Hydro 2000

Hydro 2000

Hydro 2000

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

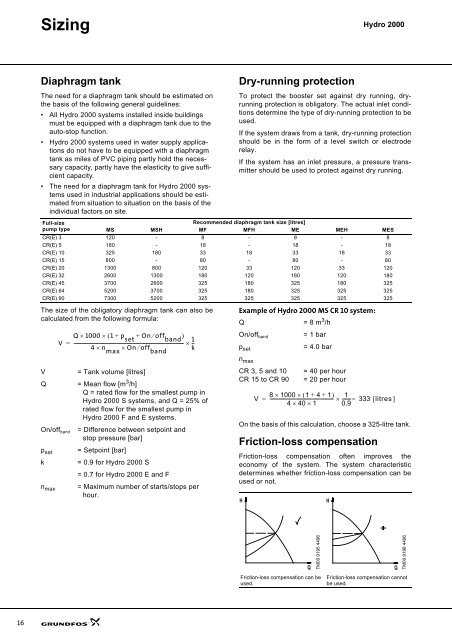

Sizing<strong>Hydro</strong> <strong>2000</strong>Diaphragm tankThe need for a diaphragm tank should be estimated onthe basis of the following general guidelines:• All <strong>Hydro</strong> <strong>2000</strong> systems installed inside buildingsmust be equipped with a diaphragm tank due to theauto-stop function.• <strong>Hydro</strong> <strong>2000</strong> systems used in water supply applicationsdo not have to be equipped with a diaphragmtank as miles of PVC piping partly hold the necessarycapacity, partly have the elasticity to give sufficientcapacity.• The need for a diaphragm tank for <strong>Hydro</strong> <strong>2000</strong> systemsused in industrial applications should be estimatedfrom situation to situation on the basis of theindividual factors on site.Full-sizepump typeThe size of the obligatory diaphragm tank can also becalculated from the following formula:Dry-running protectionTo protect the booster set against dry running, dryrunningprotection is obligatory. The actual inlet conditionsdetermine the type of dry-running protection to beused.If the system draws from a tank, dry-running protectionshould be in the form of a level switch or electroderelay.If the system has an inlet pressure, a pressure transmittershould be used to protect against dry running.Recommended diaphragm tank size [litres]MS MSH MF MFH ME MEH MESCR(E) 3 120 - 8 - 8 - 8CR(E) 5 180 - 18 - 18 - 18CR(E) 10 325 180 33 18 33 18 33CR(E) 15 800 - 80 - 80 - 80CR(E) 20 1300 800 120 33 120 33 120CR(E) 32 2600 1300 180 120 180 120 180CR(E) 45 3700 2600 325 180 325 180 325CR(E) 64 5200 3700 325 180 325 325 325CR(E) 90 7300 5200 325 325 325 325 325VQ× 1000× ( 1+ p + On ⁄ off )------------------------------------------------------------------------------------------------set band 1=× --4×n × On ⁄ off kmax bandExample of <strong>Hydro</strong> <strong>2000</strong> MS CR 10 system:Q = 8 m 3 /hOn/off band= 1 bar= 4.0 barp setVQOn/off bandp setkn max= Tank volume [litres]= Mean flow [m 3 /h]Q = rated flow for the smallest pump in<strong>Hydro</strong> <strong>2000</strong> S systems, and Q = 25% ofrated flow for the smallest pump in<strong>Hydro</strong> <strong>2000</strong> F and E systems.= Difference between setpoint andstop pressure [bar]= Setpoint [bar]= 0.9 for <strong>Hydro</strong> <strong>2000</strong> S= 0.7 for <strong>Hydro</strong> <strong>2000</strong> E and F= Maximum number of starts/stops perhour.n maxCR 3, 5 and 10CR 15 to CR 90= 40 per hour= 20 per hour8 × 1000 × ( 1 + 4+1)V --------------------------------------------------------1=× ------- = 333 [ litres ]4× 40×1 0.9On the basis of this calculation, choose a 325-litre tank.Friction-loss compensationFriction-loss compensation often improves theeconomy of the system. The system characteristicdetermines whether friction-loss compensation can beused or not.HHTM00 9195 4496Friction-loss compensation can beused.QQTM00 9196 4496Friction-loss compensation cannotbe used.16