Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

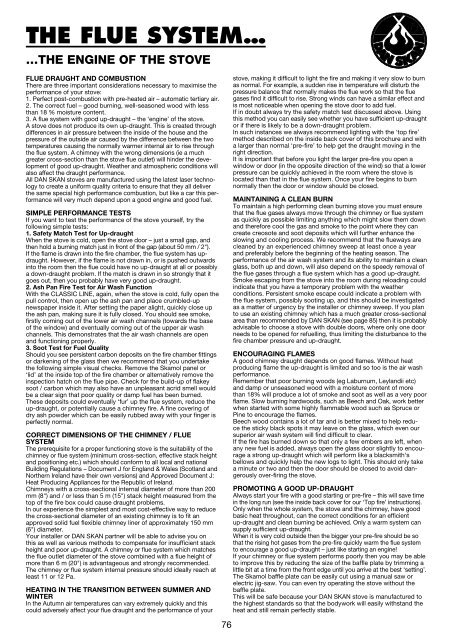

THE FLUE SYSTEM…<br />

…THE ENGINE OF THE <strong>STOVE</strong><br />

FLUE DRAUGHT AND COMBUSTION<br />

<strong>The</strong>re are three important considerations necessary to maximise the<br />

performance of your stove:<br />

1. Perfect post-combustion with pre-heated air – automatic tertiary air.<br />

2. <strong>The</strong> correct fuel – good burning, well-seasoned wood with less<br />

than 18 % moisture content.<br />

3. a flue system with good up-draught – the ‘engine’ of the stove.<br />

a stove does not produce its own up-draught. This is created through<br />

differences in air pressure between the inside of the house and the<br />

pressure of the outside air caused by the difference between the two<br />

temperatures causing the normally warmer internal air to rise through<br />

the flue system. a chimney with the wrong dimensions (ie a much<br />

greater cross-section than the stove flue outlet) will hinder the development<br />

of good up-draught. Weather and atmospheric conditions will<br />

also affect the draught performance.<br />

all Dan SKan stoves are manufactured using the latest laser technology<br />

to create a uniform quality criteria to ensure that they all deliver<br />

the same special high performance combustion, but like a car this performance<br />

will very much depend upon a good engine and good fuel.<br />

SIMPLE PERFORMANCE TESTS<br />

if you want to test the performance of the stove yourself, try the<br />

following simple tests:<br />

1. Safety Match Test for Up-draught<br />

When the stove is cold, open the stove door – just a small gap, and<br />

then hold a burning match just in front of the gap (about 50 mm / 2").<br />

if the flame is drawn into the fire chamber, the flue system has updraught.<br />

However, if the flame is not drawn in, or is pushed outwards<br />

into the room then the flue could have no up-draught at all or possibly<br />

a down-draught problem. if the match is drawn in so strongly that it<br />

goes out, then you probably have very good up-draught.<br />

2. Ash Pan Fire Test for Air Wash Function<br />

With the ClaSSiC linE, again, when the stove is cold, fully open the<br />

pull control, then open up the ash pan and place crumbled-up<br />

newspaper inside it. after setting the paper alight, quickly close up<br />

the ash pan, making sure it is fully closed. You should see smoke,<br />

firstly coming out of the lower air wash channels (towards the base<br />

of the window) and eventually coming out of the upper air wash<br />

channels. This demonstrates that the air wash channels are open<br />

and functioning properly.<br />

3. Soot Test for Fuel Quality<br />

Should you see persistent carbon deposits on the fire chamber fittings<br />

or darkening of the glass then we recommend that you undertake<br />

the following simple visual checks. remove the Skamol panel or<br />

‘lid’ at the inside top of the fire chamber or alternatively remove the<br />

inspection hatch on the flue pipe. Check for the build-up of flakey<br />

soot / carbon which may also have an unpleasant acrid smell would<br />

be a clear sign that poor quality or damp fuel has been burned.<br />

<strong>The</strong>se deposits could eventually ‘fur’ up the flue system, reduce the<br />

up-draught, or potentially cause a chimney fire. a fine covering of<br />

dry ash powder which can be easily rubbed away with your finger is<br />

perfectly normal.<br />

CORRECT DIMENSIONS OF THE CHIMNEY / FLUE<br />

SYSTEM<br />

<strong>The</strong> prerequisite for a proper functioning stove is the suitability of the<br />

chimney or flue system (minimum cross-section, effective stack height<br />

and positioning etc.) which should conform to all local and national<br />

Building regulations – Document J for England & Wales (Scotland and<br />

northern ireland have their own versions) and approved Document J:<br />

Heat Producing appliances for the republic of ireland.<br />

Chimneys with a cross-sectional internal diameter of more than 200<br />

mm (8") and / or less than 5 m (15") stack height measured from the<br />

top of the fire box could cause draught problems.<br />

in our experience the simplest and most cost-effective way to reduce<br />

the cross-sectional diameter of an existing chimney is to fit an<br />

approved solid fuel flexible chimney liner of approximately 150 mm<br />

(6") diameter.<br />

Your installer or Dan SKan partner will be able to advise you on<br />

this as well as various methods to compensate for insufficient stack<br />

height and poor up-draught. a chimney or flue system which matches<br />

the flue outlet diameter of the stove combined with a flue height of<br />

more than 6 m (20") is advantageous and strongly recommended.<br />

<strong>The</strong> chimney or flue system internal pressure should ideally reach at<br />

least 11 or 12 Pa.<br />

HEATING IN THE TRANSITION BETWEEN SUMMER AND<br />

WINTER<br />

in the autumn air temperatures can vary extremely quickly and this<br />

could adversely affect your flue draught and the performance of your<br />

76<br />

stove, making it difficult to light the fire and making it very slow to burn<br />

as normal. For example, a sudden rise in temperature will disturb the<br />

pressure balance that normally makes the flue work so that the flue<br />

gases find it difficult to rise. Strong winds can have a similar effect and<br />

is most noticeable when opening the stove door to add fuel.<br />

if in doubt always try the safety match test discussed above. Using<br />

this method you can easily see whether you have sufficient up-draught<br />

or if there is likely to be a down-draught problem.<br />

in such instances we always recommend lighting with the ‘top fire’<br />

method described on the inside back cover of this brochure and with<br />

a larger than normal ‘pre-fire’ to help get the draught moving in the<br />

right direction.<br />

it is important that before you light the larger pre-fire you open a<br />

window or door (in the opposite direction of the wind) so that a lower<br />

pressure can be quickly achieved in the room where the stove is<br />

located than that in the flue system. Once your fire begins to burn<br />

normally then the door or window should be closed.<br />

MAINTAINING A CLEAN BURN<br />

To maintain a high performing clean burning stove you must ensure<br />

that the flue gases always move through the chimney or flue system<br />

as quickly as possible limiting anything which might slow them down<br />

and therefore cool the gas and smoke to the point where they can<br />

create creosote and soot deposits which will further enhance the<br />

slowing and cooling process. We recommend that the flueways are<br />

cleaned by an experienced chimney sweep at least once a year<br />

and preferably before the beginning of the heating season. <strong>The</strong><br />

performance of the air wash system and its ability to maintain a clean<br />

glass, both up and down, will also depend on the speedy removal of<br />

the flue gases through a flue system which has a good up-draught.<br />

Smoke escaping from the stove into the room during reloading could<br />

indicate that you have a temporary problem with the weather<br />

conditions. Persistent smoke escape could indicate a problem with<br />

the flue system, possibly sooting up, and this should be investigated<br />

as a matter of urgency by the installer or chimney sweep. if you plan<br />

to use an existing chimney which has a much greater cross-sectional<br />

area than recommended by Dan SKan (see page 85) then it is probably<br />

advisable to choose a stove with double doors, where only one door<br />

needs to be opened for refuelling, thus limiting the disturbance to the<br />

fire chamber pressure and up-draught.<br />

ENCOURAGING FLAMES<br />

a good chimney draught depends on good flames. Without heat<br />

producing flame the up-draught is limited and so too is the air wash<br />

performance.<br />

remember that poor burning woods (eg laburnum, leylandii etc)<br />

and damp or unseasoned wood with a moisture content of more<br />

than 18% will produce a lot of smoke and soot as well as a very poor<br />

flame. Slow burning hardwoods, such as Beech and Oak, work better<br />

when started with some highly flammable wood such as Spruce or<br />

Pine to encourage the flames.<br />

Beech wood contains a lot of tar and is better mixed to help reduce<br />

the sticky black spots it may leave on the glass, which even our<br />

superior air wash system will find difficult to clear.<br />

if the fire has burned down so that only a few embers are left, when<br />

any new fuel is added, always open the glass door slightly to encourage<br />

a strong up-draught which will perform like a blacksmith‘s<br />

bellows and quickly help the new logs to light. This should only take<br />

a minute or two and then the door should be closed to avoid dangerously<br />

over-firing the stove.<br />

PROMOTING A GOOD UP-DRAUGHT<br />

always start your fire with a good starting or pre-fire – this will save time<br />

in the long run (see the inside back cover for our ‘Top fire’ instructions).<br />

Only when the whole system, the stove and the chimney, have good<br />

basic heat throughout, can the correct conditions for an efficient<br />

up-draught and clean burning be achieved. Only a warm system can<br />

supply sufficient up-draught.<br />

When it is very cold outside then the bigger your pre-fire should be so<br />

that the rising hot gases from the pre-fire quickly warm the flue system<br />

to encourage a good up-draught – just like starting an engine!<br />

if your chimney or flue system performs poorly then you may be able<br />

to improve this by reducing the size of the baffle plate by trimming a<br />

little bit at a time from the front edge until you arrive at the best ‘setting’.<br />

<strong>The</strong> Skamol baffle plate can be easily cut using a manual saw or<br />

electric jig-saw. You can even try operating the stove without the<br />

baffle plate.<br />

This will be safe because your Dan SKan stove is manufactured to<br />

the highest standards so that the bodywork will easily withstand the<br />

heat and still remain perfectly stable.