Extruded EMI Gaskets - Toptronic A/S

Extruded EMI Gaskets - Toptronic A/S

Extruded EMI Gaskets - Toptronic A/S

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

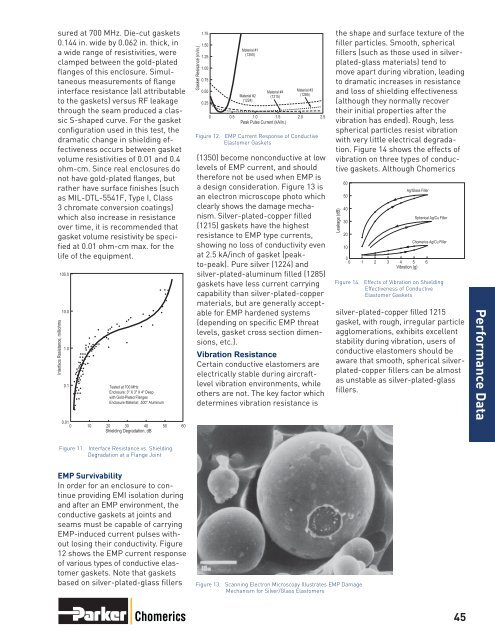

sured at 700 MHz. Die-cut gaskets0.144 in. wide by 0.062 in. thick, ina wide range of resistivities, wereclamped between the gold-platedflanges of this enclosure. Simultaneousmeasure ments of flangeinterface resistance (all attributableto the gaskets) versus RF leakagethrough the seam produced a classicS-shaped curve. For the gasketconfiguration used in this test, thedramatic change in shielding effectivenessoccurs between gasketvolume resistivities of 0.01 and 0.4ohm-cm. Since real enclosures donot have gold-plated flanges, butrather have surface finishes (suchas MIL-DTL-5541F, Type I, Class3 chromate conversion coatings)which also increase in resistanceover time, it is recommended thatgasket volume resistivity be specifiedat 0.01 ohm-cm max. for thelife of the equipment.Interface Resistance, milliohms100.010.01.00.10.01Tested at 700 MHzEnclosure: 3" X 3" X 4" Deepwith Gold-Plated FlangesEnclosure Material: .500" Aluminum0 10 20 30 40 50 60Shielding Degradation, dBGasket Resisance (m/in.)1.751.501.251.000.750.500.25Material #1(1350)Material #2(1224)Material #4(1215)Material #3(1285)0 0.5 1.0 1.5 2.0 2.5Peak Pulse Current (kA/in.)Figure 12. EMP Current Response of ConductiveElastomer <strong>Gaskets</strong>(1350) become nonconductive at lowlevels of EMP current, and shouldtherefore not be used when EMP isa design consi d eration. Figure 13 isan electron microscope photo whichclearly shows the damage mechanism.Silver-plated-copper filled(1215) gaskets have the highestresistance to EMP type currents,showing no loss of conductivity evenat 2.5 kA/inch of gasket (peakto-peak).Pure silver (1224) andsilver-plated-aluminum filled (1285)gaskets have less current carryingcapability than silver-plated-coppermaterials, but are generally acceptablefor EMP hardened systems(depending on specific EMP threatlevels, gasket cross section dimensions,etc.).Vibration ResistanceCertain conductive elastomers areelectrically stable during aircraftlevelvibration environments, whileothers are not. The key factor whichdeter mines vibration resistance isthe shape and surface texture of thefiller particles. Smooth, sphericalfillers (such as those used in silverplated-glassmaterials) tend tomove apart during vibration, leadingto dramatic increases in resistanceand loss of shielding effectiveness(although they normally recovertheir initial properties after thevibration has ended). Rough, lessspherical particles resist vibrationwith very little electrical degradation.Figure 14 shows the effects ofvibra tion on three types of conductivegaskets. Although ChomericsLeakage (dB)605040302010Ag/Glass Filler0 0 1 2 3 4 5 6Vibration (g)Spherical Ag/Cu FillerChomerics Ag/Cu FillerFigure 14. Effects of Vibration on ShieldingEffectiveness of ConductiveElastomer <strong>Gaskets</strong>silver-plated-copper filled 1215gasket, with rough, irregular particleagglomera tions, exhibits excellentstability during vibration, users ofconductive elastomers should beaware that smooth, spherical silverplated-copperfillers can be almostas unstable as silver-plated-glassfillers.Performance DataFigure 11. Interface Resistance vs. ShieldingDegradation at a Flange JointEMP SurvivabilityIn order for an enclosure to continueproviding <strong>EMI</strong> isolation duringand after an EMP environment, theconductive gaskets at joints andseams must be capable of carryingEMP-induced current pulses withoutlosing their conductivity. Figure12 shows the EMP current responseof various types of conductive elastomergaskets. Note that gasketsbased on silver-plated-glass fillersFigure 13. Scanning Electron Microscopy Illustrates EMP DamageMechanism for Silver/Glass ElastomersChomerics 45