D 4006â¢D 4060â¢D 6006â¢D 6060 - Welger Maschinenfabrik GmbH

D 4006â¢D 4060â¢D 6006â¢D 6060 - Welger Maschinenfabrik GmbH

D 4006â¢D 4060â¢D 6006â¢D 6060 - Welger Maschinenfabrik GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

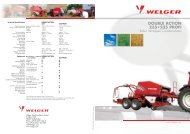

Technical Specifications D 4006 D 4060 D 6006 D <strong>6060</strong><br />

PROFICUT crop chopping unit Number of knives 0 23 0 23<br />

Bale chamber dimensions (Width x Height) 80 x 70 cm 80 x 70 cm 120 x 70 cm 120 x 70 cm<br />

Length of bale 90 - 250 cm 90 - 250 cm 90 - 250 cm 90 - 250 cm<br />

Number of knotters 4-fold 4-fold 6-fold 6-fold<br />

Tying material; plastic twine Running length 130 m/kg 130 m/kg 130 m/kg 130 m/kg<br />

Twine box size max. 16 rolls 16 rolls 24 rolls 24 rolls<br />

Twine consumption per bale Length of bale 1.6 m 19.3 m 19.3 m 29.0 m 29.0 m<br />

Length of bale 2.0 m 22.5 m 22.5 m 33.75 m 33.75 m<br />

Length of bale 2.5 m 26.5 m 26.5 m 39.75 m 39.75 m<br />

Power take-off 1000 rpm 1000 rpm 1000 rpm 1000 rpm<br />

No. of ram strokes 64 /min 64 /min 64 /min 64 /min<br />

Dimensions Length 8.2 m 8.2 m 8.2 m 8.2 m<br />

Width 2.8 m 2.8 m 2.8 m 2.8 m<br />

Height 2.7 m 2.7 m 2.7 m 2.7 m<br />

Tire equipment 500/60-22.5 12 PR 500/60-22.5 12 PR 600/50-22.5 12 PR 600/50-22.5 12 PR<br />

Horse power required 77 kW/105 HP 77 kW/105 HP 92 kW/125 HP 92 kW/125 HP<br />

Pick-up Overall width 2.25 m 2.25 m 2.25 m 2.25 m<br />

Working width 1.86 m 1.86 m 1.86 m 1.86 m<br />

Tines per row 30 30 30 30<br />

Tine spacing 64 mm 64 mm 64 mm 64 mm<br />

Equipment �=standard; �=optional D 4006 D 4060 D 6006 D <strong>6060</strong><br />

–=not available<br />

High hitch or low hitch optional � � � �<br />

Compressed-air or oil pressure brake unit<br />

optional with locking brake � � � �<br />

H.D. p.t.o. shaft with wide angle joint<br />

and Q.S. coupler at tractor end, � � � �<br />

cam clutch with free wheeling device at baler end<br />

BALERCONTROL E-LINK � � � �<br />

On-board electro-hydraulic � � � �<br />

bale pressure control<br />

Hydraulic bale removal device � � � �<br />

Pick-up with 2 caster wheels � � � �<br />

PROFICUT 23 knives – � – �<br />

HYDROFLEXCONTROL feeding channel floor � � � �<br />

Windguard roller � � � �<br />

Tire equipment, individual axle 500/60-22.5 12 PR � � – –<br />

600/50-22.5 12 PR � � � �<br />

700/45-22.5 12 PR – – � �<br />

Tandem axle with tire equipment 505/50 R 17 � � � �<br />

Cleaning fan for knotters � � � �<br />

FREE ENERGY self-contained power supply � � � �<br />

Bale chute hydraulically-folding � � � �<br />

Roller chute hydraulically-folding � � � �<br />

Baler jack hydraulically-operated � � � �<br />

Subject to alterations. Details and diagrams provided in this pamphlet are approximate and,<br />

apart from the standard scope of supply, may also include special accessories.<br />

<strong>Welger</strong> <strong>Maschinenfabrik</strong> <strong>GmbH</strong><br />

P.O.Box 1965<br />

38289 Wolfenbüttel<br />

Phone +49 (0) 5331-404-0<br />

Fax +49 (0) 5331-404-209<br />

wmf@welger.com<br />

www.welger.com<br />

BP015-0905-0946.50.22.05 Printed in Germany<br />

D 4006 • D 4060 • D 6006 • D <strong>6060</strong><br />

Big Balers<br />

www.welger.com

WELGER Big Balers –<br />

Efficient, reliable, profitable<br />

With the development of these new<br />

Big Balers, <strong>Welger</strong> proves, once<br />

again, its capability of leading the<br />

field, due to its ability to listen to<br />

customers.<br />

These skills are complemented by<br />

more than a hundred years of experience<br />

in baler manufacturing, resulting<br />

in machinery which benefit the<br />

large scale farmer and contractor.<br />

Well-proven concept –<br />

well-proven technology<br />

• Faster ram strokes – high capacity.<br />

Saving energy and fuel.<br />

•Shafts instead of chains – the<br />

ultimate drive concept for heavyduty<br />

professional machinery.<br />

• E-LINK – user-friendly baler control.<br />

•Tailor-made bales – ideal for<br />

handling and transport.<br />

•Full range of optional<br />

equipment.<br />

D 4006 D 4060<br />

Bale dimensions:<br />

Height x Width: 70 cm x 80 cm<br />

Length: 90 - 250 cm<br />

D 6006 D<strong>6060</strong><br />

Bale dimensions:<br />

Height x Width: 70 cm x 120 cm<br />

Length: 90 - 250 cm<br />

Bale dimensions:<br />

Height x Width: 70 cm x 80 cm<br />

Length: 90 - 250 cm<br />

Bale dimensions:<br />

Height x Width: 70 cm x 120 cm<br />

Length: 90 - 250 cm<br />

Benefits - at a glance!<br />

• Unrivalled crop flow protection<br />

by automatic safety systems.<br />

• Servicing-friendly safety<br />

guards – trouble-free access<br />

to all important machine<br />

components.<br />

• High output and high bale<br />

density – the essential for<br />

profitability.<br />

• <strong>Welger</strong> Big Balers<br />

have a clean design<br />

and heavy-duty build.

High performance –<br />

excellent realiability<br />

E-LINK –<br />

Everything in easy view –<br />

everything under control<br />

All machinery needs to be correctly<br />

operated, controlled and monitored.<br />

In addition to the well proven mechanical<br />

devices, <strong>Welger</strong> uses<br />

an electronic bale control system<br />

E-LINK. The most important functions<br />

can be controlled from the tractor so<br />

that for example, the bale count is<br />

easily read during work. The E-LINK<br />

incorporates a large illuminated display<br />

so that it can be operated easily<br />

and accurately in the dark.<br />

Wide pick-up –<br />

clean crop – clean field<br />

The pick-up virtually floats over the<br />

field, due to a fine adjustment of the<br />

support wheels coupled with a<br />

spring tensioned floating unit. Thus<br />

forage contamination is virtually<br />

eliminated. The pick-up, has ball<br />

bearings throughout, not bushes.<br />

The narrow spaced spring steel<br />

tines, along with a specially designed<br />

cam to retract the tines cleanly<br />

avoid any crop loss.<br />

The wide pickup width ensures a<br />

clean field with no contamination<br />

and a long working life.<br />

HYDROFLEXCONTROL –<br />

Maximum output –<br />

all of the time!<br />

In contrast to other balers the feeding<br />

channel floor is not rigidly welded<br />

to the baler chassis but is suspended<br />

with a flexible mounting.<br />

With this innovative design the floor<br />

can flex up or down slightly to allow<br />

small stones or unevenness in the<br />

swath to pass through thus avoiding<br />

any blockages of the rotor.<br />

This flexing of the feed table floor is<br />

a type of safety device which reduces<br />

the risk of damage to important<br />

machine components and therefore<br />

reducing downtime in work.<br />

The HYDROFLEXCONTROL system<br />

is only available in <strong>Welger</strong> balers<br />

and is far superior to reversing<br />

systems due to the speed in clearing<br />

a blockage simply and quickly thus<br />

reducing strain on the machine as<br />

well as maintaining output.<br />

PROFICUT –<br />

short and sweet<br />

The smooth-running PROFICUT 23<br />

blade choppimg device delivers the<br />

best quality cut, while at the same<br />

time requiring little force. The optimal<br />

cut length enables significantly<br />

higher density and thus the best silage<br />

quality. The structure in feed is<br />

improved, increasing appetite and<br />

thus the take-up quantity. Breaking<br />

down these cut bales becomes almost<br />

child’s play.

Top Technology from <strong>Welger</strong><br />

D 4006•D 4060•D 6006•D <strong>6060</strong><br />

Centralised ram<br />

lubrication –<br />

Well lubricated<br />

is well baled!<br />

A centralised grease distribution unit<br />

supplies the ram guide rollers with<br />

lubricant. Each of the rollers is lubricated<br />

with a pre-determined quantity.<br />

Easy access to the lubrication system<br />

reduces maintenance and<br />

increases working life.<br />

Power efficient –<br />

Reliable and easy-to-use<br />

More and more is expected of farm<br />

machinery today, it is therefore<br />

essential that they are efficient and<br />

easy to use. So many functions are<br />

operated electronically, or electrohydraulically.<br />

This requires a positive, stable<br />

power supply, which is difficult<br />

for some tractors.<br />

All the <strong>Welger</strong> Big Balers provide<br />

of an on-board power source and<br />

therefore are independent from<br />

the tractor.<br />

SLIP CONTROL – Intelligent<br />

overload protection<br />

All important assemblies are protected<br />

automatically. A double clutch system<br />

in the flywheel provides a flexible<br />

drive, which automatically reduces<br />

peak power. The feeder fingers<br />

are fitted with an electro-hydraulic<br />

monitoring system the E-LINK.<br />

Overloads in the intake area are detected<br />

and / or corrected as early<br />

as possible. This gives: High bale<br />

throughput: No need for shear-bolts:<br />

High bale density: Low shock load<br />

on the tractor transmission.<br />

Every Baler's reputation<br />

depends on its knotters<br />

The well-tried and proven <strong>Welger</strong><br />

tying equipment processes all commercial<br />

quality twines in a reliable<br />

and trouble-free way. The doubleloop<br />

knot that pulls off automatically<br />

has excellent tensile strength and<br />

requires no stripper arm.<br />

Maintenance-free bearings on the<br />

knotters and shafts increases service<br />

life and minimises maintenance.<br />

POWERFEED – automatically<br />

operating overload safety<br />

This clutch protects the drive and the<br />

packer from overload. Cumbersome<br />

replacement of shear pins becomes<br />

a thing of the past.<br />

Reasonable optional<br />

equipment – Everything<br />

for the professional<br />

•Hydraulic screw-jack for quick,<br />

safe and easy attachment and<br />

removal of the baler.<br />

•Hydraulic bale discharge<br />

ramp (optional with rollers) –<br />

user friendly control and<br />

careful bale placement.<br />

•Cleaning fan assembly for the<br />

knotter unit – for undisturbed<br />

working conditions.<br />

• Pick-up support wheels in<br />

swivelling design for both<br />

ground and pick-up protection.<br />

Four-wheel chassis –<br />

extremely smooth running,<br />

minimum of ground<br />

pressure<br />

Both axles are fit to a swinging<br />

chassis with spring suspension,<br />

resulting in an even distribution<br />

of the weight to all four wheels.<br />

The back trailing steering type axle<br />

allows the wheels to follow bends<br />

automatically, thus preserving the<br />

ground. For reversing, the steering<br />

mechanism can be hydraulically<br />

locked.<br />

All of the four wheels are braked,<br />

of course, which results in maximum<br />

deceleration.