You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

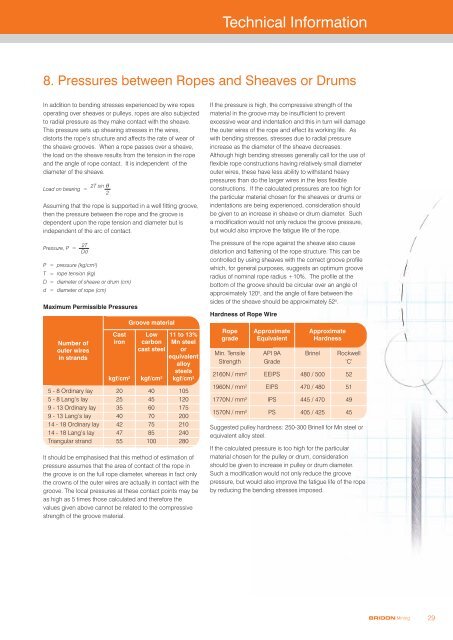

Technical Information8. Pressures between Ropes and Sheaves or DrumsIn addition to bending stresses experienced by wire ropesoperating over sheaves or pulleys, ropes are also subjectedto radial pressure as they make contact with the sheave.This pressure sets up shearing stresses in the wires,distorts the rope’s structure and affects the rate of wear ofthe sheave grooves. When a rope passes over a sheave,the load on the sheave results from the tension in the ropeand the angle of rope contact. It is independent of thediameter of the sheave.Load on bearing =Assuming that the rope is supported in a well fitting groove,then the pressure between the rope and the groove isdependent upon the rope tension and diameter but isindependent of the arc of contact.Pressure, P =2TDdP = pressure (kg/cm 2 )T = rope tension (kg)D = diameter of sheave or drum (cm)d = diameter of rope (cm)Maximum Permissible PressuresNumber ofouter wiresin strands2T sin θ25 - 8 Ordinary lay5 - 8 Lang’s lay9 - 13 Ordinary lay9 - 13 Lang’s lay14 - 18 Ordinary lay14 - 18 Lang’s layTriangular strandCastironkgf/cm 220253540424755Groove materialLow 11 to 13%carbon Mn steelcast steel orequivalentalloysteelskgf/cm 2 kgf/cm 2404560707585100105120175200210240280It should be emphasised that this method of estimation ofpressure assumes that the area of contact of the rope inthe groove is on the full rope diameter, whereas in fact onlythe crowns of the outer wires are actually in contact with thegroove. The local pressures at these contact points may beas high as 5 times those calculated and therefore thevalues given above cannot be related to the compressivestrength of the groove material.If the pressure is high, the compressive strength of thematerial in the groove may be insufficient to preventexcessive wear and indentation and this in turn will damagethe outer wires of the rope and effect its working life. Aswith bending stresses, stresses due to radial pressureincrease as the diameter of the sheave decreases.Although high bending stresses generally call for the use offlexible rope constructions having relatively small diameterouter wires, these have less ability to withstand heavypressures than do the larger wires in the less flexibleconstructions. If the calculated pressures are too high forthe particular material chosen for the sheaves or drums orindentations are being experienced, consideration shouldbe given to an increase in sheave or drum diameter. Sucha modification would not only reduce the groove pressure,but would also improve the fatigue life of the rope.The pressure of the rope against the sheave also causedistortion and flattening of the rope structure. This can becontrolled by using sheaves with the correct groove profilewhich, for general purposes, suggests an optimum grooveradius of nominal rope radius +10%. The profile at thebottom of the groove should be circular over an angle ofapproximately 120 o , and the angle of flare between thesides of the sheave should be approximately 52 o .Hardness of Rope WireRopegradeMin. TensileStrength2160N / mm 21960N / mm 21770N / mm 21570N / mm 2ApproximateEquivalentAPI 9AGradeEEIPSEIPSIPSPSApproximateHardnessBrinel480 / 500470 / 480445 / 470405 / 425Rockwell‘C’Suggested pulley hardness: 250-300 Brinell for Mn steel orequivalent alloy steel.If the calculated pressure is too high for the particularmaterial chosen for the pulley or drum, considerationshould be given to increase in pulley or drum diameter.Such a modification would not only reduce the groovepressure, but would also improve the fatigue life of the ropeby reducing the bending stresses imposed.52514945BRIDON <strong>Mining</strong>29