Mechatronic Design of a Soccer Robot for the Small-Size League of ...

Mechatronic Design of a Soccer Robot for the Small-Size League of ...

Mechatronic Design of a Soccer Robot for the Small-Size League of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FACULTEIT INGENIEURSWETENSCHAPPEN<br />

<strong>Mechatronic</strong> <strong>Design</strong> <strong>of</strong> a <strong>Soccer</strong><br />

<strong>Robot</strong> <strong>for</strong> <strong>the</strong> <strong>Small</strong>-<strong>Size</strong> <strong>League</strong><br />

<strong>of</strong> RoboCup<br />

Joris De Witte<br />

Promotor: Pr<strong>of</strong>. Dr. Ir. Bram Vanderborght<br />

Eindwerk ingediend voor het behalen van de graad van Master in de<br />

Ingenieurswetenschappen: Werktuigbouwkunde<br />

Academiejaar 2009-2010

Acknowledgments<br />

At <strong>the</strong> end <strong>of</strong> my first year at <strong>the</strong> VUB, <strong>the</strong> course ‘mechatronica’ aroused my interest<br />

in robotic systems. During this course, a small robot was built to develop our skills in<br />

this matter. With <strong>the</strong> gained knowledge, I decided to choose <strong>the</strong> <strong>the</strong>sis subject <strong>of</strong><br />

building a robot <strong>for</strong> <strong>the</strong> RoboCup <strong>Small</strong> <strong>Size</strong> <strong>League</strong>. I consider it as a privilege to be<br />

able to give a contribution in <strong>the</strong> development <strong>of</strong> <strong>the</strong>se robots.<br />

I would like to thank my promoter Dr. Ir. Bram Vanderborght <strong>for</strong> his support, guidance<br />

and enthusiasm <strong>for</strong> this subject. Many thanks go out to Jean-Paul Schepens and Ir.<br />

Ronald Van Ham <strong>for</strong> <strong>the</strong>ir time and help <strong>the</strong>y gave along <strong>the</strong> way. Also, I would like to<br />

thank <strong>the</strong> people <strong>of</strong> <strong>the</strong> workshop: Marnix and Stijn <strong>for</strong> <strong>the</strong>ir technical assistance and<br />

sharing <strong>the</strong>ir experience.<br />

As last, I would like to thank my family <strong>for</strong> <strong>the</strong>ir moral support.<br />

The auteur:<br />

Joris De Witte

Executive summaries<br />

1. Mechatronisch ontwerp van een voetbalrobot voor de<br />

RoboCup <strong>Small</strong> <strong>Size</strong> <strong>League</strong><br />

In deze <strong>the</strong>sis wordt het mechatronisch ontwerp van een voetbalrobot behandeld. De<br />

robots die deelnemen aan deze competitie doorgingen in de loop der jaren een sterke<br />

miniaturisering. Het implementeren van alle componenten in een beperkte ruimte is<br />

dan ook de uitdaging van deze <strong>the</strong>sis.<br />

Om een idee te hebben van de bestaande technologie werd voor iedere mechanische<br />

component een vergelijking gemaakt tussen de bestaande robots. Hieruit blijkt dat de<br />

deelnemende teams vergelijkbare componenten en technologieën gebruiken in hun<br />

robots. Toch kunnen enkele teams het verschil maken door een goed ontwerp en<br />

integratie van de componenten.<br />

De ontworpen robot maakt gebruik van vier gelijkstroommotoren met elektronische<br />

commutatie voor de aandrijving. Via een tandwieloverbrenging wordt de kracht<br />

overgebracht naar de onmindirectionele wielen.<br />

Om de bal weg te kunnen trappen, wordt een schietsysteem ingebouwd. Deze bestaat<br />

uit een veer die opgespannen wordt. Een sluitsysteem houdt de plunjer vast terwijl de<br />

veer wordt opgespannen. Een servomotor bedient dit sluitsysteem en kan de plunjer<br />

vrijmaken wanneer er getrapt moet worden.<br />

Een dribbelsysteem brengt de bal naar het midden van de robot en houdt de bal ook<br />

voor de robot terwijl er gemanoeuvreerd kan worden met de robot. Deze bestaat uit<br />

een sneldraaiende cilinder dewelke een backspin geeft aan de bal.<br />

Alle mechanische en elektronische systemen werden ontwikkeld en getest. Dit vormt<br />

een eerste stap naar het ontwikkelen van een complete robot, geschikt voor de<br />

deelname aan de RoboCup <strong>Small</strong> <strong>Size</strong> <strong>League</strong> hetgeen ook het doel is van deze <strong>the</strong>sis.

2. <strong>Mechatronic</strong> design <strong>of</strong> a soccer playing robot <strong>for</strong> <strong>the</strong><br />

RoboCup <strong>Small</strong> <strong>Size</strong> <strong>League</strong><br />

In this <strong>the</strong>sis, <strong>the</strong> design <strong>of</strong> a soccer-playing robot is discussed. The robots that<br />

participate in this competition are a result <strong>of</strong> a strong miniaturization during <strong>the</strong> years.<br />

The implementation <strong>of</strong> all components in a limited amount <strong>of</strong> space is <strong>the</strong>re<strong>for</strong>e <strong>the</strong><br />

challenge <strong>of</strong> this <strong>the</strong>sis.<br />

To have a notion <strong>of</strong> <strong>the</strong> existing technologies, a comparison was made between all<br />

competing robots <strong>for</strong> each mechanical component. This shows that <strong>the</strong> participating<br />

teams use similar components and technologies. Never<strong>the</strong>less, some teams can make<br />

<strong>the</strong> difference with well designed components.<br />

The developed robot uses four brushless DC motors with electronic commutation <strong>for</strong><br />

<strong>the</strong> drive unit. Via a spur-gear transmission, <strong>the</strong> power is transmitted to <strong>the</strong> omnidirectional<br />

wheels.<br />

To kick <strong>the</strong> ball, a shooting device is built. This system consists <strong>of</strong> a spring which is<br />

wound up. A lock/release system hold <strong>the</strong> plunger in place while winding up <strong>the</strong><br />

spring. A servomotor actuates <strong>the</strong> lock/release system when a kick is required.<br />

A dribbler device brings <strong>the</strong> ball to <strong>the</strong> center <strong>of</strong> <strong>the</strong> robot and hold <strong>the</strong> ball in front <strong>of</strong><br />

<strong>the</strong> robot when it is maneuvering. The dribbler is a cylinder which spins with great<br />

speed and gives a backspin to <strong>the</strong> ball.<br />

All mechanical and electronic components where developed and tested. This is a first<br />

step to developing a complete robot, fit <strong>for</strong> <strong>the</strong> RoboCup <strong>Small</strong> <strong>Size</strong> <strong>League</strong> which is<br />

<strong>the</strong> goal <strong>of</strong> this <strong>the</strong>sis.

Contents<br />

1 Introduction ................................................................................................... 1<br />

1.1 RoboCup ............................................................................................................................... 1<br />

1.2 Objectives.............................................................................................................................. 2<br />

2 Driving unit ................................................................................................... 4<br />

2.1 State <strong>of</strong> <strong>the</strong> art ...................................................................................................................... 4<br />

2.2 Omni-directional wheels ....................................................................................................... 6<br />

2.2.1 Number <strong>of</strong> wheels................................................................................................................... 6<br />

2.2.2 Dimensions <strong>of</strong> <strong>the</strong> wheel ......................................................................................................... 7<br />

2.2.3 Concepts <strong>of</strong> construction ....................................................................................................... 10<br />

2.2.4 Final design .......................................................................................................................... 14<br />

2.3 Driving Motors ................................................................................................................... 15<br />

2.4 Transmission unit ............................................................................................................... 16<br />

2.4.1 General................................................................................................................................. 16<br />

2.4.2 Spur gear .............................................................................................................................. 17<br />

2.4.3 Belt transmission .................................................................................................................. 17<br />

2.4.4 Final design .......................................................................................................................... 17<br />

2.5 Experiments ........................................................................................................................ 19<br />

2.6 Conclusions ......................................................................................................................... 20<br />

3 Kicking device ............................................................................................. 21<br />

3.1 General................................................................................................................................ 21<br />

3.2 State <strong>of</strong> <strong>the</strong> art .................................................................................................................... 21<br />

3.3 Types <strong>of</strong> shooting devices .................................................................................................... 22<br />

3.3.1 Solenoid actuated.................................................................................................................. 22<br />

3.3.2 Spring actuated ..................................................................................................................... 23<br />

3.3.3 Pneumatic actuated ............................................................................................................... 24<br />

3.3.4 O<strong>the</strong>r .................................................................................................................................... 24<br />

3.4 Shooting system model........................................................................................................ 25<br />

3.4.1 General................................................................................................................................. 25<br />

3.4.2 Application note ................................................................................................................... 32<br />

3.5 First construction ................................................................................................................ 39<br />

3.6 Second construction ............................................................................................................ 41<br />

3.7 Experiments ........................................................................................................................ 44<br />

3.7.1 Compression process ............................................................................................................ 45<br />

3.7.2 Releasing process ................................................................................................................. 46<br />

3.8 Conclusions ......................................................................................................................... 48<br />

4 Dribbler ....................................................................................................... 49<br />

4.1 General................................................................................................................................ 49<br />

4.2 State <strong>of</strong> <strong>the</strong> art .................................................................................................................... 49<br />

4.3 Dimensions <strong>of</strong> <strong>the</strong> dribbler ................................................................................................. 51<br />

4.4 <strong>Design</strong> .................................................................................................................................. 53<br />

4.5 Experiments ........................................................................................................................ 54<br />

4.6 Conclusions ......................................................................................................................... 55

5 Electronics ................................................................................................... 56<br />

5.1 Motor controller ................................................................................................................. 56<br />

5.1.1 Brushless DC drive motors controller .................................................................................... 56<br />

5.1.2 Brushed motor <strong>for</strong> kicking device and dribbler ...................................................................... 58<br />

5.2 Interface electronics ............................................................................................................ 59<br />

5.2.1 FPGA ................................................................................................................................... 59<br />

5.2.2 Voltage regulation ................................................................................................................ 59<br />

5.3 Experiments ........................................................................................................................ 60<br />

5.4 Conclusions ......................................................................................................................... 60<br />

6 S<strong>of</strong>tware ....................................................................................................... 61<br />

6.1 Motion control .................................................................................................................... 61<br />

6.1.1 General................................................................................................................................. 61<br />

6.1.2 Electronic compass ............................................................................................................... 62<br />

6.1.3 Motor speed estimation ......................................................................................................... 63<br />

6.1.4 Motor control ....................................................................................................................... 64<br />

6.2 Kicking device control ........................................................................................................ 67<br />

6.3 Dribbler control .................................................................................................................. 67<br />

6.4 Conclusions ......................................................................................................................... 68<br />

7 Conclusions and fur<strong>the</strong>r work .................................................................... 69<br />

7.1 Conclusions ......................................................................................................................... 69<br />

7.2 Fur<strong>the</strong>r work ...................................................................................................................... 71<br />

8 Appendix ...................................................................................................... 72<br />

8.1 Appendix A: Rules <strong>of</strong> play .................................................................................................. 72<br />

8.1.1 External equipment provided by RoboCup ............................................................................ 72<br />

8.1.2 <strong>Robot</strong> and internal equipment ............................................................................................... 73<br />

8.2 Appendix B: CD rom .......................................................................................................... 80<br />

9 Bibliography ................................................................................................ 81<br />

9.1 Team description papers .................................................................................................... 81<br />

9.2 Books ................................................................................................................................... 83<br />

9.3 Papers ................................................................................................................................. 83<br />

9.4 Websites .............................................................................................................................. 83<br />

9.5 Datasheets ........................................................................................................................... 83

List <strong>of</strong> figures<br />

Figure 1: RoboCup competition layout ...................................................................................... 2<br />

Figure 2: Calculation <strong>of</strong> loss in ground surface .......................................................................... 7<br />

Figure 3: Loss in ground surface <strong>of</strong> <strong>the</strong> robot compared to wheel diameter ................................ 9<br />

Figure 4: Rotacaster omniwheel .............................................................................................. 10<br />

Figure 5: Omniwheel-design by Parsian team[15] .................................................................... 11<br />

Figure 6: Kiks research[10]: Various types <strong>of</strong> small wheels design .......................................... 11<br />

Figure 7:Kiks research[10]: Average time to reach 1m/s from static condition <strong>for</strong> <strong>the</strong> robot ..... 12<br />

Figure 8: Omniwheel-design by Korea University [27]............................................................ 13<br />

Figure 9: New omniwheel-design ............................................................................................ 14<br />

Figure 10: Maxon EC 45, 30Watt motor .................................................................................. 15<br />

Figure 11: Structural design <strong>of</strong> transmission units .................................................................... 18<br />

Figure 12: Close-up <strong>of</strong> front transmission unit with spur gears………………………………………………. 23<br />

Figure 13: Close-up <strong>of</strong> rear transmission unit with pulley ...................................................... 19<br />

Figure 14: Shooting system release process parameters ........................................................... 28<br />

Figure 15: Compressed spring length as function <strong>of</strong> <strong>the</strong> time ................................................... 33<br />

Figure 16: Compression time with selected spring ................................................................... 34<br />

Figure 17: Plunger and ball speed as function <strong>of</strong> time .............................................................. 35<br />

Figure 18: Plunger velocity as function <strong>of</strong> <strong>the</strong> spring length ..................................................... 36<br />

Figure 19: Plunger acceleration as function <strong>of</strong> <strong>the</strong> spring length ............................................... 36<br />

Figure 20: Ball velocity as function <strong>of</strong> plunger mass ................................................................ 37<br />

Figure 21: Effect <strong>of</strong> <strong>the</strong> plunger <strong>of</strong>fset ..................................................................................... 38<br />

Figure 22: First shooting system, general overview ................................................................. 39<br />

Figure 23: First shooting system: view on <strong>the</strong> spindle .............................................................. 39<br />

Figure 24: First shooting system: close-up on <strong>the</strong> displacement nut (left) and guidance bush.... 40<br />

Figure 25: First shooting system, close-up on <strong>the</strong> release ring .................................................. 41<br />

Figure 26: Second shooting system, general overview ............................................................. 41

Figure 27: Second shooting system, view on <strong>the</strong> plunger and spindle ....................................... 42<br />

Figure 28: Second shooting system, close-up on <strong>the</strong> guidance bush and footstep bearing ......... 42<br />

Figure 29: Second shooting system, view on <strong>the</strong> release ring and servomotor .......................... 43<br />

Figure 30: Dribbler setup ........................................................................................................ 51<br />

Figure 31: Dribbler components .............................................................................................. 53<br />

Figure 32: Dribbler experiment ............................................................................................... 54<br />

Figure 33: Block commutation <strong>for</strong> brushless DC motor [30] .................................................... 56<br />

Figure 34: Electronic circuit <strong>for</strong> brushless motor [30] .............................................................. 57<br />

Figure 35: H-bridge <strong>for</strong> brushed motor .................................................................................... 58<br />

Figure 36: Hitachi HM55B connection scheme ........................................................................ 62<br />

Figure 37: Speed estimation using <strong>the</strong> L6235 motor driver ...................................................... 63<br />

Figure 38: <strong>Robot</strong> layout <strong>for</strong> motor control ............................................................................... 64<br />

Figure 39: Experimental results <strong>for</strong> modified kinematics per<strong>for</strong>med by Skuba-team [22] ......... 66<br />

Figure 40: Layout <strong>of</strong> <strong>the</strong> playing field...................................................................................... 72<br />

Figure 41: Maximum dimensions <strong>of</strong> <strong>the</strong> robot ......................................................................... 73<br />

Figure 42: Dimensions <strong>of</strong> <strong>the</strong> recognition pattern..................................................................... 75<br />

Figure 43: Legal color assignments ......................................................................................... 76<br />

Figure 44: 20% rule................................................................................................................. 77

List <strong>of</strong> tables<br />

Table 1: Comparison <strong>of</strong> RoboCup Teams: Driving unit ............................................................. 4<br />

Table 2: Comparison between number <strong>of</strong> wheels ....................................................................... 6<br />

Table 3: Comparison between RoboCup teams: Kicking device ............................................... 21<br />

Table 4: Shooting system components ..................................................................................... 32<br />

Table 5: Adapted values from ma<strong>the</strong>matical model .................................................................. 44<br />

Table 6: Winding time measurements ...................................................................................... 45<br />

Table 7: Ball velocity measurements ....................................................................................... 47<br />

Table 8: Comparison between RoboCup teams: Dribbler ......................................................... 49<br />

Table 9: Electronic compass commands .................................................................................. 62

Chapter 1: Introduction<br />

1 Introduction<br />

1.1 RoboCup<br />

RoboCup[29] is a competition domain designed to advance robotics and artificial<br />

intelligence research through a friendly competition. <strong>Small</strong> <strong>Size</strong> robot soccer is one<br />

<strong>of</strong> <strong>the</strong> RoboCup league divisions. <strong>Small</strong> <strong>Size</strong> robot soccer, or F180 as it is o<strong>the</strong>rwise<br />

known, focuses on <strong>the</strong> problem <strong>of</strong> intelligent multi-agent cooperation and control in<br />

a highly dynamic environment with a hybrid centralized/distributed control system.<br />

A <strong>Small</strong> <strong>Size</strong> robot soccer game takes place between two teams <strong>of</strong> five robots each.<br />

Each robot must be made con<strong>for</strong>m to <strong>the</strong> dimensions as specified in <strong>the</strong> F180 rules:<br />

The robot must fit within an 180mm diameter circle and must be no higher than<br />

150mm unless <strong>the</strong>y use on-board vision. The robots play soccer with an orange golf<br />

ball on a green carpeted field that is 6.05m long by 4.05m wide. <strong>Robot</strong>s come in two<br />

flavors, those with local on-board vision sensors and those with global vision. Global<br />

vision robots, by far <strong>the</strong> most common variety, use an overhead camera and <strong>of</strong>ffield<br />

PC to identify and track <strong>the</strong> robots as <strong>the</strong>y move around <strong>the</strong> field. The<br />

overhead camera is attached to a camera bar located 4m above <strong>the</strong> playing surface.<br />

Local vision robots have <strong>the</strong>ir sensing on <strong>the</strong> robot itself. The vision in<strong>for</strong>mation is<br />

ei<strong>the</strong>r processed on-board <strong>the</strong> robot or is transmitted back to <strong>the</strong> <strong>of</strong>f-field PC <strong>for</strong><br />

processing. An <strong>of</strong>f-field PC is used to communicate referee commands and, in <strong>the</strong><br />

case <strong>of</strong> overhead vision, position in<strong>for</strong>mation to <strong>the</strong> robots. Typically <strong>the</strong> <strong>of</strong>f-field PC<br />

also per<strong>for</strong>ms most, if not all, <strong>of</strong> <strong>the</strong> processing required <strong>for</strong> coordination and<br />

control <strong>of</strong> <strong>the</strong> robots. Communications is wireless and typically uses dedicated<br />

commercial FM transmitter/receiver units.<br />

1

Chapter 1: Introduction<br />

Figure 1: RoboCup competition layout<br />

Building a successful team requires clever design, implementation and integration<br />

<strong>of</strong> many hardware and s<strong>of</strong>tware sub-components into a robustly functioning<br />

system. This makes small-size robot soccer a very interesting and challenging<br />

domain <strong>for</strong> research and education.<br />

1.2 Objectives<br />

The design <strong>of</strong> a complete robotic system to compete in <strong>the</strong> RoboCup <strong>Small</strong> <strong>Size</strong><br />

<strong>League</strong> involves <strong>the</strong> integration <strong>of</strong> different areas <strong>of</strong> knowledge.<br />

In order to do so, a team with members <strong>of</strong> several Belgian universities is<br />

established. Each member works on a subproject which is related to <strong>the</strong>ir area <strong>of</strong><br />

knowledge.<br />

2

Chapter 1: Introduction<br />

The goal <strong>of</strong> a first subproject is to develop a s<strong>of</strong>tware plat<strong>for</strong>m <strong>for</strong> <strong>the</strong> high level<br />

control. All <strong>the</strong> strategic actions are embedded in <strong>the</strong> s<strong>of</strong>tware. The s<strong>of</strong>tware<br />

determines all <strong>the</strong> necessary actions <strong>the</strong> robots must undertake to win <strong>the</strong> game.<br />

A second subproject has <strong>the</strong> goal <strong>of</strong> processing <strong>the</strong> data from <strong>the</strong> overhead camera.<br />

The location <strong>of</strong> each robot, <strong>the</strong> robots ID and <strong>the</strong> ball location have to be<br />

determined.<br />

The goal <strong>of</strong> this <strong>the</strong>sis is to develop <strong>the</strong> mechatronic design <strong>of</strong> <strong>the</strong> small-size robot<br />

This robot houses all <strong>the</strong> systems to handle <strong>the</strong> ball and to communicate with <strong>the</strong><br />

<strong>of</strong>f-field PC. Be<strong>for</strong>e developing <strong>the</strong> robot, all requirements and limitations have to<br />

be known. In Appendix 1: <strong>the</strong> rules provided by RoboCup are summarized. These<br />

rules set <strong>the</strong> design specifications.<br />

A first major component <strong>of</strong> <strong>the</strong> robot is <strong>the</strong> drive system which includes <strong>the</strong> motors,<br />

<strong>the</strong> transmission system and a set <strong>of</strong> omni-directional wheels. These are discussed<br />

in ‘chapter 2: Drive Unit’.<br />

The second component <strong>of</strong> <strong>the</strong> robot is a system to kick <strong>the</strong> ball. A state <strong>of</strong> <strong>the</strong> art <strong>of</strong><br />

existing systems is discussed in ‘chapter 3: Kicking device’. The benefits and<br />

disadvantages <strong>of</strong> all <strong>the</strong>se systems are summarized. With this knowledge in mind, a<br />

new concept is developed.<br />

Ano<strong>the</strong>r component is <strong>the</strong> dribbler. This system has <strong>the</strong> task <strong>of</strong> giving a backspin to<br />

<strong>the</strong> ball. With this system, <strong>the</strong> robot is able to hold <strong>the</strong> ball in front <strong>of</strong> it and thus<br />

handle <strong>the</strong> ball better. This system is discussed in ‘chapter 4: Dribbler’.<br />

For this <strong>the</strong>sis, <strong>the</strong> electronics on board <strong>of</strong> <strong>the</strong> robot are all united into ‘chapter 5:<br />

electronics’. This chapter discusses all <strong>the</strong> motor-controllers and a component <strong>for</strong><br />

navigational purpose.<br />

In order to control <strong>the</strong> robot some s<strong>of</strong>tware has to be developed. The commands<br />

from <strong>the</strong> <strong>of</strong>f-field PC have to be translated to <strong>the</strong> different motors on <strong>the</strong> robot. In<br />

‘chapter 6: S<strong>of</strong>tware’, this is discussed.<br />

The last chapter provides <strong>the</strong> conclusions and future work.<br />

3

Chapter 2: Drive unit<br />

2 Driving unit<br />

2.1 State <strong>of</strong> <strong>the</strong> art<br />

Be<strong>for</strong>e discussing and constructing a drive system, <strong>the</strong> existing systems are<br />

reviewed. The next table gives an overview <strong>of</strong> <strong>the</strong>se systems, currently used in<br />

robots competing in <strong>the</strong> RoboCup <strong>Small</strong> <strong>Size</strong> <strong>League</strong>. Top teams from <strong>the</strong> last three<br />

years are printed in bold. More in<strong>for</strong>mation about <strong>the</strong> type <strong>of</strong> wheels can be found<br />

in next paragraphs.<br />

Table 1: Comparison <strong>of</strong> RoboCup Teams: Driving unit<br />

Team<br />

Number<br />

<strong>of</strong><br />

Type<br />

<strong>of</strong><br />

Motors Power Speed Spur gear<br />

ratio<br />

wheels wheels<br />

Botania Dragon 4 Brushless DC 30 W<br />

Knights [1]<br />

Brocks [2] 4 <strong>Small</strong> Brushless DC 30 W 3:1<br />

B-Smart [3] 4 <strong>Small</strong> Faulhaber 20,5 W 9000 12:1<br />

2342S006CR<br />

Brushed DC<br />

rpm<br />

CMDragons [4] 4 <strong>Small</strong> Brushless DC 30 W<br />

Eagle Knights [5] 4 <strong>Small</strong> Faulhaber<br />

14:1<br />

2224P0212<br />

ER-Force [6] 4 <strong>Small</strong> Maxon EC 45 30 W<br />

(New system)<br />

Brushless DC<br />

Field Rangers [7] 4 <strong>Small</strong> Faulhaber 9,35 W 7400 9,7:1<br />

2232U009SR<br />

rpm<br />

Immortals [8] 4 <strong>Small</strong> Maxon EC 45 50 W 45:12<br />

Brushless DC<br />

Khainui [9] 4 <strong>Small</strong> Namiki 22CL-<br />

10:1<br />

3501PG80:1<br />

KIKS [10] 4 <strong>Small</strong> Maxon EC 45<br />

Brushless DC<br />

3,6:1<br />

4

Chapter 2: Drive unit<br />

KN2C [11] 3 <strong>Small</strong> Brushed DC 8160 13,6:1<br />

rpm<br />

ODENS [12] 4 <strong>Small</strong> Maxon REmax<br />

11 W 8290 7,916:1<br />

23<br />

Brushed DC<br />

rpm<br />

OMID [13] 4 <strong>Small</strong> Maxon EC 45 30 W 5:1<br />

Brushless DC<br />

Owaribito [14] 4 <strong>Small</strong> Maxon RE-max<br />

21<br />

Brushed DC<br />

Parsian [15] 4 <strong>Small</strong> Maxon EC 45 30 W 4.7:1<br />

Brushless DC<br />

RFC Cambridge 4 <strong>Small</strong> Brushless DC<br />

[16]<br />

Robojackets [17] 3 <strong>Small</strong> Maxon EC 45<br />

4,5:1<br />

Brushless DC<br />

Robodragons 4 <strong>Small</strong> Maxon EC 45 30 W 3.047:1<br />

[18]<br />

Brushless DC<br />

RoboFEI [19] 4 <strong>Small</strong> Maxon EC 45 50 W 3:1<br />

Brushless DC<br />

(Former<br />

Faulhaber<br />

2232 DC)<br />

RoboFighties [20] 2 2,16<br />

m/s<br />

RoboPET [21] 4 <strong>Small</strong> Maxon EC 45 50 W 3,6:1<br />

Brushless DC<br />

Skuba [22] 4 <strong>Small</strong> Maxon 30 W<br />

Brushless DC<br />

MRL [23] 4 <strong>Small</strong> Brushless DC 4:1<br />

UBC Thunderbots 4 <strong>Small</strong> Maxon 30 W 3,5:1<br />

[24]<br />

Brushless DC<br />

Plasma-Z [25] 4 <strong>Small</strong><br />

5

Chapter 2: Drive unit<br />

The most commonly used motor is a Maxon EC-45 brushless motor. These are very<br />

flat motors with a slightly larger diameter compared to brushed motors. They are<br />

very suitable <strong>for</strong> this application because <strong>of</strong> <strong>the</strong>se specific dimensions. Most teams<br />

use a 30 Watt version, but some are already experimenting with more powerful<br />

versions like <strong>the</strong> 50 Watt versions. These teams are hoping <strong>for</strong> <strong>the</strong>ir robot to be<br />

faster and have more acceleration ability than <strong>the</strong>ir competitors.<br />

Almost every team is using four wheels. This approach provides more space along<br />

<strong>the</strong> roll-axis <strong>of</strong> <strong>the</strong> robot. All teams who built <strong>the</strong>ir own omni-directional wheels are<br />

using <strong>the</strong> small wheels concept. This will be discussed in next paragraph.<br />

2.2 Omni-directional wheels<br />

2.2.1 Number <strong>of</strong> wheels<br />

The number <strong>of</strong> wheels used on <strong>the</strong> robot depends on <strong>the</strong> available space and <strong>the</strong><br />

desired amount <strong>of</strong> grip on <strong>the</strong> surface. Because <strong>the</strong> available space is limited, <strong>the</strong><br />

number <strong>of</strong> wheels is limited to four. To have any stability, a minimum <strong>of</strong> three<br />

wheels is needed. There<strong>for</strong>e, a choice between <strong>the</strong>se two setups has to be made.<br />

Table 2: Comparison between number <strong>of</strong> wheels<br />

Four wheels<br />

Advantages<br />

Disadvantages<br />

- More space available along <strong>the</strong> roll axis <strong>of</strong> <strong>the</strong> robot - More expensive<br />

- More grip can be achieved<br />

- More difficult to implement and control<br />

- One motor extra can provide additional power - Less space available in general<br />

- Contact between fourth wheel and<br />

ground surface uncertain<br />

Three wheels<br />

Advantages<br />

- Less complex to implement and control<br />

-Less expensive<br />

- Always contact with ground surface<br />

-Less grip<br />

-Less power<br />

Disadvantages<br />

6

Chapter 2: Drive unit<br />

Almost all teams that are competing in <strong>the</strong> RoboCup <strong>Small</strong> <strong>Size</strong> league are using<br />

four wheels. The use <strong>of</strong> a kicking device makes a robot with three wheels difficult to<br />

built. More space is needed along <strong>the</strong> roll axis <strong>of</strong> <strong>the</strong> robot to implement <strong>the</strong> kicking<br />

device.<br />

From this, it can be concluded that <strong>the</strong> use <strong>of</strong> four wheels is <strong>the</strong> best option in this<br />

application.<br />

2.2.2 Dimensions <strong>of</strong> <strong>the</strong> wheel<br />

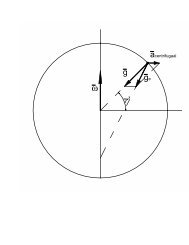

The diameter <strong>of</strong> <strong>the</strong> wheel is directly related to <strong>the</strong> loss in ground surface. A simple<br />

calculation gives an idea <strong>of</strong> <strong>the</strong> influence <strong>of</strong> <strong>the</strong> wheel diameter.<br />

The total ground surface is given by:<br />

S total = π. r² (2.1)<br />

With r <strong>the</strong> diameter <strong>of</strong> <strong>the</strong> ground circle <strong>of</strong> <strong>the</strong> robot.<br />

Figure 2: Calculation <strong>of</strong> loss in ground surface<br />

7

Chapter 2: Drive unit<br />

The area <strong>of</strong> <strong>the</strong> partial circle shown in figure 2 is given by:<br />

S partial circle<br />

= r2 . θ<br />

2<br />

(2.2)<br />

With θ given by:<br />

θ = 2. sin −1 ( D<br />

2. r ) (2.3)<br />

The area <strong>of</strong> <strong>the</strong> triangle shown in figure 2 is given by:<br />

S rectangle<br />

= D 2 . r² − D²<br />

4<br />

(2.4)<br />

The loss in surface caused by <strong>the</strong> four wheels is given by:<br />

4. S partial circle − S rectangle (2.5)<br />

In terms <strong>of</strong> percentage, <strong>the</strong> loss in surface becomes:<br />

4.<br />

r 2 . θ<br />

2 − D 2 . r 2 − D2<br />

4<br />

π. r²<br />

.100% (2.6)<br />

The loss <strong>of</strong> ground surface caused by an increasing diameter <strong>of</strong> <strong>the</strong> wheel is given in<br />

figure 3.<br />

8

Loss (%)<br />

Chapter 2: Drive unit<br />

40<br />

Loss in ground surface<br />

36<br />

32<br />

28<br />

24<br />

20<br />

16<br />

12<br />

8<br />

4<br />

0<br />

10 20 30 40 50 60 70 80 90 100 110 120 127<br />

Diameter wheel (mm)<br />

Figure 3: Loss in ground surface <strong>of</strong> <strong>the</strong> robot compared to wheel diameter<br />

The loss <strong>of</strong> space caused by a wheel with diameter between 50 and 70 mm varies<br />

from 1,86% to 5,23%. A loss <strong>of</strong> 6% is equal to a rectangle with dimensions 45x33mm<br />

on <strong>the</strong> ground surface or is approximately <strong>the</strong> coverage <strong>of</strong> a Maxon EC 45 motor<br />

(see later). This loss is assumed acceptable. Because <strong>the</strong> calculation does not<br />

include <strong>the</strong> thickness <strong>of</strong> <strong>the</strong> wheels, a slightly smaller diameter should be selected.<br />

From this, it can be concluded that a diameter <strong>of</strong> 60 mm is a good option in this<br />

application.<br />

9

Chapter 2: Drive unit<br />

2.2.3 Concepts <strong>of</strong> construction<br />

There are many options to achieve an omnidirectional drive <strong>for</strong> <strong>the</strong> robot. In this<br />

paragraph, <strong>the</strong>se options are summarized.<br />

2.2.3.1 Purchase a ready to use wheel<br />

These wheels are already tested. A good working <strong>of</strong> <strong>the</strong>se wheels is guaranteed.<br />

The friction <strong>of</strong> <strong>the</strong> tangential wheels is limited.<br />

There are also some disadvantages. The wheels are not custom made <strong>for</strong> this<br />

application. Also it isn’t an innovative implementation <strong>for</strong> this application.<br />

Figure 4: Rotacaster omniwheel<br />

2.2.3.2 <strong>Small</strong> wheels design<br />

This design is commonly used in most robots <strong>for</strong> <strong>the</strong> RoboCup <strong>Small</strong> <strong>Size</strong> league. It is<br />

a proven concept and can be custom made <strong>for</strong> <strong>the</strong> robot.<br />

Again, it is not an innovative design anymore. The surface on <strong>the</strong> contour covered<br />

by <strong>the</strong> wheels is 25% which is relatively low.<br />

10

Chapter 2: Drive unit<br />

Figure 5: Omniwheel-design by Parsian team[15]<br />

Some experiments were executed by KIKS-team [10]. They experimented with<br />

different widths <strong>of</strong> tangential wheels.<br />

(a) with single ring tires<br />

(b) with double ring tires<br />

(c) with thick rubber ring tires<br />

(d) with thick silicone rubber ring tires<br />

Figure 6: Kiks research[10]: Various types <strong>of</strong> small wheels design<br />

11

Chapter 2: Drive unit<br />

Various design types can be used. <strong>Design</strong> (a) has a low wheel to contour surface<br />

ratio. This means that <strong>the</strong> robot will bounce a lot when driving. Using design type<br />

(d), <strong>the</strong> bouncing <strong>of</strong> <strong>the</strong> robot can be reduced because <strong>the</strong> wheel to contour surface<br />

ratio is much higher in this case.<br />

Figure 7:Kiks research[10]: Average time to reach 1m/s from static condition <strong>for</strong> <strong>the</strong> robot<br />

Figure 7 shows <strong>the</strong> average time to reach 1m/s from static condition <strong>for</strong> <strong>the</strong><br />

different wheels. It is clear that wheel design (a) is <strong>the</strong> best option when choosing<br />

<strong>for</strong> this type <strong>of</strong> design. The KIKS team has no explanation why type (a) is better than<br />

o<strong>the</strong>r designs while accelerating. A better acceleration means that type (a) has<br />

better grip (more efficient power transmission) and/or lower weight because F=a.m.<br />

This remark should be tested when a design is made <strong>for</strong> this application.<br />

12

Chapter 2: Drive unit<br />

2.2.3.3 Concept by <strong>the</strong> Korea University<br />

Figure 8: Omniwheel-design by Korea University [27]<br />

This concept has been developed by <strong>the</strong> Korea University [27]. It has a wheel<br />

surface to contour ratio <strong>of</strong> 100%.<br />

The resistance to contamination is poor. Because <strong>the</strong> robot will drive on a carpet<br />

surface, <strong>the</strong> danger exists that tiny particles will get stuck in <strong>the</strong> space between <strong>the</strong><br />

tangential wheels.<br />

It is very hard to construct <strong>the</strong>se wheels especially when <strong>the</strong> diameter decreases.<br />

For this reason, this concept isn’t suited <strong>for</strong> this application.<br />

13

Chapter 2: Drive unit<br />

2.2.4 Final design<br />

Figure 9: New omniwheel-design<br />

This concept is a combination <strong>of</strong> concept 2 and 3. It uses slightly larger tangential<br />

wheels with a pr<strong>of</strong>ile according to <strong>the</strong> contour <strong>of</strong> <strong>the</strong> wheel. The wheel surface to<br />

contour ratio can be increased to 52%.<br />

This concept hasn’t been proven yet but can be constructed with a small diameter.<br />

The omniwheels exist <strong>of</strong> two disks with grooves. In <strong>the</strong>se grooves, pieces are placed<br />

to hold <strong>the</strong> tangential wheel axles. The wheels are than mounted on a bush. One<br />

bush has a hole through it and <strong>the</strong> o<strong>the</strong>r is threaded inside. These bushes are than<br />

bolted toge<strong>the</strong>r with a small bolt.<br />

The center disk has to be designed in two pieces. O<strong>the</strong>rwise, <strong>the</strong> whole structure<br />

can’t be mounted toge<strong>the</strong>r.<br />

14

Chapter 2: Drive unit<br />

2.3 Driving Motors<br />

The choice <strong>of</strong> <strong>the</strong> motors depends on <strong>the</strong> available space and required propulsion<br />

<strong>for</strong>ce. In <strong>the</strong> RoboCup <strong>Small</strong> <strong>Size</strong> <strong>League</strong>, large accelerations are needed to keep up<br />

with <strong>the</strong> o<strong>the</strong>r competing robots. It seems best to choose motors, similar to <strong>the</strong><br />

motors <strong>of</strong> o<strong>the</strong>r teams to achieve a comparable acceleration. Most teams are using<br />

a brushless type <strong>of</strong> motor because <strong>the</strong>se don’t take a lot <strong>of</strong> space according to <strong>the</strong>ir<br />

power. A motor with following parameters was chosen.<br />

- Maxon EC45 flat brushless motor<br />

- Diameter: 45 mm<br />

- Power: 30 Watt<br />

- Supply voltage: 12V<br />

- Starting current: 10A<br />

- Nominal current: 2.8 A<br />

- Stall torque: 255 mNm<br />

- Nominal torque: 59 mNm<br />

- Weight: 88 gr<br />

Figure 10: Maxon EC 45, 30Watt motor<br />

15

Chapter 2: Drive unit<br />

2.4 Transmission unit<br />

2.4.1 General<br />

The power from <strong>the</strong> motors has to be transferred to <strong>the</strong> wheels. This can be<br />

achieved by directly connecting <strong>the</strong> motor to <strong>the</strong> wheels. In this case, <strong>the</strong> wheels<br />

have a diameter <strong>of</strong> 60mm and <strong>the</strong> motor a diameter <strong>of</strong> 45mm. With a direct<br />

connection, this leaves 7mm <strong>of</strong> ground clearance, which isn’t much. Also, <strong>the</strong> space<br />

in <strong>the</strong> center <strong>of</strong> <strong>the</strong> robot isn’t used optimal with a direct connection. By using a<br />

transmission system, more space at <strong>the</strong> front <strong>of</strong> <strong>the</strong> robot can be made available <strong>for</strong><br />

o<strong>the</strong>r components by placing <strong>the</strong> motors towards <strong>the</strong> back <strong>of</strong> <strong>the</strong> robot.<br />

A second, and more important, reason <strong>for</strong> <strong>the</strong> use <strong>of</strong> a transmission system is <strong>the</strong><br />

reduction <strong>of</strong> motor speed. The motor has a no load speed <strong>of</strong> 4700 rpm which is very<br />

high <strong>for</strong> this application. The wheels have a diameter <strong>of</strong> 60mm thus <strong>the</strong> maximum<br />

speed <strong>of</strong> <strong>the</strong> robot would be 15 m/s or 54 km/h with a direct connection. A<br />

transmission system reduces <strong>the</strong> maximum speed while increasing <strong>the</strong> maximum<br />

torque on <strong>the</strong> wheels. This will have a positive influence on <strong>the</strong> acceleration <strong>of</strong> <strong>the</strong><br />

robot. A transmission system is <strong>the</strong>re<strong>for</strong>e a choice between maximum velocity and<br />

maximum acceleration.<br />

The gear ratio used by competing RoboCup teams vary from 3:1 to 5:1. Most <strong>of</strong><br />

<strong>the</strong>m have slightly smaller wheels. There<strong>for</strong>e, <strong>the</strong> gear ratio in this application<br />

should be at <strong>the</strong> higher side <strong>of</strong> <strong>the</strong> interval to have a similar velocity and<br />

acceleration.<br />

There is not much in<strong>for</strong>mation about <strong>the</strong> optimal gear ratio. Some teams [8] are<br />

now transferring to a 50W and lower gear ratio to have more velocity with <strong>the</strong> same<br />

acceleration. It seems best to consider this remark and choose a higher velocity<br />

than o<strong>the</strong>r competing teams.<br />

In <strong>the</strong> next paragraphs, different types <strong>of</strong> transmission systems are discussed.<br />

16

Chapter 2: Drive unit<br />

2.4.2 Spur gear<br />

In table1 it can be seen that all teams use a transmission system with spur gears.<br />

This seems like <strong>the</strong> most obvious choice as a transmission system. These spur gears<br />

don’t skid, which makes <strong>the</strong> control <strong>of</strong> <strong>the</strong> robot less difficult. When skid occurs, <strong>the</strong><br />

control algorithm can’t <strong>for</strong>ecast <strong>the</strong> location <strong>of</strong> <strong>the</strong> robot anymore, because <strong>the</strong><br />

encoders are mounted on <strong>the</strong> motors instead <strong>of</strong> on <strong>the</strong> wheels. There<strong>for</strong>e, this<br />

transmission system is more reliable than o<strong>the</strong>r systems. For high gear ratio’s, an<br />

internal spur gear can be used to reduce <strong>the</strong> required amount <strong>of</strong> space.<br />

2.4.3 Belt transmission<br />

Ano<strong>the</strong>r system <strong>of</strong> transmission is a belt and pulley system. These are less reliable<br />

because <strong>the</strong>y can skid. As said in previous paragraph, this makes a good control <strong>of</strong><br />

<strong>the</strong> robot difficult. The flexibility <strong>of</strong> this system is an advantage. The pulley’s can be<br />

produced using rapid prototyping. The belts can be made from a slightly elastic<br />

material which is available on a roll. The two ends <strong>of</strong> <strong>the</strong> belt can <strong>the</strong>n be melted<br />

toge<strong>the</strong>r. There<strong>for</strong>e, each desired gear ratio can easily be achieved.<br />

2.4.4 Final design<br />

Be<strong>for</strong>e starting <strong>the</strong> design <strong>of</strong> <strong>the</strong> transmission system, some comments have to be<br />

made. The batteries used in <strong>the</strong> robot should be built in as low as possible to lower<br />

<strong>the</strong> center <strong>of</strong> gravity. Because <strong>the</strong> transmission units are at an angle relative to each<br />

o<strong>the</strong>r, a small space is created between <strong>the</strong>se units. This space can be used to<br />

mount batteries to optimize <strong>the</strong> use <strong>of</strong> space. Figure 11 shows <strong>the</strong> integration <strong>of</strong> <strong>the</strong><br />

batteries in <strong>the</strong> transmission unit. The batteries have a blue color in this figure.<br />

17

Chapter 2: Drive unit<br />

Figure 11: Structural design <strong>of</strong> transmission units<br />

The four transmission units can be designed separately. This has a negative<br />

influence on <strong>the</strong> rigidness <strong>of</strong> <strong>the</strong> robot because <strong>the</strong>y are not connected. To increase<br />

rigidness, <strong>the</strong> units on each side <strong>of</strong> <strong>the</strong> robot should be connected. Two separate<br />

structures which hold two motors, wheels and transmission system are <strong>the</strong>re<strong>for</strong>e<br />

created. By opting <strong>for</strong> two separate structures, more space is available <strong>for</strong> <strong>the</strong><br />

kicking device and dribbler than in case <strong>of</strong> one large structure. Figure 12 and 13<br />

show a close-up <strong>of</strong> <strong>the</strong> transmission structure, one with a spur gear and <strong>the</strong> o<strong>the</strong>r<br />

with a pulley.<br />

18

Chapter 2: Drive unit<br />

Figure 12: Close-up <strong>of</strong> front transmission<br />

unit with spur gears<br />

Figure 13: Close-up <strong>of</strong> rear transmission<br />

unit with pulley<br />

2.5 Experiments<br />

During <strong>the</strong> first tests, it was seen that not all <strong>of</strong> <strong>the</strong> contact points <strong>of</strong> <strong>the</strong> wheels<br />

with <strong>the</strong> ground surface were located in one plane. This causes at least one wheel<br />

to lose some grip. This can cause problems <strong>for</strong> <strong>the</strong> control s<strong>of</strong>tware.<br />

A solution <strong>for</strong> this problem is to suspend <strong>the</strong> wheels like in o<strong>the</strong>r vehicles. The<br />

suspension system could also reduce <strong>the</strong> bouncing <strong>of</strong> <strong>the</strong> robot due to <strong>the</strong> noncircular<br />

wheels.<br />

An experiment was per<strong>for</strong>med to test <strong>the</strong> belt and spur gear transmission. The belt<br />

transmission skids while driving. This isn’t <strong>the</strong> case with <strong>the</strong> spur gear transmission.<br />

There<strong>for</strong>e, it is concluded that <strong>the</strong> spur gear transmission is <strong>the</strong> best option <strong>for</strong> this<br />

application.<br />

19

Chapter 2: Drive unit<br />

2.6 Conclusions<br />

In this chapter, <strong>the</strong> drive unit was discussed. From a comparison between all<br />

competing teams, it can be concluded that almost all teams use four wheels. This<br />

provides extra space along <strong>the</strong> roll axis <strong>of</strong> <strong>the</strong> robot to implement a shooting<br />

system. There<strong>for</strong>e, four wheels are used in this application.<br />

There are several possible designs <strong>for</strong> <strong>the</strong> omni-directional wheels. The competing<br />

teams all use a similar wheel design with small tangential wheels. For this<br />

application, a new concept was developed with larger tangential wheel. There<strong>for</strong>e,<br />

a higher wheels surface to contour ratio is obtained.<br />

The motors used by <strong>the</strong> competing teams have a power rating varying from 30 to 50<br />

Watts. In this application a 30 Watt EC45 Maxon motor is used, which is a<br />

commonly used motor in <strong>the</strong> RoboCup <strong>Small</strong> <strong>Size</strong> competition. This motor powers<br />

<strong>the</strong> wheels via a transmission unit. In this application, two principles <strong>of</strong> transmission<br />

are reviewed. From tests, it is concluded that a spur gear transmission is <strong>the</strong> best<br />

option. This transmission doesn’t skid like <strong>the</strong> belt transmission.<br />

20

Chapter 3: Kicking device<br />

3 Kicking device<br />

3.1 General<br />

There are several designs used by competing RoboCup Teams. The design<br />

parameters <strong>for</strong> a shooting device are <strong>the</strong> following:<br />

- Efficiency<br />

- Cost<br />

- Weight<br />

- Required space<br />

- Time between shots<br />

- Number <strong>of</strong> shots<br />

- Safety<br />

- Variable <strong>for</strong>ce<br />

3.2 State <strong>of</strong> <strong>the</strong> art<br />

Table 3: Comparison between RoboCup teams: Kicking device<br />

Team Device type Ball speed Chip-kick device<br />

(distance in <strong>the</strong> air)<br />

Botania Dragon Knights [1]<br />

Brocks [2]<br />

Solenoid<br />

B-Smart [3]<br />

CMDragons [4] Solenoid 15 m/s 4,5 m<br />

Eagle Knights [5]<br />

Solenoid<br />

ER-Force [6]<br />

Solenoid 8 m/s<br />

(New system)<br />

Field Rangers [7] Solenoid 10 m/s 6 m<br />

Immortals [8]<br />

Solenoid<br />

Khainui [9]<br />

Solenoid<br />

KIKS [10]<br />

Solenoid<br />

21

Chapter 3: Kicking device<br />

KN2C [11]<br />

Solenoid<br />

ODENS [12]<br />

Solenoid<br />

OMID [13] Solenoid 8 m/s<br />

Owaribito [14] Solenoid 10 m/s<br />

Parsian [15] Solenoid 5 m<br />

RFC Cambridge [16]<br />

Solenoid<br />

Robojackets [17]<br />

Solenoid<br />

Robodragons [18]<br />

Solenoid<br />

RoboFEI [19]<br />

Solenoid<br />

RoboFighties [20]<br />

RoboPET [21] Solenoid 10 m/s<br />

Skuba [22] Solenoid 14 m/s 7,5 m<br />

MRL [23]<br />

Solenoid<br />

UBC Thunderbots [24] Solenoid 8 m/s<br />

Plasma-Z [25]<br />

Solenoid<br />

From table 3 it can be concluded that all teams which use a shooting system have<br />

opted <strong>for</strong> a solenoid system. In <strong>the</strong> past, <strong>the</strong> Philips CFT team [28] used a<br />

mechanical spring actuated system. Back <strong>the</strong>n, larger dimensions <strong>of</strong> <strong>the</strong> robot were<br />

allowed. Such a system was easier to implement because <strong>of</strong> <strong>the</strong>se dimensions.<br />

3.3 Types <strong>of</strong> shooting devices<br />

The electrical energy stored in <strong>the</strong> batteries has to be trans<strong>for</strong>med in mechanical<br />

energy to move <strong>the</strong> ball. This can be accomplished in different ways.<br />

3.3.1 Solenoid actuated<br />

In this system, self-inductance is used. A current is send through a coil which<br />

generates a magnetic field. This field can be increased by increasing <strong>the</strong> number <strong>of</strong><br />

windings <strong>of</strong> <strong>the</strong> coil or by increasing <strong>the</strong> current through <strong>the</strong> coil. With this magnetic<br />

field, a ferromagnetic material can be attracted or repulsed.<br />

22

Chapter 3: Kicking device<br />

Most solenoids available in stores are not suitable <strong>for</strong> this application. They work on<br />

low voltage and are very slow. The <strong>for</strong>ce <strong>the</strong>y develop is ra<strong>the</strong>r low. This results in<br />

low ball velocities. In order to kick <strong>the</strong> ball at high velocities, a high voltage solenoid<br />

is required. These aren’t available in stores yet so <strong>the</strong>y have to be built a custom to<br />

<strong>the</strong> application. With <strong>the</strong>se high voltage solenoids, ball speeds <strong>of</strong> up to 10 m/s are<br />

no exception.<br />

The dimensions <strong>of</strong> <strong>the</strong> system depend on <strong>the</strong> design. For this application, typical<br />

values are <strong>the</strong> following [14]:<br />

- A total mass <strong>of</strong> up to 200 gr<br />

- Ball speeds <strong>of</strong> more than 10m/s<br />

- 200 volt circuit<br />

- 3700 µF capacitors<br />

This system is very flexible in terms <strong>of</strong> creating a variable shooting <strong>for</strong>ce. The time<br />

to reload can be kept low. The number <strong>of</strong> shots is only limited by <strong>the</strong> state <strong>of</strong> <strong>the</strong><br />

battery.<br />

The most important disadvantages are <strong>the</strong> safety risks involved in using high<br />

voltage. Also, a lot <strong>of</strong> heat is generated when activating <strong>the</strong> system. This heat has to<br />

be evacuated out <strong>of</strong> <strong>the</strong> robot. Ano<strong>the</strong>r disadvantage is <strong>the</strong> required space <strong>for</strong> <strong>the</strong><br />

capacitors and <strong>the</strong> weight <strong>of</strong> <strong>the</strong> coil.<br />

Most competing teams at present use this system. Many developments are made in<br />

terms <strong>of</strong> reducing <strong>the</strong> weight and increasing <strong>the</strong> power <strong>of</strong> <strong>the</strong> system. This system<br />

has been tested with success by many teams.<br />

3.3.2 Spring actuated<br />

This system is based on <strong>the</strong> storage <strong>of</strong> energy in a spring. It has two major functions.<br />

The first function has <strong>the</strong> task <strong>of</strong> winding <strong>the</strong> spring up. The second function is a<br />

lock/release system to hold <strong>the</strong> plunger in his place while winding up and releasing<br />

<strong>the</strong> spring when needed.<br />

23

Chapter 3: Kicking device<br />

This system is more safe <strong>the</strong>n <strong>the</strong> solenoid system because <strong>the</strong>re is no high voltage<br />

present. With a well designed system, <strong>the</strong> cost and required space can also be<br />

reduced. When friction is reduced, very high efficiency can be achieved because<br />

<strong>the</strong>re is a direct connection from <strong>the</strong> motor to <strong>the</strong> spring. The number <strong>of</strong> shots is<br />

only limited by <strong>the</strong> state <strong>of</strong> <strong>the</strong> batteries.<br />

The major disadvantage is <strong>the</strong> reload time. It takes a powerful motor to reload <strong>the</strong><br />

system in a short time. A variable shooting <strong>for</strong>ce can be achieved but again, it takes<br />

time to set <strong>the</strong> spring at this desired <strong>for</strong>ce.<br />

3.3.3 Pneumatic actuated<br />

In <strong>the</strong> past, a lot <strong>of</strong> <strong>the</strong> teams used a pneumatic actuated system [28]. The air<br />

pressure is retrieved from a large air tank on <strong>the</strong> robot that is pressurized be<strong>for</strong>e<br />

<strong>the</strong> match. Pneumatic cylinders are connected to a solenoid actuated valve which<br />

controls <strong>the</strong> airflow.<br />

A big disadvantage <strong>of</strong> this system is <strong>the</strong> large air tank that has to be built in.<br />

The number <strong>of</strong> shots depends on <strong>the</strong> volume <strong>of</strong> <strong>the</strong> tank and <strong>the</strong> pressure inside <strong>the</strong><br />

tank.<br />

3.3.4 O<strong>the</strong>r<br />

A lot <strong>of</strong> o<strong>the</strong>r systems can be designed <strong>for</strong> <strong>the</strong> purpose <strong>of</strong> shooting <strong>the</strong> ball. Most <strong>of</strong><br />

<strong>the</strong>se systems have several major flaws.<br />

For instance a rack and spur device can be used. This system needs a large motor<br />

with huge power ratings.<br />

24

Chapter 3: Kicking device<br />

3.4 Shooting system model<br />

3.4.1 General<br />

For this application, it was decided to construct a spring actuated shooting device.<br />

To wind <strong>the</strong> spring up, a spindle with nut is used. The nut presses against <strong>the</strong><br />

spring which is <strong>the</strong>reby compressed. A lock and release mechanism holds <strong>the</strong><br />

plunger in place and releases it when needed.<br />

The modeling <strong>of</strong> <strong>the</strong> shooting system will be divided into three parts. A first part is<br />

determining <strong>the</strong> maximum <strong>for</strong>ce <strong>the</strong> motor can deliver. Based on this value, a<br />

spring can be selected in <strong>the</strong> second part. In this part, <strong>the</strong> time needed <strong>for</strong> <strong>the</strong><br />

winding <strong>of</strong> <strong>the</strong> spring is modeled. The third part will determine <strong>the</strong> parameters<br />

needed to model <strong>the</strong> actual shooting process.<br />

3.4.1.1 Force in spindle<br />

The <strong>for</strong>ce that can be generated to compress <strong>the</strong> spring depends on <strong>the</strong> applied<br />

torque on <strong>the</strong> spindle. With following <strong>for</strong>mulas, this can be calculated. [26]<br />

With:<br />

T = F. d 2<br />

2 . tan φ ± ρ′ (4.1)<br />

F<br />

d 2<br />

φ<br />

longitudinal <strong>for</strong>ce in <strong>the</strong> axis<br />

pitch diameter <strong>of</strong> <strong>the</strong> screw thread<br />

lead-angle <strong>of</strong> <strong>the</strong> screw thread<br />

ρ’ screw thread friction angle.<br />

+ <strong>for</strong> tightening<br />

- <strong>for</strong> releasing<br />

Re<strong>for</strong>ming <strong>for</strong>mula 4.1 with <strong>the</strong> <strong>for</strong>ce on <strong>the</strong> right hand side:<br />

T. 2<br />

F =<br />

d 2 . tan φ ± ρ ′<br />

(4.2)<br />

25

Chapter 3: Kicking device<br />

3.4.1.2 Compression process<br />

Using <strong>the</strong> stall torque <strong>of</strong> <strong>the</strong> motor in <strong>for</strong>mula 4.2, a spring can be selected to use in<br />

<strong>the</strong> application. The parameters <strong>of</strong> <strong>the</strong> spring are <strong>the</strong> following:<br />

- F spring = Force in te spring wen compressed<br />

- l f = Free lengt<br />

- lc = Compressed lengt<br />

With <strong>the</strong>se parameters, <strong>the</strong> compression parameters can be calculated. These<br />

parameters are <strong>the</strong> <strong>for</strong>ce in <strong>the</strong> spring while compressing, <strong>the</strong> rotation speed <strong>of</strong> <strong>the</strong><br />

motor and <strong>the</strong> compression time.<br />

A <strong>for</strong>ce function can be found according to <strong>the</strong> compressed length (x) <strong>of</strong> <strong>the</strong> spring:<br />

F spring = k. x (4.3)<br />

From this <strong>for</strong>ce function, a rotation speed function can be derived. The relation<br />

between <strong>the</strong> motor torque and rotation speed according to <strong>the</strong> maxon datasheet<br />

[31] is given by:<br />

n = n 0 − n 0<br />

M H<br />

. M (4.4)<br />

With:<br />

- n 0 : No load rotation speed<br />

- M H : Stall torque<br />

- n: Rotation speed <strong>of</strong> <strong>the</strong> motor<br />

- M: Torque <strong>of</strong> <strong>the</strong> motor<br />

26

Chapter 3: Kicking device<br />

The rotation speed <strong>of</strong> <strong>the</strong> motor can be expressed as a function <strong>of</strong> <strong>the</strong> spring<br />

compression ‘x’ using <strong>for</strong>mula 4.2, 4.3 and 4.4. Rotation speed is expressed in<br />

revolutions per second.<br />

n = n 0 − x. k. d 2. n 0 . tanφ ± ρ ′<br />

2. M H<br />

(4.5)<br />

With this rotation speed function, <strong>the</strong> time needed to wind <strong>the</strong> spring up to a<br />

compressed length <strong>of</strong> ‘r’ can be calculated. When <strong>the</strong> spring is compressed an<br />

infinite part dx with rotation speed n, <strong>the</strong> time needed to do this is given by:<br />

dt = dx<br />

n. a<br />

(4.6)<br />

The total time needed to compress <strong>the</strong> spring to length ‘r’ can be calculated.<br />

t =<br />

r<br />

dx<br />

0<br />

n. a<br />

(4.7)<br />

This results in:<br />

t =<br />

−2. M H<br />

k. d 2 . tan φ ± ρ ′ . n 0 . a . ln 1 − r. k. d 2. tan φ ± ρ ′<br />

2. M H<br />

(4.8)<br />

27

Chapter 3: Kicking device<br />

3.4.1.3 Releasing process<br />

In this paragraph, <strong>the</strong> releasing process is discussed. It is assumed that <strong>the</strong> process<br />

will take place in three phases. In <strong>the</strong> first phase, <strong>the</strong> plunger will move towards <strong>the</strong><br />

ball without touching it. The second phase is <strong>the</strong> moment <strong>of</strong> impact between <strong>the</strong><br />

plunger and <strong>the</strong> ball. At this time, <strong>the</strong> preservation <strong>of</strong> impulse law can be used. For<br />

<strong>the</strong> third phase, it is assumed that <strong>the</strong> ball and plunger will move toge<strong>the</strong>r.<br />

There<strong>for</strong>e, <strong>the</strong> spring accelerates <strong>the</strong> combined system <strong>of</strong> plunger and ball. In <strong>the</strong><br />

actual system, it is possible that <strong>the</strong> ball will move faster than <strong>the</strong> plunger. The<br />

velocity <strong>of</strong> <strong>the</strong> ball will be greater than <strong>the</strong> calculated one in this case. There<strong>for</strong>e,<br />

<strong>the</strong> model gives a worst case scenario.<br />

At <strong>the</strong> <strong>of</strong> <strong>the</strong> third phase, <strong>the</strong> shooting velocity <strong>of</strong> <strong>the</strong> ball is reached.<br />

Figure 14: Shooting system release process parameters<br />

28

Chapter 3: Kicking device<br />

The following parameters will be used to per<strong>for</strong>m <strong>the</strong> calculation:<br />

- F 0 = Spring <strong>for</strong>ce be<strong>for</strong>e releasing= k.l 0<br />

- s = total stroke lengt<br />

- x = position <strong>of</strong> te plunger<br />

- F = <strong>for</strong>ce in te spring at position x<br />

- k = spring stiffness<br />

- α = plunger <strong>of</strong>fset<br />

A. Only plunger moves<br />

To make <strong>the</strong> results more logic, <strong>the</strong> origin <strong>of</strong> <strong>the</strong> x-axis is changed. It is now<br />

assumed that x is zero at <strong>the</strong> start <strong>of</strong> <strong>the</strong> releasing-process. The <strong>for</strong>ce in <strong>the</strong> spring is<br />

function <strong>of</strong> x:<br />

F = k. l 0 − x = F 0 − k. x (4.9)<br />

The acceleration is given by:<br />

a =<br />

F<br />

m plunger<br />

= F 0 − k. x<br />

m plunger<br />

(4.10)<br />

In order to solve this problem, a differential equation has to be solved:<br />

m plunger . x + k. x = F 0 (4.11)<br />

The solution <strong>of</strong> this equation has following <strong>for</strong>m:<br />

With:<br />

x t = Acos ωt + Bsin ωt + C (4.12)<br />

ω² =<br />

k<br />

m plunger<br />

(4.13)<br />

29

Chapter 3: Kicking device<br />

The boundary conditions are:<br />

x 0 = 0<br />

v 0 = 0<br />

a 0 =<br />

F 0<br />

m plunger<br />

Filling in <strong>the</strong>se boundary conditions leads to values <strong>of</strong> A,B,C:<br />

x t = F 0<br />

k<br />

. 1 − cos ωt (4.14)<br />

v t = F 0<br />

. ω. sin ωt (4.15)<br />

k<br />

F 0<br />

a t = . cos ωt (4.16)<br />

m plunger<br />

B. Impact<br />

The value <strong>of</strong> x where impact occurs is noted as ‘α’. From <strong>for</strong>mula 4.20, <strong>the</strong> time t1<br />

<strong>of</strong> impact can be determined:<br />

α = F 0<br />

k . 1 − cos ωt 1 (4.17)<br />

cos ωt 1 = 1 −<br />

ω. t 1 = cos −1 ( 1 −<br />

k. α<br />

F 0<br />

(4.18)<br />

k. α<br />

F 0<br />

) (4.19)<br />

With <strong>for</strong>mula 4.23, <strong>the</strong> velocity right be<strong>for</strong>e impact becomes:<br />

v t1 = F 0<br />

k . ω. sin k. α<br />

cos−1 ( 1 − ) (4.20)<br />

F 0<br />

v t1 = F 2<br />

0<br />

k . ω. k. α<br />

1 − 1 −<br />

F 0<br />

(4.21)<br />

v t1 =<br />

2. α. F 0 − k. α²<br />

m plunger<br />

(4.22)<br />

30

Chapter 3: Kicking device<br />

At <strong>the</strong> moment <strong>of</strong> impact, <strong>the</strong> conservation <strong>of</strong> impulse law can be used to<br />

determine <strong>the</strong> velocity after <strong>the</strong> impact.<br />

m plunger v plunger ,t1 + m bal v bal ,t1 = (m plunger + m ball ). v t2 (4.23)<br />

Assuming that <strong>the</strong> velocity <strong>of</strong> <strong>the</strong> ball is zero be<strong>for</strong>e impact:<br />

v t2 = m plunger v plunger ,t1<br />

m plunger + m ball<br />

( 4.24)<br />

v t2 =<br />

m plunger<br />

2. α. F 0 − k. α²<br />

m plunger<br />

m plunger + m ball<br />

(4.25)<br />

C. Accelerating plunger and ball<br />

This calculation is similar to those made in section A. The mass becomes <strong>the</strong><br />

combined mass <strong>of</strong> plunger and ball. Only <strong>the</strong> start conditions <strong>of</strong> <strong>the</strong> differential<br />

equation change. Variable ‘x’ is equal to α at <strong>the</strong> start. The velocity is equal to v t2 at<br />

<strong>the</strong> start and <strong>the</strong> acceleration at <strong>the</strong> start becomes:<br />

F 0 − k. α<br />

m total<br />

x t = α − F 0<br />

k<br />

. cos ωt + v t2<br />

ω . sin ωt + F 0<br />

k<br />

(4.26)<br />

v t = ω. F 0<br />

k − α . sin ωt + v t2. cos(ωt) (4.27)<br />

a t = ω 2 . F 0<br />

k − α . cos ωt − v t2. ω. sin(ωt) (4.28)<br />

31

Chapter 3: Kicking device<br />

3.4.2 Application note<br />

In this paragraph, <strong>the</strong> ma<strong>the</strong>matical model is applied on <strong>the</strong> shooting system <strong>of</strong> <strong>the</strong><br />

robot. For this application, following components will be used.<br />

Table 4: Shooting system components<br />

Motor: Steel Spindle: Plunger: Spring:<br />

P=2.5 watt M3 mass=140gr F=300N<br />

n 0: 11400 a=0.5mm lf=50 mm<br />

M H : 8,52mNm l=30mm lc=30 mm<br />

Gear ratio: 1/17<br />

d2=2.675mm<br />

φ=3. 41°<br />

ρ’=12°<br />

The motor that is used was already available and will be used <strong>for</strong> testing purposes.<br />

When this motor is proven insufficient, ano<strong>the</strong>r one can be mounted.<br />

The diameter <strong>of</strong> <strong>the</strong> spindle is kept as low as possible because it acts as a sort <strong>of</strong><br />