A Re-Examination of Failure Analysis and Root Cause Determination

A Re-Examination of Failure Analysis and Root Cause Determination

A Re-Examination of Failure Analysis and Root Cause Determination

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

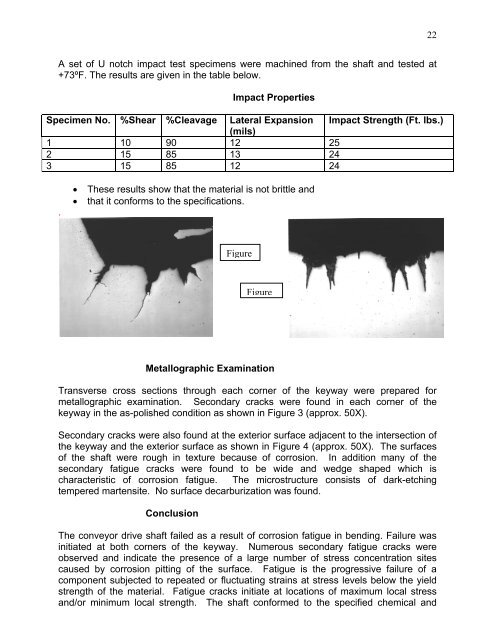

22A set <strong>of</strong> U notch impact test specimens were machined from the shaft <strong>and</strong> tested at+73ºF. The results are given in the table below.Impact PropertiesSpecimen No. %Shear %Cleavage Lateral Expansion Impact Strength (Ft. lbs.)(mils)1 10 90 12 252 15 85 13 243 15 85 12 24.• These results show that the material is not brittle <strong>and</strong>• that it conforms to the specifications.FigureFigureMetallographic <strong>Examination</strong>Transverse cross sections through each corner <strong>of</strong> the keyway were prepared formetallographic examination. Secondary cracks were found in each corner <strong>of</strong> thekeyway in the as-polished condition as shown in Figure 3 (approx. 50X).Secondary cracks were also found at the exterior surface adjacent to the intersection <strong>of</strong>the keyway <strong>and</strong> the exterior surface as shown in Figure 4 (approx. 50X). The surfaces<strong>of</strong> the shaft were rough in texture because <strong>of</strong> corrosion. In addition many <strong>of</strong> thesecondary fatigue cracks were found to be wide <strong>and</strong> wedge shaped which ischaracteristic <strong>of</strong> corrosion fatigue. The microstructure consists <strong>of</strong> dark-etchingtempered martensite. No surface decarburization was found.ConclusionThe conveyor drive shaft failed as a result <strong>of</strong> corrosion fatigue in bending. <strong>Failure</strong> wasinitiated at both corners <strong>of</strong> the keyway. Numerous secondary fatigue cracks wereobserved <strong>and</strong> indicate the presence <strong>of</strong> a large number <strong>of</strong> stress concentration sitescaused by corrosion pitting <strong>of</strong> the surface. Fatigue is the progressive failure <strong>of</strong> acomponent subjected to repeated or fluctuating strains at stress levels below the yieldstrength <strong>of</strong> the material. Fatigue cracks initiate at locations <strong>of</strong> maximum local stress<strong>and</strong>/or minimum local strength. The shaft conformed to the specified chemical <strong>and</strong>