A Re-Examination of Failure Analysis and Root Cause Determination

A Re-Examination of Failure Analysis and Root Cause Determination

A Re-Examination of Failure Analysis and Root Cause Determination

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

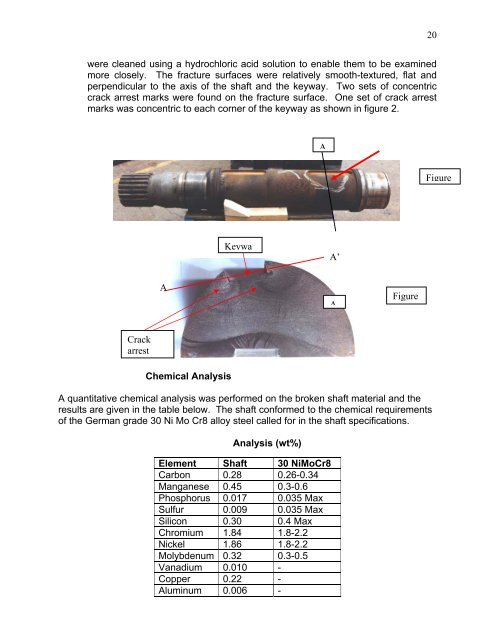

20were cleaned using a hydrochloric acid solution to enable them to be examinedmore closely. The fracture surfaces were relatively smooth-textured, flat <strong>and</strong>perpendicular to the axis <strong>of</strong> the shaft <strong>and</strong> the keyway. Two sets <strong>of</strong> concentriccrack arrest marks were found on the fracture surface. One set <strong>of</strong> crack arrestmarks was concentric to each corner <strong>of</strong> the keyway as shown in figure 2.AFigureKeywaA’AAFigureCrackarrestChemical <strong>Analysis</strong>A quantitative chemical analysis was performed on the broken shaft material <strong>and</strong> theresults are given in the table below. The shaft conformed to the chemical requirements<strong>of</strong> the German grade 30 Ni Mo Cr8 alloy steel called for in the shaft specifications.<strong>Analysis</strong> (wt%)Element Shaft 30 NiMoCr8Carbon 0.28 0.26-0.34Manganese 0.45 0.3-0.6Phosphorus 0.017 0.035 MaxSulfur 0.009 0.035 MaxSilicon 0.30 0.4 MaxChromium 1.84 1.8-2.2Nickel 1.86 1.8-2.2Molybdenum 0.32 0.3-0.5Vanadium 0.010 -Copper 0.22 -Aluminum 0.006 -