Hydro 2000

Hydro 2000

Hydro 2000

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

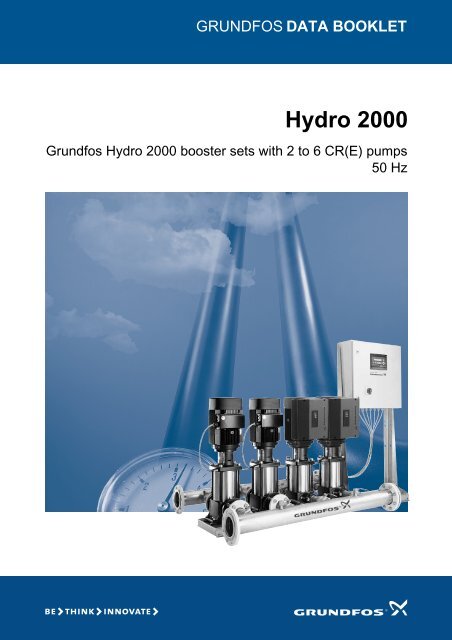

GRUNDFOS DATA BOOKLET<strong>Hydro</strong> <strong>2000</strong>Grundfos <strong>Hydro</strong> <strong>2000</strong> booster sets with 2 to 6 CR(E) pumps50 Hz

ContentsProduct dataPerformance range 3<strong>Hydro</strong> <strong>2000</strong> 4Control <strong>2000</strong> 4Functions 4Application and need 5Water supply 5Industry 5Irrigation 5Type key 6Construction 6System configuration 7Hydraulic functionsOverview of functions 8Product rangeSystem overview 10SizingGeneral information 12Consumption pattern 12System selection 13Type of booster set 14System size 15Diaphragm tank 16Dry-running protection 16Friction-loss compensation 16Understanding the curve charts 18Example: How to select a system 19Performance curves,<strong>Hydro</strong> <strong>2000</strong> SCR 3 20CR 5 22CR 10 24CR 15 26CR 20 28CR 32 30CR 45 32CR 64 34CR 90 36Performance curves,<strong>Hydro</strong> <strong>2000</strong> F-ECR 3 56CR 5 58CR 10 60CR 15 62CR 20 64CR 32 66CR 45 68CR 64 70CR 90 72Technical data, <strong>Hydro</strong> <strong>2000</strong> F-EElectrical dataCR 3 74CR 5 76CR 10 79CR 15 82CR 20 85CR 32 87CR 45 90CR 64 92CR 90 95Technical dataDimensions and weights 98Construction 98Operating conditions 98Installation 98Mechanical installation 98Electrical connection 98Further product documentationWinCAPS 99WebCAPS 100Technical data, <strong>Hydro</strong> <strong>2000</strong> SElectrical dataCR 3/ CR 5 38CR 10 40CR 15 42CR 20 45CR 32 48CR 45 50CR 64 52CR 90 542

Product data<strong>Hydro</strong> <strong>2000</strong>Performance rangeH[m]<strong>Hydro</strong> <strong>2000</strong>50 HzISO 9906 Annex A1501009080706050CR 3CR 540CR 10CR 15CR 20CR 3230CR 45CR 64CR 90201 2 4 6 8 10 20 40 60 80 100 200 400 600 800Q [m³/h]TM02 7576 38033

ResetProduct data<strong>Hydro</strong> <strong>2000</strong><strong>Hydro</strong> <strong>2000</strong>The Grundfos <strong>Hydro</strong> <strong>2000</strong> booster set consists of 2 to 6CR(E) pumps coupled in parallel and mounted on acommon base frame provided with all the necessaryfittings and a Grundfos Control <strong>2000</strong> cabinet.Booster sets with up to 8 pumps are available onrequest.When delivered, the Grundfos <strong>Hydro</strong> <strong>2000</strong> booster setis factory-tested and set according to the customer’swishes, ready for operation..Fig. 1PumpControl <strong>2000</strong>Non-returnvalvePressuretransmitter<strong>Hydro</strong> <strong>2000</strong> pressure boosting systemA Grundfos Control <strong>2000</strong> control cabinet holds aPFU <strong>2000</strong> (Pump Functional Unit <strong>2000</strong>).The Grundfos Control <strong>2000</strong> may also be supplied witha PMU <strong>2000</strong> (Pump Management Unit <strong>2000</strong>).TM00 2721 1302TM00 7023 1302PFU <strong>2000</strong>Simple operationPMU <strong>2000</strong>Advanced operationPFU <strong>2000</strong>Control <strong>2000</strong>IsolatingvalvePressure gaugeTM00 5391 1302Enables regular optimisation ofoperating conditions and read-out ofoperating data.FunctionsControl <strong>2000</strong> offers the following functions:• Performance control.• Grundfos bus communication.• Stop function when operating at low flow(increases the efficiency when operating atlow flow).• Automatic cascade control of pumps.• Automatic changeover between pumps inoperation (ensures the same number of operatinghours for all pumps).• Manual operation (enables testing of individualpumps).• Various setpoint influences:– friction-loss compensation (pressure decreaseswith a decreasing flow)– setpoint adjustment via external signals(temperature, time, level and flow).• Various digital remote-control functions:– start/stop of system– reduced operation (limits the maximum numberof pumps in operation) – 2-point control of the setpoint (enables controlof the setpoint by means of 2-point contact) – 3-point control of the setpoint (enables controlof the setpoint by means of 3-point contact) – firefighting operation .• Pump and system monitoring functions:– minimum and maximum limits for the valuemeasured – pre-pressure measurement – motor protection– Grundfos bus communication.• Display, alarm and signal functions:– 2 x 24 character LCD display – indicator lights for operating and fault indication(green and red light-emitting diodes)– potential-free changeover contacts for operatingand fault signals.• Clock program .Setting can be changed only when a PMU <strong>2000</strong> isconnected.4

Product data<strong>Hydro</strong> <strong>2000</strong>Application and needAbundant water is the key to progress and comfort.A booster set should be planned the right way whetherused for water supply, industrial purposes or irrigation.The purpose is to optimise operating costs and achievea high degree of comfort.The starting point when planning a booster set is need.Every supply area has its own consumption pattern.• the petrochemical industry• the pharmaceutical industry.In general, consumption is characterised by:• large variations from minimum load to peak load• sudden variations• constant pressure.QThe Grundfos <strong>Hydro</strong> <strong>2000</strong> booster set can be used fora wide range of applications. A number of typical examplesare shown below.Water supplyAccess to the right quantity of clean water at the righttime is the key to a healthy life.The term water supply covers:• waterworks, pressure boosting in distributioncircuits• blocks of flats, schools, hotels, hospitals, etc.Studies of the water consumption in a typical waterworkshave revealed large differences in the daily waterconsumption pattern.Consumption is characterised by:• sudden variations between min. and max. consumption• variation taking place over long periods• constant pressure.QFig. 3IrrigationTypical industrial consumption patternIn order to maintain recreational areas used for specificpurposes, it may be necessary to irrigate.The term irrigation covers:• gardening• parks• sports grounds, etc.A typical irrigation system could be used in connectionwith e.g. a golf course. When the irrigation system isstarted, consumption depends on the number of sprinklersactivated.hTM00 9200 1303A typical irrigation system is characterised by:• irrigation zones• variable, but known consumptionhTM00 9197 1303• system divided into pressure zones.QFig. 2Typical consumption pattern in waterworksIndustryIn a number of processes, water plays a vital part. Theindustrial consumption pattern varies with the type ofindustry. Many manufacturing processes consist of acycle requiring an absolute constant pressure evenwhere large and very quick flow variations areconcerned.Among others, industrial pressure boosting and liquidtransfer comprise:Fig. 4hTypical consumption pattern in irrigationapplicationTM00 9198 1303• the food industry• the textile industry5

Product data<strong>Hydro</strong> <strong>2000</strong>Type keyExample <strong>Hydro</strong> <strong>2000</strong> MEH /G /NS 2 CR 10-3 2 CRE 5-5 PMU 3 x 400/230 V, 50 HzType rangeSubgroups:MS, MSH, MF, MFH, ME, MEH, MESManifold material:: Stainless steel/C : Copper/G : Galvanised steelSuction manifold fitted:: With suction manifold/NS: Without suction manifoldNumber of full-size pumps: 2-6Full-size pump typeNumber of half-size pumps: 1-2Half-size pump typeControl panel of Control <strong>2000</strong>:PMU:PMU <strong>2000</strong>PFU:PFU <strong>2000</strong>Supply voltage, frequencyConstruction1Pos. Designation Qty.1 Control <strong>2000</strong> 12 Pressure transmitter 13 Discharge manifold (stainless steel) 14 Isolating valve 2 per pump5 Suction manifold (stainless steel) 16 Non-return valve 1 per pump7 Base frame (stainless steel) 18 CR(E) pump 2-69 Pressure gauge 110 Nameplate 18429351076TM00 9385 4796Fig. 5<strong>Hydro</strong> <strong>2000</strong> booster set6

Product data<strong>Hydro</strong> <strong>2000</strong>System configuration<strong>Hydro</strong> <strong>2000</strong> consists of three main groups:• <strong>Hydro</strong> <strong>2000</strong> S• <strong>Hydro</strong> <strong>2000</strong> F• <strong>Hydro</strong> <strong>2000</strong> E.The main groups are divided into subgroups as shown in the table below.Description of pumpsMain groupSubgroupSizeNumberNumberof controlledpumpsMode of operationCommentsMS Full-size All Mains operation (start/stop)<strong>Hydro</strong> <strong>2000</strong> S(start/stop)MSHHalf-size 1 Mains operation (start/stop)Full-sizeAll otherpumpsMains operation (start/stop)MFFull-size1 1All otherpumpsSpeed control via frequency convertermounted in control cabinetMains operation (start/stop)Frequency-converter controlalternates among all pumps in thesystem.<strong>Hydro</strong> <strong>2000</strong> F(variable speed)MFHHalf-size 2 1Speed control via frequency convertermounted in control cabinetOnly one pump is frequency-converter-controlledat a time.Frequency-converter controlalternates between the two pumps.The uncontrolled pump is mainsoperated(start/stop).Full-sizeAll otherpumpsMains operation (start/stop)ME Full-size All AllSpeed control via frequencyconverter integrated in the motorAll pumps in operation run at thesame speed.<strong>Hydro</strong> <strong>2000</strong> E(variable speed)MEHHalf-size 2 2Full-sizeAll otherpumpsSpeed control via frequencyconverter integrated in the motorMains operation (start/stop)The two pumps run at the samespeed when both are in operation.MESFull-size 1 1Full-sizeAll otherpumpsSpeed control via frequencyconverter integrated in the motorMains operation (start/stop)Abbreviations:M: Control <strong>2000</strong> features a microprocessor for thecontrol of all functions.S: Some or all of the pumps in the system are mainsoperated(start/stop).F: Control <strong>2000</strong> features a frequency converter forthe control of some of the pumps in the system.E: Some or all of the pumps in the system are fittedwith MGE motors with integrated frequency converter.H: The system has one or two half-size pumps.(One half-size pump provides approximately thesame head as one full-size pump, but only approximatelyhalf the flow).7

Hydraulic functions<strong>Hydro</strong> <strong>2000</strong>Overview of functionsGrundfos<strong>Hydro</strong> <strong>2000</strong> MSStart/stopGrundfos<strong>Hydro</strong> <strong>2000</strong> MSHGrundfos<strong>Hydro</strong> <strong>2000</strong> MFVariable speedGrundfos<strong>Hydro</strong> <strong>2000</strong> MFHPFU <strong>2000</strong>PFU <strong>2000</strong> PFU <strong>2000</strong> PFU <strong>2000</strong>TM00 2674 0294TM00 2678 0294TM00 2680 0294TM00 2677 0294One pump in operation. One half-size pump in operation. One pump in operation viafrequency converter.One half-size pump in operation viafrequency converter.HHstopHsetQTM00 2749 0294HHstopHsetQTM00 2773 0294HHsetQTM00 2757 0294HHsetQTM00 2781 0294Three pumps in operation.One full-size pump and one half-sizepump in operation.One pump in operation viafrequency converter and two mainsoperatedpumps.One half-size pump in operation viafrequency converter and one mainsoperatedfull-size pump (start/stop).HHHHHstopHsetQTM00 2751 0294HstopHsetQTM00 2775 0294HsetQTM00 2759 0294HsetQTM00 2783 0294• Maintains an almost constantpressure by cutting the pumps inor out, as required.• Pump changeover is automaticand depends on load, time andfault.• The cut-out pressure (H stop ) cannotbe set, but is calculated automatically.• Maintains an almost constantpressure by cutting the half-sizeand full-size pumps in or out, asrequired.• The half-size pump is alwaysstarted first and cut out when afull-size pump is cut in.• Pump changeover between thefull-size pumps is automatic anddepends on load, time and fault.• The cut-out pressure (H stop ) cannotbe set, but is calculated automatically.• Maintains a constant pressurethrough continuously variableadjustment of the speed of onepump. The other pumps are cutin or out on mains operation, asrequired.• The frequency-converter-controlledpump is always startedfirst.• Pump changeover is automaticand depends on load, time andfault, and all pumps are frequency-converter-controlledinrotation.• Furthermore, all pumps arecontrolled alternately by thefrequency converter.• Maintains a constant pressurethrough continuously variableadjustment of the speed of onehalf-size pump. The other pumpsare mains-operated.• The frequency-converter-controlledhalf-size pump is alwaysstarted first.• Pump changeover is automaticand depends on load, time andfault.8

Hydraulic functions<strong>Hydro</strong> <strong>2000</strong>Grundfos<strong>Hydro</strong> <strong>2000</strong> MEVariable speedGrundfos<strong>Hydro</strong> <strong>2000</strong> MEHGrundfos<strong>Hydro</strong> <strong>2000</strong> MESPFU <strong>2000</strong>PFU <strong>2000</strong>PFU <strong>2000</strong>MGE MGE MGETM00 7983 2296MGEMGETM00 7984 2296MGETM00 7985 2296One pump in operation.One half-size pump with MGEmotor in operation.One pump with MGE motor inoperation.HHHH setQTM00 7995 2296H setQTM00 7994 2296H setQTM00 7993 2296Three pumps in operation.One half-size pump with MGEmotor and the full-size pump inoperation.One pump with MGE motor andmains-operated pumps in operation.HH setQTM00 7996 2296HH setQTM00 7997 2296HH setQTM00 7998 2296• Maintains a constant pressurethrough continuously variableadjustment of the speed of thepumps connected.• The system performance isadjusted to the demand throughcutting in/out of pumps and parallelcontrol of the pumps inoperation.• Pump changeover is automaticand depends on load, time andfault.• Maintains a constant pressurethrough continuously variableadjustment of the speed of thetwo half-size pumps with MGEmotors, while the full-size pumpis mains-operated (start/stop).• The half-size pumps always startfirst.• Pump changeover is automaticand depends on load, time andfault.• Maintains a constant pressurethrough continuously variableadjustment of the speed of onepump.The other pumps are cut in or outon mains operation, accordingto demand, thus achieving aperformance corresponding tothe consumption.• The pump with MGE motor willalways be started first.• Pump changeover is automaticand depends on load, time andfault.9

Product range<strong>Hydro</strong> <strong>2000</strong>System overviewPFU <strong>2000</strong> PFU <strong>2000</strong> PFU <strong>2000</strong> PFU <strong>2000</strong>TM00 2674 0294TM00 2678 0294TM00 2680 0294TM00 2677 0294System MS MSH MF MFHRangeNumber of full-size pumps 2-6 1-3 2-6 1-2Motor [kW] 0.37-30 0.75-30 0.37-30 3-30Number of half-size pumps - 1 - 2Mechanical versionIn-line piping • • • •Stainless-steel manifold • • • •Stainless-steel base frame • • • •Identical pump size • - • -ControlPFU <strong>2000</strong> (simple operation) • • • •Bus communication • • • •Pump changeover • • Soft start - - Constant pressure - - • •Friction-loss compensation • •External frequency converter - - • •Integrated frequency converter(MGE)Quick control - • -ApplicationWater supply - - • •Industry - - • -Irrigation • • AccessoriesPMU <strong>2000</strong> (advanced operation) • • • •Diaphragm tank • - • •Dry-running protection • • • •PCU <strong>2000</strong> (Communication Unit) • • • •Expansion joint • • • •Bypass • • • •Safety switch • • • •Optional positioning ofnon-return valve• • • •HHstopHsetQTM00 2751 0294HHstopHsetQTM00 2775 0294HHsetQTM00 2759 0294HHsetQTM00 2783 0294• Standard Available on request10

Product range <strong>Hydro</strong> <strong>2000</strong>PFU <strong>2000</strong>PFU <strong>2000</strong>PFU <strong>2000</strong>MGE MGE MGETM00 7983 2296MGEMGETM00 7984 2296MGETM00 7985 2296System ME MEH MESRangeNumber of full-size pumps 2-4 1-2 2-4Motor (kW) 0.37-22 0.75-22 0.37-22Number of half-size pumps - 2 -Mechanical versionIn-line piping • • •Stainless-steel manifold • • •Stainless-steel base frame • • •Identical pump size • - -ControlPFU <strong>2000</strong> (simple operation) • • •Bus communication • • •Pump changeover • Soft start • Constant pressure • • •Friction-loss compensation • • •External frequency converter - - -Integrated frequency converter(MGE)• • •Quick control • - •ApplicationWater supply • • •Industry • - •Irrigation AccessoriesPMU <strong>2000</strong> (advanced operation) • • •Diaphragm tank • • •Dry-running protection • • •PCU <strong>2000</strong> (Communication Unit) • • •Expansion joint • • •Bypass • • •Safety switch • • •Optional positioning ofnon-return valve• • •HH setQTM00 7996 2296HH setQTM00 7997 2296HH setQTM00 7998 2296• Standard Available on request11

Sizing<strong>Hydro</strong> <strong>2000</strong>General informationWhen sizing a booster set, it is important to ensure• that the performance of the booster set can meetthe highest possible demand both in terms of flowandpressure.• that the booster set is not oversized.This is important in relation to the installation andoperating costs. If required, the performance can alwaysbe enhanced at a later stage by adding one ormore pumps connected in parallel.Consumption patternThe consumption pattern can be illustrated in different ways:24-hour profileA 24-hour profile shows the consumption at different times of the day.Q[ m3 /h ]403020103691215182124TM00 9188 1303Fig. 624-hour profileDuty-time profileBased on the 24-hour profile, a duty-time profile is worked out.This profile is used to give an overview of how long the system is operating at a specific flow.Q[ m3 /h ]38332812520507579100TM00 9189 1303Fig. 7Duty-time profileThe example in fig. 7 shows the following:• 100% of the time: flow ≥ 5 m 3 /h• 79% of the time: flow > 12 m 3 /h• 75% of the time: flow > 28 m 3 /h• 50% of the time: flow > 33 m 3 /h• 20% of the time: flow ≥ 38 m 3 /h12

Sizing<strong>Hydro</strong> <strong>2000</strong>System selectionWhen sizing, the following should be considered:1. The consumption pattern to be met by the boosterset, includingQ[ m3 /h ]4030– how much does the consumption vary,– how suddenly does the consumption vary.See page 14.2. The distribution of consumption over time.See page 14.2010Fig. 83 6 9 12Consumption pattern15182124TM00 9188 13033. The type of booster set to be selected.The selection of type should be based upon theconsumption pattern.The following types are available:– MS, MSH, MF, MFH, ME, MEH, MES.See page 14.Q[ m3 /h ]3833284. The system size to be selected (pump performanceand number of pumps). The selection of system sizeshould be based upon the consumption pattern,considering the following aspects:12520507579100TM00 9189 1303– efficiency,Fig. 9Duty-time profile– NPSH value,– are standby pumps required?See page 15.H5. The diaphragm tank to be selected.See page 16.6. The dry-running protection to be selected.See page 16.7. Is friction-loss compensation required?See page 16.H setFig. 10 System/control typeQTM00 7996 2296PFU <strong>2000</strong>MGE MGE MGETM00 7983 2296Fig. 11 System sizeTM00 9397 4896Fig. 12 Accessories13

Sizing<strong>Hydro</strong> <strong>2000</strong>Type of booster setThe booster set type should be selected on the basis ofthe consumption pattern, i.e. the 24-hour and duty-timeprofiles.If the consumption is highly variable and optimumcomfort is required, pumps with continuously variablespeed control should be used.Examples of different consumption patterns and their24-hour and duty-time profiles:Water supply Industry IrrigationQQQ24-hour profilehTM00 9197 1303hTM00 9200 1303hTM00 9198 1303Flow: High degree of variation.Flow: High and sudden variation.Flow: Constant and known.Pressure: Constant.Pressure: Constant.Pressure: Constant.QQQDuty-time profileh%As appears, consumption is highly variable.Continuously variable speed control of thepumps is recommended.TM00 9201 1303It is expedient to use any of the systems withhalf-size pumps.h%As appears, consumption is highly variableand sudden.Continuously variable speed control of thepumps is recommended.TM00 9199 1303Systems using half-size pumps should not beused if the variation in consumption over avery short time is higher than the performanceof one full-size pump.TM00 9202 1303As appears, variations in consumption are regularyet known.Simple control is recommended.h%Any system with half-size pumps may be used.Recommended system types:MF, MFH, ME, MEH, MES.Recommended system types:MF, ME, MES.Recommended system types:MS, MSH, (MF, ME, MES).14

Sizing<strong>Hydro</strong> <strong>2000</strong>System sizePump sizeAs mentioned before, the system should be capable ofmeeting the highest possible demand. But as thehighest demand will often occur for a comparativelyshort part of the duty period only, it is important toselect a type of pump which can meet the varyingdemand throughout the duty period.It is not recommended to select a pump type whoseperformance is lower than the lowest possible consumption.Nor is it recommended to select a pump typewhose performance is higher than the highest possibleconsumption.EfficiencyIn order to achieve the optimum operating economy,attempts should be made to select the pumps on thebasis of optimum efficiency, i.e. the pumps should, asfar as possible, operate within their nominal operatingranges.As the system is always sized on the basis of thehighest possible consumption, meaning that it willalways be regulated down, it is important always tohave the duty point of the pumps to the right on the efficiencycurve (see the pump performance curve), inorder to keep efficiency high when consumption drops.EtaFig. 13 Pump efficiency curveQ [ m3 /h ]The optimum efficiency is ensured by selecting a dutypoint within the hatched area.TM00 9190 1303NPSHIn order to avoid cavitation, never select a pump whoseduty point lies too far to the right on the NPSH curve.Always check the NPSH values of the pumps at thehighest possible consumption (see the pump performancecurve).NPSHFig. 15 NPSH curveStandby pumpTo most customers reliable supplies are a major factor.Often it is not acceptable if the system does not maintainits maximum flow even during pump repairs orbreakdown. In order to prevent any disruption of thesupply in such a situation, the system may be sized witha standby pump.HFig. 16 System with standby pumpIf it is acceptable that the system does not produce therequired pressure but an unchanged flow during pumprepair and breakdown, a standby pump may, in certaincircumstances, not be required.HQmax.Q [ m3 /h ]QTM00 9191 0303TM00 9193 1303H•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• •QTM00 9192 1303Qmax.Fig. 17 System without standby pumpQTM00 9194 1303Fig. 14 Area of optimum efficiency15

Sizing<strong>Hydro</strong> <strong>2000</strong>Diaphragm tankThe need for a diaphragm tank should be estimated onthe basis of the following general guidelines:• All <strong>Hydro</strong> <strong>2000</strong> systems installed inside buildingsmust be equipped with a diaphragm tank due to theauto-stop function.• <strong>Hydro</strong> <strong>2000</strong> systems used in water supply applicationsdo not have to be equipped with a diaphragmtank as miles of PVC piping partly hold the necessarycapacity, partly have the elasticity to give sufficientcapacity.• The need for a diaphragm tank for <strong>Hydro</strong> <strong>2000</strong> systemsused in industrial applications should be estimatedfrom situation to situation on the basis of theindividual factors on site.Full-sizepump typeThe size of the obligatory diaphragm tank can also becalculated from the following formula:Dry-running protectionTo protect the booster set against dry running, dryrunningprotection is obligatory. The actual inlet conditionsdetermine the type of dry-running protection to beused.If the system draws from a tank, dry-running protectionshould be in the form of a level switch or electroderelay.If the system has an inlet pressure, a pressure transmittershould be used to protect against dry running.Recommended diaphragm tank size [litres]MS MSH MF MFH ME MEH MESCR(E) 3 120 - 8 - 8 - 8CR(E) 5 180 - 18 - 18 - 18CR(E) 10 325 180 33 18 33 18 33CR(E) 15 800 - 80 - 80 - 80CR(E) 20 1300 800 120 33 120 33 120CR(E) 32 2600 1300 180 120 180 120 180CR(E) 45 3700 2600 325 180 325 180 325CR(E) 64 5200 3700 325 180 325 325 325CR(E) 90 7300 5200 325 325 325 325 325VQ× 1000× ( 1+ p + On ⁄ off )------------------------------------------------------------------------------------------------set band 1=× --4×n × On ⁄ off kmax bandExample of <strong>Hydro</strong> <strong>2000</strong> MS CR 10 system:Q = 8 m 3 /hOn/off band= 1 bar= 4.0 barp setVQOn/off bandp setkn max= Tank volume [litres]= Mean flow [m 3 /h]Q = rated flow for the smallest pump in<strong>Hydro</strong> <strong>2000</strong> S systems, and Q = 25% ofrated flow for the smallest pump in<strong>Hydro</strong> <strong>2000</strong> F and E systems.= Difference between setpoint andstop pressure [bar]= Setpoint [bar]= 0.9 for <strong>Hydro</strong> <strong>2000</strong> S= 0.7 for <strong>Hydro</strong> <strong>2000</strong> E and F= Maximum number of starts/stops perhour.n maxCR 3, 5 and 10CR 15 to CR 90= 40 per hour= 20 per hour8 × 1000 × ( 1 + 4+1)V --------------------------------------------------------1=× ------- = 333 [ litres ]4× 40×1 0.9On the basis of this calculation, choose a 325-litre tank.Friction-loss compensationFriction-loss compensation often improves theeconomy of the system. The system characteristicdetermines whether friction-loss compensation can beused or not.HHTM00 9195 4496Friction-loss compensation can beused.QQTM00 9196 4496Friction-loss compensation cannotbe used.16

Sizing<strong>Hydro</strong> <strong>2000</strong>Understanding the curve chartsThe curves should be read as follows:The x-axis, giving the flow (Q) in m 3 /h, is common to allthe curves, whereas the y-axis, giving the head (H) inm, has been adapted to the individual pump type.When operating systems with half-size pumps, theperformance of one half-size pump is illustrated in thecurve chart as a thin curve. The half-size pump type canbe read in the lower left corner.p[kPa]900800700600H[m]90807060<strong>Hydro</strong> <strong>2000</strong>CR 10-9MS-MSH50 HzISO 9906 Annex A500501 2 3 4 5 640040CR 5-14300p[kPa]70030H[m]70This axis (y-axis) is adaptedto the individual pump typeCR 10-6MS-MSH600605004005040Specification of full-sizepump type and systemtype30030CR 5-101 2 3 4 5 6200p[kPa]50020H[m]50Specification ofhalf-size pump typeCR 10-4MS-MSH40040300302001002010CR 5-8 1 2 3 4 5 60p[kPa]3000H[m]30This axis (x-axis) iscommon to all pumptypes.CR 10-3MS-MSH2002010010CR 5-51 2 3 4 5 6000 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 Q [m³/h]0 2 4 6 8 10 12 14 16 18 20 Q [l/s]TM02 7544 380318

Sizing<strong>Hydro</strong> <strong>2000</strong>Example: How to select a system• A head of 45 m is required.The pump type best meeting this specification isfound by means of the y-axis, e.g. CR 10-6.Draw a rightward, horizontal line from the head required.• A flow of 18 m 3 /h is required.Now draw an upward, vertical line from the specifiedflow. The intersection of the two lines gives thenumber of pumps required for the system (2 CR 10-6).Only systems whose operating ranges lie within thehatched area of the example should be selected.p[kPa]900800700600H[m]90807060<strong>Hydro</strong> <strong>2000</strong>CR 10-9MS-MSH50 HzISO 9906 Annex A500501 2 3 4 5 640040CR 5-14300p[kPa]70030H[m]70CR 10-6MS-MSH60060500504004030030CR 5-101 2 3 4 5 6200p[kPa]50020H[m]50CR 10-4MS-MSH40040300302001000p[kPa]30020100H[m]30CR 5-8 1 2 3 4 5 6CR 10-3MS-MSH2002010010CR 5-51 2 3 4 5 6000 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 Q [m³/h]0 2 4 6 8 10 12 14 16 18 20 Q [l/s]TM02 7578 380319

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 3p[kPa]700600500H[m]706050<strong>Hydro</strong> <strong>2000</strong>CR 3-10MS50 HzISO 9906 Annex A4004030020030201 2 3 4 5 6100p[kPa]50010H[m]50CR 3-7MS400403003020010020101 2 3 4 5 60p[kPa]40030020010000H[m]40302010CR 3-5MS1 2 3 4 5 600 2 4 6 8 10 12 14 16 18 20 22 24 Q [m³/h]0 1 2 3 4 5 6 7 Q [l/s]TM00 8763 3803Performance curves, <strong>Hydro</strong> <strong>2000</strong> SCR 320

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 3p[kPa]14001300120011001000900800H[m]1501401301201101009080<strong>Hydro</strong> <strong>2000</strong>CR 3-23MS50 HzISO 9906 Annex A7007060050060501 2 3 4 5 6p[kPa]1100H[m]120110CR 3-19MS10001009009080080700706006050040050401 2 3 4 5 630030p[kPa]900H[m]10090CR 3-15MS8008070070600605005040040300301 2 3 4 5 6200200 2 4 6 8 10 12 14 16 18 20 22 24 Q [m³/h]0 1 2 3 4 5 6 7 Q [l/s]TM00 8765 380321

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 5p[kPa]700600500H[m]706050<strong>Hydro</strong> <strong>2000</strong>CR 5-10MS50 HzISO 9906 Annex A40040300301 2 3 4 5 620020100p[kPa]60010H[m]60CR 5-8MS500504004030030200201 2 3 4 5 6100p[kPa]40010H[m]40CR 5-5MS3003020020100101 2 3 4 5 60p[kPa]3000H[m]30CR 5-4MS2002010001001 2 3 4 5 60 5 10 15 20 25 30 35 40 45 Q [m³/h]0 2 4 6 8 10 12 14 Q [l/s]TM00 8771 3803CR 522

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 5p[kPa]14001300120011001000900800H[m]1501401301201101009080<strong>Hydro</strong> <strong>2000</strong>CR 5-22MS50 HzISO 9906 Annex A70060070601 2 3 4 5 650050p[kPa]1300120011001000900800H[m]1401301201101009080CR 5-20ME7007060050060501 2 3 4 5 640040p[kPa]1000H[m]110100CR 5-16MS9009080080700706006050040050401 2 3 4 5 6300300 5 10 15 20 25 30 35 40 45 Q [m³/h]0 2 4 6 8 10 12 14 Q [l/s]TM00 8774 380323

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 10p[kPa]900800700600H[m]90807060<strong>Hydro</strong> <strong>2000</strong>CR 10-9MS-MSH50 HzISO 9906 Annex A500501 2 3 4 5 640040CR 5-14300p[kPa]70030H[m]70CR 10-6MS-MSH60060500504004030030CR 5-101 2 3 4 5 6200p[kPa]50020H[m]50CR 10-4MS-MSH400403003020020CR 5-8 1 2 3 4 5 6100100p[kPa]3000H[m]30CR 10-3MS-MSH2002010010CR 5-51 2 3 4 5 6000 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 Q [m³/h]0 2 4 6 8 10 12 14 16 18 20 Q [l/s]TM02 7544 3803CR 1024

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 10p[kPa]140013001200H[m]150140130120<strong>Hydro</strong> <strong>2000</strong>CR 10-14MS50 HzISO 9906 Annex A110011010001009009080070080701 2 3 4 5 660060p[kPa]13001200H[m]140130120CR 10-12MS-MSH1100110100010090090800807006007060CR 5-201 2 3 4 5 650050p[kPa]1000H[m]110100CR 10-10MSH900908008070070600500400605040CR 5-161 2 3 4 5 6300300 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 Q [m³/h]0 2 4 6 8 10 12 14 16 18 20 Q [l/s]TM02 7545 380325

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 15p[kPa]900800700H[m]908070<strong>Hydro</strong> <strong>2000</strong>CR 15-6MSH50 HzISO 9906 Annex A600605004005040CR 10-91 2 3 4 5 6300p[kPa]70060030H[m]7060CR 15-5MS5005040030040301 2 3 4 5 6200p[kPa]60020H[m]60CR 15-4MSH500504004030030CR 10-61 2 3 4 5 6200p[kPa]40020H[m]40CR 15-3MS-MSH3003020020CR 10-4 1 2 3 4 5 6100p[kPa]30010H[m]30CR 15-2MS-MSH200201000100CR 10-3 1 2 3 4 5 60 10 20 30 40 50 60 70 80 90 100 110 120 130 Q [m³/h]0 5 10 15 20 25 30 35 Q [l/s]TM02 7546 3803 CR 1526

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 15p[kPa]14001200H[m]140120<strong>Hydro</strong> <strong>2000</strong>CR 15-10MS-MSH50 HzISO 9906 Annex A100010080080CR 10-14 1 2 3 4 5 660060400p[kPa]14001200100040H[m]140120100CR 15-9MS80060080601 2 3 4 5 6400p[kPa]120040H[m]120CR 15-8MSH10001008008060060CR 10-121 2 3 4 5 6400p[kPa]100040H[m]100CR 15-7MS8008060060400401 2 3 4 5 60 10 20 30 40 50 60 70 80 90 100 110 120 130 Q [m³/h]0 5 10 15 20 25 30 35 Q [l/s]TM02 7547 380327

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 20p[kPa]700600H[m]8075706560<strong>Hydro</strong> <strong>2000</strong>CR 20-5MS-MSH50 HzISO 9906 Annex A55500504004540CR 10-830035301 2 3 4 5 6p[kPa]450H[m]5045CR 20-3MS-MSH40040350353002503025CR 10-5200201 2 3 4 5 61501510010p[kPa]300H[m]30CR 20-2MS-MSH250252002015015CR 10-3100101 2 3 4 5 65050 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 Q [m³/h]0 5 10 15 20 25 30 35 40 45 50 Q [l/s]TM02 7548 3803 CR 2028

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 20p[kPa]14001300120011001000900800700p[kPa]11001000900800H[m]150145140135130125120115110105100959085807570H[m]120115110105100959085801 2 3 4 5 6<strong>Hydro</strong> <strong>2000</strong>CR 20-10MS50 HzISO 9906 Annex ACR 20-7MS-MSH70060075706560CR 10-1250055501 2 3 4 5 6450 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 Q [m³/h]0 5 10 15 20 25 30 35 40 45 50 Q [l/s]TM02 7549 380329

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 32p[kPa]900800700600H[m]90807060<strong>Hydro</strong> <strong>2000</strong>CR 32-4MS-MSH50 HzISO 9906 Annex A500400300p[kPa]600504030H[m]60CR 15-6123456CR 32-3MS-MSH5005040040300200p[kPa]5003020H[m]50CR 15-41 2 3 4 5 6CR 32-2MS-MSH400403003020020CR 15-31 2 3 4 5 6100p[kPa]30010H[m]30CR 32-2-2MS2002010001001 2 3 4 5 60 20 40 60 80 100 120 140 160 180 200 220 240 Q [m³/h]0 10 20 30 40 50 60 70 Q [l/s]TM01 2763 3803CR 3230

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 32p[kPa]140013001200H[m]140130120<strong>Hydro</strong> <strong>2000</strong>CR 32-7MS-MSH50 HzISO 9906 Annex A110011010001009009080080CR 15-1070070123456600p[kPa]110060H[m]110CR 32-6-2MS-MSH100010090090800807007060060CR 15-850050123456400p[kPa]100040H[m]100CR 32-5MS900908008070070600605005012 34 5 6400400 20 40 60 80 100 120 140 160 180 200 220 240 Q 260[m³/h]0 10 20 30 40 50 60 70 Q [l/s]TM01 2764 380331

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 45p[kPa]900800700600500H[m]9080706050<strong>Hydro</strong> <strong>2000</strong>CR 45-3MS-MSH50 HzISO 9906 Annex A400300p[kPa]6004030H[m]60CR 32-41 2 3 4 5 6CR 45-2MS-MSH5005040040300200p[kPa]5003020H[m]50CR 32-31 2 3 4 5 6CR 45-2-2MS-MSH4004030030200100p[kPa]3002010H[m]30CR 32-21 2 3 4 5 6CR 45-1MS-MSH200201000100CR 32-2-21 2 3 4 5 60 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 Q [m³/h] 3800 10 20 30 40 50 60 70 80 90 100 Q [l/s]TM01 2765 3803CR 4532

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 45p[kPa]14001300120011001000900800700600p[kPa]120011001000900800700600H[m]14013012011010090807060H[m]12011010090807060CR 32-7 1 2 3 4 56<strong>Hydro</strong> <strong>2000</strong>CR 45-5MS-MSH50 HzISO 9906 Annex ACR 45-4MS-MSH50050CR 32-6-21 2 3 4 5 6400400 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 Q [m³/h] 3800 10 20 30 40 50 60 70 80 90 100 Q [l/s]TM01 2766 380333

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 64p[kPa]900800700600500H[m]9080706050<strong>Hydro</strong> <strong>2000</strong>CR 64-3-1MS-MSH50 HzISO 9906 Annex A400300p[kPa]7006004030H[m]7060CR 32-41 2 3 4 5 6CR 64-2MS-MSH5005040040300200p[kPa]5004003020H[m]5040CR 32-31 2 3 4 5 6CR 64-2-2MS-MSH300302001002010CR 32-21 2 3 4 5 60p[kPa]4000H[m]40CR 64-1MS-MSH30030200201000100CR 32-2-2 1 2 3 4 5 60 40 80 120 160 200 240 280 320 360 400 440 480 520 Q 560[m³/h]0 20 40 60 80 100 120 140 Q [l/s]TM01 2767 3803CR 6434

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 64p[kPa]13001200H[m]140130120<strong>Hydro</strong> <strong>2000</strong>CR 64-5-1MS-MSH50 HzISO 9906 Annex A11001101000100900908007008070CR 32-71 2 3 4 5 6600p[kPa]110060H[m]120110CR 64-4MS-MSH100010090090800807006007060CR 32-61 2 3 45 6500p[kPa]100090080070060050H[m]10090807060CR 64-4-2MS-MSH50050CR 32-51 2 3 4 5 6400400 40 80 120 160 200 240 280 320 360 400 440 480 520 Q 560[m³/h]0 20 40 60 80 100 120 140 Q [l/s]TM01 2768 380335

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 90p[kPa]1000900800700H[m]100908070<strong>Hydro</strong> <strong>2000</strong>CR 90-3-2MS-MSH50 HzISO 9906 Annex A600500400605040CR 45-430030200p[kPa]80070020H[m]80701 2 3 45 6CR 90-2MS-MSH600605005040040CR 45-3300200p[kPa]5004003020H[m]50401 2 3 4 5 6CR 90-2-2MS-MSH3002003020CR 45-2100101 2 3 4 560p[kPa]4000H[m]40CR 90-1MS-MSH30030200100020100CR 45-2-21 2 3 4 5 60 40 80 120 160 200 240 280 320 360 400 440 480 520 560 600 640 680 Q [m³/h]7600 20 40 60 80 100 120 140 160 180 200 Q [l/s]TM01 2769 3803CR 9036

Performance curves<strong>Hydro</strong> <strong>2000</strong> SCR 90p[kPa]120011001000900800H[m]1301201101009080<strong>Hydro</strong> <strong>2000</strong>CR 90-4MS-MSH50 HzISO 9906 Annex A70070CR 45-5600500p[kPa]1200110010009008006050H[m]13012011010090801 2 3 4 5 6CR 90-4-2MS-MSH700600500706050CR 45-5400300p[kPa]10009004030H[m]100901 2 3 4 56CR 90-3MS-MSH80080700706005006050CR 45-440030040301 2 3 4 5 60 40 80 120 160 200 240 280 320 360 400 440 480 520 560 600 640 680 Q [m³/h]7600 20 40 60 80 100 120 140 160 180 200 Q [l/s]TM01 2770 380337

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 3 / CR 5Technical data, <strong>Hydro</strong> <strong>2000</strong> S Electrical dataH1455120L650BTM00 9365 1303Control <strong>2000</strong>H1000-1500120L650BTM00 9366 1303CR 3/ CR 5H1201455L650BTM00 9367 1801For information about and , please see page 98.38

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 3 / CR 5Electrical data, weights and dimensionsNo. of pumps2Full-sizepumpsPump typeMotor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSH[mm]Weight[kg]Max.I n [A]CR 3-5 0.37553 89 2.0CR 3-7 0.55 589 92 2.8CR 3-10 0.75 Rp 2 710 600 687 98 3.8CR 3-15 1.1 777 105 5.4CR 3-19 1.5 915 119 6.8CR 3-23 2.2 987 126 9.6CR 3-5 0.37553 143 3.0CR 3-7 0.55 589 147 4.23CR 3-10 0.75 687 157 5.7Rp 2 710 1370CR 3-15 1.1 777 167 8.1CR 3-19 1.5 915 188 10.2CR 3-23 2.2 987 199 14.4CR 3-5 0.37553 197 4.04CR 3-10 0.75 Rp2½ 726 1890 687 216 7.6CR 3-15 1.1 777 229 10.8CR 3-7 0.55 589 202 5.6CR 3-19 1.5 915 257 13.6CR 3-23 2.2 987 271 19.25CR 3-5 0.37553 229 5.0CR 3-7 0.55 589 235 7.0CR 3-10 0.75 Rp726 2190 687 252 9.52½CR 3-15 1.1 777 269 13.5CR 3-19 1.5 915 304 17.0CR 3-23 2.2 987 322 24.0CR 3-5 0.37553 260 6.0CR 3-7 0.55 589 268 8.46CR 3-10 0.75 Rp726 2510 687 288 11.42½CR 3-15 1.1 777 307 16.2CR 3-19 1.5 915 350 20.4CR 3-23 2.2 987 372 28.8For information about and . please see page 98.No. of pumps2345Full-sizepumpsPump type Motor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSH[mm]Weight[kg]Max.I n [A]CR 5-4 0.55571 90 2.8CR 5-5 0.75 642 96 3.8CR 5-8 1.1 723 103 5.4CR 5-10 1.5Rp 2 710 600843 117 6.8CR 5-16 2.2 1005 127 9.6CR 5-20 3.0 1171 143 12.8CR 5-22 4.0 1262 174 16.0CR 5-4 0.55571 145 4.2CR 5-5 0.75 642 154 5.7CR 5-8 1.1 723 164 8.1CR 5-10 1.5 Rp 2 710 1370 843 184 10.2CR 5-16 2.2 1005 200 14.4CR 5-20 3.0 1171 224 19.2CR 5-22 4.0 1262 264 24.0CR 5-4 0.55571 200 5.6CR 5-5 0.75 642 211 7.6CR 5-8 1.1 723 225 10.8CR 5-10 1.5Rp2½726 1890 843 252 13.6CR 5-16 2.2 1005 273 19.2CR 5-20 3.0 1171 305 25.6CR 5-22 4.0 1262 379 32.0CR 5-4 0.55571 233 7.0CR 5-5 0.75 642 247 9.5CR 5-8 1.1Rp723 265 13.5726 2190CR 5-10 1.5 2½843 298 17.0CR 5-16 2.2 1005 324 24.0CR 5-20 3.0 1171 365 32.0CR 5-22 4.0 1262 450 40.0CR 5-4 0.55571 264 8.4CR 5-5 0.75 642 282 11.4CR 5-8 1.1Rp723 303 16.2726 25106 CR 5-10 1.5 2½843 343 20.4CR 5-16 2.2 1005 374 28.8CR 5-20 3.0 1171 423 38.4CR 5-22 4.0 1262 518 48.0For information about and . please see page 98.39

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 10150H1455L800BTM02 7754 3903CR 10150H1000-1500L800BTM02 7755 3903H1455150L800BTM02 7756 3903For information about and , please see page 98.40

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 10Electrical data, weights and dimensionsNo. ofpumps2345Full-size pumpsPump typeMotor[kW]Half-size pumpsPump typeMotor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSH[mm]Weight[kg]Max.I n [A]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSHH[mm]Weight[kg]CR 10-3 1.1 CR 5-5 0.75678 128 5.4678 147 4.6CR 10-4 1.5 CR 5-8 1.1 660 774 142 6.8 660 774 154 6.1CR 10-6 2.2 CR 5-10 1.5 834 150 9.6 843 164 8.2CR 10-9 3.0 CR 5-14 2.2 Rp 2½ 876983 164 12.8 983 177 11.2CR 10-10 4.0 CR 5-16 2.2 - - - -1050 220 12.81280CR 10-12 4.0 CR 5-20 3.0 660 1110 190 16.0 1206 227 14.4CR 10-14 5.5 - - 1221 200 22.0 - - - -CR 10-3 1.1 CR 5-5 0.75678 198 8.1678 209 7.3CR 10-4 1.5 CR 5-8 1.1 774 219 10.2 774 223 9.514001400CR 10-6 2.2 CR 5-10 1.5 834 231 14.4 843 237 13.0CR 10-9 3.0 CR 5-14 2.2 Rp 2½ 876983 252 19.2 983 257 17.6CR 10-10 4.0 CR 5-16 2.2 - - - -1050 302 20.81600CR 10-12 4.0 CR 5-20 3.01110 291 24.0 1206 315 22.41400CR 10-14 5.5 - - 1221 305 33.0 - - - -CR 10-3 1.1 CR 5-5 0.75678 284 10.8678 260 10.0CR 10-4 1.5 CR 5-8 1.1 1720 774 312 13.6 774 281 12.91920CR 10-6 2.2 CR 5-10 1.5 834 328 19.2 843 299 17.8CR 10-9 3.0 CR 5-14 2.2 DN 80 889983 356 25.6 983 326 24.0CR 10-10 4.0 CR 5-16 2.2 - - - -1050 446 28.82100CR 10-12 4.0 CR 5-20 3.0 1920 1110 410 32.0 1206 457 30.4CR 10-14 5.5 - - 1221 427 44.0 - - - -CR 10-3 1.1 - -678 336 13.5 - - - -CR 10-4 1.5 - - 2220 774 371 17.0 - - - -CR 10-6 2.2 - - 834 391 24.0 - - - -DN 80 889CR 10-9 3.0 - - 983 426 32.0 - - - -CR 10-12 4.0 - - 2420 1110 508 40.0 - - - -CR 10-14 5.5 - - 1221 549 55.0 - - - -CR 10-3 1.1 - -678 403 16.2 - - - -CR 10-4 1.5 - - 2540 774 445 20.4 - - - -6CR 10-6 2.2 - - 834 469 28.8 - - - -DN 100 914CR 10-9 3.0 - - 983 511 38.4 - - - -CR 10-12 4.0 - - 2740 1110 609 48.0 - - - -CR 10-14 5.5 - - 1221 657 66.0 - - - -For information about and . please see page 98.Max.I n [A]41

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 15H1601455L950BTM02 7757 3903CR 151000-1500160HL950BTM02 7758 3903H1455160L950BTM02 7759 3903For information about and , please see page 98.42

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 15160HL950BTM02 7788 4003For information about , please see page 98.43

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 15Electrical data, weights and dimensionsNo. ofpumps23456Full-size pumpsPump typeMotor[kW]Half-size pumpsPump typeMotor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSH[mm]Weight[kg]Max.I n [A]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSHH[mm]Weight[kg]CR 15-2 2.2 CR10-3 1.1720 766 176 9.6 720 766 178 7.5CR 15-3 3.0 CR10-4 1.5 870 186 12.8 870 190 9.8CR 15-4 4.0 CR10-6 2.2 - - - - 1310 952 224 12.8CR 15-5 4.0 - 1310 997 257 16.0 - - -CR 15-6 5.5 CR10-9 3.0DN 80 1039- - - - 1310 1093 255 17.4CR 15-7 5.5 - 1310 1138 295 22.0 - - -CR 15-8 7.5 CR10-12 4.0 - - - - 1310 1183 272 23.2CR 15-9 7.5 - 1310 1228 305 30.4 - - -CR 15-10 11.0 CR10-14 5.514101423 360 43.01410Max.I n [A]1423 318 32.5CR 15-2 2.2 CR10-3 1.1766 276 14.4766 273 12.313701430CR 15-3 3.0 CR10-4 1.5 870 291 19.2 870 287 16.2CR 15-4 4.0 CR10-6 2.2 - - - - 1630 952 327 20.8CR 15-5 4.0 - 1570 997 355 24.0 - - -CR 15-6 5.5 CR10-9 3.0DN 100 1064- - - - 1630 1093 384 28.4CR 15-7 5.5 - 1570 1138 402 33.0 - - -CR 15-8 7.5 CR10-12 4.0 - - - - 1630 1183 417 38.4CR 15-9 7.5 - 1570 1228 433 45.6 - - -CR 15-10 11.0 CR10-14 5.518101423 551 64.5 1810 1423 488 54.0CR 15-2 2.2 CR10-3 1.1766 355 19.2766 349 17.117501950CR 15-3 3.0 CR10-4 1.5 870 377 25.6 870 365 22.6CR 15-4 4.0 CR10-6 2.2 - - - - 2130 952 445 28.8CR 15-5 4.0 - 1950 997 476 32.0 - - -CR 15-6 5.5 CR10-9 3.0DN 100 1064- - - - 2130 1093 528 39.4CR 15-7 5.5 - 1950 1138 562 44.0 - - -CR 15-8 7.5 CR10-12 4.0 - - - - 2130 1183 577 53.6CR 15-9 7.5 - 1950 1228 582 60.8 - - -CR 15-10 11.0 CR10-14 5.522101423 729 86.0 2410 1423 683 75.5CR 15-2 2.2 - -2270 766 463 24.0 - - - -CR 15-3 3.0 - - 870 488 32.0 - - - -CR 15-5 4.0 - -997 601 40.0 - - - -DN 150 1118 2450CR 15-7 5.5 - - 1138 711 55.0 - - - -CR 15-9 7.5 - - 1228 738 76.0 - - - -CR 15-10 11.0 - - 1680 1423 826 107.5 - - - -CR 15-2 2.2 - -2570 766 539 28.8 - - - -CR 15-3 3.0 - - 870 569 38.4 - - - -2770CR 15-5 4.0 - -997 696 48.0 - - - -DN 150 1118CR 15-7 5.5 - - <strong>2000</strong> 1138 731 66.0 - - - -CR 15-9 7.5 - - 1228 761 91.2 - - - -CR 15-10 11.0 - -For information about . and . please see page 98.23601423 987 129.0 - - - -44

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 20H1601455L950BTM02 7757 3903CR 20160H1000-1500L950BTM02 7758 3903H1455160L950BTM02 7759 3903For information about and , please see page 98.45

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 20160HL950BTM02 7788 4003For information about , please see page 98.46

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 20Electrical data, weights and dimensionsNo. ofpumps23456Full-size pumpsPump typeMotor[kW]Half-size pumpsPump typeMotor[kW]CR20-2 2.2 CR10-3 1.1ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSH[mm]Weight[kg]Max.I n [A]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSHH[mm]Weight[kg]CR20-3 4.0 CR10-5 2.2907 236 16.0907 224 12.81310CR20-5 5.5 CR10-8 3.0 1048 280 22.0 1048 252 17.4DN 80 1039 13101410CR20-7 7.5 CR10-12 4.0 1138 295 30.41138 260 23.21410CR20-10 11.0 -1423 356 43.0 - - -720766 176 9.6720Max.I n [A]766 178 7.5CR20-2 2.2 CR10-3 1.11370 766 276 14.4 1430 766 273 12.3CR20-3 4.0 CR10-5 2.2907 331 24.0907 327 20.81630CR20-5 5.5 CR10-8 3.0 1570 1048 399 33.0 1048 378 28.4DN 100 1064CR20-7 7.5 CR10-12 4.0 1138 420 45.6 1810 1138 393 38.4CR20-10 11.0 -18101423 547 64.5 - - -CR20-2 2.2 CR10-3 1.11750 766 355 19.2 1950 766 349 17.1CR20-3 4.0 CR10-5 2.2907 449 32.0907 445 28.82130CR20-5 5.5 CR10-8 3.0 1950 1048 541 44.0 1048 519 39.4DN 100 1064CR20-7 7.5 CR10-12 4.0 1138 566 60.8 2410 1138 517 53.6CR20-10 11.0 -CR20-2 2.2 -22101423 725 86.0 - - - -CR20-3 4.0 - 2450 907 571 40.0 - - - -CR20-5 5.5 -DN 150 1118 1048 687 55.0 - - - -CR20-7 7.5 -16801138 619 76.0 - - - -CR20-10 11.0 -20401423 822 107.5 - - - -CR20-2 2.2 -2250766 463 24.0 - - - -CR20-3 4.0 -2770907 668 48.0 - - - -CR20-5 5.5 -DN 150 1118<strong>2000</strong> 1048 713 66.0CR20-7 7.5 - 1138 743 91.2CR20-10 11.0 -For information about . and . please see page 98.25702360766 539 28.8 - - - -1423 987 129.047

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 32H1751455L 950BTM01 2968 1303CR 32175HL 950BTM01 2964 1303For information about and , please see page 98.48

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 32Electrical data, weights and dimensionsNo. ofpumps2345Full-size pumpsPump typeMotor[kW]Half-size pumpsPump typeMotor[kW]CR 32-2-2 3.0 -ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSH[mm]Weight[kg]Max.I n [A]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSHH[mm]Weight[kg]CR 32-2 4.0 CR15-3 3.01017 336 16.01017 290 14.41600CR 32-3 5.5 CR15-4 4.0 1106 354 22.0 1106 311 19.0DN 100 1062CR 32-4 7.5 CR15-6 5.5 1600 1176 370 30.4 1176 349 26.2CR 32-5 11.0 - 1429 454 43.0 - - - -CR 32-6-2 11.0 CR15-8 7.5 1499 462 43.0 1600 1499 394 36.7CR 32-7 15.0 CR15-10 11.0 1623 537 57.4 1623 467 50.2CR 32-2-2 3.0 -1400Max.I n [A]980 302 12.8 - - - -CR 32-2 4.0 CR15-3 3.01017 487 24.01017 439 22.421022102CR 32-3 5.5 CR15-4 4.0 1106 514 33.0 1106 475 30.0CR 32-4 7.5 CR15-6 5.5 1176 538 45.6 1176 526 41.4DN 150 1116CR 32-5 11.0 -1429 697 64.5 - - - -CR 32-6-2 11.0 CR15-8 7.5 2302 1499 709 64.5CR 32-7 15.0 CR15-10 11.0 1623 822 86.1CR 32-2-2 3.0 -1902980 444 19.2 - - - -210223011499 612 58.21623 754 78.9CR 32-2 4.0 CR15-3 3.01017 656 32.01017 610 30.42802CR 32-3 5.5 CR15-4 4.0 1106 693 44.0 1106 661 41.0DN 150 1116CR 32-4 7.5 CR15-6 5.5 2802 1176 725 60.8 1176 723 56.6CR 32-5 11.0 - 1429 894 86.0 - - - -CR 32-6-2 11.0 CR15-8 7.5 1499 910 86.0 2802 1499 852 79.7CR 32-7 15.0 CR15-10 11.0 1623 1059 114.8 1623 996 107.6CR 32-2-2 3.0 - -2602980 583 25.6 - - - -CR 32-2 4.0 - - 3302 1017 807 40.0 - - - -CR 32-3 5.5 - - 1106 852 55.0 - - - -CR 32-4 7.5 - -DN 150 11161176 795 76.0 - - - -CR 32-5 11.0 - - 2522 1429 1005 107.5 - - - -CR 32-6-2 11.0 - - 1499 1025 107.5 - - - -CR 32-7 15.0 - - 1623 1210 143.5 - - - -CR 32-2-2 3.0 - -CR 32-2 4.0 - -3102980 724 32.0 - - - -6CR 32-3 5.5 - -DN 150 11161106 898 66.0 - - - -CR 32-4 7.5 - - 1176 946 91.2 - - - -CR 32-5 11.0 - -30221429 1198 129.0 - - - -CR 32-6-2 11.0 - - 1499 1222 129.0 - - - -CR 32-7 15.0 - - 1623 1444 172.2 - - - -For information about and . please see page 98.36023802980 851 38.4 - - - -1017 944 48.0 - - - -49

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 45H1455210L 1050BTM01 2969 1303CR 45H210L 1050BTM01 2965 1303For information about and , please see page 98.50

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 45Electrical data, weights and dimensionsNo. ofpumps2345Full-size pumpsPump typeMotor[kW]Half-size pumpsPump typeMotor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSH[mm]Weight[kg]Max.I n [A]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSHH[mm]Weight[kg]CR 45-1 4.0 CR 32-2-2 3.01040 376 16.01040 355 14.4CR 45-2-2 5.5 CR 32-2 4.0 1139 394 22.0 1139 374 19.016021602CR 45-2 7.5 CR 32-3 5.5 1146 404 30.4 1146 389 26.2CR 45-3 11.0 CR 32-4 7.5 DN 150 12161402 488 43.0 1402 438 36.7CR 45-4 15.0 CR 32-6-2 11.0 1539 563 57.4 1539 522 50.2CR 45-5 18.5 CR 32-7 15.018021623 627 71.81802Max.I n [A]1623 609 64.6CR 45-1 4.0 CR 32-2-2 3.01040 540 24.01040 518 22.421042104CR 45-2-2 5.5 CR 32-2 4.0 1139 567 33.0 1139 546 30.0CR 45-2 7.5 CR 32-3 5.5 1146 582 45.6 1146 567 41.4DN 200 1267CR 45-3 11.0 CR 32-4 7.51402 741 64.51402 658 58.223042304CR 45-4 15.0 CR 32-6-2 11.0 1539 854 86.1 1539 813 78.9CR 45-5 18.5 CR 32-7 15.0 1623 900 107.7 1623 881 100.5CR 45-1 4.0 CR 32-2-2 3.01040 725 32.01040 704 30.4CR 45-2-2 5.5 CR 32-2 4.0 1139 762 44.0 1139 741 41.0CR 45-2 7.5 CR 32-3 5.5 2804 1146 782 60.8 2804 1146 766 56.6DN 200 1267CR 45-3 11.0 CR 32-4 7.5 1402 951 86.0 1402 901 79.7CR 45-4 15.0 CR 32-6-2 11.0 1539 1100 114.8 1539 1058 107.6CR 45-5 18.5 CR 32-7 15.0 1623 1161 143.6 1623 1140 136.4CR 45-1 4.0 - -3304 1040 894 40.0 - - - -CR 45-2-2 5.5 - - 1139 939 55.0 - - - -CR 45-2 7.5 - -1146 867 76.0 - - - -DN 200 1267CR 45-3 11.0 - - 2524 1402 1077 107.5 - - - -CR 45-4 15.0 - - 1539 1262 143.5 - - - -CR 45-5 18.5 - - 1623 1336 179.5 - - - -CR 45-1 4.0 - -CR 45-2-2 5.5 - -6 CR 45-2 7.5 - - DN 200 12671146 1030 91.2 - - - -3024CR 45-3 11.0 - - 1402 1282 129.0 - - - -CR 45-4 15.0 - - 1539 1504 172.2 - - - -CR 45-5 18.5 - - 1623 1594 215.4 - - - -For information about and . please see page 98.38041040 1039 48.0 - - - -1139 1000 66.0 - - - -51

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 64H1455210L 1050BTM01 2969 1303CR 64H210L 1050BTM01 2965 1303For information about and , please see page 98.52

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 64Electrical data, weights and dimensionsNo. ofpumps2345Full-size pumpsPump typeMotor[kW]Half-size pumpsPump typeMotor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSH[mm]Weight[kg]Max.I n [A]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSHH[mm]Weight[kg]CR 64-1 5.5 CR 32-2-2 3.01062 397 22.01062 365 17.4CR 64-2-2 7.5 CR 32-2 4.0 1602 1145 415 30.4 1602 1145 384 23.2CR 64-2 11.0 CR 32-3 5.5 1328 491 43.0 1328 431 32.5CR 64-3-1 15.0 CR 32-4 7.5DN 150 12141424 568 57.4 1424 478 43.9CR 64-4-2 18.5 CR 32-5 11.0 1802 1507 630 71.8 1802 1507 533 57.4CR 64-4 22.0 CR 32-6-2 11.0 1629 739 84.0 1629 627 63.5CR 64-5-1 30.0 CR 32-7 15.020021778 944 112.02002Max.I n [A]1778 783 84.7CR 64-1 5.5 CR 32-2-2 3.02104 1062 571 33.0 2104 1062 539 28.4CR 64-2-2 7.5 CR 32-2 4.0 1145 598 45.6 1145 568 38.4CR 64-2 11.0 CR 32-3 5.51328 745 64.51328 652 54.0CR 64-3-1 15.0 CR 32-4 7.5DN 200 1265 2304 1424 861 86.1 2304 1424 773 72.6CR 64-4-2 18.5 CR 32-5 11.0 1507 904 107.7 1507 842 93.3CR 64-4 22.0 CR 32-6-2 11.0 1629 1067 126.0 1629 955 105.5CR 64-5-1 30.0 CR 32-7 15.025041778 1359 168.025041778 1199 140.7CR 64-1 5.5 CR 32-2-2 3.01062 768 44.01062 736 39.4CR 64-2-2 7.5 CR 32-2 4.0 1145 804 60.8 1145 774 53.6CR 64-2 11.0 CR 32-3 5.5 2804 1328 957 86.0 2804 1328 897 75.5CR 64-3-1 15.0 CR 32-4 7.5DN 200 1265 1424 1110 114.8 1424 1021 101.3CR 64-4-2 18.5 CR 32-5 11.0 1507 1167 143.6 1507 1104 129.2CR 64-4 22.0 CR 32-6-2 11.0 1629 1385 168.0 1629 1272 147.5CR 64-5-1 30.0 CR 32-7 15.0CR 64-1 5.5 - -CR 64-2-2 7.5 - -30041778 1764 224.030041778 1601 196.7CR 64-2 11.0 - - 1328 1084 107.5 - - - -CR 64-3-1 15.0 - -DN 200 12652524 1424 1273 143.5 - - - -CR 64-4-2 18.5 - - 1507 1344 179.5 - - - -CR 64-4 22.0 - - 1629 1614 210.0 - - - -CR 64-5-1 30.0 - - 1778 2045 280.0 - - - -33041062 946 55.0 - - - -1145 894 76.0 - - - -CR 64-1 5.5 - -1062 1009 66.0 - - - -CR 64-2-2 7.5 - - 1145 1063 91.2 - - - -CR 64-2 11.0 - - 1328 1291 129.0 - - - -6 CR 64-3-1 15.0 - - DN 200 126530241424 1519 172.2 - - - -CR 64-4-2 18.5 - - 1507 1603 215.4 - - - -CR 64-4 22.0 - - 1629 1927 252.0 - - - -CR 64-5-1 30.0 - - 1778 2443 336.0 - - - -For information about and . please see page 98.53

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 90H1455250L 1200BTM01 2971 1303CR 90H250L 1200BTM01 2967 1303For information about and , please see page 98,54

Technical data<strong>Hydro</strong> <strong>2000</strong> SCR 90Electrical data, weights and dimensionsNo. ofpumps2345Full-size pumpsPump typeMotor[kW]Half-size pumpsPump typeMotor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSH[mm]Weight[kg]Max.I n [A]L[mm]<strong>Hydro</strong> <strong>2000</strong> MSHH[mm]Weight[kg]CR 90-1 7.5 CR 45-2-2 5.51139 427 30.41139 418 26.2CR 90-2-2 11.0 CR 45-2 7.5160216021347 513 43.01347 465 36.7CR 90-2 15.0 CR 45-3 11.0 1402 580 57.4 1402 541 50.2CR 90-3-2 18.5 CR 45-4 15.0 DN 150 1364 1802 1496 644 71.8 1802 1496 627 64.6CR 90-3 22.0 CR 45-4 15.0 1575 753 84.0 1575 681 70.7CR 90-4-2 30.0 CR 45-5 18.5 2002 1734 958 112.0 2002 1734 816 91.9CR 90-4 30.0 CR 45-5 18.5 1734 958 112.0 1734 816 91.9CR 90-1 7.5 CR 45-2-2 5.5CR 90-2-2 11.0 CR 45-2 7.5CR 90-2 15.0 CR 45-3 11.0 2304 1402 881 86.1 2304 1402 840 78.9DN 200 1415CR 90-3-2 18.5 CR 45-4 15.0 1496 927 107.7 1496 908 100.5CR 90-3 22.0 CR 45-4 15.0 1575 1090 126.0 1575 1017 112.7CR 90-4-2 30.0 CR 45-5 18.5 2504 1734 1383 168.0 2504 1734 1239 147.9CR 90-4 30.0 CR 45-5 18.5 1734 1382 168.0 1734 1239 147.921041139 618 45.61347 780 64.52104Max.I n [A]1139 608 41.41347 698 58.2CR 90-1 7.5 CR 45-2-2 5.51139 830 60.81139 819 56.6CR 90-2-2 11.0 CR 45-2 7.5 1347 1003 86.0 1347 954 79.7CR 90-2 15.0 CR 45-3 11.0280428041402 1136 114.81402 1095 107.6CR 90-3-2 18.5 CR 45-4 15.0 DN 200 14151496 1197 143.6 1496 1177 136.4CR 90-3 22.0 CR 45-4 15.0 1575 1415 168.0 1575 1341 154.7CR 90-4-2 30.0 CR 45-5 18.5 3004 1734 1793 224.0 3004 1734 1648 203.9CR 90-4 30.0 CR 45-5 18.5 1734 1793 224.0 1734 1648 203.9CR 90-1 7.5 - -1139 1083 76.0 - - - -CR 90-2-2 11.0 - - 1347 1298 107.5 - - - -CR 90-2 15.0 - - 1402 1463 143.5 - - - -CR 90-3-2 18.5 - - DN 250 146925261496 1538 179.5 - - - -CR 90-3 22.0 - - 1575 1808 210.0 - - - -CR 90-4-2 30.0 - - 1734 2239 280.0 - - - -CR 90-4 30.0 - - 1734 2239 280.0 - - - -CR 90-1 7.5 - -1139 1262 91.2 - - - -CR 90-2-2 11.0 - - 1347 1520 129.0 - - - -CR 90-2 15.0 - - 1402 1718 172.2 - - - -6 CR 90-3-2 18.5 - - DN 250 146930261496 1808 215.4 - - - -CR 90-3 22.0 - - 1575 2132 252.0 - - - -CR 90-4-2 30.0 - - 1734 2648 336.0 - - - -CR 90-4 30.0 - - 1734 2648 336.0 - - - -For information about and . please see page 98.55

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 3p[kPa]700600500H[m]706050<strong>Hydro</strong> <strong>2000</strong>CR 3-10MF-ME-MES50 HzISO 9906 Annex A4004030020030201 2 3 4 5 6100p[kPa]50010H[m]50CR 3-7MF-ME-MES400403003020010020101 2 3 4 5 60p[kPa]40030020010000H[m]40302010CR 3-5MF-ME-MES1 2 3 4 5 600 2 4 6 8 10 12 14 16 18 20 22 24 Q [m³/h]0 1 2 3 4 5 6 7 Q [l/s]TM00 8767 3803Performance curves, <strong>Hydro</strong> <strong>2000</strong> F-ECR 356

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 3p[kPa]14001300120011001000900800H[m]1501401301201101009080<strong>Hydro</strong> <strong>2000</strong>CR 3-23MF-ME-MES50 HzISO 9906 Annex A7007060050060501 2 3 4 5 6p[kPa]1100H[m]120110CR 3-19MF-ME-MES10001009009080080700706006050040050401 2 3 4 5 630030p[kPa]900H[m]10090CR 3-15MF-ME-MES8008070070600605005040040300301 2 3 4 5 6200200 2 4 6 8 10 12 14 16 18 20 22 24 Q [m³/h]0 1 2 3 4 5 6 7 Q [l/s]TM00 8769 380357

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 5p[kPa]700600500H[m]706050<strong>Hydro</strong> <strong>2000</strong>CR 5-10MF-ME-MES50 HzISO 9906 Annex A40040300301 2 3 4 5 620020100p[kPa]60010H[m]60CR 5-8MF-ME-MES500504004030030200201 2 3 4 5 6100p[kPa]40010H[m]40CR 5-5MF-ME-MES3003020020100101 2 3 4 5 60p[kPa]3000H[m]30CR 5-4MF-ME-MES2002010001001 2 3 4 5 60 5 10 15 20 25 30 35 40 45 Q [m³/h]0 2 4 6 8 10 12 14 Q [l/s]TM00 8775 3803CR 558

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 5p[kPa]14001300120011001000900800H[m]1501401301201101009080<strong>Hydro</strong> <strong>2000</strong>CR 5-22MF-ME-MES50 HzISO 9906 Annex A70060070601 2 3 4 5 650050p[kPa]1300120011001000900800H[m]1401301201101009080CR 5-20MF-ME-MES7007060050060501 2 3 4 5 640040p[kPa]1000H[m]110100CR 5-16MF-ME-MES9009080080700706006050040050401 2 3 4 5 6300300 5 10 15 20 25 30 35 40 45 Q [m³/h]0 2 4 6 8 10 12 14 Q [l/s]TM00 8777 380359

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 10p[kPa]1000900800700600500400300p[kPa]700600500H[m]10090807060504030H[m]706050CR 5-14<strong>Hydro</strong> <strong>2000</strong>CR 10-9MF-ME-MEH-MES50 HzISO 9906 Annex A1 2 3 4 5 6CR 10-6MF-ME-MEH-MES4004030030CR 5-101 2 3 4 5 6200p[kPa]50020H[m]50CR 10-4MF-ME-MEH-MES4004030030200100p[kPa]3002010H[m]30CR 5-8 1 2 3 4 5 6CR 10-3MF-ME-MEH-MES2002010010CR 5-51 2 3 4 5 6000 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 Q [m³/h]0 2 4 6 8 10 12 14 16 18 20 Q [l/s]TM02 7552 3803CR 1060

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 10p[kPa]140013001200H[m]150140130120<strong>Hydro</strong> <strong>2000</strong>CR 10-14MF-ME-MEH-MES50 HzISO 9906 Annex A11001101000100900908007006008070601 2 3 4 5 6CR 5-20p[kPa]1200H[m]130120CR 10-12MF-ME-MES11001101000100900908008070060070601 2 3 4 5 650050p[kPa]1100H[m]110CR 10-10MEH10001009009080080700706005004006050401 2 3 4CR 5-160 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 Q [m³/h]0 2 4 6 8 10 12 14 16 18 20 Q [l/s]TM02 7553 380361

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 15p[kPa]900800700600H[m]90807060<strong>Hydro</strong> <strong>2000</strong>CR 15-6MEH50 HzISO 9906 Annex A5004005040CR 10-91 3 4300p[kPa]700600500400300200p[kPa]60050040030H[m]706050403020H[m]605040CR 15-5MF-ME-MES1 2 3 4 5 6CR 15-4MEH30030CR 10-61 3 4200p[kPa]40020H[m]40CR 15-3MF-ME-MEH-MES3003020020CR 10-4 1 2 3 4 5 6100p[kPa]30010H[m]30CR 15-2MF-ME-MEH-MES200201000100CR 10-3 1 2 3 4 5 60 10 20 30 40 50 60 70 80 90 100 110 120 130 Q [m³/h]0 5 10 15 20 25 30 35 Q [l/s]TM02 7554 3803CR 1562

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 15p[kPa]14001200H[m]140120<strong>Hydro</strong> <strong>2000</strong>CR 15-10MF-ME-MEH-MES50 HzISO 9906 Annex A100010080080CR 10-14 1 2 3 4 5 660060400p[kPa]14001200100040H[m]140120100CR 15-9MF-ME-MES80060080601 2 3 4 5 6400p[kPa]120040H[m]120CR 15-8MEH10001008008060060CR 10-121 3 4400p[kPa]100040H[m]100CR 15-7MF-ME-MES8008060060400401 2 3 4 5 60 10 20 30 40 50 60 70 80 90 100 110 120 130 Q [m³/h]0 5 10 15 20 25 30 35 Q [l/s]TM02 7555 380363

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 20p[kPa]700600H[m]8075706560<strong>Hydro</strong> <strong>2000</strong>CR 20-5MF-ME-MEH-MES50 HzISO 9906 Annex A55500504004540CR 10-830035301 2 3 4 5 6p[kPa]450H[m]5045CR 20-3MF-ME-MEH-MES40040350353002503025CR 10-5200201 2 3 4 5 61501510010p[kPa]300H[m]30CR 20-2MF-ME-MEH-MES250252002015015CR 10-3100101 2 3 4 5 65050 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 Q [m³/h]0 5 10 15 20 25 30 35 40 45 50 Q [l/s]TM02 7556 3803CR 2064

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 20p[kPa]14001300120011001000900800700p[kPa]11001000900800H[m]150145140135130125120115110105100959085807570H[m]120115110105100959085801 2 3 4 5 6<strong>Hydro</strong> <strong>2000</strong>CR 20-10MF-ME-MES50 HzISO 9906 Annex ACR 20-7MF-ME-MEH-MES70060075706560CR 10-1250055501 2 3 4 5 6450 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 Q [m³/h]0 5 10 15 20 25 30 35 40 45 50 Q [l/s]TM02 7557 380365

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 32p[kPa]900800700H[m]908070<strong>Hydro</strong> <strong>2000</strong>CR 32-4MF-MFH-ME-MEH-MES50 HzISO 9906 Annex A60060500400300p[kPa]600504030H[m]60CR 15-6123456CR 32-3MF-MFH-ME-MEH-MES5005040040300200p[kPa]5003020H[m]50CR 15-41 2 3 4 5 6CR 32-2MF-MFH-ME-MEH-MES400403003020020CR 15-31 2 3 4 5 6100p[kPa]30010H[m]30CR 32-2-2MF-MFH-ME-MEH-MES200201000100CR 15-21 2 3 4 5 60 20 40 60 80 100 120 140 160 180 200 220 240 Q [m³/h]0 10 20 30 40 50 60 70 Q [l/s]TM01 2771 3803CR 3266

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 32p H[kPa] [m]<strong>Hydro</strong> <strong>2000</strong>1400140CR 32-81300130ME-MES1200 12050 Hz1100ISO 9906 Annex A1101000 100900 90800 80234700 70p H[kPa] [m]CR 32-71300130MF-MFH-MEH1200 1201100 1101000 100900 90800 80CR 15-10700 70123456600 60p H[kPa] [m]CR 32-61000 100ME-MES900 90800 80700600 602 3 4500 50p H[kPa] [m]CR 32-6-2100090010090MF-MFH-MEH800 80700 70600 60 CR 15-8500 50123456400 40p H[kPa] [m]CR 32-5900 90MF800 807006005004007070605012 34 5 6400 20 40 60 80 100 120 140 160 180 200 220 240 Q 260[m³/h]0 10 20 30 40 50 60 70 Q [l/s]TM01 2772 380367

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 45p[kPa]900800700H[m]908070<strong>Hydro</strong> <strong>2000</strong>CR 45-3MF-MFH-ME-MEH-MES50 HzISO 9906 Annex A600605005040040CR 32-41 2 3 4 5 6300p[kPa]60030H[m]60CR 45-2MF-MFH-ME-MEH-MES5005040040300200p[kPa]5003020H[m]50CR 32-31 2 3 4 5 6CR 45-2-2MF-MFH-ME-MEH-MES4004030030200100p[kPa]3002010H[m]30CR 32-21 2 3 4 5 6CR 45-1MF-MFH-ME-MEH-MES200201000100CR 32-2-2 1 2 3 4 5 60 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 Q [m³/h] 3800 10 20 30 40 50 60 70 80 90 100 Q [l/s]TM01 2773 3803CR 4568

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 45p[kPa]14001300120011001000H[m]150140130120110100<strong>Hydro</strong> <strong>2000</strong>CR 45-6ME-MES50 HzISO 9906 Annex A90080090802 3 4700p[kPa]1300120011001000900800700600p[kPa]12001100100090080070070H[m]14013012011010090807060H[m]120110100908070CR 45-5MF-MFH-ME-MEH-MESCR 32-7 1 2 3 4 56CR 45-4MF-MFH-ME-MEH-MES6005006050CR 32-6-21 2 3 4 5 6400400 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 Q [m³/h] 3800 10 20 30 40 50 60 70 80 90 100 Q [l/s]TM01 2774 380369

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 64p[kPa]900800700H[m]908070<strong>Hydro</strong> <strong>2000</strong>CR 64-3-1MF-MFH-ME-MEH-MES50 HzISO 9906 Annex A6006050050400300p[kPa]7006004030H[m]7060CR 32-41 2 3 4 5 6CR 64-2MF-MFH-ME-MEH-MES5005040040300200p[kPa]5004003020H[m]5040CR 32-31 2 3 4 5 6CR 64-2-2MF-MFH-ME-MEH-MES300302001002010CR 32-21 2 3 4 5 60p[kPa]4000H[m]40CR 64-1MF-MFH-ME-MEH-MES30030200201000100CR 32-2-21 2 3 4 5 60 40 80 120 160 200 240 280 320 360 400 440 480 520 Q 560[m³/h]0 20 40 60 80 100 120 140 Q [l/s]TM01 2775 3803CR 6470

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 64p[kPa]1600150014001300120011001000900800700600H[m]17016015014013012011010090807060CR 32-9CR 32-71 2 3 4 5 6<strong>Hydro</strong> <strong>2000</strong>CR 64-5-1MF-MFH50 HzISO 9906 Annex Ap[kPa]1200H[m]130120CR 32-7CR 64-4MF-MFH-ME-MEH-MES110011010001009009080080700600500706050CR 32-61 2 3 45 6p[kPa]1000H[m]110100CR 32-6CR 64-4-2MF-MFH-ME-MEH-MES9009080080700706006050050CR 32-51 2 3 4 5 6400400 40 80 120 160 200 240 280 320 360 400 440 480 520 Q 560[m³/h]0 20 40 60 80 100 120 140 Q [l/s]TM01 2776 380371

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 90p[kPa]1000900800H[m]1009080CR 45-4<strong>Hydro</strong> <strong>2000</strong>CR 90-3-2MF-MFH-ME-MEH50 HzISO 9906 Annex A70070600605005040040CR 45-330030200p[kPa]80070020H[m]80701 2 3 45 6CR 90-2MF-MFH-ME600605005040040CR 45-3300200p[kPa]5004003020H[m]50401 2 3 4 5 6CR 90-2-2MF-MFH-ME-MEH3002003020CR 45-2100101 2 3 4 560p[kPa]4000H[m]40CR 90-1MF-MFH-ME-MEH-MES30030200100020100CR 45-2-21 2 3 4 5 60 40 80 120 160 200 240 280 320 360 400 440 480 520 560 600 640 680 Q [m³/h]7600 20 40 60 80 100 120 140 160 180 200 Q [l/s]TM01 2777 3803CR 9072

Performance curves<strong>Hydro</strong> <strong>2000</strong> F-ECR 90p[kPa]120011001000900800H[m]1301201101009080<strong>Hydro</strong> <strong>2000</strong>CR 90-4MF-MFH-MEH50 HzISO 9906 Annex A70070CR 45-5600500p[kPa]1200110010009008006050H[m]13012011010090801 2 3 4 5 6CR 90-4-2MF-MFH-MEH700600500706050CR 45-5400300p[kPa]10009008007004030H[m]1009080701 2 3 4 5CR 90-3MF-MFH-ME-MEH-MES66005006050CR 45-440030040301 2 3 4 5 60 40 80 120 160 200 240 280 320 360 400 440 480 520 560 600 640 680 Q [m³/h]7600 20 40 60 80 100 120 140 160 180 200 Q [l/s]TM01 2778 380373

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 3Technical data, <strong>Hydro</strong> <strong>2000</strong> F-EElectrical dataH1201455L650BTM02 7732 3903H1201000-1500L650BTM02 7733 3903CR 3H120L650BTM02 7734 3903For information about and , please see page 98.74

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 3Electrical data, weights and dimensions for <strong>Hydro</strong> <strong>2000</strong> ENo. ofpumpsFull-size pumpsPump typeMotor[kW]ConnectionB[mm]L[mm]H[mm]<strong>Hydro</strong> <strong>2000</strong> MEWeight[kg]Max.I n [A]Max.I 0 [A]L[mm]Electrical data, weights and dimensions for <strong>Hydro</strong> <strong>2000</strong> F<strong>Hydro</strong> <strong>2000</strong> MESCR(E) 3-5 0.37553 90 2.7 2.7553 93 3.7 2.7CR(E) 3-7 0.55 589 95 3.9 3.9 589 96 5.3 3.9600 600 CR(E) 3-10 0.75 687 102 5.1 5.1 687 103 7.0 5.12Rp 2 710CR(E) 3-15 1.1 777 118 7.4 7.4 777 114 10.0 7.4CR(E) 3-19 1.5915 131 6.6 -915 125 6.7 -10501050CR(E) 3-23 2.2 1027 138 9.2 - 1027 132 9.4 -CR(E) 3-5 0.37553 151 2.7 2.7553 145 4.7 2.7CR(E) 3-7 0.55 589 158 3.9 3.9 589 150 6.78 3.93CR(E) 3-10 0.75 687 169 5.1 5.1 687 160 8.9 5.1Rp 2 710 13701370CR(E) 3-15 1.1 777 193 7.4 7.4 777 175 12.6 7.4CR(E) 3-19 1.5 915 204 9.9 - 915 193 10.1 -CR(E) 3-23 2.2 1027 214 13.8 - 1027 204 14.1 -CR(E) 3-5 0.37- - - -553 200 5.7 2.7CR(E) 3-7 0.55 - - - - 589 207 8.2 3.94CR(E) 3-10 0.75 - - - - 687 220 10.8 5.1Rp 2½ 726 18901890CR(E) 3-15 1.1 - - - - 777 238 15.2 7.4CR(E) 3-19 1.5 915 269 13.2 - 915 263 13.5 -CR(E) 3-23 2.2 1027 283 18.4 - 1027 277 18.9 -For information about , please see page 98.Specification of maximum current in neutral lead Max. I 0 [A] applies to single-phase MGE motors.Note: CRE pumps marked with "" are fitted with single-phase motors.No. ofpumpsFull-size pumpsPump typeMotor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MFH[mm]Weight[kg]Max.I n [A]CR 3-5 0.37553 66 2.0CR 3-7 0.55 589 69 2.92CR 3-10 0.75 600 687 76 3.8Rp 2 710CR 3-15 1.1 777 82 5.2CR 3-19 1.5 915 96 6.8CR 3-23 2.2 987 104 9.5CR 3-5 0.37553 98 3.0CR 3-7 0.55 589 102 4.33CR 3-10 0.75 920 687 112 5.7Rp 2 710CR 3-15 1.1 777 122 7.8CR 3-19 1.5 915 143 10.2CR 3-23 2.2 987 154 14.3CR 3-5 0.37553 141 4.0CR 3-7 0.55 589 146 5.84CR 3-10 0.75 1240 687 160 7.6Rp 2½ 726CR 3-15 1.1 777 172 10.4CR 3-19 1.5 915 201 13.6CR 3-23 2.2 987 215 19.0CR 3-5 0.37553 174 5.0CR 3-7 0.55 589 181 7.25CR 3-10 0.75 1560 687 198 9.5Rp 2½ 726CR 3-15 1.1 777 214 13.0CR 3-19 1.5 915 249 17.0CR 3-23 2.2 987 267 23.75CR 3-5 0.37553 203 6.0CR 3-7 0.55 589 211 8.66CR 3-10 0.75 1880 687 231 11.4Rp 2½ 726CR 3-15 1.1 777 250 15.6CR 3-19 1.5 915 293 20.4CR 3-23 2.2 987 315 28.5For information about , please see page 98.All pumps are fitted with three-phase motors.Dimensions may vary by ±10 mm.H[mm]Weight[kg]Max.I n [A]Max.I 0 [A]75

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 5H1201455L650BTM02 7732 3903CR 5H1201000-1500L650BTM02 7733 3903H120L650BTM02 7734 3903For information about and , please see page 98.76

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 5Electrical data, weights and dimensions for <strong>Hydro</strong> <strong>2000</strong> ENo. ofpumps23Full-size pumpsPump typeMotor[kW]ConnectionB[mm]L[mm]H[mm]<strong>Hydro</strong> <strong>2000</strong> MEWeight[kg]Max.I n [A]Max.I 0 [A]L[mm]<strong>Hydro</strong> <strong>2000</strong> MESH[mm]Weight[kg]CR(E) 5-4 0.55571 94 3.9 3.9571 95 5.3 3.9CR(E) 5-5 0.75 600 642 100 5.1 5.1 600 642 101 7.0 5.1CR(E) 5-8 1.1 723 116 7.4 7.4 723 113 10.0 7.4CR(E) 5-10 1.5 Rp 2 710843 129 6.6 -843 123 6.7 -CR(E) 5-16 2.2 1045 139 9.2 - 1045 133 9.4 -10501050CR(E) 5-20 3.0 1171 155 12.4 - 1171 149 12.6 -CR(E) 5-22 4.0 1262 181 16.2 - 1262 183 16.1 -CR(E) 5-4 0.55571 157 3.9 3.9571 148 6.8 3.9CR(E) 5-5 0.75 642 166 5.1 5.1 642 157 8.9 5.1CR(E) 5-8 1.1 723 190 7.4 7.4 723 172 12.6 7.4CR(E) 5-10 1.5 Rp 2 710 1370 843 200 9.9 - 1370 843 190 10.1 -CR(E) 5-16 2.2 1045 216 13.8 - 1045 205 14.1 -CR(E) 5-20 3.0 1171 240 18.6 - 1171 230 19.0 -CR(E) 5-22 4.0 1262 278 24.3 - 1262 274 24.1 -CR(E) 5-4 0.55- - - -571 204 8.2 3.9CR(E) 5-5 0.75 - - - - 642 216 10.8 5.1CR(E) 5-8 1.1 - - - - 723 235 15.2 7.44 CR(E) 5-10 1.5 Rp 2½ 726 1890 843 264 13.2 - 1890 843 258 13.5 -CR(E) 5-16 2.2 1045 285 18.4 - 1045 279 18.9 -CR(E) 5-20 3.0 1171 317 24.8 - 1171 311 25.4 -CR(E) 5-22 4.0 1262 368 32.4 - 1262 356 32.1 -For information about , please see page 98.Specification of maximum current in neutral lead Max. I 0 [A] applies to single-phase MGE motors.Note: CRE pumps marked with "" are fitted with single-phase motors.Max.I n [A]Max.I 0 [A]77

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 5Electrical data, weights and dimensions for <strong>Hydro</strong> <strong>2000</strong> FNo. ofpumps2345Full-size pumpsPump typeMotor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MFH[mm]Weight[kg]Max.I n [A]CR 5-4 0.55571 68 2.9CR 5-5 0.75 642 74 3.8CR 5-8 1.1 723 81 5.2CR 5-10 1.5 Rp 2 710600843 94 6.8CR 5-16 2.2 1005 104 9.5CR 5-20 3.0 1171 121 12.8CR 5-22 4.0 1262 140 16.0CR 5-4 0.55571 100 4.3CR 5-5 0.75 642 109 5.7CR 5-8 1.1 723 120 7.8CR 5-10 1.5 Rp 2 710920843 140 10.2CR 5-16 2.2 1005 155 14.3CR 5-20 3.0 1171 180 19.2CR 5-22 4.0 1262 209 24.0CR 5-4 0.55571 144 5.8CR 5-5 0.75 642 155 7.6CR 5-8 1.1 723 169 10.4CR 5-10 1.5 Rp 2 ½ 7261240843 196 13.6CR 5-16 2.2 1005 217 19.0CR 5-20 3.0 1171 249 25.6CR 5-22 4.0 1262 288 32.0CR 5-4 0.55571 178 7.2CR 5-5 0.75 642 192 9.5CR 5-8 1.1 723 210 13.0CR 5-10 1.5 Rp 2½ 7261560843 243 17.0CR 5-16 2.2 1005 269 23.8CR 5-20 3.0 1171 310 32.0CR 5-22 4.0 1262 358 40.0CR 5-4 0.55571 207 8.6CR 5-5 0.75 642 225 11.4CR 5-8 1.1 723 246 15.66 CR 5-10 1.5 Rp 2½ 7261880843 286 20.4CR 5-16 2.2 1005 317 28.5CR 5-20 3.0 1171 366 38.4CR 5-22 4.0 1262 424 48.0For information about , please see page 98.All pumps are fitted with three-phase motors.Dimensions may vary by ±10 mm.78

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 10150H1455L800BTM02 7735 3903CR 101000-1500150HL800BTM02 7736 3903150HL950BTM02 7737 3903For information about and , please see page 98.79

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 10Electrical data, weights and dimensions for <strong>Hydro</strong> <strong>2000</strong> ENo. of pumpsFull-size pumpsPump typeMotor[kW]Half-size pumpsPump typeMotor[kW]CR(E) 10-3 1.1 - -CR(E) 10-4 1.5 - -ConnectionB L H[mm] [mm] [mm]660<strong>Hydro</strong> <strong>2000</strong> ME <strong>Hydro</strong> <strong>2000</strong> MEH <strong>Hydro</strong> <strong>2000</strong> MESWeight[kg]Max. Max. L HI n [A] I 0 [A] [mm] [mm]Weight[kg]Max. Max. L HI n [A] I 0 [A] [mm] [mm]Weight[kg]Max. Max.I n [A] I 0 [A]678 124 7.4 7.4 - - - - - - - - - -774 140 6.6 - - - - - -774 135 6.7 -2 CR(E) 10-6 2.2 - - R 2½ 876 1080 834 158 9.2 - - - - - - 1080 834 153 9.35 -CR(E) 10-9 3.0 - - 983 172 12.4 - - - - - - 983 187 12.6 -CR(E) 10-12 4.0 - - 1080 1110 174 16.2 - - - - - - 1110 215 16.1 -1280CR(E) 10-14 5.5 - - 1221 184 22.0 - - - - - - 1221 239 22.0 -CR(E) 10-3 1.1 CR(E) 5-5 0.751400 678 200 7.4 7.4 1400 678 179 7.7 5.1 - - - - -CR(E) 10-4 1.5 CR(E) 5-8 1.1 - - - - - 814 191 10.8 7.4 - - - - -CR(E) 10-4 1.5 - -774 230 9.9 - - - - - - 774 206 10.1 -CR(E) 10-6 2.2 CR(E) 5-10 1.5 1400 834 257 13.8 - 874 197 11.4 - 834 234 14.1 -3R 2½ 876CR(E) 10-9 3.0 CR(E) 5-14 2.2 983 294 18.6 - 1600 983 210 15.6 - 1400 983 280 19.0 -CR(E) 10-10 4.0 CR(E) 5-16 2.2 - - - - 1050 260 17.2 - - - - -CR(E) 10-12 4.0 - -1400 1110 276 24.3 - - - - - - 1110 287 24.1 -1600CR(E) 10-14 5.5 CR(E) 5-20 3.0 1221 281 33.0 - 1600 1221 295 23.4 - 1221 337 33.0 -CR(E) 10-3 1.1 CR(E) 5-5 0.751920 678 278 7.4 7.4 1720 678 276 10.3 5.1 - - - - -CR(E) 10-4 1.5 CR(E) 5-8 1.1 - - - - - 814 323 14.2 7.4 - - - - -CR(E) 10-4 1.5 - -774 301 13.2 - - - - - 774 306 13.5 -CR(E) 10-6 2.2 CR(E) 5-10 1.5 1920 834 337 18.4 - 874 339 16.1 - 834 354 18.85 -4DN 80 889CR(E) 10-9 3.0 CR(E) 5-14 2.2 983 367 24.8 - 1920 983 358 22.0 - 1920 983 375 25.4 -CR(E) 10-10 4.0 CR(E) 5-16 2.2 - - - - - 1050 406 25.2 - - - - - -CR(E) 10-12 4.0 - -1920 1110 373 32.4 - - - - - - 1110 386 32.1 -1920CR(E) 10-14 5.5 CR(E) 5-20 3.0 1221 387 44.0 - 1920 1221 425 34.4 - 1221 461 44.0 -For information about . please see page 98.Specification of maximum current in neutral lead Max. I 0 [A] applies to single-phase MGE motors.Note: CRE pumps marked with "" are fitted with single-phase motors.80

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 10Electrical data, weights and dimensions for <strong>Hydro</strong> <strong>2000</strong> FNo. ofpumps2345Full-size pumpsPump typeMotor[kW]Half-size pumpsPump typeMotor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MFH[mm]Weight[kg]Max.I n [A]CR 10-3 1.1 - -678 104 5.2CR 10-4 1.5 - - 660 774 118 6.8CR 10-6 2.2 - - 834 126 9.5CR 10-9 3.0 - -Rp 2½ 876983 141 12.8CR 10-12 4.0 - - 660 1110 167 16.0CR 10-14 5.5 - - 1221 177 22.0CR 10-3 1.1 CR 5-5 0.75980678 152 7.8CR 10-4 1.5 - -980774 173 10.2CR 10-6 2.2 CR 5-10 1.5 Rp 2½ 876 834 185 14.3CR 10-9 3.0 CR 5-14 2.2983 207 19.2CR 10-12 4.0 - - 980 1110 246 24.0CR 10-14 5.5 CR 5-20 3.0 1221 260 33.0CR 10-3 1.1 CR 5-5 -1300678 227 10.4CR 10-4 1.5 -1300774 256 13.6CR 10-6 2.2 CR 5-10 1.5 DN 80 889 834 272 19.0CR 10-9 3.0 CR 5-14 2.2983 300 25.6CR 10-12 4.0 - - 1300 1110 352 32.0CR 10-14 5.5 CR 5-20 3.0 1221 369 44.0CR 10-3 1.1 - -678 277 13.0CR 10-4 1.5 - - 774 312 17.0CR 10-6 2.2 - - 1620 834 332 23.8DN 80 889 CR 10-9 3.0 - - 983 367 32.0CR 10-12 4.0 - - 1110 433 40.0CR 10-14 5.5 - - 1221 453 55.0CR 10-3 1.1 - -678 343 15.6CR 10-4 1.5 - - 774 385 20.46CR 10-6 2.2 - - 1940 834 409 28.5DN 100 914 CR 10-9 3.0 - - 983 421 38.4CR 10-12 4.0 - - 1110 530 48.0CR 10-14 5.5 - - 1221 557 66.0For information about , please see page 98.All pumps are fitted with three-phase motors.Dimensions may vary by ±10 mm.81

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 15H1455160L950BTM02 7738 3903CR 15H1000-1500160L950BTM02 7739 3903H160L950BTM02 7740 3903For information about and , please see page 98.82

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 15Electrical data, weights and dimensions for <strong>Hydro</strong> <strong>2000</strong> ENo. of pumps234Full-size pumps Half-size pumpsPumptypeMotor[kW]Pump typeMotor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> ME <strong>Hydro</strong> <strong>2000</strong> MEH <strong>Hydro</strong> <strong>2000</strong> MESH[mm]Weight[kg]Max. Max.I n [A] I 0 [A]L[mm]H[mm]Weight[kg]Max. Max.I n [A] I 0 [A]L[mm]H[mm]Weight[kg]Max. Max.I n [A] I 0 [A]CR(E) 15-2 2.2 - -806 186 9.2 - - - - - -806 181 9.4 -1110CR(E) 15-3 3.0 - - 870 196 12.4 - - - - - - 870 191 12.6 -CR(E) 15-5 4.0 - - 1110 997 233 16.2 - - - - - -997 256 16.1 -CR(E) 15-7 5.5 - - DN 80 1037 1138 268 22.0 - - - - - - 1310 1138 315 22.0 -CR(E) 15-9 7.5 - - 1228 289 30. - - - - - - 1228 322 30.2 -CR(E) 15-1011.0 - -820 1423 348 42.8 - - - - - - 8201423 386 42.8 -CR(E) 15-2 2.2 - -806 291 13.8 - - - - - -806 281 14.1 -14301430CR(E) 15-3 3.0 CR(E) 10-4 1.5 870 306 18.6 - 1430 870 279 13.0 - 870 296 19.0 -CR(E) 15-4 4.0 CR(E) 10-6 2.2 - - - - - 1630 952 323 17.2 - - - - -CR(E) 15-5 4.0 - - 1430 997 361 24.3 - - - - - - 1630 997 356 24.1 -CR(E) 15-6 5.5 CR(E) 10-9 3.0 - - - - - 1630 1093 376 23.4 - - - - - -CR(E) 15-7 5.5 - -DN 100 10621430 1138 433 33.0 - - - - - - 1630 1138 428 33.0 -CR(E) 15-8 7.5CR(E) 10-124.0 - - - - - 1630 1183 420 31.4 - - - - - -CR(E) 15-9 7.5 - - 1430 1228 466 45.0 - - - - - - 1228 445 45.4 -CR(E) 15-1011.0CR(E) 10-145.5124016301423 515 64.2 - 1810 1423 434 43.4 - 1423 510 64.2 -CR(E) 15-2 2.2 - -806 366 18.4 - - - - - -806 362 18.9 -19501950CR(E) 15-3 3.0 CR(E) 10-4 1.5 870 388 24.8 - 1750 870 326 19.4 - 870 384 25.4 -CR(E) 15-4 4.0 CR(E) 10-6 2.2 - - - - - 1950 952 378 25.2 - - - - - -CR(E) 15-5 4.0 - - 1950 997 460 32.4 - - - - - - 1950 997 444 32.1 -CR(E) 15-6 5.5 CR(E) 10-9 3.0 - - - - - 1950 1093 496 34.4 - - - - - -CR(E) 15-7 5.5 - -DN 100 10621950 1138 514 44.0 - - - - - - 1950 1138 540 44.0 -CR(E) 15-8 7.5CR(E) 10-124.0 - - - - - 2135 1183 585 46.6 - - - - - -CR(E) 15-9 7.5 - - 1950 1228 558 60.0 - - - - - - 1228 557 60.6 -CR(E) 15-1011.0CR(E) 10-145.51640For information about , please see page 98.Specification of maximum current in neutral lead Max. I 0 [A] applies to single-phase MGE motors.19501423 586 85.6 - 2410 1423 625 64.8 - 1423 615 85.6 -83

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 15Electrical data, weights and dimensions for <strong>Hydro</strong> <strong>2000</strong> FNo. ofpumps23456Full-size pumpsPump typeMotor[kW]Half-size pumpsPump type Motor[kW]ConnectionB[mm]L[mm]<strong>Hydro</strong> <strong>2000</strong> MFH[mm]Weight[kg]Max.I n [A]CR 15-2 2.2 - -766 153 9.5CR 15-3 3.0 - - 870 163 12.8700CR 15-5 4.0 - - 997 230 16.0CR 15-7 5.5 - - DN 80 1037 1138 248 22.0CR 15-9 7.5 - - 1228 248 30.4CR 15-10 11.0 - -8201423 318 42.8CR 15-2 2.2 - -1040 766 233 14.3CR 15-3 3.0 CR 10-4 1.5 870 248 19.21040CR 15-5 4.0 - -997 348 24.0DN 100 1062CR 15-7 5.5 - - 1040 1138 375 33.0CR 15-9 7.5 - - 1228 375 45.6CR 15-10 11.0 CR 10-14 5.512401423 482 64.2CR 15-2 2.2 - -1360 766 302 19.0CR 15-3 3.0 CR 10-4 1.5 870 322 25.6CR 15-5 4.0 - -CR 15-7 5.5 - -CR 15-9 7.5 - -CR 15-10 11.0 CR 10-14 5.5DN 100 10621360136013601640997 456 32.01138 492 44.01228 492 60.81423 636 85.6CR 15-2 2.2766 406 23.8CR 15-3 3.0 870 431 32.01680CR 15-5 4.0 997 598 40.0CR 15-7 5.5 DN 150 1116 1138 643 55.0CR 15-9 7.5 1228 643 76.0CR 15-10 11.02040 1423 831 107.0CR 15-2 2.2766 482 28.5CR 15-3 3.0 870 512 38.4<strong>2000</strong>CR 15-5 4.0 997 713 48.0CR 15-7 5.5 DN 150 1116 1138 767 66.0CR 15-9 7.5 1228 767 91.2CR 15-10 11.0For information about , please see page 98.All pumps are fitted with three-phase motors.Dimensions may vary by ±10 mm.2360 1423 993 128.484

Technical data<strong>Hydro</strong> <strong>2000</strong> F-ECR 20H1455160L950BTM02 7738 3903CR 20H1000-1500160L950BTM02 7739 3903H160L950BTM02 7740 3903For information about and , please see page 98.85