Fuel Cell Systems Explained - from and for SET students

Fuel Cell Systems Explained - from and for SET students

Fuel Cell Systems Explained - from and for SET students

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

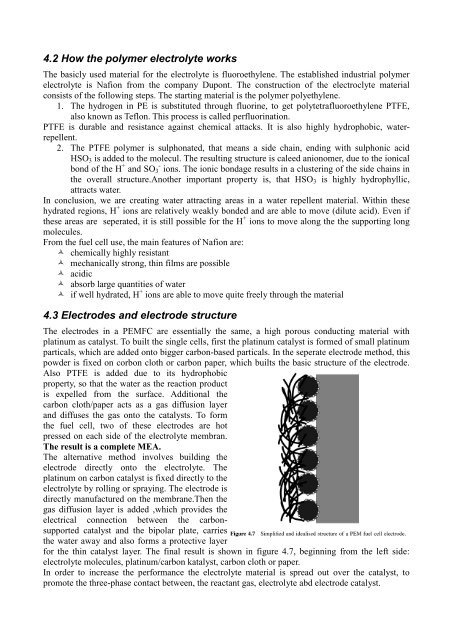

4.2 How the polymer electrolyte worksThe basicly used material <strong>for</strong> the electrolyte is fluoroethylene. The established industrial polymerelectrolyte is Nafion <strong>from</strong> the company Dupont. The construction of the electroclyte materialconsists of the following steps. The starting material is the polymer polyethylene.1. The hydrogen in PE is substituted through fluorine, to get polytetrafluoroethylene PTFE,also known as Teflon. This process is called perfluorination.PTFE is durable <strong>and</strong> resistance against chemical attacks. It is also highly hydrophobic, waterrepellent.2. The PTFE polymer is sulphonated, that means a side chain, ending with sulphonic acidHSO 3 is added to the molecul. The resulting structure is caleed anionomer, due to the ionicalbond of the H + <strong>and</strong> SO 3 - ions. The ionic bondage results in a clustering of the side chains inthe overall structure.Another important property is, that HSO 3 is highly hydrophyllic,attracts water.In conclusion, we are creating water attracting areas in a water repellent material. Within thesehydrated regions, H + ions are relatively weakly bonded <strong>and</strong> are able to move (dilute acid). Even ifthese areas are seperated, it is still possible <strong>for</strong> the H + ions to move along the the supporting longmolecules.From the fuel cell use, the main features of Nafion are: chemically highly resistant mechanically strong, thin films are possible acidic absorb large quantities of water if well hydrated, H + ions are able to move quite freely through the material4.3 Electrodes <strong>and</strong> electrode structureThe electrodes in a PEMFC are essentially the same, a high porous conducting material withplatinum as catalyst. To built the single cells, first the platinum catalyst is <strong>for</strong>med of small platinumparticals, which are added onto bigger carbon-based particals. In the seperate electrode method, thispowder is fixed on corbon cloth or carbon paper, which builts the basic structure of the electrode.Also PTFE is added due to its hydrophobicproperty, so that the water as the reaction productis expelled <strong>from</strong> the surface. Additional thecarbon cloth/paper acts as a gas diffusion layer<strong>and</strong> diffuses the gas onto the catalysts. To <strong>for</strong>mthe fuel cell, two of these electrodes are hotpressed on each side of the electrolyte membran.The result is a complete MEA.The alternative method involves building theelectrode directly onto the electrolyte. Theplatinum on carbon catalyst is fixed directly to theelectrolyte by rolling or spraying. The electrode isdirectly manufactured on the membrane.Then thegas diffusion layer is added ,which provides theelectrical connection between the carbonsupportedcatalyst <strong>and</strong> the bipolar plate, carriesthe water away <strong>and</strong> also <strong>for</strong>ms a protective layer<strong>for</strong> the thin catalyst layer. The final result is shown in figure 4.7, beginning <strong>from</strong> the left side:electrolyte molecules, platinum/carbon katalyst, carbon cloth or paper.In order to increase the per<strong>for</strong>mance the electrolyte material is spread out over the catalyst, topromote the three-phase contact between, the reactant gas, electrolyte abd electrode catalyst.