Range Rover Workshop Manual - System Description and Operation ...

Range Rover Workshop Manual - System Description and Operation ...

Range Rover Workshop Manual - System Description and Operation ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

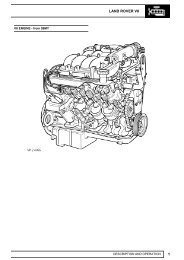

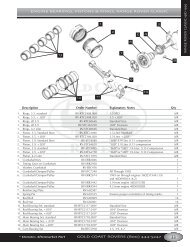

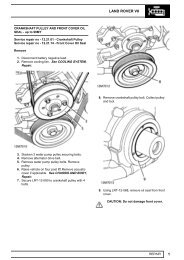

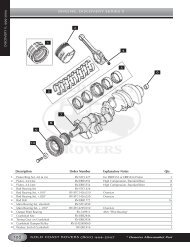

ENGINE – TD6The valve springs are made from spring steel <strong>and</strong> are of the parallel single-coil type. The bottom end of each springrests on the flange of a spring retainer which has an integral valve stem seal. The top end of the spring is held in placeby a spring retainer which is held in position at the top end of the valve stem by split taper collets. The taper colletshave grooves on the internal bore that locate to grooves ground into the upper stems of the valves.Valve seats <strong>and</strong> valve guides are an interference fit in the cylinder head.Hydraulic Lash Adjusters <strong>and</strong> Roller Finger RockersThe valves are operated through roller-type finger rockers <strong>and</strong> hydraulic lash adjusters, actuated by the camshaftlobes. When the camshaft lobe presses down on the top of a finger rocker, roller mechanism, the respective valve isforced down, opening the affected inlet or exhaust port. The use of this type of actuation method helps reduce frictionin the valve timing mechanism.The body of the hydraulic lash adjusters contains a plunger <strong>and</strong> two chambers for oil feed <strong>and</strong> pressurised oil. Thepressurised oil is supplied to the lash adjusters via the main oil galleries in the cylinder head <strong>and</strong> through a hole in theside of the lash adjuster body. The oil passes into a feed chamber in the lash adjuster <strong>and</strong> then through to a separatepressure chamber via a one way ball valve.Oil flow from the pressure chamber is determined by the amount of clearance between the lash adjuster outer body<strong>and</strong> the centre plunger. Oil escapes up the side of the plunger every time the lash adjuster is operated, the downwardpressure on the plunger forcing a corresponding amount of oil in the lash adjuster body to be displaced. When thedownward pressure from the camshaft <strong>and</strong> finger rocker is removed (i.e. after the trailing flank of the camshaft lobehas passed), oil pressure forces the lash adjuster's plunger up again. This pressure is not sufficient to effect the valveoperation, but eliminates the clearance between the finger rocker <strong>and</strong> top of the valve stem.Electronic Fuel InjectorsThere are six electronic fuel injectors (one for each cylinder), each located in the centre of a cylinder's four valves.The electronic fuel injectors are supplied with fuel from the fuel rail <strong>and</strong> deliver finely atomised fuel directly into thefuel chambers.For more information on the Fuel injector operation, refer to the Engine Management – Td6 section of this workbook.Ancillary Components <strong>and</strong> Belt DrivesThe ancillary components, which comprise the torsional vibration damper, alternator, A/C compressor, steering pump<strong>and</strong> water pump, are driven by the engine crankshaft via the ancillary drive belts.The belts, which are maintenance free poly-V type belts, are automatically pre-loaded by the tensioning rollers <strong>and</strong>are routed over deflection pulleys in order to maintain sufficient adhesion about the drive wheels. This ensures slipfreedrive of the ancillary components.DESCRIPTION AND OPERATION 12-1-11