AIRSTREAM OWNERS MANUAL

AIRSTREAM OWNERS MANUAL

AIRSTREAM OWNERS MANUAL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

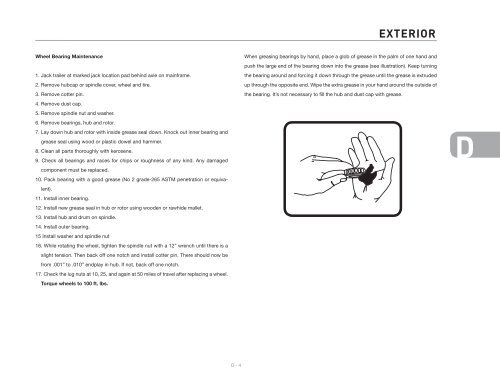

Wheel Bearing Maintenance1. Jack trailer at marked jack location pad behind axle on mainframe.2. Remove hubcap or spindle cover, wheel and tire.3. Remove cotter pin.4. Remove dust cap.5. Remove spindle nut and washer.6. Remove bearings, hub and rotor.7. Lay down hub and rotor with inside grease seal down. Knock out inner bearing andgrease seal using wood or plastic dowel and hammer.8. Clean all parts thoroughly with kerosene.9. Check all bearings and races for chips or roughness of any kind. Any damagedcomponent must be replaced.10. Pack bearing with a good grease (No 2 grade-265 ASTM penetration or equivalent).11. Install inner bearing.12. Install new grease seal in hub or rotor using wooden or rawhide mallet.13. Install hub and drum on spindle.14. Install outer bearing.15 Install washer and spindle nut16. While rotating the wheel, tighten the spindle nut with a 12” wrench until there is aslight tension. Then back off one notch and install cotter pin. There should now befrom .001” to .010” endplay in hub. If not, back off one notch.17. Check the lug nuts at 10, 25, and again at 50 miles of travel after replacing a wheel.Torque wheels to 100 ft. lbs.EXTERIORWhen greasing bearings by hand, place a glob of grease in the palm of one hand andpush the large end of the bearing down into the grease (see illustration). Keep turningthe bearing around and forcing it down through the grease until the grease is extrudedup through the opposite end. Wipe the extra grease in your hand around the outside ofthe bearing. It’s not necessary to fill the hub and dust cap with grease.DD - 4