Model BV88L Elongated Digital Control Valve - Brodie International

Model BV88L Elongated Digital Control Valve - Brodie International

Model BV88L Elongated Digital Control Valve - Brodie International

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

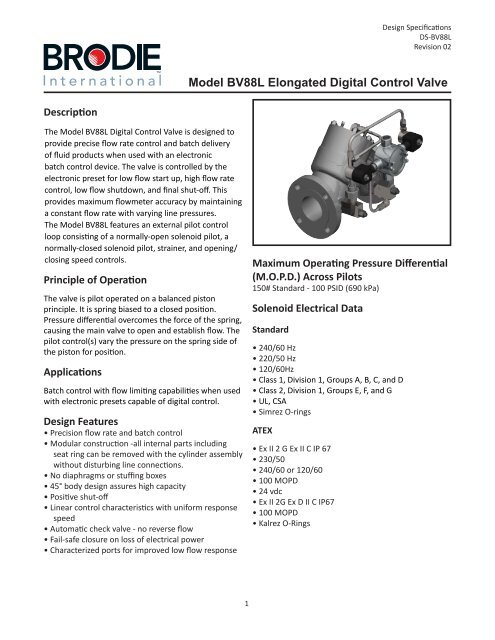

Design SpecificaonsDS-<strong>BV88L</strong>Revision 02TM<strong>Model</strong> <strong>BV88L</strong> <strong>Elongated</strong> <strong>Digital</strong> <strong>Control</strong> <strong>Valve</strong>DescriponThe <strong>Model</strong> <strong>BV88L</strong> <strong>Digital</strong> <strong>Control</strong> <strong>Valve</strong> is designed toprovide precise flow rate control and batch deliveryof fluid products when used with an electronicbatch control device. The valve is controlled by theelectronic preset for low flow start up, high flow ratecontrol, low flow shutdown, and final shut-off. Thisprovides maximum flowmeter accuracy by maintaininga constant flow rate with varying line pressures.The <strong>Model</strong> <strong>BV88L</strong> features an external pilot controlloop consisng of a normally-open solenoid pilot, anormally-closed solenoid pilot, strainer, and opening/closing speed controls.Principle of OperaonThe valve is pilot operated on a balanced pistonprinciple. It is spring biased to a closed posion.Pressure differenal overcomes the force of the spring,causing the main valve to open and establish flow. Thepilot control(s) vary the pressure on the spring side ofthe piston for posion.ApplicaonsBatch control with flow liming capabilies when usedwith electronic presets capable of digital control.Design Features• Precision flow rate and batch control• Modular construcon -all internal parts includingseat ring can be removed with the cylinder assemblywithout disturbing line connecons.• No diaphragms or stuffing boxes• 45° body design assures high capacity• Posive shut-off• Linear control characteriscs with uniform responsespeed• Automac check valve - no reverse flow• Fail-safe closure on loss of electrical power• Characterized ports for improved low flow responseMaximum Operang Pressure Differenal(M.O.P.D.) Across Pilots150# Standard - 100 PSID (690 kPa)Solenoid Electrical DataStandard• 240/60 Hz• 220/50 Hz• 120/60Hz• Class 1, Division 1, Groups A, B, C, and D• Class 2, Division 1, Groups E, F, and G• UL, CSA• Simrez O-ringsATEX• Ex II 2 G Ex II C IP 67• 230/50• 240/60 or 120/60• 100 MOPD• 24 vdc• Ex II 2G Ex D II C IP67• 100 MOPD• Kalrez O-Rings1

Typical InstallaonClosed or Closing PosionThe normally closed solenoid is closed. The normally open solenoid is open. Y-Port (P3) to Z-Port (P2) is closed.X-Port (P1) and Y-Port (P3) pressures are balanced. The main valve spring being the differenal force, closes thepiston and keeps it seated.2

Open PosionThe normally closed solenoid is open. The normally open solenoid is closed. Y-Port (P3) is open to Z-Port (P2).X-Port (P1) is closed off by the normally open solenoid. The pressure on the boom of the piston (P1) is greaterthan the pressure at (P3) plus the spring force; (P1 minus P2) is equal to or greater than the spring force.Therefore, (P1) pressure pushes the spring open.<strong>Control</strong>ling PosionThe normally closed solenoid is closed. The normally open solenoid is closed. Y-Port (P3) to Z-Port (P2) is closed.X-Port (P1) to Y-Port (P3) is closed. Note: The product cannot flow to or from the top of the piston (Y-Port). Thepiston is hydraulically locked in posion unl the PC-IMS commands the valve to open or close as required tomaintain the desired flow rate.3

Materials of ConstruconMain <strong>Valve</strong> Body: Steel-ASTM-A216-GR-WCBMain <strong>Valve</strong> Cylinder: 17-4 Stainless Steel, Heat TreatedMain <strong>Valve</strong> Piston: Stainless SteelSeat Ring: Stainless SteelMain <strong>Valve</strong> O-Rings: Viton Standard, Flouro Silicon forEthanol ServiceOther Internal Parts: Stainless SteelPilot <strong>Valve</strong> Strainer/Needle <strong>Valve</strong> Strainer:Standard: SteelTubings and Fings: Standard: SteelDimensions (For Cerfied DimensionalPrints - Consult Factory)Standard Equipment• Opening and closing speed controls• Self-cleaning strainer (<strong>Valve</strong> Inlet)• Stainless steel solenoid pilotsOponal Equipment• Manual Override• Thermal ReliefRecommended Spare PartsO-RingsOrdering InformaonIn order to accurately process an order, such informaon asproduct to be controlled, product viscosity, product temperaturerange, ambient temperature range, rate of flow,operang pressure, and oponal features required must bespecified by the customer.Flange Connecons<strong>Valve</strong>SizeConnectionsMax Working Pressure@ 100F4” 150# ANSI 285 PSITemperature Range: -20F to 150F (-29C to 66C)Oponal 250F (121C)Shipping Weight and Volume(Approximate)140# @ 2.51 Cu Feet63.5 kgs @ .071 Cu Meters<strong>Valve</strong>Sizemm A Dimension B Dimensioninches 150# 150#4”4”mm 340 292inches 13 1/2 11 1/2Engineering the FutureTM<strong>Brodie</strong> Internaonal19267 Highway 301 North • Statesboro, GA 30461Phone: 001.912.489.0200 • Fax: 001.912.489.0294A <strong>Brodie</strong> Meter Co., LLC Companywww.brodieintl.comThe contents of this publicaon are presented for informaonal purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranes or guarantees, expressor implied, regarding the products or services described herein or their use or applicability. <strong>Brodie</strong> Meter Co., LLC reserves the right to modify or improve the designs or specificaons of such products at any mewithout noce.