DOUBLE ACTION 235 PROFI - Welger Maschinenfabrik GmbH

DOUBLE ACTION 235 PROFI - Welger Maschinenfabrik GmbH

DOUBLE ACTION 235 PROFI - Welger Maschinenfabrik GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

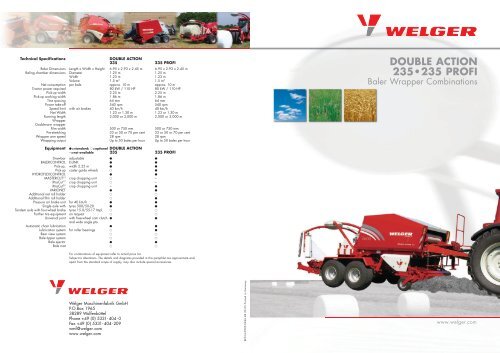

Technical Specifications <strong>DOUBLE</strong> <strong>ACTION</strong><br />

<strong>235</strong> <strong>235</strong> <strong>PROFI</strong><br />

Baler Dimensions Length x Width x Height 6.95 x 2.93 x 2.45 m 6.95 x 2.93 x 2.45 m<br />

Baling chamber dimensions Diameter 1.25 m 1.25 m<br />

Width 1.23 m 1.23 m<br />

Volume 1.5 m3 1.5 m3 Net consumption per bale approx. 10 m approx. 10 m<br />

Tractor power required 80 kW / 110 HP 80 kW / 110 HP<br />

Pick-up width 2.25 m 2.25 m<br />

Pick-up working width 1.86 m 1.86 m<br />

Tine spacing 64 mm 64 mm<br />

Power take-off 540 rpm 540 rpm<br />

Speed limit with air brakes 40 km/h 40 km/h<br />

Net Width 1.23 or 1.30 m 1.23 or 1.30 m<br />

Running length<br />

Wrapper<br />

Double-arm wrapper<br />

2,000 or 3,000 m 2,000 or 3,000 m<br />

Film width 500 or 750 mm 500 or 750 mm<br />

Pre-stretching 33 or 50 or 70 per cent 33 or 50 or 70 per cent<br />

Wrapper arm speed 28 rpm 28 rpm<br />

Wrapping output Up to 50 bales per hour Up to 50 bales per hour<br />

Equipment �=standard; �=optional <strong>DOUBLE</strong> <strong>ACTION</strong><br />

–=not available <strong>235</strong> <strong>235</strong> <strong>PROFI</strong><br />

Drawbar adjustable � �<br />

BALERCONTROL E-LINK � �<br />

Pick-up, width 2.25 m � �<br />

Pick-up caster guide wheels � �<br />

HYDROFLEXCONTROL � �<br />

MASTERCUT 13 crop chopping unit � –<br />

XtraCut 17 crop chopping unit � –<br />

XtraCut 25 crop chopping unit – �<br />

VARIONET � �<br />

Additional net roll holder � �<br />

Additional film roll holder � �<br />

Pressure air brake unit for 40 km/h � �<br />

Single axle with tyres 500/50-20 � �<br />

Tandem axle with four-wheel brake tyres 15.0/55-17 Impl. � �<br />

Further tire equipment on request � �<br />

Universal joint with free-wheel cam clutch � �<br />

and wide angle pto<br />

Automatic chain lubrication � �<br />

Lubrication system for roller bearings � �<br />

Rear view system � �<br />

Bale tipper system � �<br />

Bale ejector � �<br />

Bale mat � �<br />

For combinations of equipment refer to actual price list.<br />

Subject to alterations. The details and diagrams provided in this pamphlet are approximate and,<br />

apart from the standard scope of supply, may also include special accessories.<br />

<strong>Welger</strong> <strong>Maschinenfabrik</strong> <strong>GmbH</strong><br />

P.O.Box 1965<br />

38289 Wolfenbüttel<br />

Phone +49 (0) 5331-404-0<br />

Fax +49 (0) 5331-404-209<br />

wmf@welger.com<br />

www.welger.com<br />

BP016-0905-0946.48.20.05 Printed in Germany<br />

<strong>DOUBLE</strong> <strong>ACTION</strong><br />

<strong>235</strong>•<strong>235</strong> <strong>PROFI</strong><br />

Baler Wrapper Combinations<br />

www.welger.com

WELGER <strong>DOUBLE</strong> <strong>ACTION</strong> –<br />

the name says it all<br />

Time is money! But there is the <strong>Welger</strong> <strong>DOUBLE</strong> <strong>Welger</strong> <strong>DOUBLE</strong> <strong>ACTION</strong> –<br />

During the silage season time is <strong>ACTION</strong> <strong>235</strong>. This one doesn’t everything else is wasting<br />

playing a master roll. Who does not give away just a second.<br />

time and money!<br />

know, rain clouds are threatening or<br />

Two actions take place simultaneously<br />

on the contrary, the sun burns so hot,<br />

in the <strong>Welger</strong> <strong>DOUBLE</strong> <strong>ACTION</strong>. This<br />

that the grass will wilt in moments.<br />

reduces the total working time by half.<br />

Then every minute counts,<br />

even every second.<br />

Neither at picking up the grass and<br />

compacting the bale nor whilst wrapping.<br />

Not at all passing the bale from<br />

baler to wrapper!<br />

This also produces a reduction in the<br />

costs for fuel and tractor wear.

More bales per hour<br />

The RP <strong>235</strong> baler, mounted in front of<br />

the machine, is world-famous for the<br />

exceptional compaction and outstanding<br />

performance.<br />

All further advantages of a solo baler<br />

are part of the <strong>DOUBLE</strong> <strong>ACTION</strong><br />

as a matter of course.<br />

POWERGRIP<br />

Basis of the high compaction of the<br />

bale are the POWERGRIP steel rollers<br />

arranged round the bale chamber.<br />

In a special manufacturing process<br />

ten longitudinal ribs are formed<br />

into a thick walled, seamless tube<br />

creating a roller with unique loading<br />

capacity.<br />

Additional supporting plates or<br />

similar are not necessary.<br />

HYDROFLEXCONTROL<br />

A particularly impressive feature of the<br />

baler is the HYDROFLEXCONTROL.<br />

(available at listed at last page)<br />

The flexible mounted feeding channel<br />

floor levels irregular quantities in the<br />

swath thus avoiding blockages largely<br />

in the intake area.<br />

Other blockages resulting from<br />

massive overfilling or foreign objects<br />

can be removed easy and especially<br />

quick by hydraulically dropping<br />

the channel floor.<br />

HYDROFLEXCONTROL is able to<br />

increase the baler performance by<br />

15 % and more. A reverting device,<br />

which does not eliminate but only<br />

moves the blockage, is therefore<br />

superfluous.<br />

HYDROFLEXCONTROL –<br />

exclusively only to <strong>Welger</strong> balers!<br />

Central lubrication system<br />

Centrally situated, permanent lubrication<br />

with a large supply tank enables<br />

long periods of uninterrupted<br />

operation.<br />

All lubrication nozzles, particularly<br />

those of the roller bearings, are easily<br />

accessible.<br />

MasterCut 13<br />

The wide range of newly developed<br />

<strong>Welger</strong> chopping units starts with the<br />

MasterCut 13<br />

. 13 extra long blades<br />

that project deep into the ring zone<br />

of the rotor ensure reliable cutting of<br />

the crop.<br />

This increases not only the bale density<br />

but also accelerates the fermentation<br />

process and gives the fodder<br />

an improved structure especially for<br />

ruminants.<br />

In addition, the digestibility of the<br />

fodder is greatly improved.<br />

XtraCut 17 –<br />

Increased working time<br />

The new system offers many features,<br />

improved material flow and due to<br />

longer knives an improved quality<br />

of cut. XtraCut 17<br />

offers even more.<br />

As well as using 17 blades they can<br />

be divided into two groups, Group A<br />

with 9 blades and Group B with the<br />

remaining 8 blades.<br />

Advantage: increased working time<br />

between regrinding stops.<br />

Naturally, the blades can be quickly<br />

removed and are also protected<br />

against overload.<br />

Varionet-Net wrapping<br />

with EasyLoadSystem (ELS)<br />

The net wrapping, VARIONET, which<br />

has been well proven to be extremely<br />

reliable, has again been considerably<br />

improved.<br />

With the „EASY LOAD SYSTEM“<br />

insertion of the net roll could not<br />

be any easier.<br />

After being loaded in from the side,<br />

the new net roll is simply located to<br />

the back of the storage container,<br />

and then loaded into the operating<br />

position where it is locked in place.<br />

This saves time and effort!<br />

Fast bale handling<br />

Passing the bale is the distinctive feature.<br />

In the <strong>Welger</strong> <strong>DOUBLE</strong> <strong>ACTION</strong><br />

the wrapping table pivots with its loading<br />

arms directly under the tailgate<br />

of the baler taking the bale that leaves<br />

the bale chamber.<br />

When the table is panning backwards<br />

the tailgate closes already.<br />

With this procedure <strong>DOUBLE</strong><br />

<strong>ACTION</strong> is as fast as a solo RP <strong>235</strong><br />

baler, i.e. it reaches exactly the<br />

same outstanding performance<br />

like a round baler alone.<br />

Leaded by the oversized guiding<br />

rollers the bale rotates safely on the<br />

wrapping desk. This is an advantage<br />

when working under difficult conditions<br />

e.g. on hilly ground.<br />

Observing the correct running of the<br />

wrapping film is controlled by a light<br />

barrier.<br />

If one of the two film rolls is used<br />

up or the film has torn, the rotating<br />

speed of the table is reduced by the<br />

system to half, so the actual bale can<br />

be finished with the preselected number<br />

of wrapping layers.

<strong>DOUBLE</strong> <strong>ACTION</strong> <strong>235</strong> <strong>PROFI</strong> –<br />

high performance in silage<br />

For best performances in silage<br />

the <strong>DOUBLE</strong> <strong>ACTION</strong> <strong>235</strong> <strong>PROFI</strong><br />

comes with the newly developed<br />

chopping unit:<br />

XtraCut 25<br />

With its 25 extra long blades, the cutting<br />

quality is considerably improved.<br />

Just like the XtraCut 17 , this chopping<br />

unit can also be used with the group<br />

control of 25, 13, 12 or 0 blades to<br />

increase working time between sharpening.<br />

The hydraulic protection against foreign<br />

objects, as well as the quick removal<br />

of the knives, are also a matter<br />

of course for this cutting unit.<br />

Well lubricated for success<br />

The roller lubricating device, available<br />

as an optional extra for <strong>DOUBLE</strong><br />

<strong>ACTION</strong> <strong>235</strong>, minimizes the maintenance<br />

required and provides an extension<br />

to the service life of the roller<br />

bearings. This provides the peace of<br />

mind that the professional requires!<br />

Everything in view –<br />

Everything to hand<br />

The new <strong>Welger</strong> RP <strong>235</strong> <strong>PROFI</strong> is<br />

supplied as standard with the very<br />

easy to use BALER CONTROL E-LINK.<br />

This electronic control provides information<br />

about all operating functions<br />

and enables easy preselection, and<br />

adjustment of the various operating<br />

units.<br />

The equipment of the <strong>DOUBLE</strong> AC-<br />

TION <strong>235</strong> and <strong>235</strong> <strong>PROFI</strong> can be<br />

completed with a number of sensible<br />

special equipments.<br />

When manoeuvering the machine<br />

backwards and for supervision of the<br />

wrapping process the area behind<br />

the machine can be watched from the<br />

tractor seat with the rear view<br />

camera system.<br />

For the work in a difficult area, particularly<br />

on wet meadows, the tandem<br />

axle can be ordered, which<br />

can be adapted with different sets of<br />

wide tyres in respect to the harvest<br />

conditions.<br />

It can be of advantage in particularly<br />

hilly area not to put down the bales<br />

in the normal way. With the bale<br />

tipping device the bales are prevented<br />

reliably from rolling away.<br />

With the additional film roll<br />

holder you always have enough<br />

film available, even on longest working<br />

days.<br />

As special equipment also available<br />

is the permanent roller lubricating<br />

device to minimize the<br />

maintenance effort and extend the<br />

life time of the roller bearings.<br />

This gives the operational safety<br />

which is needed by the professional!