HBS-05- 9/04-E HALFEN Reinforcement Screw Connections Type ...

HBS-05- 9/04-E HALFEN Reinforcement Screw Connections Type ...

HBS-05- 9/04-E HALFEN Reinforcement Screw Connections Type ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

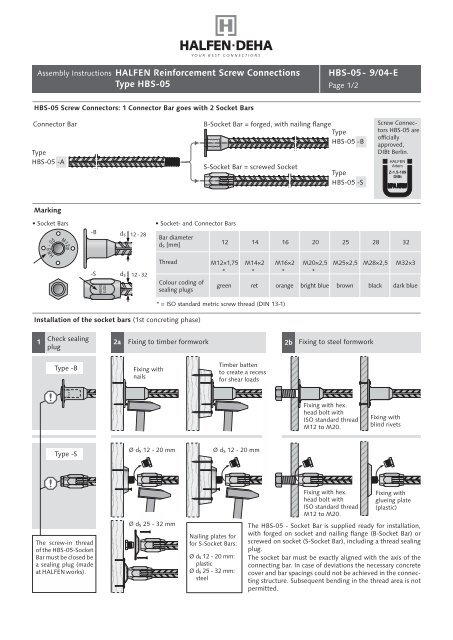

Assembly Instructions<strong>HALFEN</strong> <strong>Reinforcement</strong> <strong>Screw</strong> <strong>Connections</strong> <strong>HBS</strong>-<strong>05</strong>- 9/<strong>04</strong>-E<strong>Type</strong> <strong>HBS</strong>-<strong>05</strong> Page 1/2<strong>HBS</strong>-<strong>05</strong> <strong>Screw</strong> Connectors: 1 Connector Bar goes with 2 Socket BarsConnector Bar<strong>Type</strong><strong>HBS</strong>-<strong>05</strong> -AB-Socket Bar = forged, with nailing flange<strong>Type</strong><strong>HBS</strong>-<strong>05</strong> -BS-Socket Bar = screwed Socket<strong>Type</strong><strong>HBS</strong>-<strong>05</strong> -S<strong>Screw</strong> Connectors<strong>HBS</strong>-<strong>05</strong> areofficiallyapproved,DIBt Berlin.Marking• Socket Bars-Bds 12-28• Socket- and Connector BarsBar diameterd [mm] s12 14 16 20 25 28 32-Sds 12-32ThreadColour coding ofsealing plugsM12×1,75 M14×2 M16×2 M20×2,5 M25×2,5 M28×2,5 M32×3* * * *green ret orange bright blue brown black dark blueInstallation of the socket bars (1st concreting phase)* = ISO standard metric screw thread (DIN 13-1)1Check sealing2a Fixing to timber formwork2bplugFixing to steel formwork<strong>Type</strong> -BFixing withnailsTimber battento create a recessfor shear loadsFixing with hex.head bolt withISO standard threadM12 to M20.Fixing withblind rivets<strong>Type</strong> -SØ d 12 - 20 mmsØ d 12 - 20 mmsThe screw-in threadof the <strong>HBS</strong>-<strong>05</strong>-SocketBar must be closed bea sealing plug (madeat <strong>HALFEN</strong> works).Ø d 25 - 32 mmsNailing plates forfor S-Socket Bars:Øds12-20mm:plasticØds25-32mm:steelFixing with hex.head bolt withISO standard threadM12 to M20.Fixing withglueing plate(plastic)The <strong>HBS</strong>-<strong>05</strong> - Socket Bar is supplied ready for installation,with forged on socket and nailing flange (B-Socket Bar) orscrewed on socket (S-Socket Bar), including a thread sealingplug.The socket bar must be exactly aligned with the axis of theconnecting bar. In case of deviations the necessary concretecover and bar spacings could not be achieved in the connectingstructure. Subsequent bending in the thread area is notpermitted.

Assembly Instructions<strong>HALFEN</strong> <strong>Reinforcement</strong> <strong>Screw</strong> <strong>Connections</strong> <strong>HBS</strong>-<strong>05</strong>- 9/<strong>04</strong>-E<strong>Type</strong> <strong>HBS</strong>-<strong>05</strong> Page 2/22nd concreting phaseConnector barsAfter removing of the thread protectioncap the connector bar <strong>HBS</strong>-<strong>05</strong>-A isinitially screwed in by hand until it reachesthe conical area of the thread. Thefinal screwing in and tightening requiresan appropriate tool (e.g. quick screwer orpipe wrench); the connection bar mustbe turned until it is fully screwed into thesocket bar and the thread is no morevisible. Thus the conical socket end isexpanded and a slip free connectionbetween the socket and the connectorthreads is achieved (self locking system, atorque wrench is therefore not required).Non turnable bent connector barscombined with righthand/lefthandthreaded connector socketThis connection is applied, when theconnecting bars can not or shall not beturned. In the first phase of concreting arighthand threaded connector bar <strong>HBS</strong>-<strong>05</strong>-A is installed.In the second step a lefthand threadedconnector bar <strong>HBS</strong>-<strong>05</strong>-ALG (bent) isconnected using the righthand/lefthandthreaded connector socket.Righthand/lefthand connectorsocket<strong>HBS</strong>-<strong>05</strong>-RLPositioning socket <strong>HBS</strong>-<strong>05</strong>-PThe positioning socket <strong>HBS</strong>-<strong>05</strong>-P is usedto connect <strong>HBS</strong>-<strong>05</strong> reinforcement barswhich cannot be turned nor shifted inaxial direction.MF<strong>HBS</strong>-<strong>05</strong>-Sor -Bd sFFMF= locking nut, loose= fixed nutM<strong>HBS</strong>-<strong>05</strong>-P M Install. length A<strong>HBS</strong>-<strong>05</strong>-AAd sUE - 300 - 09/<strong>04</strong>Bent connector barsThe same assembly procedure appliesalso for bent connector bars. When theconnecting thread is fully turned into thesocket bar type <strong>HBS</strong>-<strong>05</strong>-S, the connectorbar can be turned at least at one moreturn. When turning is continued beyondthis point, the abutting faces of the twobars become locked.The bent connector bar can only beturned in, if it can be rotated freelyand if there are no obstructions suchas adjacent bars, parts of the formworkor other inserts.Socket bar<strong>HBS</strong>-<strong>05</strong>-SConnector bar<strong>HBS</strong>-<strong>05</strong>-AG,bent<strong>HALFEN</strong>-DEHA Vertriebsgesellschaft mbHLiebigstr. 1440764 Langenfeld+49 - (0)2173 / 970-0+49 - (0)2173 / 970 123www.halfen-deha.deCast-in connector bar<strong>HBS</strong>-<strong>05</strong>-AConnector bar <strong>HBS</strong>-<strong>05</strong>-ALGbent, lefthand threadedR<strong>HBS</strong>-<strong>05</strong>-RL<strong>HBS</strong>-<strong>05</strong>-A <strong>HBS</strong>-<strong>05</strong>-AL .To install the the righthand/lefthandthreaded connector socket <strong>HBS</strong>-<strong>05</strong>-RLcorrectly it must be placed in such a way,that after one turn both left- and righthandthreads have seized. At each connectionthis must be checked by pullungat the bars that are to be connected.The righthand/lefthand threaded connectorsocket <strong>HBS</strong>-<strong>05</strong>-RL is initially turnedby hand and then furtheron with anappropriate tool (e.g. pipe wrench) untilboth connector bars are fully screwed intothe righthand/lefthand connector socketover the entire length of the thread.To assist with installation of the righthandthreaded bar (1.phase), plastic trapezoidalrecess formers are available.Checking the assemblyTechnical advice<strong>Reinforcement</strong> Systems:+49 - (0)2173 / 970 422+49 - (0)2173 / 970 420E-Mail: bewehrung@halfen-deha.deFor all <strong>HBS</strong>-<strong>05</strong> connections applies: Thereis no requirement to use a special tool toapply any specified torques.The bars are correctly installed, if thethread is screwed into the socket over theentire length of the thread. This allows asimple visual check of the correct installation,which is easily carried out.LFA min.MCheck lengthKA max.Turn long socket on the thread of the<strong>HBS</strong>-<strong>05</strong> connector bar, then turn threadedrod into the <strong>HBS</strong>-<strong>05</strong> socket barwith torque MAand tighten the loosenut M against the long socket. The checklength K must not be exceeded (seetable below).ds mm 12 14 16 20 25 28 32A mm 171 187 203 270 314 336 385max.K*mm 97 1<strong>04</strong> 111 150 170 179 206MANm 30 40 60 80 100 140 190* Values max.K apply for <strong>HBS</strong>-<strong>05</strong>-P standard lengths.Bending on the site or atthe plantBending of the socket and connector barson the site or at the plant is only permissible,if the spacing b 5 ds between theend of the thread or the socket and thebeginning of the bend is maintained.At spacings of 2 dsb 5 dsthe bars mustbe bent at the manufacturers plant on aspecial bending machine.d sd BRbBeginning of bendThe <strong>HALFEN</strong>-DEHA Quality Management Systemis certified for the locations in Gemany, Switzerlandand Poznan/Poland according toDIN EN ISO 9001, Certificate No. QS-281 HH.bd BRd s