ferro alloy design, ferro alloy selection and utilisation ... - Pyro.co.za

ferro alloy design, ferro alloy selection and utilisation ... - Pyro.co.za

ferro alloy design, ferro alloy selection and utilisation ... - Pyro.co.za

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

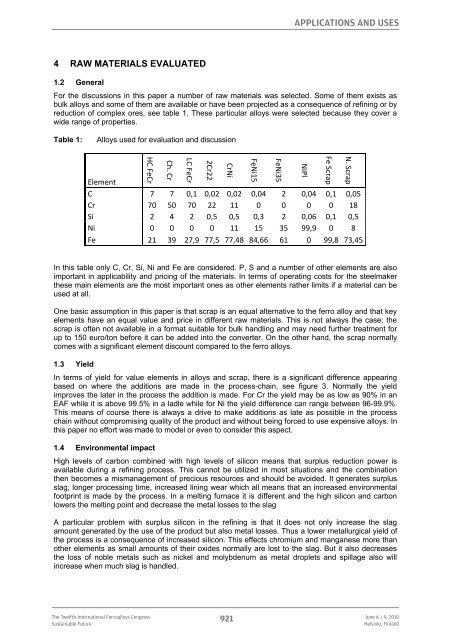

Applications <strong>and</strong> Uses4 RAW MATERIALS EVALUATED1.2 GeneralFor the discussions in this paper a number of raw materials was selected. Some of them exists asbulk <strong>alloy</strong>s <strong>and</strong> some of them are available or have been projected as a <strong>co</strong>nsequence of refining or byreduction of <strong>co</strong>mplex ores, see table 1. These particular <strong>alloy</strong>s were selected because they <strong>co</strong>ver awide range of properties.Table 1:Alloys used for evaluation <strong>and</strong> discussionHC FeCrCh. CrLC FeCr2Cr22ElementC 7 7 0,1 0,02 0,02 0,04 2 0,04 0,1 0,05Cr 70 50 70 22 11 0 0 0 0 18Si 2 4 2 0,5 0,5 0,3 2 0,06 0,1 0,5Ni 0 0 0 0 11 15 35 99,9 0 8Fe 21 39 27,9 77,5 77,48 84,66 61 0 99,8 73,45CrNiFeNi15FeNi35NiPlFe ScrapN. ScrapIn this table only C, Cr, Si, Ni <strong>and</strong> Fe are <strong>co</strong>nsidered. P, S <strong>and</strong> a number of other elements are alsoimportant in applicability <strong>and</strong> pricing of the materials. In terms of operating <strong>co</strong>sts for the steelmakerthese main elements are the most important ones as other elements rather limits if a material can beused at all.One basic assumption in this paper is that scrap is an equal alternative to the <strong>ferro</strong> <strong>alloy</strong> <strong>and</strong> that keyelements have an equal value <strong>and</strong> price in different raw materials. This is not always the case; thescrap is often not available in a format suitable for bulk h<strong>and</strong>ling <strong>and</strong> may need further treatment forup to 150 euro/ton before it can be added into the <strong>co</strong>nverter. On the other h<strong>and</strong>, the scrap normally<strong>co</strong>mes with a significant element dis<strong>co</strong>unt <strong>co</strong>mpared to the <strong>ferro</strong> <strong>alloy</strong>s.1.3 YieldIn terms of yield for value elements in <strong>alloy</strong>s <strong>and</strong> scrap, there is a significant difference appearingbased on where the additions are made in the process-chain, see figure 3. Normally the yieldimproves the later in the process the addition is made. For Cr the yield may be as low as 90% in anEAF while it is above 99.5% in a ladle while for Ni the yield difference can range between 96-99.9%.This means of <strong>co</strong>urse there is always a drive to make additions as late as possible in the processchain without <strong>co</strong>mpromising quality of the product <strong>and</strong> without being forced to use expensive <strong>alloy</strong>s. Inthis paper no effort was made to model or even to <strong>co</strong>nsider this aspect.1.4 Environmental impactHigh levels of carbon <strong>co</strong>mbined with high levels of sili<strong>co</strong>n means that surplus reduction power isavailable during a refining process. This cannot be utilized in most situations <strong>and</strong> the <strong>co</strong>mbinationthen be<strong>co</strong>mes a mismanagement of precious resources <strong>and</strong> should be avoided. It generates surplusslag, longer processing time, increased lining wear which all means that an increased environmentalfootprint is made by the process. In a melting furnace it is different <strong>and</strong> the high sili<strong>co</strong>n <strong>and</strong> carbonlowers the melting point <strong>and</strong> decrease the metal losses to the slagA particular problem with surplus sili<strong>co</strong>n in the refining is that it does not only increase the slagamount generated by the use of the product but also metal losses. Thus a lower metallurgical yield ofthe process is a <strong>co</strong>nsequence of increased sili<strong>co</strong>n. This effects chromium <strong>and</strong> manganese more thanother elements as small amounts of their oxides normally are lost to the slag. But it also decreasesthe loss of noble metals such as nickel <strong>and</strong> molybdenum as metal droplets <strong>and</strong> spillage also willincrease when much slag is h<strong>and</strong>led.The Twelfth International Ferro<strong>alloy</strong>s CongressSustainable Future921June 6 – 9, 2010Helsinki, Finl<strong>and</strong>