2 / Samsung Electronics Sustainability Report 2012 /

2 / Samsung Electronics Sustainability Report 2012 /

2 / Samsung Electronics Sustainability Report 2012 /

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

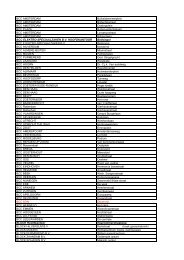

Management Structure<br />

<strong>Samsung</strong> <strong>Electronics</strong>’ GHG emission management structure is as follows.<br />

GHG Management Committee<br />

Scope 1, 2 Emissions Management<br />

Scope 1, 2 Emissions Management Process<br />

Emission Management Structure The operation sites included in the GHG emission management scope are production plants and buildings under<br />

direct operational control of <strong>Samsung</strong> <strong>Electronics</strong>. Monthly GHG emission data from eight Korean plants and buildings, 30 overseas production plants,<br />

and 76 non-production subsidiaries (sales, logistics, and R&D centers) are collected through the environmental management system, G-EHS. The emission<br />

data from each site are checked against targets and improvement measures are formulated. The GHG emissions data and reduction achievements<br />

against targets are reported to environmental managers at each site, in addition to the corporate environmental affairs management team and top<br />

management.<br />

Emission Calculation Method GHG emissions were calculated with management data at each site and the national guidelines of each country as well<br />

as international standards including the IPCC Guidelines, ISO 14064 were used as reference for matters not specifi ed in the national guidelines.<br />

GHG Emissions (Scope 1, 2) <strong>Samsung</strong> <strong>Electronics</strong>’ GHG emissions intensity in 2011 was reduced to 4.46 tons/KRW 100 million. which was 13% lower<br />

than 2010 fi gures. We have taken various measures including the installation of facilities for reducing GHG emissions from indutrial processes, improvement<br />

in energy effi ciency of production facilities, installation of high effi cient facilities and will continue to implement various GHG reduction measures.<br />

GHG Emissions Intensity (tons CO2/KRW 100 million)<br />

Korea<br />

Global<br />

Name<br />

Green Management Committee<br />

Eco-Product Council<br />

GHG/Energy Executive Committee<br />

GHG/Energy Committee<br />

Category<br />

Target<br />

Actual<br />

Actual<br />

Indicator<br />

GHG emission intensity: Total CO 2 emissions 1 ÷ (Sales[Korea] / price index 2 )<br />

1 Total GHG emissions from production plants in Korea, expressed in CO2-equivalent<br />

2 Producer price index in Bank of Korea public notice (Base year 2005: PPI = 1)<br />

Calculation Method (Global): Global total CO 2 emissions / Global Sales<br />

10 / <strong>Samsung</strong> <strong>Electronics</strong> <strong>Sustainability</strong> <strong>Report</strong> <strong>2012</strong> /<br />

Detail<br />

Discuss and make decisions on corporate-level strategic decisions on<br />

climate change response<br />

Set development goals and implementation strategies on high energy<br />

effi ciency and low power-consumption products<br />

Establishment and implementation of production plant GHG reduction<br />

strategy<br />

Climate change risks analysis and monitoring<br />

2009<br />

6.85<br />

5.83<br />

4.35<br />

CEO<br />

2010<br />

Host<br />

Head of CS Environmental Center<br />

Head of CS Environmental Center<br />

Head of Environmental Strategy team<br />

5.65<br />

5.11<br />

4.15<br />

Twice a year<br />

Twice a year<br />

Twice a year<br />

Frequency<br />

Five times a year<br />

2011<br />

4.62<br />

4.46<br />

3.70