Installation Guideline MPC Micro-Topping System Interior ... - Miracote

Installation Guideline MPC Micro-Topping System Interior ... - Miracote

Installation Guideline MPC Micro-Topping System Interior ... - Miracote

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

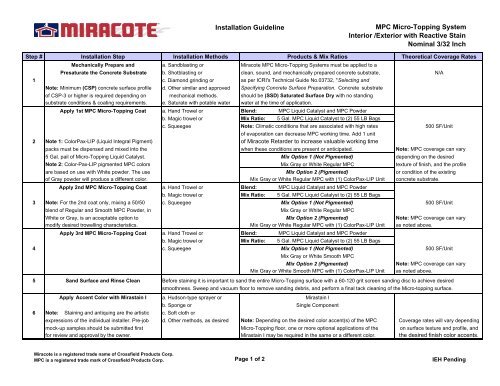

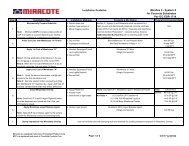

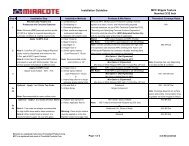

<strong>Installation</strong> <strong>Guideline</strong><strong>MPC</strong> <strong>Micro</strong>-<strong>Topping</strong> <strong>System</strong><strong>Interior</strong> /Exterior with Reactive StainNominal 3/32 InchStep # <strong>Installation</strong> Step <strong>Installation</strong> Methods Products & Mix Ratios Theoretical Coverage RatesMechanically Prepare and a. Sandblasting or <strong>Miracote</strong> <strong>MPC</strong> <strong>Micro</strong>-<strong>Topping</strong> <strong>System</strong>s must be applied to aPresaturate the Concrete Substrate b. Shotblasting or clean, sound, and mechanically prepared concrete substrate, N/A1 c. Diamond grinding or as per ICRI's Technical Guide No.03732, "Selecting andNote: Minimum (CSP) concrete surface profile d. Other similar and approved Specifying Concrete Surface Preparation. Concrete substrateof CSP-3 or higher is required depending on mechanical methods. should be (SSD) Saturated Surface Dry with no standingsubstrate conditions & coating requirements. e. Saturate with potable water water at the time of application.Apply 1st <strong>MPC</strong> <strong>Micro</strong>-<strong>Topping</strong> Coat a. Hand Trowel or Blend: <strong>MPC</strong> Liquid Catalyst and <strong>MPC</strong> Powderb. Magic trowel or Mix Ratio: 5 Gal. <strong>MPC</strong> Liquid Catalyst to (2) 55 LB Bagsc. Squeegee Note: Climatic conditions that are associated with high rates 500 SF/Unitof evaporation can decrease <strong>MPC</strong> working time. Add 1 unit2 Note 1: ColorPax-LIP (Liquid Integral Pigment) of <strong>Miracote</strong> Retarder to increase valuable working timepacks must be dispensed and mixed into the when these conditions are present or anticipated. Note: <strong>MPC</strong> coverage can vary5 Gal. pail of <strong>Micro</strong>-<strong>Topping</strong> Liquid Catalyst. Mix Option 1 (Not Pigmented) depending on the desiredNote 2: Color-Pax-LIP pigmented <strong>MPC</strong> colors Mix Gray or White Regular <strong>MPC</strong> texture of finish, and the profileare based on use with White powder. The use Mix Option 2 (Pigmented) or condition of the existingof Gray powder will produce a different color. Mix Gray or White Regular <strong>MPC</strong> with (1) ColorPax-LIP Unit concrete substrate.Apply 2nd <strong>MPC</strong> <strong>Micro</strong>-<strong>Topping</strong> Coat a. Hand Trowel or Blend: <strong>MPC</strong> Liquid Catalyst and <strong>MPC</strong> Powderb. Magic trowel or Mix Ratio: 5 Gal. <strong>MPC</strong> Liquid Catalyst to (2) 55 LB Bags3 Note: For the 2nd coat only, mixing a 50/50 c. Squeegee Mix Option 1 (Not Pigmented) 500 SF/Unitblend of Regular and Smooth <strong>MPC</strong> Powder, inMix Gray or White Regular <strong>MPC</strong>White or Gray, is an acceptable option to Mix Option 2 (Pigmented) Note: <strong>MPC</strong> coverage can varymodify desired trowelling characteristics. Mix Gray or White Regular <strong>MPC</strong> with (1) ColorPax-LIP Unit as noted above.Apply 3rd <strong>MPC</strong> <strong>Micro</strong>-<strong>Topping</strong> Coat a. Hand Trowel or Blend: <strong>MPC</strong> Liquid Catalyst and <strong>MPC</strong> Powderb. Magic trowel or Mix Ratio: 5 Gal. <strong>MPC</strong> Liquid Catalyst to (2) 55 LB Bags4 c. Squeegee Mix Option 1 (Not Pigmented) 500 SF/UnitMix Gray or White Smooth <strong>MPC</strong>Mix Option 2 (Pigmented)Note: <strong>MPC</strong> coverage can varyMix Gray or White Smooth <strong>MPC</strong> with (1) ColorPax-LIP Unit as noted above.5 Sand Surface and Rinse Clean Before staining it is important to sand the entire <strong>Micro</strong>-<strong>Topping</strong> surface with a 60-120 grit screen sanding disc to achieve desiredsmoothness. Sweep and vacuum floor to remove sanding debris, and perform a final tack cleaning of the <strong>Micro</strong>-topping surface.Apply Accent Color with Mirastain I a. Hudson-type sprayer or Mirastain Ib. Sponge or Single Component6 Note: Staining and antiquing are the artistic c. Soft cloth orexpressions of the individual installer. Pre-job d. Other methods, as desired Note: Depending on the desired color accent(s) of the <strong>MPC</strong> Coverage rates will vary dependingmock-up samples should be submitted first <strong>Micro</strong>-<strong>Topping</strong> floor, one or more optional applications of the on surface texture and profile, andfor review and approval by the owner. Mirastain I may be required in the same or a different color. the desired finish color accents.<strong>Miracote</strong> is a registered trade name of Crossfield Products Corp.<strong>MPC</strong> is a registered trade mark of Crossfield Products Corp. Page 1 of 2 IEH Pending

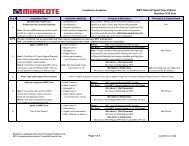

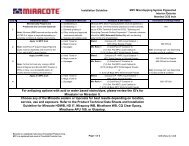

<strong>Installation</strong> <strong>Guideline</strong><strong>MPC</strong> <strong>Micro</strong>-<strong>Topping</strong> <strong>System</strong><strong>Interior</strong> /Exterior with Reactive StainNominal 3/32 InchStep # <strong>Installation</strong> Step <strong>Installation</strong> Methods Products & Mix Ratios Theoretical Coverage RatesPrepare a mixture of 1/2 cup baking soda to 5 gallons potable water. Spread solution onto floor and scrub with broom or auto7 Neutralize Stained Concrete Surface scrubber/floor machine with white buffing pad. Vacuum residue, and rinse floor with clean water. Repeat this process until PHtests verify a neutral condition before applying any top coat or sealer.Option 1 - Application of <strong>MPC</strong> <strong>Micro</strong>-<strong>Topping</strong> Clear Sealers - For both Exterior & <strong>Interior</strong> UseOptional - Apply 1 or 2 Coats of Clear Sealer a. Hudson-type sprayer or HD II Clear, Gloss or Matte 400 SF/Gal(For Exterior & <strong>Interior</strong> Use) b. Roller, Applicator Pad or Note: HD II may be thinned with Acetone by 25% max.8aor8b Note 1: Two coats are always recommended Mirathane U/A, Gloss or Matte 400 SF/Galfor high traffic areas and/or stain resistence. Warning: Clear acrylic sealers orNote 2: When matte finish is desired, it is must be applied in a thin film. Miraseal 600 SF/Galrecommended to apply 1st coat with gloss. Maintain stated coverage rates.Option 2 - Application of <strong>MPC</strong> <strong>Micro</strong>-<strong>Topping</strong> Clear Top Coat (Required) and Clear Finish Coats (Optional) - For <strong>Interior</strong> Use Only9Apply Clear Top Coat a. Squeegee and Backroll CQ Matrix Clear(For <strong>Interior</strong> Applications Only) Mix Ratio A:B = 2:1 by Volume 250 SF/GalNote: It is important to maintain a wet edgewhen installing clear sealer coats & finishes.Optional - Apply 1 or 2 Clear Finish Coats a. Squeegee and Backroll Mirathane APU Clear Gloss or Matte 325 SF/Galfor <strong>Interior</strong> Use Only Mix Ratio A:B = 1:1 5 mils WFT10aor10b Note 1: Two coats are always recommended Glazetop XT Clear Gloss 325 SF/Galfor high traffic areas and/or stain resistence. Mix Ratio A:B = 1:1 5 mils WFTNote 2: When matte finish is desired, it isrecommended to apply 1st coat with gloss.Note:Prior to starting the application of any <strong>Miracote</strong> Product or <strong>System</strong> be sure to read the <strong>Installation</strong> <strong>Guideline</strong> Manual. Appendices, Product Data Sheets, MSDS and other pertinent documentspublished by Crossfield Product Corp. for information, including but not limited to, Precautions, Limitations, Disclaimers and Warranties.Pay special attention to substrate moisture content, physical condition of the substrate, method(s) of surface preparation, surface restoration, detailing of cracks, joints, transitions and terminations,and any applicable specifications. Review carefully for unknown site conditions or defects.The theoretical coverage rates stated in the <strong>Installation</strong> Guides are for estimating purposes only. Factors, such as, allowance for material waste, unusual or abnormal substrate conditions and otherunforeseen job site conditions that may affect actual product yields are the responsibility of the installer.<strong>Miracote</strong> is a registered trade name of Crossfield Products Corp.<strong>MPC</strong> is a registered trade mark of Crossfield Products Corp. Page 2 of 2 IEH Pending