Extruded EMI Gaskets - Toptronic A/S

Extruded EMI Gaskets - Toptronic A/S

Extruded EMI Gaskets - Toptronic A/S

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

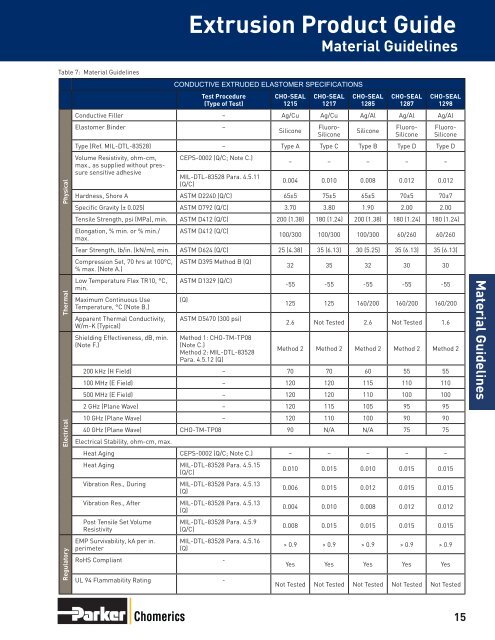

Extrusion Product GuideMaterial GuidelinesTable 7: Material GuidelinesPhysicalThermalElectricalRegulatoryCONDUCTIVE EXTRUDED ELASTOMER SPECIFICATIONSTest Procedure(Type of Test)CHO-SEAL1215CHO-SEAL1217CHO-SEAL1285CHO-SEAL1287CHO-SEAL1298Conductive Filler – Ag/Cu Ag/Cu Ag/Al Ag/Al Ag/AlElastomer Binder –Fluoro-Fluoro- Fluoro-SiliconeSiliconeSiliconeSilicone SiliconeType (Ref. MIL-DTL-83528) – Type A Type C Type B Type D Type DVolume Resistivity, ohm-cm,max., as supplied without pressuresensitive adhesiveCEPS-0002 (Q/C; Note C.)MIL-DTL-83528 Para. 4.5.11(Q/C)– – – – –0.004 0.010 0.008 0.012 0.012Hardness, Shore A ASTM D2240 (Q/C) 65±5 75±5 65±5 70±5 70±7Specific Gravity (± 0.025) ASTM D792 (Q/C) 3.70 3.80 1.90 2.00 2.00Tensile Strength, psi (MPa), min. ASTM D412 (Q/C) 200 (1.38) 180 (1.24) 200 (1.38) 180 (1.24) 180 (1.24)Elongation, % min. or % min./ ASTM D412 (Q/C)max.100/300 100/300 100/300 60/260 60/260Tear Strength, lb/in. (kN/m), min. ASTM D624 (Q/C) 25 (4.38) 35 (6.13) 30 (5.25) 35 (6.13) 35 (6.13)Compression Set, 70 hrs at 100°C, ASTM D395 Method B (Q)% max. (Note A.)32 35 32 30 30Low Temperature Flex TR10, °C,min.Maximum Continuous UseTemperature, °C (Note B.)Apparent Thermal Conductivity,W/m-K (Typical)Shielding Effectiveness, dB, min.(Note F.)ASTM D1329 (Q/C)(Q)ASTM D5470 (300 psi)Method 1: CHO-TM-TP08(Note C.)Method 2: MIL-DTL-83528Para. 4.5.12 (Q)-55 -55 -55 -55 -55125 125 160/200 160/200 160/2002.6 Not Tested 2.6 Not Tested 1.6Method 2 Method 2 Method 2 Method 2 Method 2200 kHz (H Field) – 70 70 60 55 55100 MHz (E Field) – 120 120 115 110 110500 MHz (E Field) – 120 120 110 100 1002 GHz (Plane Wave) – 120 115 105 95 9510 GHz (Plane Wave) – 120 110 100 90 9040 GHz (Plane Wave) CHO-TM-TP08 90 N/A N/A 75 75Electrical Stability, ohm-cm, max.Heat Aging CEPS-0002 (Q/C; Note C.) – – – – –Heat Aging MIL-DTL-83528 Para. 4.5.15(Q/C)0.010 0.015 0.010 0.015 0.015Vibration Res., During MIL-DTL-83528 Para. 4.5.13(Q)0.006 0.015 0.012 0.015 0.015Vibration Res., After MIL-DTL-83528 Para. 4.5.13(Q)0.004 0.010 0.008 0.012 0.012Post Tensile Set VolumeResistivityEMP Survivability, kA per in.perimeterMIL-DTL-83528 Para. 4.5.9(Q/C)MIL-DTL-83528 Para. 4.5.16(Q)RoHS Compliant -UL 94 Flammability Rating -0.008 0.015 0.015 0.015 0.015> 0.9 > 0.9 > 0.9 > 0.9 > 0.9Yes Yes Yes Yes YesNot Tested Not Tested Not Tested Not Tested Not TestedMaterial GuidelinesChomerics 15