Design of arsenic removal plant by coagulation, sedimentation

Design of arsenic removal plant by coagulation, sedimentation

Design of arsenic removal plant by coagulation, sedimentation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

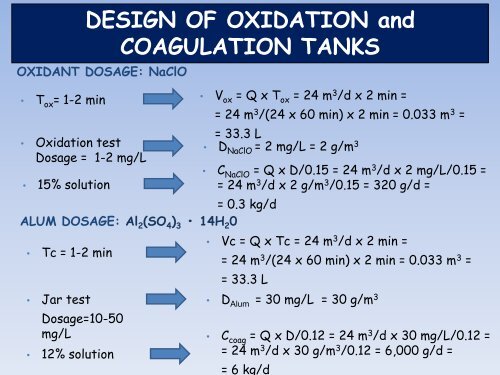

DESIGN OF OXIDATION and<br />

COAGULATION TANKS<br />

OXIDANT DOSAGE: NaClO<br />

• T ox= 1-2 min • V ox = Q x T ox = 24 m 3 /d x 2 min =<br />

= 24 m 3 /(24 x 60 min) x 2 min = 0.033 m 3 =<br />

• Oxidation test<br />

Dosage = 1-2 mg/L<br />

• 15% solution<br />

= 33.3 L<br />

= 0.3 kg/d<br />

ALUM DOSAGE: Al2(SO4) 3 • 14H20 • Tc = 1-2 min<br />

• Jar test<br />

Dosage=10-50<br />

mg/L<br />

• 12% solution<br />

• D NaClO = 2 mg/L = 2 g/m 3<br />

• C NaClO = Q x D/0.15 = 24 m 3 /d x 2 mg/L/0.15 =<br />

= 24 m 3 /d x 2 g/m 3 /0.15 = 320 g/d =<br />

• Vc = Q x Tc = 24 m 3 /d x 2 min =<br />

= 24 m 3 /(24 x 60 min) x 2 min = 0.033 m 3 =<br />

= 33.3 L<br />

• D Alum = 30 mg/L = 30 g/m 3<br />

• C coag = Q x D/0.12 = 24 m 3 /d x 30 mg/L/0.12 =<br />

= 24 m 3 /d x 30 g/m 3 /0.12 = 6,000 g/d =<br />

= 6 kg/d