You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

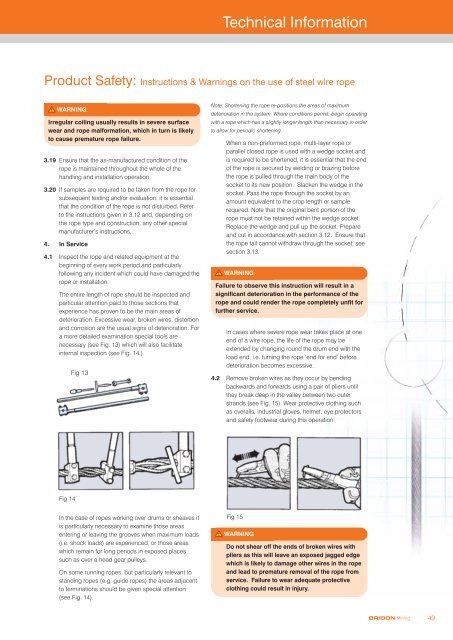

Technical InformationProduct Safety: Instructions & Warnings on the use of steel wire ropeWARNINGIrregular coiling usually results in severe surfacewear and rope malformation, which in turn is likelyto cause premature rope failure.3.19 Ensure that the as-manufactured condition of therope is maintained throughout the whole of thehandling and installation operation.3.20 If samples are required to be taken from the rope forsubsequent testing and/or evaluation, it is essentialthat the condition of the rope is not disturbed. Referto the instructions given in 3.12 and, depending onthe rope type and construction, any other specialmanufacturer’s instructions.4. In Service4.1 Inspect the rope and related equipment at thebeginning of every work period and particularlyfollowing any incident which could have damaged therope or installation.The entire length of rope should be inspected andparticular attention paid to those sections thatexperience has proven to be the main areas ofdeterioration. Excessive wear, broken wires, distortionand corrosion are the usual signs of deterioration. Fora more detailed examination special tools arenecessary (see Fig. 13) which will also facilitateinternal inspection (see Fig. 14.)Fig 13Note: Shortening the rope re-positions the areas of maximumdeterioration in the system. Where conditions permit, begin operatingwith a rope which has a slightly longer length than necessary in orderto allow for periodic shortening.When a non-preformed rope, multi-layer rope orparallel closed rope is used with a wedge socket andis required to be shortened, it is essential that the endof the rope is secured by welding or brazing beforethe rope is pulled through the main body of thesocket to its new position. Slacken the wedge in thesocket. Pass the rope through the socket by anamount equivalent to the crop length or samplerequired. Note that the original bent portion of therope must not be retained within the wedge socket.Replace the wedge and pull up the socket. Prepareand cut in accordance with section 3.12. Ensure thatthe rope tail cannot withdraw through the socket, seesection 3.13.WARNINGFailure to observe this instruction will result in asignificant deterioration in the performance of therope and could render the rope completely unfit forfurther service.In cases where severe rope wear takes place at oneend of a wire rope, the life of the rope may beextended by changing round the drum end with theload end, i.e. turning the rope ‘end for end’ beforedeterioration becomes excessive.4.2 Remove broken wires as they occur by bendingbackwards and forwards using a pair of pliers untilthey break deep in the valley between two outerstrands (see Fig. 15). Wear protective clothing suchas overalls, industrial gloves, helmet, eye protectorsand safety footwear during this operation.Fig 14In the case of ropes working over drums or sheaves itis particularly necessary to examine those areasentering or leaving the grooves when maximum loads(i.e. shock loads) are experienced, or those areaswhich remain for long periods in exposed placessuch as over a head gear pulleys.On some running ropes, but particularly relevant tostanding ropes (e.g. guide ropes) the areas adjacentto terminations should be given special attention(see Fig. 14).Fig 15WARNINGDo not shear off the ends of broken wires withpliers as this will leave an exposed jagged edgewhich is likely to damage other wires in the ropeand lead to premature removal of the rope fromservice. Failure to wear adequate protectiveclothing could result in injury.BRIDON <strong>Mining</strong>49