Fuel Indexes: A Novel Method for the Evaluation of Relevant ...

Fuel Indexes: A Novel Method for the Evaluation of Relevant ...

Fuel Indexes: A Novel Method for the Evaluation of Relevant ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

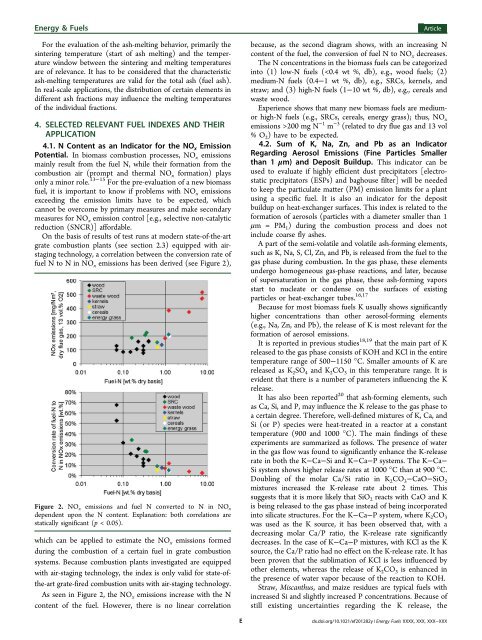

Energy & <strong>Fuel</strong>sFor <strong>the</strong> evaluation <strong>of</strong> <strong>the</strong> ash-melting behavior, primarily <strong>the</strong>sintering temperature (start <strong>of</strong> ash melting) and <strong>the</strong> temperaturewindow between <strong>the</strong> sintering and melting temperaturesare <strong>of</strong> relevance. It has to be considered that <strong>the</strong> characteristicash-melting temperatures are valid <strong>for</strong> <strong>the</strong> total ash (fuel ash).In real-scale applications, <strong>the</strong> distribution <strong>of</strong> certain elements indifferent ash fractions may influence <strong>the</strong> melting temperatures<strong>of</strong> <strong>the</strong> individual fractions.4. SELECTED RELEVANT FUEL INDEXES AND THEIRAPPLICATION4.1. N Content as an Indicator <strong>for</strong> <strong>the</strong> NO x EmissionPotential. In biomass combustion processes, NO x emissionsmainly result from <strong>the</strong> fuel N, while <strong>the</strong>ir <strong>for</strong>mation from <strong>the</strong>combustion air (prompt and <strong>the</strong>rmal NO x <strong>for</strong>mation) playsonly a minor role. 13−15 For <strong>the</strong> pre-evaluation <strong>of</strong> a new biomassfuel, it is important to know if problems with NO x emissionsexceeding <strong>the</strong> emission limits have to be expected, whichcannot be overcome by primary measures and make secondarymeasures <strong>for</strong> NO x emission control [e.g., selective non-catalyticreduction (SNCR)] af<strong>for</strong>dable.On <strong>the</strong> basis <strong>of</strong> results <strong>of</strong> test runs at modern state-<strong>of</strong>-<strong>the</strong>-artgrate combustion plants (see section 2.3) equipped with airstagingtechnology, a correlation between <strong>the</strong> conversion rate <strong>of</strong>fuel N to N in NO x emissions has been derived (see Figure 2),Figure 2. NO x emissions and fuel N converted to N in NO xdependent upon <strong>the</strong> N content. Explanation: both correlations arestatically significant (p < 0.05).which can be applied to estimate <strong>the</strong> NO x emissions <strong>for</strong>medduring <strong>the</strong> combustion <strong>of</strong> a certain fuel in grate combustionsystems. Because combustion plants investigated are equippedwith air-staging technology, <strong>the</strong> index is only valid <strong>for</strong> state-<strong>of</strong><strong>the</strong>-artgrate-fired combustion units with air-staging technology.As seen in Figure 2, <strong>the</strong> NO x emissions increase with <strong>the</strong> Ncontent <strong>of</strong> <strong>the</strong> fuel. However, <strong>the</strong>re is no linear correlationArticlebecause, as <strong>the</strong> second diagram shows, with an increasing Ncontent <strong>of</strong> <strong>the</strong> fuel, <strong>the</strong> conversion <strong>of</strong> fuel N to NO x decreases.The N concentrations in <strong>the</strong> biomass fuels can be categorizedinto (1) low-N fuels (200 mg N −1 m −3 (related to dry flue gas and 13 vol%O 2 ) have to be expected.4.2. Sum <strong>of</strong> K, Na, Zn, and Pb as an IndicatorRegarding Aerosol Emissions (Fine Particles Smallerthan 1 μm) and Deposit Buildup. This indicator can beused to evaluate if highly efficient dust precipitators [electrostaticprecipitators (ESPs) and baghouse filter] will be neededto keep <strong>the</strong> particulate matter (PM) emission limits <strong>for</strong> a plantusing a specific fuel. It is also an indicator <strong>for</strong> <strong>the</strong> depositbuildup on heat-exchanger surfaces. This index is related to <strong>the</strong><strong>for</strong>mation <strong>of</strong> aerosols (particles with a diameter smaller than 1μm = PM 1 ) during <strong>the</strong> combustion process and does notinclude coarse fly ashes.A part <strong>of</strong> <strong>the</strong> semi-volatile and volatile ash-<strong>for</strong>ming elements,such as K, Na, S, Cl, Zn, and Pb, is released from <strong>the</strong> fuel to <strong>the</strong>gas phase during combustion. In <strong>the</strong> gas phase, <strong>the</strong>se elementsundergo homogeneous gas-phase reactions, and later, because<strong>of</strong> supersaturation in <strong>the</strong> gas phase, <strong>the</strong>se ash-<strong>for</strong>ming vaporsstart to nucleate or condense on <strong>the</strong> surfaces <strong>of</strong> existingparticles or heat-exchanger tubes. 16,17Because <strong>for</strong> most biomass fuels K usually shows significantlyhigher concentrations than o<strong>the</strong>r aerosol-<strong>for</strong>ming elements(e.g., Na, Zn, and Pb), <strong>the</strong> release <strong>of</strong> K is most relevant <strong>for</strong> <strong>the</strong><strong>for</strong>mation <strong>of</strong> aerosol emissions.It is reported in previous studies 18,19 that <strong>the</strong> main part <strong>of</strong> Kreleased to <strong>the</strong> gas phase consists <strong>of</strong> KOH and KCl in <strong>the</strong> entiretemperature range <strong>of</strong> 500−1150 °C. Smaller amounts <strong>of</strong> K arereleased as K 2 SO 4 and K 2 CO 3 in this temperature range. It isevident that <strong>the</strong>re is a number <strong>of</strong> parameters influencing <strong>the</strong> Krelease.It has also been reported 20 that ash-<strong>for</strong>ming elements, suchas Ca, Si, and P, may influence <strong>the</strong> K release to <strong>the</strong> gas phase toa certain degree. There<strong>for</strong>e, well-defined mixtures <strong>of</strong> K, Ca, andSi (or P) species were heat-treated in a reactor at a constanttemperature (900 and 1000 °C). The main findings <strong>of</strong> <strong>the</strong>seexperiments are summarized as follows. The presence <strong>of</strong> waterin <strong>the</strong> gas flow was found to significantly enhance <strong>the</strong> K-releaserate in both <strong>the</strong> K−Ca−Si and K−Ca−P systems. The K−Ca−Si system shows higher release rates at 1000 °C than at 900 °C.Doubling <strong>of</strong> <strong>the</strong> molar Ca/Si ratio in K 2 CO 3 −CaO−SiO 2mixtures increased <strong>the</strong> K-release rate about 2 times. Thissuggests that it is more likely that SiO 2 reacts with CaO and Kis being released to <strong>the</strong> gas phase instead <strong>of</strong> being incorporatedinto silicate structures. For <strong>the</strong> K−Ca−P system, where K 2 CO 3was used as <strong>the</strong> K source, it has been observed that, with adecreasing molar Ca/P ratio, <strong>the</strong> K-release rate significantlydecreases. In <strong>the</strong> case <strong>of</strong> K−Ca−P mixtures, with KCl as <strong>the</strong> Ksource, <strong>the</strong> Ca/P ratio had no effect on <strong>the</strong> K-release rate. It hasbeen proven that <strong>the</strong> sublimation <strong>of</strong> KCl is less influenced byo<strong>the</strong>r elements, whereas <strong>the</strong> release <strong>of</strong> K 2 CO 3 is enhanced in<strong>the</strong> presence <strong>of</strong> water vapor because <strong>of</strong> <strong>the</strong> reaction to KOH.Straw, Miscanthus, and maize residues are typical fuels withincreased Si and slightly increased P concentrations. Because <strong>of</strong>still existing uncertainties regarding <strong>the</strong> K release, <strong>the</strong>Edx.doi.org/10.1021/ef201282y | Energy <strong>Fuel</strong>s XXXX, XXX, XXX−XXX