Subsoiler - Vogel Noot

Subsoiler - Vogel Noot

Subsoiler - Vogel Noot

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

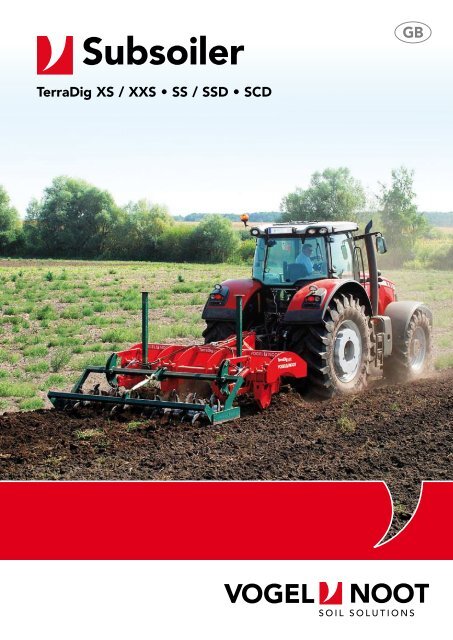

<strong>Subsoiler</strong><br />

TerraDig XS / XXS • SS / SSD • SCD<br />

GB

<strong>Subsoiler</strong>s – the most comprehensive range<br />

TerraDig XXS<br />

Perfect maintenance for your soil<br />

Constantly wet soils, soils that<br />

tend towards layer formation<br />

or fields with deep tyre tracks<br />

caused by heavy harvest machinery<br />

or transport vehicles in<br />

wet harvest conditions — these<br />

are just a few of the challenges<br />

faced by farmers which often<br />

2<br />

react very positively to subsoiling.<br />

By breaking up compressed<br />

soil horizons at natural fracture<br />

points and increasing the soil‘s<br />

porosity, the infiltration and<br />

drainage of water, the permeability<br />

of the soil and oxygen<br />

exchange within the soil are<br />

significantly improved, which<br />

then stimulates the ecosystem<br />

within the soil and encourages<br />

plant growth. This effectively<br />

combats deep-rooted weeds<br />

such as couch grass or thistle.

VN subsoiler application areas:<br />

There are basically two methods of subsoiling to choose from, depending on your particular cultivation<br />

strategy, soil supply and local conditions.<br />

Subsoiling in up to a max. of 40 cm of<br />

organic layer<br />

The subsoilers in the SS/SSD range were developed for locations<br />

with shallow soil, in order to maintain the soil‘s natural<br />

horizons. Thanks to the shape of the share and the guide plates,<br />

compressed soil is broken up and hollows are created in the soil.<br />

The slender shape of the tines helps maintain the soil‘s natural<br />

horizons, by avoiding mixing deeper soil with shallow soil. If mixing<br />

crop remains is not the objective, the SS/SSD subsoilers<br />

can also be used in locations with deep soil. Another advantage<br />

of this range is that when a subsoiler is used immediately after<br />

the grain harvest without the stubble being processed in advance,<br />

any spilt grain remains on the soil surface and can be made<br />

to germinate by subsequent stubble processing. This method<br />

causes no problems with secondary growth even if crops are<br />

intensively rotated.<br />

the range<br />

Subsoiling with topsoil cultivation for locations<br />

with deep soil<br />

The VN subsoilers in the TerraDig XS/XXS range are designed for<br />

working depths up to 55 or 70 cm and can thus be optimised for<br />

particular soil conditions and volumes of crop remains. The special<br />

shape of the tines means that this equipment is especially suitable<br />

for deep and humus-rich soils, whilst simultaneously completely<br />

cultivating the topsoil and mixing the crop remains. The tines aggressively<br />

penetrate the soil, making it particularly easy to achieve<br />

very deep working depths. The soil is raised throughout the entire<br />

working depth; coarse clods of earth are chopped up by the cutting<br />

wedges. The winged coulters mounted on the upper area of<br />

the tine allow the soil to be completely cultivated; these subsoilers<br />

are an ideal choice for topsoil cultivation with simultaneous subsoiling.<br />

These subsoilers can also be used for both conservational<br />

mulch sowing and direct sowing processes as well as conventional<br />

cultivation methods.<br />

terraDig SS / SSD XS / XXS SCD<br />

No. of tines 3 - 8 5 - 11 4 - 8<br />

Working widths fixed 3,00 m<br />

2,50 m / 3,00 m / 4,00 m /<br />

5,00 m<br />

3,00 m<br />

folding 4,00 m 4,00 m<br />

Working depth 40 cm / 55 cm 55 cm / 70 cm 55 cm<br />

3

SSD6<br />

SS/SSD subsoilers<br />

Maintains the soil‘s natural layers<br />

Tough frame with a pass of 650 to<br />

900 mm<br />

Optimum design and position of the<br />

tines to ensure perfect penetration of<br />

the soil<br />

Can be fitted with three to eight<br />

curved tines<br />

Excessively wide models can be<br />

folded to a transport width of 3 m<br />

(mechanical)<br />

mechanical overload protection system<br />

using shearbolts or a hydraulic<br />

stump-jump system<br />

4<br />

Advantages at a glance:<br />

These subsoilers combine all the advantages of a modern implement<br />

for loosening soil — a solid frame (200 x 100 x 10 mm) and a<br />

special steel tine design which requires little traction. This equipment<br />

guarantees perfect penetration of the soil: the soil‘s structure<br />

is maintained and is able to store water well again. The subsoilers<br />

feature an overload protection system using shearbolts, a cat. II or<br />

III linkage and two pneumatic depth guide wheels (235 x 15).

SSD subsoilers SS subsoilers<br />

The SSD subsoiler is designed for 4 to 8 tines with a working width of<br />

3.0 and 4.0 metres. Its standard frame design of 80 cm means that it<br />

can work at depths of approx. 55 cm.<br />

tines<br />

the tines:<br />

• break up subsoil compaction<br />

• make root growth easier<br />

• improve rainwater drainage<br />

The tines do not mix soil horizons and leave the topsoil uncultivated.<br />

The tine design of the SSD subsoiler allows the soil to be<br />

loosened in strips. In contrast, the SS leaves only slots in the soil.<br />

Manual folding system<br />

<strong>Subsoiler</strong>s with a 4-metre working width can be delivered with<br />

a manual folding system and can be folded to a transport width<br />

of 3 metres.<br />

Rollers<br />

In contrast, the SS subsoiler has a lower frame design (75 cm), which<br />

allows for a working depth of approx. 40 cm (optional frame design<br />

of 90 cm possible). This model is available with 3 to 7 tines (working<br />

width of 3.0 and 4.0 metres).<br />

ssd tines ss tines<br />

Stump-jump system<br />

Both subsoilers are equipped with shearbolts as standard. However,<br />

an optional hydraulic stump-jump system is available, which<br />

makes the subsoilers even more efficient.<br />

Both subsoilers can be equipped with rollers. Packer rollers (500<br />

mm diameter) and cage rollers (450 mm diameter) are available.<br />

Packer roller (ø 500 mm) Cage roller (ø 450 mm)<br />

5

terraDig XS / XXS<br />

TerraDig XXS<br />

Highly efficient for conservational soil cultivation<br />

Two-beam frame design with large<br />

pass ensures blockage-free operation<br />

at large working depths<br />

Blockage-free operation even when<br />

there are large quantities of crop remains<br />

Tines penetrate the soil aggressively,<br />

allowing for outstanding penetration<br />

and fine crumbling of the<br />

soil by the winged coulters<br />

Tines with reversible chisels reduce<br />

wear costs. A shearbolt prevents<br />

overload of tines and frame<br />

6<br />

Advantages at a glance:<br />

This subsoiler model combines an intensive loosening of subsoil layers<br />

with the crumbling and mixing of topsoil. This intensive loosening<br />

results from the aggressive way in which the tines cut through<br />

the soil. The work tools leave no tracks and the soil is left raised and<br />

loose.

TerraDig XS TerraDig XXS<br />

The TerraDig XS is designed for 5, 7 and 9 tines with working<br />

widths of 2.5, 3.0 and 4.0 metres. Its frame design and long tines<br />

mean that it can work at depths of approx. 55 cm.<br />

overload protection<br />

All TerraDig models are fitted with tine overload<br />

protection in the form of a shearbolt.<br />

This is located in a protected position at the<br />

very top of the tine and reliably protects the<br />

tines and frame against overloading. The<br />

bolt‘s position means that it can easily be<br />

replaced afterwards by the operator if it is<br />

deployed.<br />

Roller adjustment<br />

All TerraDig subsoilers are designed with<br />

hydraulic roller adjustment as standard.<br />

edge plates<br />

The edge plates (optional) ensure a clean<br />

connection between the individual working<br />

widths when travelling backwards<br />

and forwards. The edge plates prevent the<br />

soil being thrown out beyond the working<br />

width of the equipment and automatically<br />

adapt to the specific working depths.<br />

The TerraDig XXS has a larger frame height and can therefore work<br />

to depths of up to 70 cm. This model is available in a 5, 7, 9 or 11 tine<br />

version (working widths of 2.5, 3.0, 4.0 or 5.0 m).<br />

Rollers<br />

Both models are usually equipped with a double spiked roller. This roller design helps<br />

to enhance the crumbling of the soil and the intensive incorporation of fouling and<br />

crop remains. Moreover, it ensures that the topsoil is left loose and largely uncompacted.<br />

The height of both rollers can be adjusted in relation to one another; the equipment<br />

functions more efficiently when the front roller is in a higher position.<br />

TerraPak rollers, tapered drum rollers and packer rollers are alternatively available.<br />

Tapered drum roller (ø 660 mm)<br />

Double spiked roller<br />

Terrapak roller (ø 600 mm) Packer roller (ø 500 mm)<br />

7

SCD subsoilers<br />

scd subsoilers<br />

Combines perfectly with VN cultivation implements<br />

In addition to loosening the soil, this implement can also be combined with other cultivation implements,<br />

such as the <strong>Vogel</strong> & <strong>Noot</strong> rotary harrow. For this purpose, a special frame has been designed,<br />

which enables the SCD subsoiler to be combined with PTO shaft-driven implements, using a threepoint<br />

linkage, cat. II (or alternatively, cat. III).<br />

Advantages at a glance:<br />

Short design with well-positioned<br />

centre of gravity<br />

Can be combined with PTO shaft-driven<br />

implements<br />

Equipped with a three-point linkage<br />

with adjustable height<br />

Blockage-free operation thanks to<br />

large passes<br />

8<br />

This model also has a solid frame (200 x 100 x 10 mm) and a special steel tine design<br />

which requires little traction. If desired, this subsoiler can also be supplemented with<br />

a cage roller (ø 450 mm), a stump-jump system and depth wheels.

terraDig subsoilers – technical specifications<br />

SSD / SS<br />

Key data SSD4 SSD6 SSD8 SS3 SS4 SS5 SS6 SS7<br />

Working width cm 300 300 400 300 300 300 400 400<br />

Line spacing cm 40-76 46 40-48 34-115 68-78 34-58 68 34-55<br />

No. of tines 4 6 8 3 4 5 6 7<br />

Working depth cm 55 55 55 40 40 40 40 40<br />

Frame width cm 300 300 300+(2x50) 300 300 300 300+(2x50) 300+(2x50)<br />

Frame height cm 90 90 90 75 (opt. 90) 75 (opt. 90) 75 (opt. 90) 75 (opt. 90) 75 (opt. 90)<br />

Weight without<br />

roller<br />

Weight incl. packer<br />

roller (ø 450 mm)<br />

Performance<br />

kw (HP)<br />

kg 825 965 1190 751 834 911 1038 1071<br />

kg 1175 1315 1630 1101 1184 1261 1478 1511<br />

approx.<br />

* packer roller (ø 450 mm)<br />

66-88<br />

(90-120)<br />

96-118<br />

(130-160)<br />

125-147<br />

(170-200)<br />

52-74<br />

(70-100)<br />

66-88<br />

(90-120)<br />

81-103<br />

(110-140)<br />

96-118<br />

(130-160)<br />

XS/XXS SCD<br />

110-132<br />

(150-180)<br />

Key data XS/5 XS/7 XS/9 XXS/5 XXS/7 XXS/9 XXS/11 300/4 300/6 400/6 400/8<br />

Working width cm 250 300 400 250 300 400 500 300 300 400 400<br />

Line spacing cm 43-50 43-50 44,50 43-50 43-50 43-50 45,50 40-76 46 50-70 40-48<br />

No. of tines 5 7 9 5 7 9 11 4 6 6 8<br />

Working depth cm 55 55 55 70 70 70 70 55 55 55 55<br />

Frame width cm 230 290 385 230 290 385 490 300 300<br />

300+<br />

(2x50)<br />

300+<br />

(2x50)<br />

Frame height cm 95 95 95 110 110 110 110 90 90 90 90<br />

Weight without<br />

roller<br />

kg 1180 1375 1470 1780 2075 2270 2560 755 895 960 1100<br />

incl. packer roller (ø<br />

500 mm)<br />

kg 1530 1815 2080 2130 2515 2880 3260 1105* 1245* 1400* 1540*<br />

incl. Terrapak tapered<br />

ring roller (ø 600 mm)<br />

incl. double<br />

spiked roller<br />

incl. tapered drum<br />

roller (ø 660 mm)<br />

Performance<br />

kw (HP)<br />

kg 1640 1905 2230 2240 2605 3030 3480 – – – –<br />

kg 1700 2000 2300 2300 2700 3100 3600 – – – –<br />

kg – 2005 2370 – 2705 3170 – – – – –<br />

approx. 74-147<br />

(100-200)<br />

103-184<br />

(140-250)<br />

132-221<br />

(180-300)<br />

103-221<br />

(140-300)<br />

132-257<br />

(180-350)<br />

147-294<br />

(200-400)<br />

184-368<br />

(250-500)<br />

bis 88<br />

(bis 120)<br />

bis 118<br />

(bis 160)<br />

bis 132<br />

(bis 180)<br />

bis 147<br />

(bis 200)<br />

9

10<br />

testimonials<br />

MB-tRANS-AgRAR, Mr Bruno Moosbrugger on<br />

using <strong>Vogel</strong> & <strong>Noot</strong> equipment:<br />

We are a transport and trading company from<br />

Rankweil in Vorarlberg, Austria, and hold the modern<br />

technology of <strong>Vogel</strong> & noot‘s soil cultivation<br />

equipment in high regard.<br />

We have had the best soil cultivation results particularly<br />

with the <strong>Vogel</strong> & <strong>Noot</strong> SSD subsoiler.<br />

Tóth farm, Mr Tóth on the SSD<br />

subsoiler:<br />

We use this implement primarily for mediumheavy<br />

to very heavy soils in cultivation of cereals,<br />

corn and catch crop. With it, we can achieve the<br />

best permeability and water infiltration without<br />

mixing the individual soil horizons. By using this<br />

implement regularly we have succeeded in getting<br />

rid of standing water that is unable to drain<br />

and soil compaction. This was particularly helpful<br />

for us when we experienced<br />

heavy rainfall in<br />

summer 2009; we were<br />

able to make maximum<br />

profit despite the bad<br />

weather conditions.<br />

Success is no coincidence;<br />

it requires hard<br />

work!<br />

As we have been using <strong>Vogel</strong> & <strong>Noot</strong><br />

equipment for several years, this year<br />

we bought the SSD subsoiler. The most<br />

important advantage of the SSD is that<br />

you can also work with slightly damp<br />

soils. The implement raises the soil and<br />

then closes it with the packer roller. This<br />

method keeps the water in the soil.

Hegedűs farm, Mr<br />

Hegedűs on <strong>Vogel</strong> &<br />

<strong>Noot</strong> subsoilers:<br />

Voll FARM,<br />

Mr Voll on his new terraDig<br />

XXS:<br />

i got the ssd subsoiler last year and<br />

it achieved really great results both in<br />

summer on very dry soil and in autumn<br />

on very wet soil. In my opinion, the SSD<br />

does the least harm to the soil and you<br />

can work really well with it even in problematic<br />

conditions. We are so happy with<br />

this subsoiler that we‘ve even bought another<br />

<strong>Vogel</strong> & <strong>Noot</strong> subsoiler, the TerraDig XXS. With<br />

the new subsoiler, we work at depths of 65–70<br />

cm before cultivating sugar beet.<br />

I‘ve been using tried-and-tested <strong>Vogel</strong><br />

& <strong>Noot</strong> models for six years on my farm<br />

in sunny southern Germany. My most<br />

recent investment has been the TerraDig XXS<br />

for my 315 HP tractor. I can already say that it‘s<br />

been a worthwhile investment. Because 80% of<br />

my land is cultivated without a plough, this implement<br />

is essential for cultivating vegetables. Despite<br />

the oversized work tools, the TerraDig XXS is<br />

very easy to pull and has great fuel economy.<br />

11

Your Vn dealer:<br />

expertise – Advice – Service – Worldwide<br />

VN – the product range from the soil specialists<br />

Ploughs cultivators Rotary harrows<br />

mulchers/shredders seed drills sprayers<br />

<strong>Vogel</strong> & <strong>Noot</strong> Landmaschinen Gmbh & co KG<br />

A 8661 Wartberg/Mürztal • T +43 (0) 3858/605-0 • F +43 (0) 3858/605-109<br />

info@vogel-noot.net • www.vogel-noot.info<br />

Rössler Consult • 02/10