Hydro 2000

Hydro 2000

Hydro 2000

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

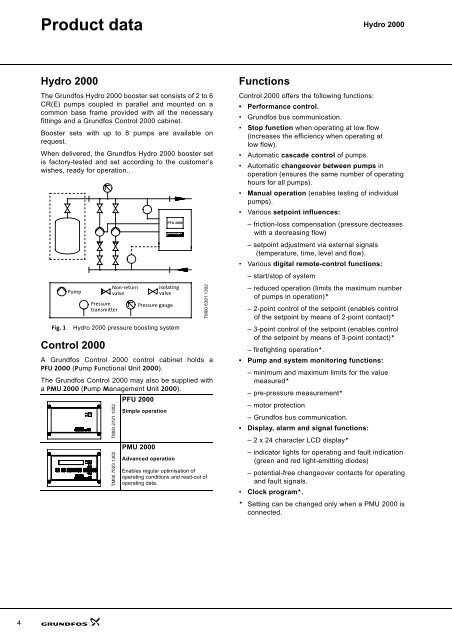

ResetProduct data<strong>Hydro</strong> <strong>2000</strong><strong>Hydro</strong> <strong>2000</strong>The Grundfos <strong>Hydro</strong> <strong>2000</strong> booster set consists of 2 to 6CR(E) pumps coupled in parallel and mounted on acommon base frame provided with all the necessaryfittings and a Grundfos Control <strong>2000</strong> cabinet.Booster sets with up to 8 pumps are available onrequest.When delivered, the Grundfos <strong>Hydro</strong> <strong>2000</strong> booster setis factory-tested and set according to the customer’swishes, ready for operation..Fig. 1PumpControl <strong>2000</strong>Non-returnvalvePressuretransmitter<strong>Hydro</strong> <strong>2000</strong> pressure boosting systemA Grundfos Control <strong>2000</strong> control cabinet holds aPFU <strong>2000</strong> (Pump Functional Unit <strong>2000</strong>).The Grundfos Control <strong>2000</strong> may also be supplied witha PMU <strong>2000</strong> (Pump Management Unit <strong>2000</strong>).TM00 2721 1302TM00 7023 1302PFU <strong>2000</strong>Simple operationPMU <strong>2000</strong>Advanced operationPFU <strong>2000</strong>Control <strong>2000</strong>IsolatingvalvePressure gaugeTM00 5391 1302Enables regular optimisation ofoperating conditions and read-out ofoperating data.FunctionsControl <strong>2000</strong> offers the following functions:• Performance control.• Grundfos bus communication.• Stop function when operating at low flow(increases the efficiency when operating atlow flow).• Automatic cascade control of pumps.• Automatic changeover between pumps inoperation (ensures the same number of operatinghours for all pumps).• Manual operation (enables testing of individualpumps).• Various setpoint influences:– friction-loss compensation (pressure decreaseswith a decreasing flow)– setpoint adjustment via external signals(temperature, time, level and flow).• Various digital remote-control functions:– start/stop of system– reduced operation (limits the maximum numberof pumps in operation) – 2-point control of the setpoint (enables controlof the setpoint by means of 2-point contact) – 3-point control of the setpoint (enables controlof the setpoint by means of 3-point contact) – firefighting operation .• Pump and system monitoring functions:– minimum and maximum limits for the valuemeasured – pre-pressure measurement – motor protection– Grundfos bus communication.• Display, alarm and signal functions:– 2 x 24 character LCD display – indicator lights for operating and fault indication(green and red light-emitting diodes)– potential-free changeover contacts for operatingand fault signals.• Clock program .Setting can be changed only when a PMU <strong>2000</strong> isconnected.4