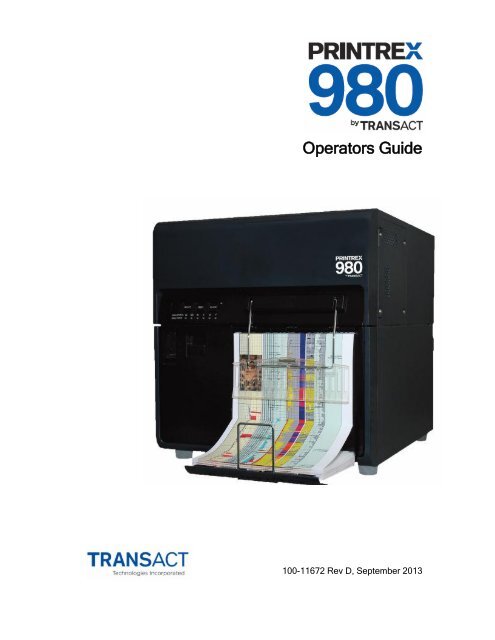

Printrex 980 Operator's Guide - TransAct

Printrex 980 Operator's Guide - TransAct

Printrex 980 Operator's Guide - TransAct

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

This page intentionally left blankPage ii100-11672 - Rev D

DisclaimerNOTICE TO ALL PERSONS RECEIVING THIS DOCUMENT:The information in this document is subject to change without notice. No partof this document may be reproduced, stored or transmitted in any form or byany means, electronic or mechanical, for any purpose, without the expresswritten permission of <strong>TransAct</strong> Technologies, Inc. ("<strong>TransAct</strong>"). Thisdocument is the property of and contains information that is both confidentialand proprietary to <strong>TransAct</strong>. Recipient shall not disclose any portion of thisdocument to any third party.TRANSACT DOES NOT ASSUME ANY LIABILITY FOR DAMAGESINCURRED, DIRECTLY OR INDIRECTLY, FROM ANY ERRORS,OMISSIONS OR DISCREPANCIES IN THE INFORMATION CONTAINED INTHIS DOCUMENT.<strong>TransAct</strong> cannot guarantee that changes in software and equipment made byother manufacturers, and referred to in this publication, do not affect theapplicability of information in this publication.Copyright© 2013 <strong>TransAct</strong> Technologies, Inc. All rights reserved. Printed in USARevision Level D September 2013TrademarksSome of the product names mentioned herein are used for identificationpurposes only and may be trademarks and/or registered trademarks of theirrespective companies.<strong>TransAct</strong>, <strong>Printrex</strong>, and Atlantek are registered trademarks of <strong>TransAct</strong>Technologies, Inc.Microsoft and Windows are registered trademarks of Microsoft Corporation inthe United States and/or other countries.Adobe and the Adobe logo are trademarks of Adobe Systems, Inc.Page iv100-11672 - Rev D

Paper Loading Procedure (Rear) .................................................................. 48Replacing Ink Tanks ...................................................................................... 54Replacing the Maintenance Cartridge ........................................................... 59Checking the Test Prints ............................................................................... 62Printing and Examining Nozzle Check Pattern .......................................... 62Cleaning Procedure .................................................................................. 65Printing TK-GAP Adjustment Pattern ........................................................ 67Examining and Adjusting TK-GAP ............................................................ 68Printing Slant Adjustment Pattern ............................................................. 71Examining and Adjusting Slant ................................................................. 72Printing Head Position Adjustment Pattern ............................................... 75Examining and Adjusting Printhead Position............................................. 77Action of Relocating Printer ........................................................................... 86<strong>Printrex</strong> ® <strong>980</strong> Specifications and Requirements..............................................................91<strong>Printrex</strong> ® <strong>980</strong> Specifications and Requirements ............................................ 93Standard Features ........................................................................................ 93Physical Printer Specifications ...................................................................... 94Environmental Conditions ......................................................................... 94Electrical Specifications ................................................................................ 95Media Specifications ..................................................................................... 95Paper ....................................................................................................... 95USB Interface ................................................................................................ 95Printer Maintenance ..................................97Cleaning the Printer ...................................................................................... 99Clearing Paper Jams ................................................................................... 104Moving the printer ....................................................................................... 106Shipping the Printer ..................................................................................... 109Troubleshooting ...................................... 111Initial Check Items ....................................................................................... 113Checking the Installation Environment .................................................... 113Checking the Paper ................................................................................ 113Checking Settings .................................................................................. 113Procedures for Operation Failure ................................................................ 114Rear Feeder Sensor Cleaning ................................................................ 114Trailing Edge Sensor Cleaning ............................................................... 115Image Defect Recovery ............................................................................... 116Vertical White Streak (Non-Discharge) ................................................... 116Faint Image (Distortion) .......................................................................... 117Void ........................................................................................................ 118Abnormal Discharge ............................................................................... 119Uneven Image (Cross Feeding Direction) ............................................... 120Uneven Image (Feeding Direction) ......................................................... 121Relative Misregistration in Colors in X or Y Direction .............................. 122Misregistration (Leading edge and side edge) ........................................ 123Blank Image ........................................................................................... 124Paper Skew ............................................................................................ 125Spur Marks (White Dotted Lines) ............................................................ 126Ink Smearing (Due to Printhead Crash) ................................................... 127Page vi100-11672 - Rev D

Spur Marks (Dotted Lines) ...................................................................... 128Ink Adhesion (Ink Dripping) .................................................................... 129Defect Recovery Procedures ....................................................................... 130Adjustment .................................................................................................. 137Adjustment When Replacing Parts ......................................................... 137Head Position Adjustment ...................................................................... 138Print Module Replacement ..................................................................... 139Work at Printhead Replacement ............................................................. 144Work at Purge Unit Replacement ........................................................... 144Work at Transport Unit Replacement ...................................................... 145Work at Rack Unit Replacement ............................................................. 148Rear Feeder Sensor Adjustment ............................................................ 148Work at Stacker Rail and/or Front Tray Unit Replacement ...................... 151Work at Printer Controller PCB Replacement ......................................... 152Work at DC Power Supply PCB Unit Replacement ................................. 153Head Position Adjustment ........................................................................... 154TK-GAP Adjustment ............................................................................... 154Slant Adjustment .................................................................................... 158Head Position Adjustment ...................................................................... 164Backfeed Gap Adjustment ...................................................................... 174Head Position Fine Adjustment ............................................................... 178Error Codes ................................................................................................. 184Service Call Error(Fatal Error) ................................................................ 184Operator Call Error ................................................................................. 207Warning .................................................................................................. 213Installing the Maintenance Tool (Service Utility) .......................................... 215Operation Procedures ................................................................................. 217Start Procedure ...................................................................................... 217Printer Information .................................................................................. 218Head Information .................................................................................... 219Cleaning, User Setting ............................................................................ 220Test Print, Adjustment ............................................................................ 227Head Position Fine Adjustment ............................................................... 249Update, Time Setting .............................................................................. 254History .................................................................................................... 257Self Diagnostics ...................................................................................... 258Troubleshooting ...................................................................................... 259Parts Replacement ................................................................................. 260Test Print .................................................................................................... 274Setting Parameters ................................................................................. 274Nozzle Check Pattern ............................................................................. 275Paper Transport Pattern ......................................................................... 276100% Block Pattern ................................................................................ 276Image Position Pattern ........................................................................... 277Backfeed Pattern .................................................................................... 281Version Upgrade Procedure ........................................................................ 281Other Troubleshooting Issues ..................................................................... 282Power is Off ............................................................................................ 282Printer Does Not Start or Stops During Print Jobs ................................... 282Paper is Not Feeding Correctly ............................................................... 283Status Monitor Does Not Start ................................................................ 283Random, Bizarre Characters Are Printed ................................................ 284100-11672 - Rev D Page vii

Slow To Print .......................................................................................... 284Print Quality Is Poor ................................................................................ 284Appendix A: Ordering Supplies ................. 285Drivers Available ......................................................................................... 285Index ..................................................... 287Page viii100-11672 - Rev D

Chapter 1Introducing your <strong>Printrex</strong> ® <strong>980</strong> Printer100-11672 - Rev D Page 1

This page intentionally left blankPage 2100-11672 - Rev D

About Your <strong>Printrex</strong> ® <strong>980</strong> PrinterAbout your <strong>Printrex</strong> ® <strong>980</strong> PrinterThe <strong>Printrex</strong> ® <strong>980</strong> printer by <strong>TransAct</strong> ® represents the very latest technologyfor use for high-speed continuous form plotting, specifically designed for theneeds of the oil and gas industry. It builds upon the experience of the <strong>Printrex</strong> ®line of inkjet printers with a host of features specifically designed to improvethe performance of well log printing, including:8 inches per second plot speedNo limitation on plot length, allowing plotting of continuous logsPrint quality enhancement features, including:o Depth Line Accuracy, ensuring accuracy of scaleo Stitching Stream Technology, to ensure no gaps in plotting evenwhen the printer temporarily lacks datao Automatic Image Shifter, to extend print head lifeFour separate ink tanks for easy exchange of individual colorsLow total cost of ownershipThese features and more let you quickly and easily integrate the <strong>Printrex</strong> ® <strong>980</strong>with your oil and gas industry office applications, while giving you the quality,durability and uptime you have come to expect from <strong>Printrex</strong> ® by <strong>TransAct</strong> ®printers.100-11672 - Rev D Page 3

About Your <strong>Printrex</strong> ® <strong>980</strong> PrinterWho Should Read This <strong>Guide</strong>?This document provides information useful for end users who will install,configure, and operate the <strong>Printrex</strong> ® <strong>980</strong> printer in their operations.What Is Included in This <strong>Guide</strong>?This Operators <strong>Guide</strong> includes information on the installation, specifications,and operation of the <strong>Printrex</strong> ® <strong>980</strong> printer. It provides the following informationto support your installation and operational efforts:Warranty and technical support informationSpecifications and functionality descriptionInstallation and operational proceduresConfiguration, testing, and troubleshooting proceduresWe want you to have a trouble-free implementation with your <strong>TransAct</strong> ®printer. For any issues not covered in this guide, quality technical support isavailable on-line at www.Transact-tech.com, or by telephone or fax – consultthe following pages for more details about our support services.Page 4100-11672 - Rev D

About Your <strong>Printrex</strong> ® <strong>980</strong> PrinterTechnical and Sales SupportYour printer is backed by the resources of <strong>Printrex</strong>, a division of <strong>TransAct</strong>Technologies, a global technology firm with dedicated technical support andsales assistance. Here is how we can help you:On-line Technical SupportOur web site at www.Transact-tech.com is your on-line portal to obtainingtechnical assistance with your <strong>Printrex</strong> ® printer. Click on the Support link tofind support information for your <strong>Printrex</strong> ® <strong>980</strong> printer, including online accessto drivers and documentation, or contact us via e-mail at support@transacttech.com.Telephone Technical SupportLive telephone support is available by contacting <strong>Printrex</strong> or one of its regionalaffiliates via the contact information listed in this section. To help us serve youfaster, please have the following information ready when you call:The Model Number and Serial Number of the printer.A list of any other peripheral devices attached to the same port as theprinter.What application software, operating system, and network (if any) you areusing.What happened and what you were doing when the problem occurred.How you tried to solve the problem.Warranty Information<strong>Printrex</strong> ® <strong>980</strong> Printers come with a standard warranty that commences uponshipment from factory, and covers parts and labor. An optional warranty,covering both parts and labor, may be purchased separately.100-11672 - Rev D Page 5

About Your <strong>Printrex</strong> ® <strong>980</strong> PrinterReturn Materials Authorization and Return PoliciesIf a support technician determines that the printer should be serviced at a<strong>Printrex</strong> facility, and you want to return the printer for repair, we will issue youthe Returned Materials Authorization (RMA) number that is required beforereturning the printer. Please prepare the printer being returned for repair asfollows:Pack the printer to be returned in the original packing material.Do not return any accessories unless asked to do so by a supporttechnician.Write the RMA number clearly on the outside of the box.Shipping PrintersNever ship a printer by any means with any ink cartridge installed. Besure to save the packing materials in the event that you need to send theprinter in for servicing. <strong>Printrex</strong> is not responsible for damaged return itemsthat are not packaged in original shipping material.Sales SupportTo order supplies, receive information about other <strong>Printrex</strong> products, or obtaininformation about your warranty, contact our Sales Department at the contacttelephone or fax numbers listed below or visit our web site at www.Transacttech.com.Page 6100-11672 - Rev D

About Your <strong>Printrex</strong> ® <strong>980</strong> PrinterContact InformationUSA<strong>TransAct</strong> Technologies IncorporatedIthaca Facility20 Bomax DriveIthaca, NY 14850 USA<strong>TransAct</strong> TechnologiesWorld Gaming Headquarters& Western Regional Repair Center6700 Paradise RoadSuite DLas Vegas, NV 89119 USATelephone (877) 7ithaca or (607) 257-8901Main fax (607) 257-8922Sales fax (607) 257-3868Technical Support fax (607) 257-3911Web sitewww.transact-tech.comWestern United States: 877.822.8923, Fax: 702.254.7796United Kingdom: 011-44-170-977-2500, Fax: 011-44-170-977-2505R – Associates Inc.6610 Gant RoadHouston, Texas 77066 USATelephone 713.973.1500Fax 713.598.8311Web Site: www.r-associates.comUnited KingdomAVNET Embedded5a Waltham Park, White WalthamMaidenheadBerkshire, SL63TNTelephone +44 1628 518900Web Site: www.adnet-embedded.euCanadaKesh Downhole Measurements, Inc.P.O. Box 246Clyde, Alberta T0G 0P0 CanadaTelephone 780.348.5278Fax 780.348.5731Email: kevindm2@clearwave.ca100-11672 - Rev D Page 7

About Your <strong>Printrex</strong> ® <strong>980</strong> PrinterGermanyElkutec Electronic GmbHPostfach 11 33D-85386 Eching bei MünchenErfurter Straße 31 GermanyTelephone (49)-89-31-90-91-0Fax (49)-89-31-90-91-91Web Site: www.elkutec.deEmail: sales@elkutec.deChinaStar-Luck Enterprises, Inc.Beijing OfficeRoom 328, Grand Vision Business Building,No.2 Jiuxianqiao Road,Chaoyang DistrictBeijing 100015 ChinaTelephone 86-10-51305677Fax 86-10-51305658SingaporeHABS Industries Pte Ltd.2 Kensington Park Drive#04-04Singapore 557320Telephone 65-967 32002 or 65 816 32322Fax 65-234 3158Email: habsindustries@gmail.comPage 8100-11672 - Rev D

Chapter 2Safety Precautions100-11672 - Rev D Page 9

This page intentionally left blankPage 10100-11672 - Rev D

Important Safety PrecautionsGeneral PrecautionsNever place items on the printer such as a flower vase, potted plant,cosmetics, any liquid filled container, or metal fasteners. If such items wereto fall on the printer, this could cause a fire, electrical shock, or damage tothe printer.The electrical contacts inside the printer become extremely hot duringnormal operation. To avoid causing a fire, never store flammablesubstances like alcohol, thinner, etc. near the printer.Never place the printer where it is exposed to open air or high humidity.This could cause a fire, serious electrical shock, or damage to the printer.Also, if the printer is carried into a warm room on a cold day, this couldcause condensation inside the printer. If this happens, allow the printer tosit for at least 1 hour at room temperature to adapt to the ambienttemperature and humidity.Never place the printer on a slanted or unstable stand or table. If theprinter is dropped or slides off, this could cause personal injury. Also,never place a heavy object on top of the printer. If the object is dropped orfalls, this could cause personal injury.Never expose the printer to open air or dust. This could cause a fire,serious electrical shock, or damage to the printer. Also, never locate theprinter near a water faucet or in any other location where it will be exposedto water. This could cause serious electrical shock.Never place the printer where it will be exposed to rapid changes intemperature, such as in direct sunlight, near an air conditioner, on a hotday. This could cause a fire or damage to the printer.Place the printer in a location that meets the specified ranges oftemperature and humidity. If the printer is either too cold or too hot, it maynot operate normally. Operating environment: 15 - 30°C (59 - 86°F) RH 10- 80% (with no condensation).To ensure normal operation of the printer and avoid possible damage,never install the printer near large office equipment or any other type ofelectrical devices that emit strong magnetic fields.Never block the ventilation ports on the printer. A blocked ventilation portcould cause heat to build up inside the printer and cause a fire. Also, placethe printer in an area where you can disconnect the power cordimmediately; keep the area around the power cord connection free fromobstacles. This allows you to unplug the power cord quickly in anemergency.100-11672 - Rev D Page 11

Power Supply and Power CordTo avoid the risk of fire, electrical shock, personal injury, or damage to theprinter:Always use the power cord provided with this printer. To avoid a fire orelectrical shock, do not use an extension cord.Connect the printer power cord to an independent power source that is notshared by other equipment or appliances.Make sure that the power plug is securely and completely inserted into thepower source.Do not cut, damage, or otherwise alter the power cord. Never place aheavy object on the power cord, never expose it to heat, and never pull thecord to disconnect it. If the power cord is damaged in any way(condensation on exposed wires, broken wires, etc.) contact customerservice where you purchased the printer.Never handle the power cord or plug when your hands are wet.Never knot the power cord or wrap it around itself.Disconnect the printer power cord during severe electrical storms.Lightning could cause a fire or severe electrical shock or damage to theprinter.To avoid a fire hazard, occasionally disconnect the power cord from theprinter and the power supply, and use a soft dry cloth to clean the cordconnectors and the connection points. Leaving the cord plugged in and notcleaned for a long period, especially in an area subject to dust, oil, andhigh humidity, could cause the insulation material to deteriorate.Turn off the main power before removing the power plug from the outlet.Check the power plug and cord for any problem (abnormal heat, rust,bend, cracks, scratches, etc.) at least once a month.If any problem is found with the power plug or cord, contact customerservice regarding a replacement cord/Never pull on the power cord to unplug the cord from the power supply.Always grip the plug to remove it from the power supply.If the printer will not be used for a long period, disconnect the power cordfrom the power source.Always keep the area around the power plug free of obstacles so that youcan unplug it easily. This allows you to unplug the power cord quickly in anemergency.Never use any power source other than the one rated for the printer. Thisprinter is designed to be used in the region where you purchased. Also,make sure that the power source can supply sufficient power for theprinter.Supply Voltage:AC 100-240 V, 50/60 HzPower Consumption:640 W (max.)Sleep Mode :41 WPage 12100-11672 - Rev D

Handling the Printer and AccessoriesTo avoid the risk of fire, electrical shock, personal injury, or damage to theprinter:If you find a large ink leak, switch the printer off immediately, disconnectthe power plug from the power source, and call for service.Never clean the printer with water or any flammable liquid (alcohol,benzene, thinner, etc.) either applied directly or with a cloth. If youaccidentally spill liquid on the printer, switch the printer off immediately,disconnect the power plug from the power source, and call for service.If the printer emits smoke, unusual odors, or makes noises, leaving it couldcause a fire or serious electrical shock or damage to the printer. Switch theprinter off immediately, disconnect the power plug from the power source,make sure that the printer has stopped smoking, and call for service. Donot attempt to repair the printer by yourself.Use only a slightly damp cloth, thoroughly wrung out, to clean the printersurfaces. Never use alcohol, thinner or any other flammable liquids, or riskhaving them come into contact with electrical components inside theprinter.There are high voltage points inside the printer. Never attempt todisassemble or repair the printer.Never insert or drop any metal objects into the printer when it is open. Thiscould cause a fire or serious electrical shock, or damage the printer. Ifsomething falls into the printer accidentally, switch the printer offimmediately, disconnect the power plug from the power source and call forservice.If the printer is dropped and damaged, switch the printer off immediately,disconnect the power plug from the power source, and call for service.Never use flammable sprays around the printer.Never remove the cover from the printer.Before cleaning the printer, switch it off and disconnect the power plugfrom the power source. This can prevent personal injury or damage to theprinter if you make a mistake during cleaning.Its is dangerous to put your fingers deep inside the ink cartridge boxes.There are pin-sharp parts which may hurt you; alternatively you may causedamage that could lead to a breakdown.Keep children from touching the power cord, internal parts of the printerwhen it is open, and moving parts inside the printer (gears, belts, rollers,and electrical components). This could cause personal injury or damagethe printer.To prevent machine failures, do not open the ink tank door or maintenancecartridge exchange door, do not turn off the printer, and do not remove thepower plug from the outlet while the printer is printing. If you do so, theprint head protection function is not performed properly, resulting in amachine failure or ink leakage which can soil your clothes and thesurrounding area.Do not apply excessive force or strong shocks to the upper unit. Doing socan result in a machine failure or impair print quality. Be sure to open/closethe upper unit slowly.100-11672 - Rev D Page 13

Do not place the printer close to devices such as televisions, radioreceivers, loudspeakers, etc. The magnetic fields these devices producemay cause the printer to malfunction, and the printer may interfere withTV/radio reception.Note: Be sure to turn off the power switch after the printer has stopped printing. Do not rapidly switch the printer off and on. This could damage the printer.After switching the printer off, wait at least 5 seconds before switching it onagain.Ink Tank and Maintenance CartridgesAlways store these items out of the reach of small children. This preventsaccidents. If a child accidentally swallows ink, seek medical attentionimmediately.If ink gets into your eyes, wash it out with flowing water immediately. Ifirritation persists, consult a physician.If ink comes into contact with your skin, rinse it off with flowing waterimmediately. If irritation persists, consult a physician.Never drop or apply excessive force to an ink tank or the maintenancecartridge. Ink can stain clothing and the work area.Never attempt to disassemble or modify the ink tanks. They contain ink,which may leak out and smear your clothes or things around you.Do not install or remove the ink tank or maintenance cartridge unless itneeds to be replaced. Doing so can accelerate wear of the printercomponents.Page 14100-11672 - Rev D

Chapter 3Step-by-Step Installation Procedures100-11672 - Rev D Page 15

This page intentionally left blankPage 16100-11672 - Rev D

Step-by-Step Installation InstructionsHow to Read This ProcedureWhen Using the Included PartsAfter unpacking this product, check the included parts against the illustrationsshown in “Checking the Included Parts” in this <strong>Guide</strong>.When the parts supplied with this product are required to be used in theinstallation procedure, the following symbol indicating that the parts aresupplied with the product is shown in the illustration. Confirm the symbol anduse the necessary included parts.About the Symbols Used in IllustrationsIn this guide, operations performed frequently are represented by the followingsymbols:100-11672 - Rev D Page 17

Step-by-Step Installation InstructionsSelecting the Installation SiteInstallation requirements are listed below. It is recommended that the user’sinstallation site be checked before delivery of the printer.1) Power Cord of the printer must connectable to the outlet (100V - 240V AC+10%/-15%)Caution: There must be an easily accessible outlet near the printer.2) The installation environment must be as described below. Avoid installingthe printer near a faucet, water heater, humidifier, or refrigerator. Operating temperature range: 5 to 35 degrees celsius Operating humidity range: 10%RH to 90%RH3) Avoid installing the printer near a fire, in a dusty place, or in a place whereammonia gas is generated. When installing the printer in a place exposed todirect sunlight, it is recommended that curtains be hung over the window.4) Any foot of the printer must not be floating above the floor . The printer mustbe kept in a horizontal position.5) The desk or table on which the printer is placed must be sturdy and stableenough to support the weight of the printer.6) Install the printer in a well-ventilated place, excluding the area near the airinlet of the room.7) Install the printer at least 100 mm away from each wall with a sufficient workspace around it.Page 18100-11672 - Rev D

Step-by-Step Installation InstructionsChecking the Installation Space1. The minimum space required for installation and maintenance is shownbelow.100-11672 - Rev D Page 19

Step-by-Step Installation InstructionsInstallation PrecautionsWhen installing the printer, observe the following precautions:1) Condensation can occur when the printer is moved from a low-temperatureplace to a high-temperature installation place. In such a case, leave the printeras it stands for at least 2 hours until it adjusts to the ambient temperature andhumidity, before starting the installation work.2) The printer weighs about 60 kg. At least 3 persons are required to install it.Page 20100-11672 - Rev D

Step-by-Step Installation InstructionsUnpacking Printer and Checking the Components1) Check that the following parts are included:100-11672 - Rev D Page 21

Step-by-Step Installation InstructionsUnpacking the Printer and Removing the FixturesNote: The printer is secured using fixing tape and cushioning materials toprotect it against the vibrations and shocks applied during transportation. Byfollowing the procedure described below, remove all pieces of fixing tape andcushioning materials before installing the printer. Keep the removedcushioning materials for future transportation for relocation or repair of theprinter.1) Remove two bands from the packing carton, and then remove the outercasing.2) Remove the upper pads and the accessory box.Page 22100-11672 - Rev D

Step-by-Step Installation Instructions3) Lift either side of the printer temporarily to remove the 2 lower pads. Next,lift the other side of the printer to remove the remaining 2 lower pads.4) Strip the plastic bag from the top to the bottom.100-11672 - Rev D Page 23

Step-by-Step Installation Instructions5) Holding the handles at the bottom of the printer, lift the printer to take it outfrom the package base.Caution: At least 3 persons are required to lift the printer. Do not hold the front side of the printer.Page 24100-11672 - Rev D

Step-by-Step Installation Instructions6) Place the printer on a horizontal table, and then remove all pieces of fixingtape and cushioning material visible on the exterior of the printer.7) Open Ink Tank Door, and then push Upper Unit Open Lever to open UpperUnit.8) Remove all pieces of fixing tape and cushioning material around thetransport area.Caution: There are Paper Holding Wheel Units in the circle of illustrationabove. Do not remove these units when removing tapes around.100-11672 - Rev D Page 25

Step-by-Step Installation Instructions9) Close Upper Unit and Ink Tank Door.Page 26100-11672 - Rev D

Step-by-Step Installation InstructionsMounting Rear Feeder <strong>Guide</strong>1) Mount the included Rear Feeder <strong>Guide</strong> on Rear Feeder Slot of Printer using2 included screws (TP screws, M4×8).100-11672 - Rev D Page 27

Step-by-Step Installation InstructionsLoading Ink Tanks1) Open Ink Tank Door.2) Open Ink Tank Lever for each color while pushing it downward.3) Take included Ink Tank out of Package, and then remove cushioningmaterial.Page 28100-11672 - Rev D

Step-by-Step Installation Instructions4) Slowly insert Ink Tank as far as it will go.Caution: Ink Tank cannot be loaded properly if it is inserted in the wrong Ink TankSlot. Insert Ink Tank securely and push it all the way as far as it will go.5) Close Ink Tank Lever.6) After checking that all Ink Tanks have been loaded, close Ink Tank Door.100-11672 - Rev D Page 29

Step-by-Step Installation InstructionsInitial Loading of Ink1) Connect the included Power Cord to the printer.2) Connect Power Cord to the outlet.3) Turn on Main Power Switch. Initial ink loading starts automatically whenMain Power Switch is turned on. About 25 minutes are required for initial inkloading. When initial ink loading is completed, the STATUS lamp lights and notblinking. Make sure that the STATUS lamp lights before proceeding to the nextstep.Caution: Do not turn off Main Power Switch during ink loading. If Main Power Switch is turned off during ink loading, Printer stops inkloading. In such a case, turn on Main Power Switch to start ink loadingagain. Restarting the ink loading causes extra waste-ink. Ink loading time might be changed due to the design change.Page 30100-11672 - Rev D

Step-by-Step Installation InstructionsPrinter Part Names and FunctionFront View[1] Upper unitOpen this unit when set paper or removing the paper jammed in the paperfeed path or cleaning inside of the machine. This unit incorporates printmodules, PCBs, and so on.[2] Operation panelThis panel has the key switches necessary for printer operation and the lampsthat indicate printer status.[3] Power switchUse this switch when the printer is scheduled to be unused for a long period oftime or it is relocated.[4] Ink tank doorOpen this door when replacing ink tanks. Ink tank door is locked while theprinter operates.[5] Paper delivery slotPaper is ejected through this slot.[6] Paper retainerThis retainer allows paper to be ejected steadily.[7] Maintenance cartridge doorOpen this door when replacing the maintenance cartridge. Maintenancecartridge door is locked while the printer operates.100-11672 - Rev D Page 31

Step-by-Step Installation Instructions[8] Stacker unitThis unit contains the tray to receive the ejected paper. Draw it out when usingit.Back View[1] LAN portConnect a LAN cable here to connect to the computer.[2] USB portConnect a USB cable here to connect to the computer.[3] Rear feeder slotThis slot is used to feed paper exceeding the paper tray capacity.[4] Rear Feeder <strong>Guide</strong>This component is the paper entrance guide used to feed paper from the rearof printer.[5] Power connectorConnect the power cord here.[6] USB cable clampCable clamps are provided to prevent the USB cable from being disconnectedcarelessly.Page 32100-11672 - Rev D

Step-by-Step Installation InstructionsInside the Printer[1] Upper unit release leverPush this lever up to release the upper unit.[2] Paper trayLoad paper in this tray.[3] Lift button for paper trayPressing this button moves the paper tray up and down.[4] Ink tanksBlack (Bk), Cyan (C), Magenta (M), and Yellow (Y) ink tanks are loaded.[5] Transport unitPaper is fed by this unit. Clean it if soiled by paper dust or ink.[6] Maintenance cartridgeInk used to clean the print head is collected here.100-11672 - Rev D Page 33

Step-by-Step Installation InstructionsOperation Panel[1] Power key/lampTurns power on/off, and wakes the printer up from the sleep mode. Lampstatus are as follows:OnPower-on.OffPower-off.Blinking Sleep mode.[2] RESET keyPressing this key down for about 1 second during printing cancels all jobs toabort printing.[3] FEED keyPressing this key in the offline mode feeds paper.[4] ONLINE keyPressing this key suspends/resumes printing.[5] ONLINE lampOnOffReady to print.Not ready to print.[6] Ink Warning lampOnNo ink or tank.Blinking Low ink.OffSufficient ink.[7] Maintenance Cartridge Warning lampOnFull.Blinking Nearly full.OffSufficient room to collect ink.Page 34100-11672 - Rev D

Step-by-Step Installation Instructions[8] Paper residual quantity lampOnNo paper.Blinking The remaining amount of paper is low. (Only when sheetsare supplied through Feeder Lift Tray. Lamp starts flashingwhen remaining papers become about 100 sheets).OffSufficient paper or during paper feed from rear feeder slot.[9] ERROR lampOnBlinkingOffOperator-call error (can be recovered by user operation).Fatal error.Normal.[10] STATUS lampOnOnline mode.Blinking Data being received (printing, cleaning, initializing,shut-down).OffPrinting is not possible (during error, sleep, pause etc.).Note: Never turn off the main power switch during a print job. This couldcause damage, because the printhead cannot return to the home position.Note: Never attempt to open the Upper unit by force or hit the door. This coulddamage the printer or result in poor print quality. Always open and close theUpper unit slowly.100-11672 - Rev D Page 35

Step-by-Step Installation InstructionsConnecting the Communication CableThe <strong>Printrex</strong> ® <strong>980</strong> is equipped with two interface ports. These interfaces are: USB 2.0 Gigabit EthernetConnect the appropriate communications cable to the printer as shown in thefollowing figures. Cables are provided by your dealer, the system installer orare available through <strong>Printrex</strong>.Connect a USB cableNote: You can disconnect the USB cable even while the printer and computerare on, but do not disconnect the USB cable in the cases described below.This could prevent the printer from operating normally. While the computer is starting up (until the desktop display appears). While the printer is printing. While you install the printer driver.To disconnect the USB cable while the computer and the printer are on,disconnect it at the computer or the USB hub. To reconnect the USB cable,wait at least 5 seconds before you connect it again. If you reconnect itimmediately, the printer may not operate correctly.Note: A USB cable is not provided with the printer. Please prepare a cablethat matches the port on your computer.Connect the USB cable to the printer first, as shown in the figure, and then tothe computer.Page 36100-11672 - Rev D

Step-by-Step Installation InstructionsNote: Whenever connecting a USB cable to the printer, put the USB cable inthe cable clamps as shown in the figure.Connect a LAN cableConnect the LAN cable to the printer, as shown in the figure, and then thecomputer.Note: Please consult your network administrator when connecting to an officeLAN.Note: If a printer driver has not been installed in the computer to which youwant to connect your printer, install it before connecting the USB cable or LANcable.Switching the Printer On and OffSwitching the Printer On1. Turn on the power switch.When the [STATUS] lamp which has been blinking stays lit, the printer isready for printing.100-11672 - Rev D Page 37

Step-by-Step Installation Instructions2. The STATUS lamp stays lit.Note: When the printer is in the sleep mode, press the power key to return theprinter to Online mode. Printer will also wake up from the sleep modeautomatically as soon as it starts receiving a print job.Page 38100-11672 - Rev D

Step-by-Step Installation InstructionsSwitching the Printer Off1. Press the power key for a few seconds more than one second.Power lamp blinks and the printer enters the sleep mode.2. Turn off the power switch.If the printer is already in the sleep mode, just turn off the power switch.100-11672 - Rev D Page 39

Step-by-Step Installation InstructionsPaper Loading Procedure (Inside)This section describes how to load paper.1. Make sure that the Power key lamp on the operation lamp stays lit. If theprinter has been turned off completely, turn on the main power switch. Whenthe printer is in the sleep mode, press the Power key.2. Open the ink tank door.3. Push the upper unit release lever up to open the upper unit.Page 40100-11672 - Rev D

Step-by-Step Installation Instructions4. Open the upper unit.5. Press the lift button for paper tray. The paper tray moves up.100-11672 - Rev D Page 41

Step-by-Step Installation InstructionsNote: Do not touch the lifting mechanism while the paper tray is movingup/down. Your fingers could be caught in the machine and this could causeinjury.6. Draw out the paper tray slowly.Page 42100-11672 - Rev D

Step-by-Step Installation Instructions7. Load paper in the paper tray.Load paper with the black mark located on the tip right side of the back of theprinting surface.100-11672 - Rev D Page 43

Step-by-Step Installation Instructions8. After loading paper, push the paper tray all the way.9. Press the lift button for paper tray to move the paper tray down.Note: Follow the same procedure when replacing paper. When the paper trayhas been set in position, the "lift" button for paper residual quantity lamp.Page 44100-11672 - Rev D

Step-by-Step Installation Instructions10. When the paper tray has moved down completely, draw out the stackerunit, then raise the bar.11. Pull out paper, and then place paper on the stacker unit.100-11672 - Rev D Page 45

Step-by-Step Installation InstructionsNote: When setting paper in transport area, place it against paper guides onthe right side. Set paper such that it is not slackened.Note: Largely slack paper can jam. To prevent this, pull out paper over thetransport unit as straight as possible.12. Close the upper unit and then close the ink tank door.Page 46100-11672 - Rev D

Step-by-Step Installation InstructionsNote: Close the upper unit gently to avoid catching your hands, as this mayresult in personal injury.13. Paper is automatically fed to the printing position.Note: Load paper in printer immediately after unpacking it. Paper remainingafter completion of printing may be held loaded in printer or stored in the paperstorage box. If printer is not used for an extended period of time, be sure tostore paper in the paper storage box.100-11672 - Rev D Page 47

Step-by-Step Installation InstructionsPaper Loading Procedure (Rear)This section describes the method for loading the paper to be fed from the rearof printer.1. Make sure that the Power key lamp on the operation lamp stays lit.If the printer has been turned off completely, turn on the power switch. Whenthe printer is in the sleep mode, press the Power key.2. Open the ink tank door.Note: If there is paper in the paper tray, remove it and then move the papertray down.3 Push the upper unit release lever up to open the upper unit.Page 48100-11672 - Rev D

Step-by-Step Installation Instructions4. Open the upper unit.5. When the paper tray has moved down completely, draw out the stacker unit,then raise the bar.100-11672 - Rev D Page 49

Step-by-Step Installation Instructions6. Insert paper in the feeder slot provided on the back of the printer.Note: When supplying paper from the rear of printer, place the paper storagebox containing paper below Feeder Slot at the back of printer, at a height thatis 100-820 mm lower than Feeder Slot, and then load paper in printer.Note: Place the paper storage box in such a manner that paper is not fed toprinter askew.Page 50100-11672 - Rev D

Step-by-Step Installation Instructions7. Pull out paper from the paper tray.8. Pull out paper, and then place paper on the stacker unit.100-11672 - Rev D Page 51

Step-by-Step Installation InstructionsNote: When setting paper in transport area, place it against paper guides onthe right side. Set paper such that it is not slackened.Note: Largely slack paper can jam. To prevent this, pull out paper over thetransport unit as straight as possible.9. Close the upper unit and then close the ink tank door.Page 52100-11672 - Rev D

Step-by-Step Installation InstructionsNote: Close the upper unit gently to avoid catching your hands, as this mayresult in personal injury.10. Paper is automatically fed to the printing position.Note: Load paper in printer immediately after unpacking it. Paper remainingafter completion of printing may be held loaded in printer or stored in the paperstorage box. If printer is not used for an extended period of time, be sure tostore paper in the paper storage box.100-11672 - Rev D Page 53

Step-by-Step Installation InstructionsReplacing Ink TanksWhen the ink in an ink tank runs low, the Status Monitor displays [XXXX inklow] message to alert you that ink is about to run out. You can continue toprint, and when the ink supply is exhausted, the [Out of XXXX ink] error will bedisplayed.There are four colors of ink cartridges: Black (Bk), Cyan (C), Magenta (M), andYellow (Y).Note: To maintain print head quality, the printer stops operating before it iscompletely out of ink. That is, a small amount of unusable ink remains inthe used ink tank. To get a good printing result, use up each ink tank within six months of firstopening the package. Do not remove an ink tank unless you must replace it. This could shortenthe life of the consumables. Complete the ink tank replacement procedure as quickly as possible. Donot leave the printer with ink tanks removed. An ink tank left in a high-temperature place can deform. However, there isnothing wrong with its functions. It is recommended that ink tanks be stored in a place where thetemperature does not rise to extreme ranges.Note: When a message “XXX ink low” appears, get a new ink tank as soon aspossible. You cannot open the ink tank door while the printer is operating. To maintain the best printing quality, please use only <strong>Printrex</strong> ® <strong>980</strong> inktanks.The positions of the ink tanks are as shown below.The printer is designed so that ink tanks cannot be inserted in wrong ink tankslots. Do not attempt to insert ink tanks in wrong ink tank slots forcibly.Page 54100-11672 - Rev D

Step-by-Step Installation Instructions1. Open the ink tank door.2. Pull the lever down.100-11672 - Rev D Page 55

Step-by-Step Installation Instructions3. Remove the empty ink tank.Note: Do not touch the ink outlet and terminal to prevent soiling of the thesurrounding work area, damage to the ink tank, and poor printing.Note: Never apply excessive force nor drop an ink tank. Ink can stain clothingand the work area.Page 56100-11672 - Rev D

Step-by-Step Installation Instructions4. Slowly insert a new ink tank all the way.5. Close the ink tank lever securely.Note: There are sharp pins in ink tank slots. Never put your fingers into thisarea. This could cause personal injury or damage the printer.100-11672 - Rev D Page 57

Step-by-Step Installation Instructions6. Close the ink tank door.Note: After installing an ink tank, do not remove it unless you must replace it.This could shorten the life of the consumables. Complete the ink tank replacement procedure as quickly as possible. Donot leave the printer with ink tanks removed. Be careful not to stain your clothes and the surrounding work area by theused ink tanks.Page 58100-11672 - Rev D

Step-by-Step Installation InstructionsReplacing the Maintenance CartridgeWhen there remains no maintenance cartridge space to collect ink, an errormessage, “Maintenance Cartridge full,” is displayed on the status monitor, andprinting stops. Replace the maintenance cartridge with a new one.Note: For safety, keep the Maintenance Cartridge out of the reach of children.If ink is accidentally ingested, contact a physician immediately.Note: To prevent ink from leaking from a used Maintenance Cartridge, avoiddropping the cartridge or storing it at an angle. Otherwise, ink may leak and cause stains. Ink adheres to the top of the Maintenance Cartridge after it has been used.Handle the Maintenance Cartridge carefully during replacement. The ink maystain clothing.1. While lifting the eject guide slightly, open the maintenance cartridge door.100-11672 - Rev D Page 59

Step-by-Step Installation Instructions2. Draw out the maintenance cartridge slowly.3. Take out new maintenance cartridge from a box.4. While lifting the eject guide slightly, insert a new maintenance cartridge.Page 60100-11672 - Rev D

Step-by-Step Installation Instructions5. While lifting the eject guide slightly, close the maintenance cartridge door.6. Put the used maintenance cartridge in a bundled plastic bag and dispose ofit.Note: Please dispose the old maintenance cartridge according to federal,state and local laws after being packed in a bundled plastic bag and placed inthe box.100-11672 - Rev D Page 61

Step-by-Step Installation InstructionsChecking the Test PrintsMake the following test prints and confirm that all the print images arecorrectly tuned. Should the image in each test print need to be tuned, take anadjustment procedure corresponding to each test print: Nozzle check pattern TK-GAP adjustment pattern Slant Adjustment Pattern Head Position Adjustment PatternPrinting and Examining Nozzle Check Pattern1) Start the PC.Note: Printer driver must be installed in the PC in advance.2) Connect Printer to the PC using a USB cable.3) Click [Start] > click [Devices and Printers] > right click [<strong>980</strong>] > click [Printerproperties] > click [Utility] > click [Service]Page 62100-11672 - Rev D

Step-by-Step Installation Instructions4) Open the [Test Print, Adjustment] tab of the "<strong>980</strong> Service Utility" dialog box.5) Click [Nozzle Check Pattern] to print the nozzle check pattern.100-11672 - Rev D Page 63

Step-by-Step Installation Instructions6) Check the printed nozzle check pattern. If a non-discharge is detected,perform cleaning with reference to the next section “Cleaning Procedure”.Page 64100-11672 - Rev D

Step-by-Step Installation InstructionsCleaning Procedure1) Open the [Cleaning, User Setting] tab of the "<strong>980</strong> Service Utility" dialog box.2) Select Print Module to be cleaned.100-11672 - Rev D Page 65

Step-by-Step Installation Instructions3) Perform the printhead cleaning according to the table below.ModeTime required for DescriptioncleaningLight CleaningMediumAbout 0.5minutesAbout 3 minutesIf an ink injection problem is detected, perform“Light Cleaning” first. If the problem persists evenafter “Light Cleaning” is performed several times,CleaningStrong Cleaning About 7 minutesperform “Medium Cleaning”. If the problem stillpersists after “Medium Cleaning” is performedseveral times, perform “Strong Cleaning”.Page 66100-11672 - Rev D

Step-by-Step Installation InstructionsPrinting TK-GAP Adjustment Pattern1) Open the [Test Print, Adjustment] tab and click [Adjust TK-GAP] to displaythe "Print TK-GAP" dialog box.2) Click [Print] to print the TK-GAP adjustment pattern.100-11672 - Rev D Page 67

Step-by-Step Installation InstructionsExamining and Adjusting TK-GAP1) Observe the TK-GAP Adjustment Pattern and examine if the TK-GAPadjustment is necessary for Print Modules according to the following. Performthe adjustment, if necessary.Find where the paper perforation is located on the TK-GAP adjustmentpattern scale. If the paper perforation is at the “+2” position on the TK-GAPadjustment pattern scale, the adjustment value is “+2”.Page 68100-11672 - Rev D

Step-by-Step Installation Instructions2) Enter the adjustment values in the TK-GAP adjustment value entry boxes inthe "Print TK-GAP" dialog box.3) After entering the TK-GAP adjustment values, click [Send] to send theadjustment values to Printer.4) If the TK-GAP adjustment pattern is not required to print again for a review,click [NO] and proceed to the step 6).100-11672 - Rev D Page 69

Step-by-Step Installation Instructions5) If the TK-GAP adjustment pattern is desired for reviewing, click [Yes].6) Click [Next] to proceed to the slant adjustment.Page 70100-11672 - Rev D

Step-by-Step Installation InstructionsPrinting Slant Adjustment Pattern1) Open the [Test Print, Adjustment] tab and click [Adjust Slant] to display the"Print Head Slant" dialog box.2) Click [Print] to print the slant adjustment pattern.100-11672 - Rev D Page 71

Step-by-Step Installation InstructionsExamining and Adjusting Slant1) Read values at which Black lines are in line with line of each color (Cyan,Magenta, or Yellow).When a value of A is the same as a value of B:• Example 1: When the value of C1A (+2) is the same as the value of C1B(+2), no adjustment is required for C1 (Cyan Printhead 1).When a value of A is different from a value of B:• Example 2: When the value of Y1A (+2) is different from the value of Y1B(+3), the adjustment has to be made for Y1.Page 72100-11672 - Rev D

Step-by-Step Installation Instructions2) Enter necessary adjustment values in the slant adjustment value entryboxes in the "Print Head Slant" dialog box.3) After entering the slant adjustment values, click [Send] to send theadjustment values to Printer.4)If the slant adjustment pattern is not required to print again for a review, click[NO] andproceed to the step 6).100-11672 - Rev D Page 73

Step-by-Step Installation Instructions5) If the slant adjustment pattern is desired for reviewing, click [Yes].6) Click [Next] to proceed to the head position adjustment.Page 74100-11672 - Rev D

Step-by-Step Installation InstructionsPrinting Head Position Adjustment Pattern1) Open the [Test Print, Adjustment] tab and click [Adjust Position] to displaythe "Print Head Position Adjustment" dialog box.100-11672 - Rev D Page 75

Step-by-Step Installation Instructions2) Click [Print] to print the head position adjustment pattern.Page 76100-11672 - Rev D

Step-by-Step Installation InstructionsExamining and Adjusting Printhead Position1) Module-to-Module AdjustmentThis adjustment is to align the relative print positions of 2 Print Modules toeach other.The relative print positions in the feeding direction can be examined in the"KV" scale.For the example shown in the figure, the 2 elements are in line at "+2". Thus,the adjustment value is "+2".The relative print positions in the cross-feeding direction can be examined inthe "KH" scale. For the example shown in the figure, the 2 elements are in lineat "+2". The adjustment value is therefore "+2".100-11672 - Rev D Page 77

Step-by-Step Installation Instructions2) Head Position AdjustmentThis adjustment is to align the relative color registrations in all the printheads.The relative color registrations in the feeding direction can be examined in the"xxV" scale and the ones in the cross-feeding direction can be examined in the"xxH" scale.Determine at which division of a scale, two color elements are in line for all the12 blocks. For the example in the "M1V" block, the Magenta and Blackelements meet at "+4".Page 78100-11672 - Rev D

Step-by-Step Installation Instructions3) Enter adjustment values in the Module-to-Module adjustment value entryboxes in the "Print Head Position Adjustment" dialog box.100-11672 - Rev D Page 79

Step-by-Step Installation Instructions4) Click [Go to Step 3].Page 80100-11672 - Rev D

Step-by-Step Installation Instructions5) Enter the adjustment values in the Head Position Adjustment value entryboxes.100-11672 - Rev D Page 81

Step-by-Step Installation Instructions6) Click [Go to Step 4].Page 82100-11672 - Rev D

Step-by-Step Installation Instructions7) Enter the adjustment values in the Head Position Adjustment value entryboxes.100-11672 - Rev D Page 83

Step-by-Step Installation Instructions8) Click [Send] to send all the adjustment values to Printer.9) If the head position adjustment pattern is not required to print again for areview, click [NO]and proceed to step 10.10) If the head position adjustment pattern is desired for reviewing, click [Yes].Page 84100-11672 - Rev D

Step-by-Step Installation Instructions11)Press Power Key for at least 1 second to place Printer in the sleep mode(Power Lamp blinks), and then turn off Main Power Switch.100-11672 - Rev D Page 85

Step-by-Step Installation InstructionsAction of Relocating PrinterThe Printer is filled with ink in its Ink Supply System, Imaging System andelsewhere. Implement items suggested below thoroughly and explain tocustomers fully to prevent ink spills in or outside Printer or to avoidunexpected failures when Printer is transported.Caution:Do not incline Printer more than 15° degrees during relocation.Relocating from One Place to Another on Same Floor or in Same BuildingPrinter required to drain (suction) remaining ink in Purge Unit before movingPrinter on the same floor or in the same building. Ink drainage is performedwith service utility .Ink drainage procedure1) Connect PC to Printer, and then start service utility.2) Open the [Cleaning,User Setting] tab, and then click [Moving the printer].Page 86100-11672 - Rev D

Step-by-Step Installation Instructions2) When the following message is displayed, click [Yes] to drain remaining inkin Purge Unit.Note: Ink drainage takes approximately 2 minutes. The time might be changed due to the specification change.Long Distance RelocationPrinter required to return ink from Print Module to Ink Tank and to drain(suction) remaining ink in Purge Unit before shipping Printer long distance. Inkreturning and drainage is performed with service utility.Ink returning and drainage procedure1) Connect PC to Printer, and then start service utility.2) Open the [Cleaning, User Setting] tab, and then click [Shipping the printer].100-11672 - Rev D Page 87

Step-by-Step Installation Instructions3) When the following message is displayed, click [Yes] to start return ink fromPrint Module to Ink Tank, and wait for a while.Note: Ink returning and drainage takes approx. 20 minutes. The time might be changed due to the specification change.4) When the following message is displayed, remove Ink Tanks, and thenclose Ink Tank Door.Page 88100-11672 - Rev D

Step-by-Step Installation Instructions5) When the following message is displayed, turn off Main Power Switch.100-11672 - Rev D Page 89

Chapter 4<strong>Printrex</strong> ® <strong>980</strong> Specifications andRequirements100-11672 - Rev D Page 91

This page intentionally left blankPage 92100-11672 - Rev D

<strong>Printrex</strong> ® <strong>980</strong> Specifications and Requirements<strong>Printrex</strong> ® <strong>980</strong> Specifications and RequirementsStandard FeaturesThe following features are standard for <strong>Printrex</strong> ® <strong>980</strong> printers:Massively parallel bubble jet technology8 inches per second plot speed9.25" wide media, 8.25" (216 mm) print widthPrint head resolution: 1200 dots per inch horizontal, 600 dots per inchverticalNo limitation on plot length, allowing plotting of continuous logsPrint quality enhancement features, including:o Depth Line Accuracy, ensuring accuracy of scaleo Stitching Stream Technology, to ensure no gaps in plotting evenwhen the printer temporarily lacks datao Automatic Image Shifter, to extend print head lifeHigh capacity (240 ml) ink tankso 25,000 standard pages at 5% coverageFour separate ink tanks for easy exchange of individual colorsAutomatic head cleaning cycleUSB 2.0 High Speed and Gigabit Ethernet100-11672 - Rev D Page 93

<strong>Printrex</strong> ® <strong>980</strong> Specifications and RequirementsPhysical Printer Specifications15.5"20.0"19.0"Max DimensionsDimensions ininchesW D H15.5 20.0 19.0Weight:approx. 123 lbs. (56 kg)InterfaceUSB 2.0 High Speed and Gigabit EthernetEnvironmental ConditionsThe <strong>Printrex</strong> ® <strong>980</strong>0 is designed to be placed on a flat, stable surface that cansupport the weight of the printer (about 123 lbs. or 56 kg). Be aware that theenvironmental conditions of the location where you place the printer will havean effect on the printer’s performance and longevity. The printer will run itsbest when stored and operated in an environment that meets the temperatureand humidity conditions described below.Typical operating range: 5°C to 35°C / 50°F to 104°FPage 94100-11672 - Rev D

<strong>Printrex</strong> ® <strong>980</strong> Specifications and RequirementsElectrical Specifications100 VAC - 240 VAC, 50-60 Hz650 watts maximumMedia SpecificationsPaperPaper feed methodPaper widthPaper thicknessFriction feed9.25 inches0.003 - 0.0035 inchesUSB InterfaceThe USB interface is a Version 2.0 interface card is implemented through astandard Series "B" receptacle as defined in the USB Specification. Theprinter is self-powered and does not draw power from the standard Type BUSB interface cable.The standard USB Type B connector has the following pin functions:Pin Signal1 Vbus (+5 V dc) (Not used in the <strong>Printrex</strong> ® <strong>980</strong>)2 Minus data3 Plus data4 GroundNote: The standard USB interface does not have sufficient power to run theprinter.100-11672 - Rev D Page 95

Chapter 5Printer Maintenance100-11672 - Rev D Page 97

This page intentionally left blankPage 98100-11672 - Rev D

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> PrinterCleaning the PrinterAs the printer is used, ink and paper dust will be collected inside the printer. Ifthe interior of the printer becomes dirty, this will cause printouts to becomedirty, affect print quality, or interfere with smooth paper feeding.Clean the printer periodically to keep the printer in optimum working condition.Moisten a clean cloth in a weak solution of water and detergent, wring it outthoroughly, then use it to clean the exterior covers of the printer.Note: Use only a slightly damp cloth, thoroughly wrung out, to clean the printerinterior. Never use alcohol, thinner, benzene or any other flammable liquids. Thiscould cause a fire or serious electrical shock.Note: Before cleaning the printer, switch it off and disconnect the power plugfrom the power source. This can prevent personal injury or damage to theprinter if you make a mistake during cleaning. There are four sharp pins inside the ink tank slots. Never put your fingersinto this area. This could cause personal injury or damage to the printer.1. Press the Power key for a few seconds. The Power lamp will blink, and theprinter will enter sleep mode.100-11672 - Rev D Page 99

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> Printer2. Turn off the main power switch, and then remove the power plug from thewall outlet.3. Open the ink tank door.Page 100100-11672 - Rev D

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> Printer4. Push the upper unit release lever up to open the Upper unit.5. Open the upper unit.100-11672 - Rev D Page 101

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> Printer6. Wipe off ink, dust and paper dust adhered around transport and upper unit’sbottom areas (spur, roller, paper ejection slot) with a cloth dipped in water andtightly wrung out.Note: Do not clean the printer with tissues or paper towels. Torn pieces ofpaper or paper dust may get inside the printer and cause malfunctions.Note: If "Paper length error" or "Paper jam error" has occurred and an errormessage is continuously displayed, the paper detection area may be soiledwith paper dust or the like. Clean the area with a cotton swab.Page 102100-11672 - Rev D

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> Printer7. Close the upper unit and then close the ink tank door.100-11672 - Rev D Page 103

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> PrinterClearing Paper JamsIf the paper jams while the printer is printing, the printer will stop and theStatus Monitor will display a paper jam message. Follow the procedure belowto remove the jammed paper.1. Open the ink tank door, and then push the upper unit release lever up toopen the upper unit.2. Remove the paper jammed on the transport unit.Page 104100-11672 - Rev D

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> Printer3. Cut the paper along the perforation.100-11672 - Rev D Page 105

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> PrinterMoving the printerAfter moving the printer on the same floor or to another floor, install it properlyfollowing the procedure described below.1. Press the Power key to place the printer in the sleep mode. If the printer isalready in sleep mode, go to step 2.2. Press the main power switch below the operation panel to turn the printeroff completely.3. Disconnect the interface cable and power cord.4. Make sure that the upper unit is closed securely.Page 106100-11672 - Rev D

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> Printer5. Move the printer.Note: To move the printer on the same floor or within the same building, the inktanks need not be removed. If the ink tanks are removed before movingthe printer, ink can leak from the needle sections in the ink tank slots,which may stain clothes and/or the surrounding work area. Always hold the printer level and carry it slowly. If ink is spilled inside theprinter while moving it, this could cause a fire or serious electrical shock ordamage the printer. The printer weighs about 123 pounds (57kg). Three persons are alwaysrequired to move the printer. When lifting and moving the printer, theyshould hold the handles at the bottom so that they do not injurethemselves. If they hold other parts of the printer, the printer can bedamaged and/or it can drop and injure people. Do not move the printer with the upper unit, ink tank door, or maintenancecartridge door open. This can damage the printer.6. After moving the printer to the destination, connect the power cord and thenconnect the interface cable.7. Turn on the main power switch.100-11672 - Rev D Page 107

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> Printer8. After completion of the initial operation, the printer is ready for printing.Page 108100-11672 - Rev D

How to Operate the <strong>Printrex</strong> ® <strong>980</strong> PrinterShipping the PrinterWhen transporting printer over a long distance, observe the followingprocedures:Contact <strong>Printrex</strong> technical support for advice before you ship the printer along distance or move the printer via car, truck or airplane. Moving theprinter without proper preparation could subject it to shock and vibration,which could damage the printer and/or cause a fire.Before transporting the printer, be sure to drain the printer of ink. If inktanks are removed before draining the printer of ink, ink leaks from theneedle sections in the ink tank slots could stain your clothes andsurrounding work areas.The printer weighs about 123 pounds (57kg). Three persons are alwaysrequired to move the printer. When lifting and moving the printer, theyshould hold the handles at the bottom so that they do not injurethemselves. If they hold other parts of the printer, the printer can bedamaged and/or it can drop and injure people.Note: Do not move the printer with the upper unit, ink tank door, ormaintenance cartridge door open. This can damage the printer.100-11672 - Rev D Page 109

Chapter 6Troubleshooting100-11672 - Rev D Page 111

This page intentionally left blankPage 112100-11672 - Rev D

Appendix A: Ordering Genuine Ithaca SuppliesInitial Check ItemsChecking the Installation EnvironmentCheck whether the installation place meets the following requirements:1) The power supply voltage must be the rated voltage from -15% to +10%and the power supply frequency must be the rated frequency ±2Hz.2) The printer must be held horizontal.3) The ambient temperature must be held at 15-30 degrees and the humidityat 10-80%.4) Avoid the place where both the temperature and humidity are high (near thefaucet, boiler, or humidifier), the temperature is extremely low, the temperaturechanges greatly. Also avoid placement near fire or flame.5) Avoid dusty locations.6) Avoid the place exposed to direct sunlight. If it is inevitable to install theprinter in such a place, instruct the customer to hang curtains.7) The room must be well-ventilated.Checking the Paper1) Check whether dedicated paper is used.2) Check whether the paper is moist. Unpack new paper, load it in the printer,and check for printing.3) Check whether the paper is curled.Checking SettingsCheck whether the settings made for the printer are suitable for the paperused and other requirements, specifically, in terms of the following:1) Paper settingPaper size (height and width)2) Printing conditionNumber of prints3) Interface settingUSB 2.0 High Speed Function (1ch)Giga Bit Ether Net4) Saving of set conditionsCheck whether settings have been saved properly.100-11672 - Rev D Page 113

Appendix B: Frequently Asked QuestionsProcedures for Operation FailurePaper dust falling from the paper pass on the reflecting plate may reflect thelight to the receiving of Rear Feeder Sensor and/or Trailing Edge Sensor.Those reflecting plates need to be cleaned.Rear Feeder Sensor Cleaning1) Remove Right Cover.("Removing Right Cover" section)2) Remove Left Cover.("Removing Left Cover" section)3) Remove Rear Lower Cover.("Removing Rear Lower Cover" section)4) Remove Rear Feeder Sensor.• 1 Screw• 1 Clamp5) Wipe reflecting plate with the cotton swab.Page 114100-11672 - Rev D

Appendix A: Ordering Genuine Ithaca SuppliesTrailing Edge Sensor Cleaning1) Open Upper Unit.2) Wipe reflecting plate with a cotton swab.100-11672 - Rev D Page 115

Appendix B: Frequently Asked QuestionsImage Defect RecoverySamples of image defects that can be detected through test printing aredescribed below. When an image defect is found, carry out test printing todetermine the image defect type, and then perform an appropriate procedure.Vertical White Streak (Non-Discharge)This is a state in which ink drops cannot be discharged from Printhead nozzlesdue to dust, bubbles, thickened ink, wetting, etc. around Printhead nozzle.Page 116100-11672 - Rev D

Appendix A: Ordering Genuine Ithaca SuppliesFaint Image (Distortion)This is a state in which ink drops cannot be discharged from Printhead nozzlesdue to dust, bubbles, thickened ink, wetting, etc. around Printhead nozzle, or astate in which a condensed ink film is formed on the surfaces of Printheadnozzles, and as a result ink drops are not ejected.100-11672 - Rev D Page 117

Appendix B: Frequently Asked QuestionsVoidThis is a state in which a void is generated due to defective parts of Printhead,Flexible Cable, PCB, etc. or a bad connection.Page 118100-11672 - Rev D

Appendix A: Ordering Genuine Ithaca SuppliesAbnormal DischargeThis is a state in which ink is ejected to an area having no image data due todefective parts of the Printhead, Flexible Cable, PCB, etc. or a badconnection.100-11672 - Rev D Page 119

Appendix B: Frequently Asked QuestionsUneven Image (Cross Feeding Direction)This is a state in which stripes differing in thickness are generated in thelongitudinal direction of the Printhead.Page 120100-11672 - Rev D

Appendix A: Ordering Genuine Ithaca SuppliesUneven Image (Feeding Direction)This is a state in which stripes differing in thickness are generated in thetransport direction.100-11672 - Rev D Page 121

Appendix B: Frequently Asked QuestionsRelative Misregistration in Colors in X or Y DirectionThis is a state in which registration positions of individual colors are deviated,and as a result colors look shifted.Page 122100-11672 - Rev D

Appendix A: Ordering Genuine Ithaca SuppliesMisregistration (Leading edge and side edge)Print image coordinate is not aligned with the paper. The following sampleshows misregistration in the side edge.100-11672 - Rev D Page 123

Appendix B: Frequently Asked QuestionsBlank ImageThis is a state in which the print sheet is ejected with no image printed on it.Page 124100-11672 - Rev D

Appendix A: Ordering Genuine Ithaca SuppliesPaper SkewThis is a state in which an image is printed on a skew in relation to the left andright edges of the print sheet.100-11672 - Rev D Page 125

Appendix B: Frequently Asked QuestionsSpur Marks (White Dotted Lines)This is a state in which pressed Spur marks are made on the print sheet.Page 126100-11672 - Rev D

Appendix A: Ordering Genuine Ithaca SuppliesInk Smearing (Due to Printhead Crash)This is a state in which the print sheet touches the Printhead and is stainedwith ink.100-11672 - Rev D Page 127

Appendix B: Frequently Asked QuestionsSpur Marks (Dotted Lines)This is a state in which ink is transferred to Spur or Spur cleaner due to inkdripping, fixing error, etc. and as a result Spur ink marks are made on the printsheet.Page 128100-11672 - Rev D

Appendix A: Ordering Genuine Ithaca SuppliesInk Adhesion (Ink Dripping)This is a state in which ink collected in Printhead or Purge Unit drips off totransport area, and as a result ink adheres to the front/back surface of the printsheet.100-11672 - Rev D Page 129

Appendix B: Frequently Asked QuestionsDefect Recovery ProceduresVertical White Streak or Faint ImageCause Procedure Check Item ActionInk Supply 1 Carry out Light Cleaning, Medium EndSystemCleaning, and Strong Cleaning 2 or 3times for each cleaning, and then checkthat the defect has been recovered.Ink Supply 2 Carry out Ink Loading, and then check EndSystemthat the defect has been recoveredPrinthead 3 Carry out Printhead face cleaning, andthen check that the defect has beenrecovered.EndPurge Unit 4 Blade, cap, or cap base is contaminatedwith dust or foreign matter, or it isscratched or deformed.Printhead 5 Replace Printhead, and then check thatthe defect has been recovered.Print Module 6 Replace Print Module, and then checkthat the defect has been recovered.PrinterControllerPCB7 Replace Printer Controller PCB, and thencheck that the defect has beenrecovered.Replace PurgeUnit.Void or Abnormal Discharge (Test Printing Result: NG)Cause Procedure Check Item ActionConnection of 1 Proceed reconnection recovery *1, and EndPrinthead toPrintheadRelay PCBthen check that the defect has beenrecovered.FlexibleCable2 The connector of Flexible Cable is notconnected securely.Connect itproperly.3 Flexible Cable has a defect such as ReplacePrintheadRelay PCBdisconnection, crack, or ink adhesion.4 Replace Printhead Relay PCB, and thencheck that the defect has beenrecovered.Printhead 5 Replace Printhead, and then check thatthe defect has been recovered.PrinterControllerPCB6 Replace Printer Controller PCB, and thencheck that the defect has beenrecovered.Print Module 7 Replace Print Module, and then checkthat the defect has been recovered.EndEndEndFlexible CableEndEndEndEndPage 130100-11672 - Rev D

Appendix A: Ordering Genuine Ithaca Supplies*1 Reconnection Recovery Procedure:1) Service Utility > Troubleshooting2) Choose Print Module #1 and/or #23) Click "Head Install Position"4) Turn off the power.5) Remove covers.6) Rotate up Upper Printhead Release Lever until it stops.7) Rotate down Upper Printhead Release Lever until it stops.8) Attach covers.9) Turn on the power.100-11672 - Rev D Page 131

Appendix B: Frequently Asked QuestionsVoid or Abnormal Discharge (Test Printing Result: OK)Cause Procedure Check Item ActionInterfaceCable1 Interface Cable is not connectedsecurely.Connect itproperly.2 The cable has a defect such asdisconnection or crack.Replace thecable.Printer Driver 3 Any setting or stored print data iserroneous.Correct thesetting or printdata.4 Reinstall printer driver, and then check EndPrinterControllerPCBthat the defect has been recovered.5 Replace Printer Controller PCB, and thencheck that the defect has beenrecovered..Uneven Image (Cross Feeding Direction)Cause Procedure Check Item ActionInk Supply 1 Carry out Light Cleaning, Medium EndSystemCleaning, and Strong Cleaning 2 or 3times for each cleaning, and then checkthat the defect has been recovered.Printhead 2 Replace Printhead, and then check that EndPrinterControllerPCBthe defect has been recovered.3 Replace Printer Controller PCB, and thencheck that the defect has beenrecovered.Print Module 4 Replace Print Module, and then checkthat the defect has been recovered.EndEndEndUneven Image (Feeding Direction)Cause Procedure Check Item ActionRegistrationAdjustment1 Carry out registration adjustment, andthen check that the defect has beenEndrecovered.Printhead 2 Printhead Unit is not assembledproperly.3 Unit is not installed properly. Reinstall itproperlyPinch Roller 4 Unit is not installed properly. Reinstall itUnit or SpurproperlyUnitTransportUnit5 Pinch Roller or Spur does not rotatesmoothly.6 Transport Belt is not located at thecorrect position.7 Replace Transport Motor, and thencheck that the defect has beenrecovered.Reassemble itproperlyReplace PinchRoller Unit orSpur UnitMove TransportBelt back to thecorrect position.EndPage 132100-11672 - Rev D