You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DIBt<br />

SETTING THE STANDARDS FOR <strong>STOVE</strong>S OPERATING<br />

WITH INDEPENDENT EXTERNAL AIR<br />

<strong>The</strong> german institute for Buildings (DiBt) gives technical approval only to those stoves which, having undergone official laboratory<br />

tests, conform to its strict criteria for safe burning without the use of the surrounding air, thus relying solely on an external independent<br />

air source to provide all necessary combustion air. <strong>The</strong> tests check for CO concentration (ppm) in the flue gases and the leak rate<br />

(m³/h) at 10 Pa after thermal and mechanical stress. For example, this includes testing the stove‘s door seal for air-tightness after<br />

being opened and closed for a minimum of 6,000 times. all Dan SKan MODErn linE stoves conform to DiBt criteria.<br />

APPLICATIONS<br />

DiBt approved stoves need to be connected with a well sealed external air connection which has a valve mechanism to close the<br />

external air off when the stove is not in use. approved stoves can only be installed in rooms where it is proven that even with air<br />

removed from the room by, for example, ventilation fans, extractor cooker hoods, hot-air heating systems and air dryers etc it is<br />

guaranteed never to be less than 8 Pa negative pressure in the room or house.<br />

<strong>The</strong> ideal pressure for the operation of a stove is 4 Pa and this is generally to be desired. it is also important that all flue pipe and<br />

flue system connections are also well sealed. important: Please check your local and national building regulations to ensure that<br />

your proposed installation conforms.<br />

AIRBOX: THE BENEFITS OF THE PATENTED AUTOMATIC AIR<br />

REGULATION AND HEAT EXCHANGER<br />

Cold air, drawn in from outside, should always be heated before arriving into the combustion chamber, in order to maintain the fire<br />

chamber temperature which will ensure clean and efficient burning. External air can sometimes be extremely cold, often with<br />

freezing temperatures, and would make the stove burn poorly, possibly even putting the stove out, and also making it burn dirty so<br />

that it could fail today‘s environmental and emissions standards.<br />

Our patented airBOX (which heats the air at the rear convection area of the stove) combinded with our intelligent automatic air<br />

regulation system outlined earlier, enables you to get the very best out of your Dan SKan stove and fuel every time by supplying<br />

the fire chamber with the optimal quantity of air at a highly efficient pre-combustion temperature.<br />

SITE REQUIREMENTS<br />

<strong>The</strong> external air supply to the rear or base of the stove should be delivered through a 100 mm diameter duct provided that there is<br />

only one bend and that the distance to the outside air is less than 5 m. all joints should be well sealed. Should the distance be greater<br />

or the route require more than one bend then a 150 mm diameter duct must be used only reverting to 100 mm diameter when close to<br />

the stove connection point.<br />

Subject to local and national building regulations this duct should feature a shut off valve close to the outside air end to prevent cold<br />

air entering the house when the stove is not in use.<br />

<strong>The</strong> installation of a Dan SKan stove incorporating the airBOX system within a house with a heat recovery system must comply with<br />

local and national building regulations ventilation requirements. Please consult your installer or Dan SKan partner who will be able to<br />

advise.<br />

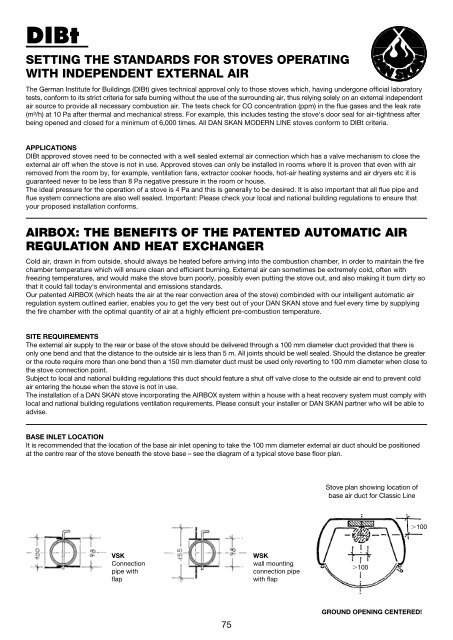

BASE INLET LOCATION<br />

it is recommended that the location of the base air inlet opening to take the 100 mm diameter external air duct should be positioned<br />

at the centre rear of the stove beneath the stove base – see the diagram of a typical stove base floor plan.<br />

VSK<br />

Connection<br />

pipe with<br />

flap<br />

75<br />

WSK<br />

wall mounting<br />

connection pipe<br />

with flap<br />

<strong>Stove</strong> plan showing location of<br />

base air duct for Classic line<br />

�100<br />

�100<br />

GROUND OPENING CENTERED!