AEROSIL® for Adhesives and Sealants - Adhesives & Sealants by ...

AEROSIL® for Adhesives and Sealants - Adhesives & Sealants by ...

AEROSIL® for Adhesives and Sealants - Adhesives & Sealants by ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

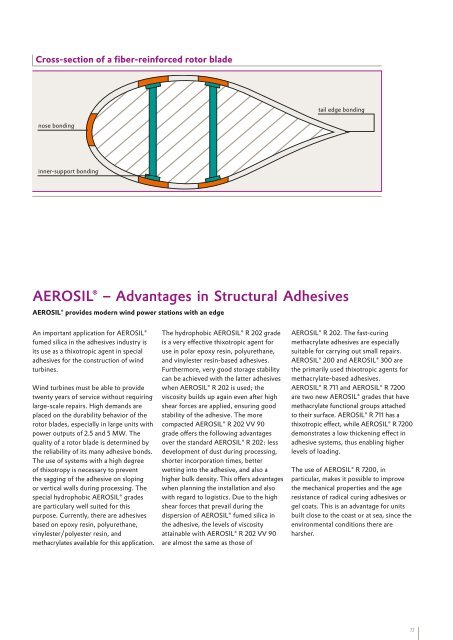

Cross-section of a fiber-rein<strong>for</strong>ced rotor bladetail edge bondingnose bondinginner-support bonding<strong>AEROSIL®</strong> – Advantages in Structural <strong>Adhesives</strong><strong>AEROSIL®</strong> provides modern wind power stations with an edgeAn important application <strong>for</strong> <strong>AEROSIL®</strong>fumed silica in the adhesives industry isits use as a thixotropic agent in specialadhesives <strong>for</strong> the construction of windturbines.Wind turbines must be able to providetwenty years of service without requiringlarge-scale repairs. High dem<strong>and</strong>s areplaced on the durability behavior of therotor blades, especially in large units withpower outputs of 2.5 <strong>and</strong> 5 MW. Thequality of a rotor blade is determined <strong>by</strong>the reliability of its many adhesive bonds.The use of systems with a high degreeof thixotropy is necessary to preventthe sagging of the adhesive on slopingor vertical walls during processing. Thespecial hydrophobic <strong>AEROSIL®</strong> gradesare particulary well suited <strong>for</strong> thispurpose. Currently, there are adhesivesbased on epoxy resin, polyurethane,vinylester/polyester resin, <strong>and</strong>methacrylates available <strong>for</strong> this application.The hydrophobic <strong>AEROSIL®</strong> R 202 gradeis a very effective thixotropic agent <strong>for</strong>use in polar epoxy resin, polyurethane,<strong>and</strong> vinylester resin-based adhesives.Furthermore, very good storage stabilitycan be achieved with the latter adhesiveswhen <strong>AEROSIL®</strong> R 202 is used; theviscosity builds up again even after highshear <strong>for</strong>ces are applied, ensuring goodstability of the adhesive. The morecompacted <strong>AEROSIL®</strong> R 202 VV 90grade offers the following advantagesover the st<strong>and</strong>ard <strong>AEROSIL®</strong> R 202: lessdevelopment of dust during processing,shorter incorporation times, betterwetting into the adhesive, <strong>and</strong> also ahigher bulk density. This offers advantageswhen planning the installation <strong>and</strong> alsowith regard to logistics. Due to the highshear <strong>for</strong>ces that prevail during thedispersion of <strong>AEROSIL®</strong> fumed silica inthe adhesive, the levels of viscosityattainable with <strong>AEROSIL®</strong> R 202 VV 90are almost the same as those of<strong>AEROSIL®</strong> R 202. The fast-curingmethacrylate adhesives are especiallysuitable <strong>for</strong> carrying out small repairs.<strong>AEROSIL®</strong> 200 <strong>and</strong> <strong>AEROSIL®</strong> 300 arethe primarily used thixotropic agents <strong>for</strong>methacrylate-based adhesives.<strong>AEROSIL®</strong> R 711 <strong>and</strong> <strong>AEROSIL®</strong> R 7200are two new <strong>AEROSIL®</strong> grades that havemethacrylate functional groups attachedto their surface. <strong>AEROSIL®</strong> R 711 has athixotropic effect, while <strong>AEROSIL®</strong> R 7200demonstrates a low thickening effect inadhesive systems, thus enabling higherlevels of loading.The use of <strong>AEROSIL®</strong> R 7200, inparticular, makes it possible to improvethe mechanical properties <strong>and</strong> the ageresistance of radical curing adhesives orgel coats. This is an advantage <strong>for</strong> unitsbuilt close to the coast or at sea, since theenvironmental conditions there areharsher.13