of</strong> soundoccurs in an (unconfined) air volume. Indeed, <strong>the</strong> damping <strong>of</strong> sound at 1000Hz is only 5 decibel per km. One can show that <strong>the</strong> damping is proportionalto <strong>the</strong> square <strong>of</strong> <strong>the</strong> frequency according to :α = ω2 τc(1.6)With τ <strong>the</strong> relaxation time (around 0.2 ns for monatomic gases). Consequentlyfor high frequencies damping in air may not be neglected. Concerning<strong>the</strong> periodic character, we know that <strong>the</strong> exponential function withimaginary exponent has a periodicity equal to 2π :1. Time periodicity: u(t + T,x) = u(t,x) with period T. From whichfollows that ωT = 2π and fur<strong>the</strong>r ω = 2π = 2πf with f = 1 <strong>the</strong>T Tfrequency.2. Space periodicity: u(t,x + λ) with wavelength λ, from which followsthat λk = 2π. Replacing k = ω c yields : ωλ c = 2π and finally ω = 2πλ c3. Combining 1. and 2. gives us <strong>the</strong> relation between <strong>the</strong> spatial andfrequency domain wave propagation parameters :with c <strong>the</strong> speed <strong>of</strong> sound.1.2.2 The speed <strong>of</strong> soundλf = c (1.7)The speed <strong>of</strong> sound is <strong>the</strong> velocity at which a perturbation, a wave front,propagatesin<strong>the</strong>givenmedium. Itdependson<strong>the</strong>properties<strong>of</strong>thismedium,

1.2. PLANE SOUND WAVES 7Material Speed <strong>of</strong> SoundGlass 5400Steel 5000Aluminium 5200Nickel 4800Wood 4000Copper 3500Plumbum 1300Platinum 2800Silver 2600Water 1460Seawater 1500Mercury 1407Hydrogen 1260Table 1.1: Speed <strong>of</strong> sound for common materialsespecially density and elasticity.In gases <strong>the</strong> following equation is applicable [19] :√ √γP O Kc = = = √ γrT (1.8)ρ 0 ρ 0withK = γP 0 <strong>the</strong> compression– or bulk modulus for gases andwhere γ represents<strong>the</strong> heat capacity ratio and P 0 <strong>the</strong> atmospheric air pressureT <strong>the</strong> absolute temperature inKr <strong>the</strong> specific gas constant√BIn fluids : c = with ρB <strong>the</strong> compression– or bulk modulus for fluids (in Pa)√EIn solids c = with ρE <strong>the</strong> elastic– or Young’s modulusThe speed <strong>of</strong> sound for some common materials, gases and fluids are tabulatedin Table 1.1.

8 CHAPTER 1. FUNDAMENTAL CONCEPTS OF ACOUSTICS1.2.3 The one-dimensional wave equationFollowing parameters are considered :x coordinate <strong>of</strong> elementary particle in equilibrium.u particle displacement with respect to equilibrium.v particle velocity v = ∂u∂t .ρ <strong>the</strong> instantaneous value <strong>of</strong> <strong>the</strong> fluid density.ρ 0 fluid density in equilibrium (considered constant)s condensationinapoint(defacto: relativechangeindensity). Thisvariableis defined as :s . = ρ−ρ 0ρ 0or ρ = ρ 0 (1+s) (1.9)p <strong>the</strong> sound pressure P = P 0 +pc wave propagation speedGravitation is not considered and thus ρ 0 and P 0 areconstant. The gas orfluid is assumed to behomogeneous isotropic elastic : <strong>the</strong>re are no dissipativeforces due to viscosity or heat conduction. We limit this study to waves withsmall amplitude such that <strong>the</strong> condensation s can be considered to be small :ρ−ρ 0 ≪ ρ 0 . While <strong>the</strong> wave propagates along <strong>the</strong> x-axis through <strong>the</strong> fluid,<strong>the</strong> adjacent fluid layers are also disturbed from <strong>the</strong>ir equilibrium position.This displacement u is function <strong>of</strong> x and t.In order to derive <strong>the</strong> wave equation we will use three physical laws:1. The mass conservation principle.2. Thermodynamic change <strong>of</strong> state.3. Newtons equation.Firstly, <strong>the</strong> mass conservation principle is applied on a volume between xand x+dx and a deformed volume :ρ 0 Sdx = ρSdx(1+ ∂u∂x ) (1.10)

1.2. PLANE SOUND WAVES 9Substituting ρ = ρ 0 (1+s) :assuming that s ∂x∂u ≪ s.ρ 0 = ρ 0 (1+s)(1+ ∂u∂x )1 = 1+ ∂u∂x +s+s∂u ∂xs = − ∂x∂uSecondly, we use <strong>the</strong>rmodynamic change <strong>of</strong> state (adiabatic assumption :noheattransferbetweenfluidelementandsurroundingfluid). Thisisallowedbecause p ≪ P 0 : ( ) γP ρ=(1.11)P 0 ρ 0with γ = cpc v<strong>the</strong> adiabatic constant (around 1.4 for air). The right– hand side<strong>of</strong> Equation 1.11 is developed as a Taylor series and only <strong>the</strong> first two termsare conserved (s ≪ 10 −4 in common acoustic problems). It <strong>the</strong>n follows√:pγPP 0= γs or p = P 0 γs. From <strong>the</strong> definition <strong>of</strong> <strong>the</strong> speed <strong>of</strong> sound : c = 0ρ 0,we have c 2 = γP 0ρ 0. Rewriting and substituting in <strong>the</strong> previous equations thisgives (with s = − ∂u ) : ∂xp = −c 2 ∂uρ 0 (1.12)∂xThe fundamental equation <strong>of</strong> dynamics :dF x = ρ 0 Sdx ∂2∂t 2 (1.13)The elementary force dF x is generated by a difference in pressure : dF x =[p−(p+ ∂p ∂pdx)]S = Sdx After substitution :∂x ∂x∂ 2∂p∂x = ρ 0(1.14)∂t 2If we fill in p, given by Formula 1.12, one obtains (after taking <strong>the</strong> derivative)<strong>the</strong> wave equation.It issufficient to findasolution foruinfunction<strong>of</strong> xandtinorder t<strong>of</strong>ind<strong>the</strong>o<strong>the</strong>r parameters <strong>of</strong> <strong>the</strong> propagating wave with e.g. <strong>the</strong> following equations :Pressure: p = −ρ 0 c 2∂u∂x .For an harmonic sound wave(u = Uexp(iωt)exp(−kx)) one has ∂u∂x =

10 CHAPTER 1. FUNDAMENTAL CONCEPTS OF ACOUSTICS−i ω ∂uu en = iωu. It <strong>the</strong>n follows (using <strong>the</strong> defintion <strong>of</strong> v and abovec ∂tequation <strong>of</strong> pressure) :p = ρ 0 cv (1.15)Condensation: s = − ∂u∂xParticle velocity: v = ∂u∂tOne can make <strong>the</strong> remark that a fluid doesn’t consist <strong>of</strong> molecules, eachhaving a fixed mean position in space, like we did above in order to derive<strong>the</strong> wave equation. Indeed, even in <strong>the</strong> presence <strong>of</strong> <strong>the</strong> sound wave, <strong>the</strong>particles are continuously in movement with mean velocities far greater than<strong>the</strong> particle velocity due to <strong>the</strong> wave.However one has to look at it in a statistical way : <strong>the</strong> molecules leaving<strong>the</strong> elementary control volume are forthwith replaced by o<strong>the</strong>r moleculeswhich possesses on average <strong>the</strong> same properties. Consequently it allows us toconsider particle displacements and particle velocities in our ma<strong>the</strong>maticalapproach. Note that a statistical variable like <strong>the</strong> sound pressure is moresuited for describing sound waves than <strong>the</strong> displacement. For this reason<strong>the</strong> pressure is <strong>of</strong> practical use and also used for measurements. Besides, <strong>the</strong>sound pressure is almost <strong>the</strong> only acoustic variable measurable on a relativeeasy manner.In an harmonic wave <strong>the</strong> displacement u, <strong>the</strong> wave velocity v as well as<strong>the</strong> sound pressure p varies periodically in time and space and all satisfy<strong>the</strong> wave equation. In acoustics our interest is mainly focused on <strong>the</strong> soundpressure. The sound pressure p in a plane wave satisfy <strong>the</strong> wave equation :∂ 2 p∂x = 1 ∂ 2 p(1.16)2 c 2 ∂t 2with solution : p(t,x) = p 1 (t−x/c)+p 2 (t+x/c). The harmonic solution is :p(t,x) = Aexp(iωt−ikx) (1.17)The solutions <strong>of</strong> this one–dimensional wave equation shows that <strong>the</strong> amplitudeA is independent <strong>of</strong> <strong>the</strong> distance : sound propagating as a planewave does not fade away with <strong>the</strong> distance to <strong>the</strong> source. This can lead totroublesome consequences like explained in <strong>the</strong> two following examples :1. Consider a street in <strong>the</strong> city with on both sides high buildings. Peopleliving in <strong>the</strong> higher levels <strong>of</strong> <strong>the</strong> buildings are as much bo<strong>the</strong>red by <strong>the</strong>noise as people from <strong>the</strong> lower levels. The reason is that when plenty<strong>of</strong> cars are circulating in <strong>the</strong> street it can be seen as a source <strong>of</strong> planenoise which will propagate upwards as a plane wave. This is not truefor one car in <strong>the</strong> street.

1.3. SPHERICAL SOUND WAVES 112. In a ventilation system <strong>the</strong> rooms are connected with <strong>the</strong> ventilatorby means <strong>of</strong> long ductwork usually having a constant section. Noisegenerated by ventilation will propagate as plane waves through <strong>the</strong>secanals reaching <strong>the</strong> rooms and thus <strong>the</strong> users.1.2.4 Acoustic impedance <strong>of</strong> a mediumThe specific acoustic impedance <strong>of</strong> a medium, for a given type <strong>of</strong> wave propagation,is defined as <strong>the</strong> ratio <strong>of</strong> sound pressure to particle velocity. For aplane wave with propagation along <strong>the</strong> positive x-axis :z + = p +v += ρcv +v += ρc = K c(1.18)with use <strong>of</strong> Equations 1.8 and 1.15. For a plane wave propagating along <strong>the</strong>negative x-axis we have z − = −ρc. So for a plane wave, independently <strong>of</strong><strong>the</strong> propagation direction, <strong>the</strong> specific acoustic impedance is a real variable.In <strong>the</strong> MKS unit system <strong>the</strong> unit <strong>of</strong> z is kg/(m 2 sec) or simply rayl (namedafter Lord Rayleigh). Due to <strong>the</strong> greater role <strong>of</strong> <strong>the</strong> product ρc comparedto ρ and c separately its also known as <strong>the</strong> characteristic impedance or waveimpedance <strong>of</strong> <strong>the</strong> medium. At room temperature <strong>the</strong> impedance <strong>of</strong> air isapproximatively 400 Rayl.1.3 Spherical sound wavesLet us take a small spherical surface whom all points move radially in a periodicalway, with same amplitude, frequency and phase, around equilibriumposition: this is <strong>the</strong> monopole or isotropic radiator. The surface will exerta periodic pressure on <strong>the</strong> fluid in contact with that surface. Consequently<strong>the</strong> perturbation <strong>of</strong> fluid equilibrium will propagate radially in <strong>the</strong> shape <strong>of</strong>spherical waves. We will assume that contact with <strong>the</strong> surrounding fluid ispreserved. A lot <strong>of</strong> acoustic problems are related to this divergent sphericalshaped sound waves, radiated by a point source (limit <strong>of</strong> <strong>the</strong> monopole). Togive an example on a distant large enough with respect to a physical dimensionone can consider a machine, a car or aircraft as a point source. Dampingis not considered here. In analogy with plane waves one can obtain (see [19]for <strong>the</strong> derivation <strong>of</strong> <strong>the</strong> equation) :∂ 2 p∂x 2 + ∂2 p∂y 2 + ∂2 p∂z 2 = 1 c 2 ∂ 2 p∂t 2 (1.19)

12 CHAPTER 1. FUNDAMENTAL CONCEPTS OF ACOUSTICSTransformation into a spherical coordinate system one can obtain (see[19]) <strong>the</strong> following form <strong>of</strong> <strong>the</strong> wave equation :∂ 2 rp∂r 2 + = 1 c 2 ∂ 2 rp∂t 2 (1.20)with r = √ x 2 +y 2 +z 2 .Taking rp as one variable we get a spherical wave equation <strong>of</strong> <strong>the</strong> sameform as <strong>the</strong> equation for plane waves. A general solution <strong>of</strong> this equation, astraveling waves, is thus :rp(r,t) = p 1 (t−r/c)+p 2 (t+r/c) or p(r,t) = 1 r p 1(t−r/c)+ 1 r p 2(t+r/c)(1.21)with<strong>the</strong>firsttermrepresenting adivergent spherical wave and<strong>the</strong>secondonea convergent spherical wave. Both waves exhibit <strong>the</strong> same propagation speedc and <strong>the</strong>ir amplitudes decreases with increasing distance r, radially from<strong>the</strong> point source. Convergent waves have so to say no acoustical application,while <strong>the</strong> divergent waves have . Indeed, this latter is present as soon as <strong>the</strong>distance from <strong>the</strong> sound source becomes larger than <strong>the</strong> physical dimensions<strong>of</strong> that source. If <strong>the</strong> point source produces an harmonic wave one may writefor <strong>the</strong> divergent wave :p(r,t) = A rexp(iωt−ikr) (1.22)1.4 Cylindrical sound wavesFor a cylindrical line sound source one can show that <strong>the</strong> solution can bewritten as (see [19]) :p(r,t) = A √ rexp(iωt−ikr) (1.23)An important conclusion concerning <strong>the</strong> three simple types <strong>of</strong> sources is <strong>the</strong>following :For plane sound waves <strong>the</strong> sound pressures does not decrease with <strong>the</strong>distance.For spherical sound waves <strong>the</strong> sound pressure decreases linearly withincreasing distance.

1.5. SOUND LEVELS 13For cylindrical sound waves <strong>the</strong> sound pressure decreases inversely proportionalto <strong>the</strong> square root <strong>of</strong> <strong>the</strong> distance.1.5 Sound levels1.5.1 The effective sound pressureSuppose a given source <strong>of</strong> sound produces sound, i.e. <strong>the</strong> quickly fluctuatingair pressure makes our eardrum to vibrate which causes through our earand nervous system a sensation <strong>of</strong> sound. Total pressure can be writtenas : p = p atm + p sound . One could think that (subjectively) if we have<strong>the</strong> impression <strong>of</strong> a constant sound level, intensity or loudness it implies(objectively) a constant sound pressure in time. Nothing appears to be lesstrue. The sound perceived with a constant loudness may be both a pure sinetone and a stochastic sound generated by a source with constant parameter:p(t) is extremely complicated, and yet <strong>the</strong> human ear have <strong>the</strong> impression <strong>of</strong>a constant loudness. Our purpose is to describe ma<strong>the</strong>matically this soundloudness. Afirst conclusion : <strong>the</strong>instantaneous valueand<strong>the</strong> algebraicmeanvalue does not matter (this latter is eventually zero). The human hearingsystem is quite insensitive for sharp positive and negative peaks, which maybe cut <strong>of</strong>f. In contrast, it seems to be sensitive to <strong>the</strong> energy <strong>of</strong> sound waves.This led to <strong>the</strong> consideration <strong>of</strong> <strong>the</strong> effective– or Root-Mean-Square (RMS)value <strong>of</strong> <strong>the</strong> sound pressure, over a certain time interval, as an measure <strong>of</strong>intensity :p eff =√1t 2 −t 1∫ t2t 1p 2 (t)dt (1.24)Foranharmonicwave(withDCvalueequal tozero) thisis: p eff = p max / √ 2.As can be seen in <strong>the</strong> definition <strong>the</strong> effective value p eff depends <strong>of</strong> <strong>the</strong> timeinterval as well as <strong>the</strong> type <strong>of</strong> sound. E.g. :1. We listen to a noise which seems to be constant in time. To describe<strong>the</strong> intensity one can thus use p 2 averaging over a relative small orrelative large time interval – this changes not much to <strong>the</strong> result <strong>of</strong> <strong>the</strong>measurement. In this case <strong>the</strong> time interval does not play a major role.2. When a plane flies over one hear <strong>the</strong> sound surging followed by extinctionduring a specific time interval. If we want to use p eff in thiscase to describe <strong>the</strong> instantaneous numerical value giving a reasonableimpression <strong>of</strong> <strong>the</strong> perceived sound intensity, we would have to average

14 CHAPTER 1. FUNDAMENTAL CONCEPTS OF ACOUSTICSp 2 over a short time period, negligible with respect to <strong>the</strong> fly over time.In this case <strong>the</strong> time interval for integration is important.3. Physiological experiments have allowed to see that for <strong>the</strong> human ear<strong>the</strong>soundintensityimpressioncansometimenoticeablychangein0.1sec.Consequently this is a maximum value <strong>of</strong> time integration for variablesound.4. Technical application (<strong>the</strong> measuring equipment is based on this) : <strong>the</strong>integrationinterval istakenrelatively short (e.g. 125ms), such that<strong>the</strong>needle<strong>of</strong><strong>the</strong>measuring equipment iscapable<strong>of</strong>detecting relative quickfluctuations <strong>of</strong> <strong>the</strong> sound pressure; a sound whose variating intensity intime is perceived by <strong>the</strong> human ear. The measurement system deliversa result that variates in time approximately in <strong>the</strong> same way. Themeasured values for p eff are more or less located between followinglimits :2×10 −5 Pa < p eff < 200 Pa (1.25)The ratio <strong>of</strong> <strong>the</strong> largest limit to <strong>the</strong> smallest is 10 7 , which is very large.All <strong>the</strong> common sounds are situated between those limits. For this reason,andalso because earlier onebelieved thatahuman hearsaccordingto <strong>the</strong> law <strong>of</strong> Weber–Fechner, i.e. logarithmic, one have introduced <strong>the</strong>dB-scale (response proportional with <strong>the</strong> logarithm <strong>of</strong> <strong>the</strong> stimulus).1.5.2 The dB-scaleThe dB-scale allows us to describe sound, like a person perceives, in a correctway. The sound pressure level (SPL) is defined as :L p = 10log p2p 2 0= 20log p p 0(1.26)with p 0 = 20 × 10 −6 Pa <strong>the</strong> reference pressure (it equals <strong>the</strong> threshold <strong>of</strong>human hearing). An example <strong>of</strong> <strong>the</strong> dB-scale and a comparison with <strong>the</strong>linear scale is given in Figure 1.2.The hearing threshold equals 0 dB, <strong>the</strong> pain threshold is 120 dB. Calculatingwith dB causes <strong>of</strong>ten problems because <strong>of</strong> <strong>the</strong> fact that we are used towork with <strong>the</strong> linear scale. Summation and subtraction are best performedby first transforming to <strong>the</strong> linear scale, <strong>the</strong>n by executing <strong>the</strong> operation andfinally by transforming back to <strong>the</strong> dB-scale. For <strong>the</strong> sum <strong>of</strong> two values L p1en L p1 :L p = 10log(10 Lp 1 /10 +10 Lp 2 /10 ) (1.27)

1.5. SOUND LEVELS 15Figure 1.2: Some sound values in <strong>the</strong> linear and dB scale. Source:Bruël&Kjær.Note that when on a given position a certain source produces a sound pressurelevel 10 dB smaller than <strong>the</strong> sound pressure level <strong>of</strong> ano<strong>the</strong>r source, thisfirst source has no big contribution (less than 1 dB) to <strong>the</strong> sound pressurelevel in that point. This will enable us to perform measurement <strong>of</strong> soundsources without <strong>the</strong> need <strong>of</strong> shutting down all o<strong>the</strong>r sources.When multiplying a sound pressure in <strong>the</strong> linear scale with a certainfactor this results in <strong>the</strong> addition <strong>of</strong> a value in <strong>the</strong> dB scale. Examples (seealso Figure 1.3 :Multiplication with a factor 2 equals an addition <strong>of</strong> around 6 dB.Multiplication with a factor 3 equals an addition <strong>of</strong> around 10 dB.Multiplication with a factor 10 equals an addition <strong>of</strong> around 20 dB.Attention: <strong>the</strong>se rules are only valid for sound pressures p. Later <strong>the</strong>concepts <strong>of</strong> sound intensity and sound power will be introduced. These parametersare proportional to <strong>the</strong> energy <strong>of</strong> sound (i.e. ∼ p 2 ) and this is forexample <strong>the</strong> reason that a multiplication <strong>of</strong> <strong>the</strong> sound power with 10 equalsan addition <strong>of</strong> 10 dB.

16 CHAPTER 1. FUNDAMENTAL CONCEPTS OF ACOUSTICSFigure 1.3: Multiplication in <strong>the</strong> linear scale equals an addition in dB scalel.Source: Bruël&Kjær.1.5.3 Superposition <strong>of</strong> two soundsIn this section we will see in more detail how to superpose two sound waves.The resulting instantaneous pressure in a given point is <strong>the</strong> sum <strong>of</strong> <strong>the</strong> instantaneousvalues measured in that point : p(t) = p 1 (t)+p 2 (t). Due to <strong>the</strong>factthat oneonlyhear andmeasure effective pressure values, <strong>the</strong>question is:what is <strong>the</strong> link between <strong>the</strong> effective pressures p total , p 1 en p 2 . This relationseems to depend on <strong>the</strong> nature <strong>of</strong> <strong>the</strong> sound and <strong>the</strong> distance between <strong>the</strong>sources. The total effective sound pressure is given by :√∫1 Tp eff = (p 1 (t)+p 2 (t)) 2 )dt=T√1T0∫ TTwo cases can be distinguished :0(p 2 1(t)+p 2 2(t)+2p 1 (t)p 2 (t))dtIncoherent sources One speak <strong>of</strong> incoherent sources if∫ T0(1.28)p 1 (t)p 2 (t)dt = 0 (1.29)

1.5. SOUND LEVELS 17InthiscasewecanthussaythatRMS(p total ) 2 = RMS(p 1 ) 2 +RMS(p 2 ) 2 .Examples <strong>of</strong> incoherent sources :two pure sine tones with differen ferquencies (e.g.two rotating machinesnot rotating synchronous)two independent stochastic soundstwo sources with energy in different frequency bandsSpecial case: iftwo coherent sourcesproducesoundpressure withsameamplitude we have p eff,1 = p eff,2 en dus p 2 eff,total = 2p 2 eff,1 , or in <strong>the</strong>dB scale :L p,total = L p,1 +3dB (1.30)The total sound pressure level is thus 3 dB higher compared to <strong>the</strong> case<strong>of</strong> only one source present. And thus <strong>the</strong> noise is not twice as strong(an increase with factor two equals a rise <strong>of</strong> 6 dB).In general : for n independent sound sources we have that <strong>the</strong> effectivesound∑pressure in a given point equals <strong>the</strong> square root <strong>of</strong> p 2 eff,total =ni=1 p2 eff,i .Example : machines in an enterprise or cars in <strong>the</strong> street.In general : <strong>the</strong> n sources are independent but <strong>the</strong>y cause <strong>the</strong> sameeffective pressure in a given point : p 2 eff,total = np2 eff,1 , or in dB scale :L p,total = L p,1 +10logn dBCoherent sources For coherent sources <strong>the</strong> following is valid :∫ T0p 1 (t)p 2 (t)dt ≠ 0 (1.31)In this case <strong>the</strong> total effective sound pressure depends on <strong>the</strong> phasedifference between <strong>the</strong> two single sound waves and <strong>the</strong> amplitudes.Suppose we have two sound waves p 1 en p 2 in a point x and defined asp 1 = Aexp(iωt) en p 2 = Aexp(iωt+φ) (for simplicity we consider <strong>the</strong>case were <strong>the</strong> amplitudes <strong>of</strong> <strong>the</strong> waves are equal).One distinguish a few special cases :If φ = 0 we have that p 2 eff,total = 4p 2 eff,1 and for <strong>the</strong> dB value :L p,total = L p,1 +20logn dB (1.32)If φ = π than follows p 2 eff,total = 0. Considered apart p 1 andp 2 are audible, but toge<strong>the</strong>r no sound is generated (ant-noise).

18 CHAPTER 1. FUNDAMENTAL CONCEPTS OF ACOUSTICSThis property is used in active noise control. E.g. : anti-noisetechnique in some headphones to reduce background noise as wellas for reducing noise generated by aircrafts in <strong>the</strong> cabin <strong>of</strong> <strong>the</strong>SAAB2000 plane.1.5.4 Types <strong>of</strong> soundBased on <strong>the</strong> frequency spectrum some types <strong>of</strong> sound can be distinguished :Pure tone : A sound characterized by only one frequency and can onlybe generated, approximatively, by a tone generatorMusical tone : (Figure 1.4-above) : It consists <strong>of</strong> a fundamental withovertones and are toge<strong>the</strong>r called partials. (Harmonics are partials).The number and <strong>the</strong> nature <strong>of</strong> <strong>the</strong> harmonics define <strong>the</strong> so-called ’tonecolor’.Chaotic or stochastic sound (Figure 1.4-middle) : (noise, hiss, etc.) Itcovers a wide frequency spectrum (where sounds with a specific frequencyand higher amplitudes than <strong>the</strong> o<strong>the</strong>r, are typical for <strong>the</strong> machineinvolved), think <strong>of</strong> ventilators, traffic noise, factory noise, jets,and so on. In acoustics a very detailed analysis will not be performed(cost) but an analysis in 1/1 octave band or 1/3 octave band. Theseare normalized. More detailed analysis e.g. 1/12 octave or even moredetailed are sometimes used in research.Impulse noise (Figure 1.4-below) : is a type <strong>of</strong> sound which is <strong>of</strong> veryshort duration, mostly generated by an impact.Sound can also be classified in o<strong>the</strong>r ways like considering <strong>the</strong> change <strong>of</strong>amplitude in function <strong>of</strong> time. This classification will be described in Part III<strong>of</strong> <strong>the</strong> text where <strong>the</strong> legislation regarding environmental noise is discussed.1.6 The acoustic intensity1.6.1 DefinitionA sound source delivers energy in <strong>the</strong> form <strong>of</strong> kinetic and potential energy,that is transported by <strong>the</strong> sound wave. Assume we have a ’free field’, i.e. noreflection possible. Consider a plane <strong>of</strong> 1 m 2 perpendicular to <strong>the</strong> directionin which we want to determine <strong>the</strong> intensity <strong>of</strong> a traveling plane wave.

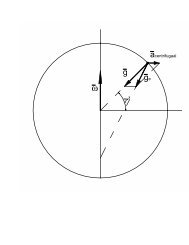

1.6. THE ACOUSTIC INTENSITY 19Figure 1.4: Some types <strong>of</strong> sound. Source: Bruël&Kjær.Definition : <strong>the</strong> intensity I is <strong>the</strong> sound energy that propagates in onedirection and that is incident on 1 m 2 per sec (or <strong>the</strong> sound power per unitarea (in Watt/m 2 )). One can easily show for a sound wave along <strong>the</strong> rdirection that :I r = dE rdtdS= F rdrdtdS= pdSdrdtdS= pv rLet p represent <strong>the</strong> sound pressure in <strong>the</strong> considered point (<strong>the</strong> atmosphericpressure does indeed not deliver energy) and v <strong>the</strong> particle velocity.We have than that <strong>the</strong> power per m 2 or intensity vectorĪ(t) : Ī(t) = p(t)¯v(t)(instantaneous values).Important remark : in contrast to <strong>the</strong> sound pressure p <strong>the</strong> sound intensityis a vector quantity (considering it being proportional to <strong>the</strong> velocity). If onewant to know <strong>the</strong> magnitude <strong>of</strong> <strong>the</strong> intensity in a certain direction ē it hasto be calculated with : I(t) = p(t)v(t)cosφ, where φ = ∠(ē,¯v).For an harmonic plane wave we know that (equation 1.15) : p = ρcv. It <strong>the</strong>nfollows for a traveling harmonic plane wave :I = p effρc = ρcv eff (1.33)

20 CHAPTER 1. FUNDAMENTAL CONCEPTS OF ACOUSTICSNote that a spherical wave behaves like a plane wave if <strong>the</strong> observer is faraway from <strong>the</strong> point source (in practice for distances larger than 3λ). For adiffuse sound field, where <strong>the</strong> waves are in all directions just as strong andindependent, we may find (no pro<strong>of</strong> is given in this text) :I diffuus = p ρc = ρcv eff (1.34)1.6.2 The sound intensity levelDefinition : <strong>the</strong> sound intensity level (SIL) L I is defined as :L I = 10log I I 0(dB) (1.35)with I 0 = 10 −12 W/m 2 <strong>the</strong> standard reference sound intensity level.Notethatforatraveling planewavepropagatinginair<strong>the</strong>soundintensitylevel is approximately equal to <strong>the</strong> sound pressure level : L I ≈ L p . Indeed :L I = 10log I I 0= 10log p2ρcI 0met ρc ≈ 412≈ L p1.7 Source power1.7.1 DefinitionDefinition : The sound power is <strong>the</strong> acoustic power (Watt) delivered by asound source : ∫W = IdS (1.36)with I <strong>the</strong> intensity in W/m 2 over <strong>the</strong> elementary surface dS. If I is constantin all directions (nondirectional source) : W = IS.In analogy with <strong>the</strong> sound pressure level and sound intensity level onecan define <strong>the</strong> sound power level.Definition : The sound power level (SWL) is defined as :SL W = 10log W W 0(1.37)

1.7. SOURCE POWER 21with W 0 = 10 −12 W <strong>the</strong> reference level.One have to pay attention to <strong>the</strong> terms we use because all those differentlevels have <strong>the</strong> same units (dB).1.7.2 The sound field produced by a point sourceFor a spherical source <strong>the</strong> source power is W = I4πr 2 , with I <strong>the</strong> intensityaccording to <strong>the</strong> radius <strong>of</strong> this sphere on a distance r from <strong>the</strong> source. In adistant sound field r ≫ λ we can write I = p2 effρcand thus :W = p2 eff 4πr2ρc(1.38)from which one can get an expression for <strong>the</strong> effective sound pressure, measuredat a distance r from <strong>the</strong> source :√Wρcp eff =(1.39)4πr 2With known source acoustic power <strong>the</strong> sound pressure can be calculatedin a given point. The effective sound pressure decreases with increasingdistance 1 . One may rewrite Equation 1.39 as a function <strong>of</strong> values in dB.r√412Wp eff = ρc = 400 for air4πr 2⇒ p 2 eff = 412W4πr 2⇒p2 eff 412W=400∗10 −12 4πr 2 400∗10 −12⇒ L p = L W −10log(4πr 2 )For r = 1 one has approximately :L p = L W −10 (1.40)

22 CHAPTER 1. FUNDAMENTAL CONCEPTS OF ACOUSTICS

Chapter 2The human hearing system2.1 Anatomy <strong>of</strong> <strong>the</strong> earThe hearing organ is sketched in Figure 2.1 and consists <strong>of</strong> three parts :<strong>the</strong> external hearing organ, <strong>the</strong> middle ear and <strong>the</strong> inner ear. The externalhearing organconsists <strong>of</strong><strong>the</strong>pinna (also calledauricle), <strong>the</strong> external auditorycanaland<strong>the</strong>eardrum. Themiddleearconsists<strong>of</strong><strong>the</strong>hammer, anvil, stirrupand also <strong>the</strong> eardrum. The inner ear consists <strong>of</strong> <strong>the</strong> cochlea.2.1.1 The external earThe external ear consists <strong>of</strong> <strong>the</strong> auricle. The use <strong>of</strong> both ears allows us todetermine <strong>the</strong> direction where a sound comes from. The brain measures <strong>the</strong>time delay in between <strong>the</strong> sound arriving at both ears. The sound receivedby <strong>the</strong> auricle is converted in a vibration <strong>of</strong> <strong>the</strong> eardrum at <strong>the</strong> end <strong>of</strong> <strong>the</strong>external auditory canal.2.1.2 The middle earThe middle ear contains <strong>the</strong> hearing ossicles : <strong>the</strong> hammer, anvil, stirrup(see Figure 2.1). The middle ear cavity is connected with <strong>the</strong> nasal cavityvia <strong>the</strong> Eustachian tube. This allows to have <strong>the</strong> same pressure as outside.The ossicles are responsible for <strong>the</strong> transmission <strong>of</strong> <strong>the</strong> sound wave from<strong>the</strong> eardrum to <strong>the</strong> oval window <strong>of</strong> <strong>the</strong> inner ear. The ossicles are attachedto <strong>the</strong> sides <strong>of</strong> <strong>the</strong> middle ear cavity with ligaments and muscles. Whena strong sound stimulant enters (more than 80 dB at 1000 Hz), a muscleattached to <strong>the</strong> stirrup contracts to restrict <strong>the</strong> movement : this is called<strong>the</strong> acoustic reflex (Stapediusreflex). This reflex provides <strong>the</strong> ear with aninternal protection <strong>of</strong> order 10 dB at low frequent sound : <strong>the</strong> protecting23

24 CHAPTER 2. THE HUMAN HEARING SYSTEMFigure 2.1: The anatomy <strong>of</strong> <strong>the</strong> human ear r : 1) skull External ear : 2)external auditory canal, 3) auricle Middle ear : 4) eardrum, 5) oval window,6)hamer, 7)anvil, 8)stirrup, 12)Eustachian tubeInternal ear : 9) labyrinth,10) cochlea, 11) cochlear nerve. Source : nl.wikipedia.orgeffect decreases with increasing frequency anddisappears above 2000Hz. Thelatency <strong>of</strong> <strong>the</strong> reflex decreases with <strong>the</strong> intensity <strong>of</strong> <strong>the</strong> stimulus : it variesfrom a mean value <strong>of</strong> 150ms with a tone <strong>of</strong> 80dB to 40ms with a tone higherthan 100dB.2.1.3 The internal earThe inner ear consists <strong>of</strong> two organs : <strong>the</strong> half circular channels that provide<strong>the</strong> balance, and <strong>the</strong> cochlea, that accounts for <strong>the</strong> hearing function. Thecochlea consists <strong>of</strong> a spiral shaped cavity that is divided into two channels by<strong>the</strong> cochlear tube : <strong>the</strong> two channels are filled with a liquid, <strong>the</strong> perilymphand are connected at <strong>the</strong> end <strong>of</strong> <strong>the</strong> spiral. The upper channel starts at <strong>the</strong>oval window and <strong>the</strong> lower channel ends at <strong>the</strong> round window. When a soundwave arrives on <strong>the</strong> eardrum, <strong>the</strong> ossicles pass <strong>the</strong> motion on to <strong>the</strong> stirrupthat compresses <strong>the</strong> oval window and creates a pressure wave in <strong>the</strong> upperchannel. This wave propagates far<strong>the</strong>r in <strong>the</strong> upper channel as <strong>the</strong> tone <strong>of</strong><strong>the</strong> sound decreases. The transversal component <strong>of</strong> <strong>the</strong> wave (remark thatthis exists in a fluid) exerts its force directly on <strong>the</strong> cochlear duct where <strong>the</strong>

2.2. PHYSIOLOGY OF THE EAR 25organ <strong>of</strong> Corti is located. This is <strong>the</strong> actual organ that serves to perceivesound. The membrane that separates <strong>the</strong> upper channel from <strong>the</strong> cochlearduct is compressed and gives rise to a pressure wave in <strong>the</strong> liquid <strong>of</strong> <strong>the</strong>cochlea (<strong>the</strong> endolymph), which in turn compresses <strong>the</strong> basilar membrane onwhich <strong>the</strong> organ <strong>of</strong> Corti is situated. The organ <strong>of</strong> Corti consists <strong>of</strong> hair cellsinternally arrangedinarowandexternally arrangedin3to5rows. Thehairs<strong>of</strong> <strong>the</strong> cells are in direct contact with a heavy membrane, called <strong>the</strong> tektorialmembrane. When <strong>the</strong> basilar membrane is compressed, <strong>the</strong> contact <strong>of</strong> <strong>the</strong>hairs with <strong>the</strong> tektorial membrane will be lost beginning with <strong>the</strong> externalrows. Every time <strong>the</strong> contact is broken or recovered, <strong>the</strong> electrical potential<strong>of</strong><strong>the</strong>cells ischanged. Thechangesin<strong>the</strong>electrical potential aretransmittedto<strong>the</strong>brainvia<strong>the</strong>fibres<strong>of</strong><strong>the</strong>cochlear nerve. In<strong>the</strong>brain<strong>the</strong>y aredecodedand converted into a perception <strong>of</strong> sound. Due to <strong>the</strong> interaction between <strong>the</strong>waves in <strong>the</strong> two canals, <strong>the</strong> maximal displacement <strong>of</strong> <strong>the</strong> basilar membranebecomes larger as <strong>the</strong> incoming tone gets lower. Sharp tones only stimulatea small band near <strong>the</strong> oval and round window. The maximal amplitude <strong>of</strong> awave at a certain frequency always stimulates <strong>the</strong> same hair cells, allowingto precisely distinct between different frequencies.Moreover, <strong>the</strong> displacement <strong>of</strong> <strong>the</strong> basilar membrane (and with this <strong>the</strong>number <strong>of</strong> hair cells that are in a working state) is proportional to <strong>the</strong> intensity<strong>of</strong> <strong>the</strong> sound : for a non intense sound, only <strong>the</strong> outer row <strong>of</strong> haircells will send pulses to <strong>the</strong> brain. While for a very intense sound all outerrows and eventually <strong>the</strong> inner row send pulses. The cochlear nerve or rectocochlearpart <strong>of</strong> <strong>the</strong> sound perception, is situated directly behind <strong>the</strong> organ.As happens with <strong>the</strong> eyes, it is here that <strong>the</strong> overlap between left and rightnerves takes place. The stimuli come to consciousness in <strong>the</strong> auditive cortex.This is situated near <strong>the</strong> temple.2.2 Physiology <strong>of</strong> <strong>the</strong> ear2.2.1 The auditory fieldThe sensitivity <strong>of</strong> <strong>the</strong> ear is phenomenal. If it were 20dB better, we wouldhave been capable to hear <strong>the</strong> pressure fluctuations caused by <strong>the</strong> Brownsemovement <strong>of</strong> <strong>the</strong> air molecules! For a tone <strong>of</strong> 1kHz that we are just ableto hear, <strong>the</strong> eardrum moves 10 −6 mm. This are distances smaller than <strong>the</strong>wavelength <strong>of</strong> visible light : 0.5 µm. The range <strong>of</strong> audible frequencies <strong>of</strong> <strong>the</strong>human ear is situated between 20 and 20000 Hz. Tones below 20 Hz arecalled subsonic and those above 20 kHz ultrasonic. The absolute threshold<strong>of</strong> hearing is at its lowest for frequencies around 1000 : this is why 1 kHz

26 CHAPTER 2. THE HUMAN HEARING SYSTEMFigure 2.2: The anatomy <strong>of</strong> <strong>the</strong> cochlea. Source : Encarta Winkler Prins2004is chosen as <strong>the</strong> reference frequency for <strong>the</strong> dB-scale. The pain threshold isvirtually independent <strong>of</strong> <strong>the</strong> frequency and corresponds to 130 or 140 dB.Speech is above all a complex mixture <strong>of</strong> tones, with a frequency spectrumrangingfrom200to4000Hz. Thiszonein<strong>the</strong>auditoryfieldiscalled<strong>the</strong>zone<strong>of</strong> speech. The protection <strong>of</strong> <strong>the</strong> ear in this zone is <strong>of</strong> <strong>the</strong> utmost importancefor a persons <strong>the</strong> social life (Figure 2.4).2.2.2 Amplification <strong>of</strong> signals in hearingThe amplification <strong>of</strong> sound happens in <strong>the</strong> external ear (external auditorycanal), middle- and inner ear. The amplification in <strong>the</strong> external auditorycanal relies on resonator-operation and happens predominantly in <strong>the</strong> speechintelligibility area(Figure2.4). In<strong>the</strong>external auditorycanal, thatresemblesa open-closed tube, a standing wave originates with if <strong>the</strong> wavelength <strong>of</strong> <strong>the</strong>sound isgiven by λ = 4L, with L ≈ 0.03m<strong>the</strong> length<strong>of</strong> <strong>the</strong> external auditory

2.2. PHYSIOLOGY OF THE EAR 27Figure 2.3: The organ <strong>of</strong> Corti. Source : anatomie.med.vu.nl andwww.audiologieboek.nlcanal. This means that <strong>the</strong> resonance frequency <strong>of</strong> <strong>the</strong> acoustic system canbe found as follows :f = c4L = 340m/s ≈ 3000Hz (2.1)4∗0.03mBecause <strong>the</strong> inner ear contains a liquid, <strong>the</strong>re is an impedance mismatchbetween <strong>the</strong> outer and inner ear. To overcome this mismatch <strong>the</strong> hearingsystem has two mechanisms that are used to amplify <strong>the</strong> force that can beexerted on <strong>the</strong> liquid. The first amplification in <strong>the</strong> middle ear relies on <strong>the</strong>mechanical amplification <strong>of</strong> <strong>the</strong> vibrations <strong>of</strong> <strong>the</strong> ossicles. The system <strong>of</strong> ossicles(hammer - anvil - stirrup) weakens low and high tones and amplifies

28 CHAPTER 2. THE HUMAN HEARING SYSTEMFigure 2.4: The zone <strong>of</strong> speech. Source : Bruël&Kjær.tones in <strong>the</strong> speech intelligibility area. Due to a leverage effect, <strong>the</strong> forcesexerted on <strong>the</strong> middle ear are amplified with approximately factor three (seeFigure 2.5). Note that although <strong>the</strong> forces are amplified, <strong>the</strong> displacementsare attenuated (due to <strong>the</strong> conservation <strong>of</strong> energy <strong>of</strong> <strong>the</strong> sound wave). Secondly,an amplification <strong>of</strong> <strong>the</strong> forces is realised due to <strong>the</strong> ratio between <strong>the</strong>section <strong>of</strong> <strong>the</strong> eardrum (where <strong>the</strong> sound wave strikes) and <strong>the</strong> oval window(where <strong>the</strong> sound wave is transmitted to <strong>the</strong> cochlea).The amplification in <strong>the</strong> inner ear depends on <strong>the</strong> frequency <strong>of</strong> <strong>the</strong> stimulants,acting on different locations in <strong>the</strong> cochlea (Figure 2.6). The functioning<strong>of</strong> <strong>the</strong> inner ear relies on <strong>the</strong> propagation <strong>of</strong> waves on <strong>the</strong> basilarmembrane. At low frequencies <strong>the</strong> maximum <strong>of</strong> <strong>the</strong> displacement is situatedfur<strong>the</strong>r away in <strong>the</strong> cochlea (since at any wave length energy is lost,<strong>the</strong> low frequencies propagate fur<strong>the</strong>r in comparison with higher tones). Athigh frequencies, <strong>the</strong> maximum is situated near <strong>the</strong> oval window. moreover,<strong>the</strong> stiffness <strong>of</strong> <strong>the</strong> membranes in <strong>the</strong> organ <strong>of</strong> Corti tuned on <strong>the</strong> differentfrequency bands that need to be perceived in <strong>the</strong> different places along <strong>the</strong>cochlear duct.

2.2. PHYSIOLOGY OF THE EAR 29Figure 2.5: Amplification <strong>of</strong> <strong>the</strong> sound by <strong>the</strong> ossicles.Figure 2.6: Changing cross section <strong>of</strong> <strong>the</strong> cochlea to realize a frequency dependen<strong>the</strong>aring mechanism.

30 CHAPTER 2. THE HUMAN HEARING SYSTEM2.3 Pathology <strong>of</strong> <strong>the</strong> ear2.3.1 IntroductionWhen considering hearing disabilities, distinction between conductive hearingloss and perception hearing disorders should be made. The conductivehearing loss concerns all defects that prevent all mechanical conduction <strong>of</strong>vibrations to <strong>the</strong> oval window. For example : constipation <strong>of</strong> <strong>the</strong> externalauditory canal, stiffening <strong>of</strong> <strong>the</strong> eardrum, concrescence <strong>of</strong> <strong>the</strong> ossicles, concrescence<strong>of</strong><strong>the</strong>ossicles to<strong>the</strong>side <strong>of</strong><strong>the</strong>cochlea,... Otosclerosis isacommondisorder where <strong>the</strong> bone growth hinders <strong>the</strong> movement <strong>of</strong> <strong>the</strong> ossicles, in particular<strong>the</strong> stirrup. The surgical procedure in which <strong>the</strong> stirrup is removed(stapedectomy) and is replaced with a pro<strong>the</strong>se, <strong>of</strong>fers a good chance on fullrecovery <strong>of</strong> <strong>the</strong> hearing capabilities. Perception hearing disorder includes alldefects in <strong>the</strong> cochlea, like : wear <strong>of</strong> <strong>the</strong>hair cells, tinnitus, impairment <strong>of</strong> <strong>the</strong>nerves. At <strong>the</strong> moment <strong>the</strong>re is no cure for tinnitus. Devices that look like ahearing aid are sometimes used to generate masking noise to make <strong>the</strong> disorderbearable. Some medications can be <strong>the</strong> cause <strong>of</strong> tinnitus to. Cochlearimplants use an electrostimulation <strong>of</strong> <strong>the</strong> cochlea on <strong>the</strong> round window or in<strong>the</strong> cochlea itself. The electronic signal originates from a speech processorand is induced by a coil outside <strong>the</strong> body on an implanted receiver coil in<strong>the</strong> body. This is an aid for people who have a serious hearing disorder orare deaf. It is however still to be considered as <strong>the</strong> generation <strong>of</strong> a soundperception far from normal hearing.2.3.2 Development <strong>of</strong> <strong>the</strong> ear with ageThe sensitivity <strong>of</strong> <strong>the</strong> ear tends to diminish with age, and loss <strong>of</strong> hearingarises faster at high frequencies in general. The span <strong>of</strong> <strong>the</strong> effect <strong>of</strong> age,called presbycusis, varies strongly from individual to individual. The loss <strong>of</strong>hearing at a certain frequency as a consequence <strong>of</strong> <strong>the</strong> presbycusis effect is<strong>the</strong>difference between <strong>the</strong>absolutethreshold <strong>of</strong>hearingatthisfrequency and<strong>the</strong> ’normal’ absolute threshold <strong>of</strong> hearing. According to ISO 389 standard,’normal’ thresholds are <strong>the</strong> median thresholds <strong>of</strong> a normal hearing, young (20years old) population. Table 2.1 shows <strong>the</strong> values at <strong>the</strong> frequencies normallyused in audiometry.In loss <strong>of</strong> hearing an enormous individual variability exists. For example,atafrequency<strong>of</strong>4000Hz<strong>the</strong>losscanbe5dBfor<strong>the</strong>leastsensitiveindividuals(sensitivity = 10%) and 45dB for <strong>the</strong> most sensitive (sensitivity = 90%).

2.4. THE HUMAN PERCEPTION OF SOUND 31Frequency Threshold125 Hz 45.0 dB250Hz 25.5 dB500Hz 11.5 dB1 kHz 7.0 dB2kHz 9.0 dB3 kHz 10.0 dB4kHz 9.5 dE6kHz 15.5 dB8kHz 13.5 dBTable 2.1: Hearing threshold <strong>of</strong> a normal hearing young population (20years).2.4 The human perception <strong>of</strong> sound2.4.1 The phonThe sensitivity <strong>of</strong> <strong>the</strong> ear is function <strong>of</strong> <strong>the</strong> frequency. Thanks to <strong>the</strong> experiments<strong>of</strong> Fletcher and Munson [15] in <strong>the</strong> early nineteen thirties thissensitivity was mapped (see Figure 2.7). During <strong>the</strong>se experiments a tone<strong>of</strong> 40 dB <strong>of</strong> 1 kHz was presented to <strong>the</strong> test subjects. Next <strong>the</strong> frequencywas adjusted and <strong>the</strong> test subjects were asked to indicate <strong>the</strong> sound pressurelevel at which <strong>the</strong> tone sounded equally loud as <strong>the</strong> original sound at 1 kHz.The resulting curve is <strong>the</strong> co called 40 dB isophone. The experiment wasrepeated for o<strong>the</strong>r sound pressure levels (see Figure 2.7). It follows from thisthat frequency sensitivity depends on <strong>the</strong> sound levels : at a higher soundintensity <strong>the</strong> curves get flatter.2.4.2 The sone as measure <strong>of</strong> loudnessStarting from <strong>the</strong> results <strong>of</strong> Fletcher and Munson one could think that forexample a sound <strong>of</strong> 80 phon has a sound level about ten times as high as asound <strong>of</strong> 60 phon (remember : a 20dB SPL increase corresponds to a factor10 in sound pressure). In reality, humans experience <strong>the</strong> sound <strong>of</strong> 80 phon asfour times louder than 60 phon. Extensive experimental and psychologicalresearch was performed to find a ma<strong>the</strong>matical relation between <strong>the</strong> loudness(in phon) and <strong>the</strong> sound level. We can observe from this :loudness level + 10 dB (phon) = loudness X 2

32 CHAPTER 2. THE HUMAN HEARING SYSTEMFigure 2.7: The isophone curves. Source : Bruël&Kjær.Increase/decrease (dB) Experienced change in loudness3 just observable5 Notable difference10 Twice as loud15 Important increase20 Four times as loudTable 2.2: Qualitative experience <strong>of</strong> loudness with an increase in dB.This relation is valid for 20 phon < L p < 120 phon. This is why <strong>the</strong> sonescale is introduced to fix a linear relation. An international standard defines<strong>the</strong> sone (S) as measure for loudness as follows:S = 2 P−4010 (2.2)A sound <strong>of</strong> 120 phon is 256 times louder than a sound <strong>of</strong> 40 phon. Inverselyone has: P = 40 + 33.3logS. The qualitative experience with <strong>the</strong>increase/decrease <strong>of</strong> sound levels is displayed in Table 2.2.

Chapter 3Measuring sound3.1 Introduction: why measure soundIn order to select a useful measuring technique we need to determine what<strong>the</strong> purpose <strong>of</strong> <strong>the</strong> sound measurement is. A first important objective can beto determine a sound pollution problem. To do this extend, measurements <strong>of</strong><strong>the</strong> sound pressure level are usually sufficient. In such a case <strong>the</strong> availability<strong>of</strong> a simple, portable measuring system is desirable. It <strong>the</strong> hindrance ismomentary, one wishes a swift registration <strong>of</strong> <strong>the</strong> peak levels. For a longobservation, an automatic averaging and statistical processing is advised andmost <strong>of</strong> <strong>the</strong> times required by <strong>the</strong> legislator. A second objective can be <strong>the</strong>reduction <strong>of</strong> noise after <strong>the</strong> confirmation <strong>of</strong> nuisance. One speaks <strong>of</strong> soundsanitation. Mostly, <strong>the</strong>re is a need to examine <strong>the</strong> frequency spectrum <strong>of</strong><strong>the</strong> sound to accomplish this task. To this extend specific measuring devicesare developed. Measurements in frequency bands gives <strong>the</strong> general picture<strong>of</strong> <strong>the</strong> composition whereas <strong>the</strong> linear spectrum can be an important aid inlocalizing <strong>the</strong> source <strong>of</strong> <strong>the</strong> sound. The latter can also be done by usingvector intensity measurements, which will not be discussed in this course.A third objective <strong>of</strong> sound measurements is to investigate if <strong>the</strong> norms andregulations concerning noise pollution are not violated. In this case, as weshall see in later modules, <strong>the</strong> measuring parameters as well as <strong>the</strong> measuringconditions are <strong>of</strong>ten prescribed.3.2 The measurement microphoneA measurement system to measure sound pressure consists <strong>of</strong> a microphone,signal amplifier, conditionings unit and a measuring device. The microphoneconverts vibrations <strong>of</strong> <strong>the</strong> air into mechanical vibrations, <strong>the</strong>se are in turn33

34 CHAPTER 3. MEASURING SOUNDconverted in an electric signal. This is amplified and optionally filtered in <strong>the</strong>frequency domain. The electrical signal is <strong>the</strong>n read out by <strong>the</strong> measuringdevice. This reading can be done in several ways (digital display, computerscreen, analog display.The microphone is <strong>the</strong> critical element in every measuring system forsound. The microphone detects <strong>the</strong> sound pressure variations and converts<strong>the</strong>m into electrical signals. This can be done in several ways:Ceramic or piezoelectrical microphones. The working principle <strong>of</strong>ceramic or piezoelectrical microphones is based on <strong>the</strong> properties <strong>of</strong> <strong>the</strong>piezoelectrical material. This material generates an electrical voltagewhen mechanical pressure is applied on it. Ceramic microphones arerobust and not sensitive to moisture and o<strong>the</strong>r environmental impacts.O<strong>the</strong>r advantages are <strong>the</strong>ir relatively low cost and <strong>the</strong> fact that noexternal voltage source is necessary.Condenser microphones. The condenser microphone is used to executeprecise measurements. Condenser microphones make use <strong>of</strong> twoelectrically chargedplates withanair gapinbetween. One<strong>of</strong><strong>the</strong>platesis a light membrane that moves under influence <strong>of</strong> <strong>the</strong> incoming soundwaves. Figure 3.1 displays a construction <strong>of</strong> such a microphone. Between<strong>the</strong> membrane and <strong>the</strong> base plate an electrical charge is createdby a voltage supply. Due to <strong>the</strong> incoming sound wave <strong>the</strong> distancebetween <strong>the</strong> base plate and membrane changes, casing <strong>the</strong> capacityto change. This results in variations on <strong>the</strong> voltage over <strong>the</strong> microphonethat that proportional with <strong>the</strong> incoming pressure (see Figure3.2). Condenser microphones can be designed to have a sensitivitythat does not change much over time and to have a frequency responsethat is very flat (<strong>the</strong> sensitivity is <strong>the</strong> ratio <strong>of</strong> <strong>the</strong> measured tensionover <strong>the</strong> sound pressure, this value is <strong>of</strong> <strong>the</strong> order <strong>of</strong> a few mV/Pa).Moreover <strong>the</strong>y are very insensitive to temperature changes. Due tothis stability condenser microphones are designated to use for precisionmeasurements. Since an notable polarisation tension needs to be appliedover <strong>the</strong> capacitor, a to high humidity can give problems. The use<strong>of</strong> a heating element can present a solution to this problem, if lengthymeasurements need to be conducted.Electret microphones an electret is a polymer film with an electricalcharge bound to <strong>the</strong> molecules. An electret condenser microphone ismade by applying <strong>the</strong> electret on a perforated metal plate, and shieldit <strong>of</strong>f on <strong>the</strong> front side with a plastic membrane on which a thin metal