attis hr 16 - Welger Maschinenfabrik GmbH

attis hr 16 - Welger Maschinenfabrik GmbH

attis hr 16 - Welger Maschinenfabrik GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

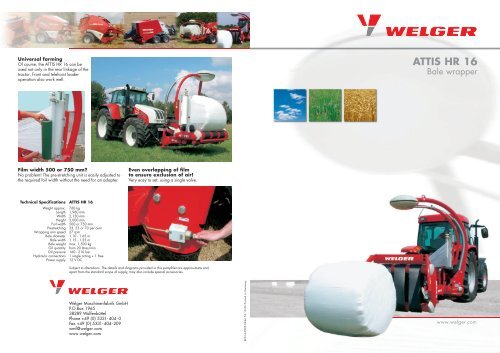

Universal farming<br />

Of course, the ATTIS HR <strong>16</strong> can be<br />

used not only in the rear linkage of the<br />

tractor. Front and telehoist loader<br />

operation also work well.<br />

Film width 500 or 750 mm?<br />

No problem! The pre-stretching unit is easily adjusted to<br />

the required foil width without the need for an adapter.<br />

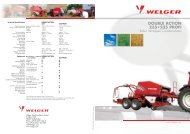

Technical Specifications ATTIS HR <strong>16</strong><br />

Weight approx. 760 kg<br />

Length 1,960 mm<br />

Width 2,150 mm<br />

Height 3,000 mm<br />

Foil width 500 or 750 mm<br />

Prestretching 33, 55 or 70 per cent<br />

Wrapping arm speed 27 rpm<br />

Bale diameter 1.10 - 1.65 m<br />

Bale width 1.15 - 1.25 m<br />

Bale weight max. 1,500 kg<br />

Oil quantity from 20 litres/min<br />

Oil pressure <strong>16</strong>0 - 210 bar<br />

Hydraulic connections 1 single acting + 1 free<br />

Power supply 12 V DC<br />

Subject to alterations. The details and diagrams provided in this pamphlet are approximate and,<br />

apart from the standard scope of supply, may also include special accessories.<br />

<strong>Welger</strong> <strong>Maschinenfabrik</strong> <strong>GmbH</strong><br />

P.O.Box 1965<br />

38289 Wolfenbüttel<br />

Phone +49 (0) 5331-404-0<br />

Fax +49 (0) 5331-404-209<br />

wmf@welger.com<br />

www.welger.com<br />

Even overlapping of film<br />

to ensure exclusion of air!<br />

Very easy to set, using a single valve.<br />

BP014-0905-0946.53.10.06 Printed in Germany<br />

ATTIS HR <strong>16</strong><br />

Bale wrapper<br />

www.welger.com

Best feed quality – healthy animals<br />

The principal prerequisite for creating<br />

high quality silage is the fastest<br />

possible production of anaerobic<br />

conditions, i.e. the immediate, sure<br />

exclusion of air.<br />

The <strong>Welger</strong> engineers followed these<br />

principles consistently in the development<br />

of the round bale wrapping machine<br />

ATTIS HR <strong>16</strong>.<br />

As a result, <strong>Welger</strong> makes available<br />

a machine which distinguishes itself<br />

with its high power, optimally simple<br />

operation and its unique operational<br />

reliability.<br />

The wrapping control of the ATTIS HR<br />

<strong>16</strong> allows pre-selection of these different<br />

operating modes:<br />

1. Fully automatic operation<br />

A single press of a button is all that<br />

is needed, and both loading and<br />

wrapping process run fully automatically,<br />

completely by themselves.<br />

2. Semi-automatic<br />

In this mode, the loading process is<br />

first started. The loading arms grip<br />

the bales, the table pivots to the wrapping<br />

position, and the loading arms<br />

move to their idle position.<br />

When the Start key is pressed again,<br />

the wrapping program is activated.<br />

Soft runup and wrapping of the start<br />

positions, release of the start from the<br />

foil holder, complete wrapping of the<br />

bale, and finally cutting and clamping<br />

the foil all take place under electronic<br />

control.<br />

For safety reasons, automatic unloading<br />

is always activated by pressing<br />

a button. The loading arms clamp<br />

and hold the bale until the table has<br />

pivoted to the vertical position and the<br />

bale is in contact with the ground. Only<br />

now do the arms open and release<br />

the bale. The advantage of this process<br />

is that the bales do not fall to the<br />

ground, but are gently set down. This<br />

helps to avoid damage to the foil and<br />

inhibits rolling away in hilly terrain.<br />

3. Manual operation<br />

In this setting, all functions can be<br />

pre-selected and carried out at the<br />

push of a button. This provides the<br />

opportunity to react quickly to unusual<br />

operating conditions.<br />

Further advantages,<br />

at a glance:<br />

Safe bale take-up!<br />

Because of the refined clamping elements,<br />

even awkwardly formed bales<br />

are gripped tight and safely loaded.<br />

Universal operation!<br />

Due to the robust construction, bales<br />

with a diameter of up to 1.65 m and<br />

a weight of up to 1,500 kg can be<br />

handled. Secure baling!<br />

The bales are securely positioned an<br />

the wrapping table by large, specially<br />

formed rollers. This makes wrapping<br />

possible even when driving<br />

an a slope.<br />

Simple operation!<br />

Wrapping control with E-LINK, the<br />

operating device with fully graphic<br />

display, makes working with this<br />

machine child’s play. All functions<br />

and parameters are clear and easy<br />

to recognise, even in the dark.