PWO Water Oil Cooler - Olaer

PWO Water Oil Cooler - Olaer

PWO Water Oil Cooler - Olaer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

OLAER | <strong>PWO</strong><strong>Olaer</strong> is a global player specialising in innovative, efficient system solutions for temperature optimisation and energy storage.All over the world, our products are working in the most diverse environments and applications.Unique designOptimal performance as well as maintenance freeThe <strong>PWO</strong> is a compact and lightweight water oil coolerwith a high cooling capacity compared to size. Thislightweight and compact water oil cooler consistsof corrugated channel plates sandwiched betweenthe front and rear cover plates. The channel platesare pressed and vacuum brazed in the sameautomated procedure, and with rigorous standards ofquality control.<strong>PWO</strong> WATER OIL COOLER• Light and compact• Suitable for many applications• Ease of installation• Cost efficient and environmentally friendlyThe unique plate design provides high turbulent flowconditions throughout the cooler, the key to efficientcooling. This turbulent flow reduces the risk forclogging, which in turn makes this <strong>PWO</strong> virtuallymaintenance free.A wide number of possibilitiesThe unique design emphasizes a number of possibilitiesfor versatile and efficient solutions. The <strong>PWO</strong> can easilybe adapted to a variety of needs and special applicationsincluding seawater, aggressive oils, high pressure andhigh temperature applications. With a <strong>PWO</strong> water oilcooler in your system, you can be assured that the fluidin your system is working at the correct temperature,providing maximum performance and reliability inyour system.2 www.olaer.com

OLAER | <strong>PWO</strong><strong>PWO</strong>Complete system for water oil cooling<strong>PWO</strong>standard range......of water oil coolers is available in a wide number ofsizes and is in general available for immediateoff-the-shelf delivery. The basic material is stainlesssteel (AISI 316/304), vacuum brazed with pure copper.AISI 316 can be limited to the parts of the <strong>PWO</strong> thatactually come in contact with fluid, i.e. the channelplates. <strong>PWO</strong> requires small hold up volumes , i.e. a lowercost and a more environmentally-friendly solution.Low installation cost allows for oversizing for futurerequirements or peak loads<strong>PWO</strong>in Mo-steel......provides higher resistance vs. AISI 316 to pittingand crevice corrosion and chloride-rich fluids. <strong>PWO</strong>’sstate-of-the-art brazing technology eliminates the riskof intergranular corrosion. Mo-steel can be limited tothe parts of the <strong>PWO</strong> that actually come in contactwith corrosive fluid, i.e. the channel plates. Typicalapplications for the Mo-series are in industrialapplications where high chloride concentrations puthigh demands on corrosion resistance. Another typicalapplication is in the pulp and paper industries thatoften process with chloride-rich fluids.<strong>PWO</strong>in stainless steel......free from copper. The nickel-based brazing materialhas increased durability to aggressive media and theycan also endure higher working temperatures thannormal copper-brazed <strong>PWO</strong>. <strong>PWO</strong> in stainless steel isused where the water supply is corrosive to copper.Other applications are cooling or heating of oil witha high content of sulphur, ammonia-based coolingsystems where copper is prohibited as well aspharmaceutical and chemical applications wherecopper-brazed coolers are susceptible to corrosionfrom acids and bases. Another field of application isin high-temperature applications, e.g. heating of oils.<strong>PWO</strong>-M......is an extremely small <strong>PWO</strong> water oil cooler, perfectwherever compactness is crucial. The gaskets and theplates can be of various materials to ensure compatibilitywith the refrigerant. Even if a costlier, highperformancemetal is required for the heat transfer surfaces, the frontand back plates can be made of more basic materialsto cut costs. The snap-in-place connections allow easyassembly and the use of different metals without therisk of weld deterioration. The <strong>PWO</strong>-M with plates madeof titanium resists corrosive seawater in onboard enginecoolers and applications containing de-ionized water oraggressive fluids. See separate pamphlet, which can bedownloaded from www.olaer.se .<strong>PWO</strong> withdouble walled channel plates......are designed for applications where high thermalefficiency is a requirement, and the risk of internalleakage must be minimized. Thanks to excellent thermalefficiency, compactness, low weight and quick responsetime, it is primarily used in sanitary water applications,coolers for the chemical process industries, food andpharmaceutical industries and wherever required bylaw or other regulations.<strong>PWO</strong>for high pressure......is designed to meet the high demands for a coolerin applications with working pressures up to 45bar (Note: special models and configurations areavailable for max working pressure 120 bar!).With the exception of high-pressure applications e.g.within the process industry, the <strong>PWO</strong>is perfect for use with new, highcapacity,environmentally-friendlyrefrigerants. The <strong>PWO</strong>’s greaterheat transfer efficiency providesopportunites linked to energy-costand environmental savings.The Professional Choice 3

OLAER | <strong>PWO</strong><strong>Oil</strong> type: ISO VG 46<strong>Oil</strong>/water flow ratio: 2/1Inlet oil temperature 60°C at Δ p max 2 barInlet water temperature 20°CHeat Load (kW)B15<strong>Oil</strong> Flow (l/min)Pressure Drop (bar)B15<strong>Oil</strong> Flow (l/min)Heat Load (kW)B10T<strong>Oil</strong> Flow (l/min)Pressure Drop (bar)B10T<strong>Oil</strong> Flow (l/min)The Professional Choice 5

OLAER | <strong>PWO</strong><strong>Oil</strong> type: ISO VG 46<strong>Oil</strong>/water flow ratio: 2/1Inlet oil temperature 60°C at Δ p max 2 barInlet water temperature 20°CHeat Load (kW)B16<strong>Oil</strong> Flow (l/min)Pressure Drop (bar)B16<strong>Oil</strong> Flow (l/min)Heat Load (kW)B28<strong>Oil</strong> Flow (l/min)Pressure Drop (bar)B28<strong>Oil</strong> Flow (l/min)The Professional Choice 7

OLAER | <strong>PWO</strong><strong>Oil</strong> type: ISO VG 46<strong>Oil</strong>/water flow ratio: 2/1Inlet oil temperature 60°C at Δ p max 2 barInlet water temperature 20°CHeat Load (kW)B35<strong>Oil</strong> Flow (l/min)Pressure Drop (bar)B35<strong>Oil</strong> Flow (l/min)Heat Load (kW)B120T<strong>Oil</strong> Flow (l/min)Pressure Drop (bar)B120T<strong>Oil</strong> Flow (l/min)8 www.olaer.com

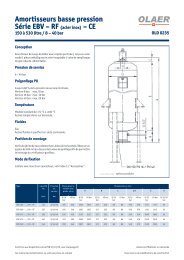

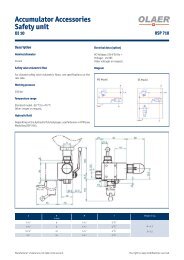

OLAER | <strong>PWO</strong><strong>PWO</strong> STANDARD range of water oil coolers isavailable in a wide number of sizes and is ingeneral available for immediate off-the-shelfdelivery. The basic material is AISI 316 stainlesssteel, vacuum brazed with pure copper. <strong>PWO</strong>requires little refrigerant volume resulting inlower cost and a more environmentally-friendlyinstallation. Low installation cost allows foroversizing to accommodate for future increase inrequirements or peak loads.TYPEAmm(±2)Bmm(±1)Cmm(±1)Dmm(±1)Emm(±1) (+0.5% - 1.5%)F* = x number of plates(±1)B5T 187 72 154 40 20.1 2x¾” - 2x ½” 2.24 x * + 4 7 16B8T 310 72 278 40 20.1 2x¾” - 2x ½” 2.24 x * + 4 7 16B10T 289 119 243 72 20.1 2x1” - 2x ¾” 2.24 x * + 4 6 22B12 287 117 234 63 27.1 2x1¼” - 2x 1” 2.24 x * + 4 6 22B15 465 72 432 40 20.1 2x¾” - 2x ½” 2.24 x * + 4 7 16B16 376 119 320 63 27.1 2x1¼” - 2x 1¼” 2.24 x * + 4 6 23B25T 526 119 479 72 20.1 2x1¼” - 2x 1” 2.24 x * + 4 6 23B28 526 119 470 63 27.1 2x1¼” - 2x 1¼” 2.24 x * + 4 6 23B35 393 243 324 174 27.1 2x1½” - 2x 1¼” 2.34 x * + 8 3 35B120T 525 243 456 174 27.1 2x1½” - 2x 1¼” 2.29 x * + 10 4 35B56 525 243 430 148 54.2 ISO G 4x 2½” 2.44 x * + 14 3 48GmmRmmUnits size >B35-90 should always be fixed withtwo clamps per cooler >B35-90Clamp Type A BFK-B5T 219 90FK-B8T 342 90FK-B10T, B12 319 135FK-B15 496 90FK-B16 408 139FK-B25T, B28 554 135FK-B35 422 259FK-B56/B120T 554 25910 www.olaer.com

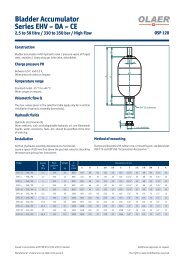

OLAER | <strong>PWO</strong>B5TDimensions72 x 187 mmB8TDimensions72 x 310 mmB10TDimensions119x 289 mmB12Dimensions117 x 287 mmB15Dimensions72 x 465 mmB16Dimensions119 x 376 mmB25TDimensions119 x 526 mmB28Dimensions119 x 526 mmB35Dimensions243 x 393 mmB56Dimensions243 x 525 mmB120TDimensions243 x 525 mmTYPEMax Temp°CMin Temp°CWorking Pressure155 °C barTest PressurebarB5T 225 -196 31 50B8T 225 -196 31 50B10T 225 -196 31 50B12 225 -196 31 50B15 225 -196 31 50B16 225 -196 28 45B25T 225 -196 31 50B28 225 -196 28 45B35 225 -196 31 50B120T 225 -196 31 50B56 225 -196 31 50Empty Weightkg* = number of plates0.50 + NoP* x 0.050.81 + NoP* x 0.081.39 + NoP* x 0.101.44 + NoP* x 0.121.31 + NoP* x 0.101.73 + NoP* x 0.122.15 + NoP* x 0.182.26 + NoP* x 0.166.99 + NoP* x 0.3410.27 + NoP* x 0.4016.27 + NoP* x 0.42Material:Plates: EN 10028/7-1.4401 (AISI 316)Brazing: Pure copperConnections: EN 10272-1.4401 (AISI 316)The Professional Choice 11

The Professional Choice- in Fluid Energy ManagementGlobal perspectiveand local entrepreneurial flair<strong>Olaer</strong> is a global player specialising in innovative,efficient system solutions for temperature optimisationand energy storage. <strong>Olaer</strong> develops, manufactures andmarkets products and systems for a number of differentsectors, e.g. the aircraft, engineering, steel andmining industries, as well as for sectors such as oil andgas, contracting and transport, farming and forestry,renewable energy, etc.All over the world, our products operate in the mostdiverse environments and applications. One constantlyrepeated demand in the market is for optimal energystorage and temperature optimisation. We work at alocal level with a whole world as our workplace – localentrepreneurial flair and a global perspective go handin hand.Our local presence, long experience and a wealth ofknowledge combine with our cutting-edge expertiseto give you the best possible conditions for making aprofessional choice.Copyright © January 2011 OLAER - The information in this brochure is subject to change without prior notice.www.olaer.com