Fifth Street Pedestrian Plaza Bridge - Aspire - The Concrete Bridge ...

Fifth Street Pedestrian Plaza Bridge - Aspire - The Concrete Bridge ...

Fifth Street Pedestrian Plaza Bridge - Aspire - The Concrete Bridge ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

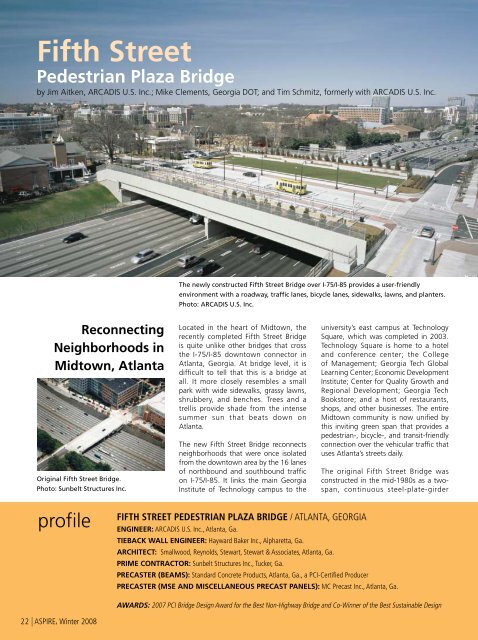

<strong>Fifth</strong> <strong>Street</strong><strong>Pedestrian</strong> <strong>Plaza</strong> <strong>Bridge</strong>by Jim Aitken, ARCADIS U.S. Inc.; Mike Clements, Georgia DOT; and Tim Schmitz, formerly with ARCADIS U.S. Inc.<strong>The</strong> newly constructed <strong>Fifth</strong> <strong>Street</strong> <strong>Bridge</strong> over I-75/I-85 provides a user-friendlyenvironment with a roadway, traffic lanes, bicycle lanes, sidewalks, lawns, and planters.Photo: ARCADIS U.S. Inc.ReconnectingNeighborhoods inMidtown, AtlantaOriginal <strong>Fifth</strong> <strong>Street</strong> <strong>Bridge</strong>.Photo: Sunbelt Structures Inc.Located in the heart of Midtown, therecently completed <strong>Fifth</strong> <strong>Street</strong> <strong>Bridge</strong>is quite unlike other bridges that crossthe I-75/I-85 downtown connector inAtlanta, Georgia. At bridge level, it isdifficult to tell that this is a bridge atall. It more closely resembles a smallpark with wide sidewalks, grassy lawns,shrubbery, and benches. Trees and atrellis provide shade from the intensesummer sun that beats down onAtlanta.<strong>The</strong> new <strong>Fifth</strong> <strong>Street</strong> <strong>Bridge</strong> reconnectsneighborhoods that were once isolatedfrom the downtown area by the 16 lanesof northbound and southbound trafficon I-75/I-85. It links the main GeorgiaInstitute of Technology campus to theuniversity’s east campus at TechnologySquare, which was completed in 2003.Technology Square is home to a hoteland conference center; the Collegeof Management; Georgia Tech GlobalLearning Center; Economic DevelopmentInstitute; Center for Quality Growth andRegional Development; Georgia TechBookstore; and a host of restaurants,shops, and other businesses. <strong>The</strong> entireMidtown community is now unified bythis inviting green span that provides apedestrian-, bicycle-, and transit-friendlyconnection over the vehicular traffic thatuses Atlanta’s streets daily.<strong>The</strong> original <strong>Fifth</strong> <strong>Street</strong> <strong>Bridge</strong> wasconstructed in the mid-1980s as a twospan,continuous steel-plate-girderprofile<strong>Fifth</strong> <strong>Street</strong> <strong>Pedestrian</strong> <strong>Plaza</strong> <strong>Bridge</strong> / Atlanta, GeorgiaEngineer: ARCADIS U.S. Inc., Atlanta, Ga.Tieback Wall Engineer: Hayward Baker Inc., Alpharetta, Ga.Architect: Smallwood, Reynolds, Stewart, Stewart & Associates, Atlanta, Ga.Prime Contractor: Sunbelt Structures Inc., Tucker, Ga.Precaster (beams): Standard <strong>Concrete</strong> Products, Atlanta, Ga., a PCI-Certified ProducerPrecaster (MSE and miscellaneous precast panels): MC Precast Inc., Atlanta, Ga.AwardS: 2007 PCI <strong>Bridge</strong> Design Award for the Best Non-Highway <strong>Bridge</strong> and Co-Winner of the Best Sustainable Design22 | ASPIRE, Winter 2008

Precast, prestressed concrete beams wereselected as the most economical solution.bridge, 228 ft 4 in. long and 70 ft 5in. wide. <strong>The</strong> roadway carried four12-ft-wide lanes and two 8-ft-widesidewalks. <strong>Concrete</strong> parapets with achain link fence formed the railings oneach side of the bridge. <strong>The</strong> end bentswere constructed on retaining walls ateach end, with a cast-in-place (CIP) wallat the west end and a tieback wall atthe east end. During the constructionof Technology Square, <strong>Fifth</strong> <strong>Street</strong>underwent a major renovation thatfeatured wide sidewalks and speciallighting, both on and off campus. Tocomplete the renovation, Georgia Techinitiated a meeting with the GeorgiaDepartment of Transportation (GDOT)officials to discuss replacement of the<strong>Fifth</strong> <strong>Street</strong> <strong>Bridge</strong>.<strong>The</strong> university wanted a signature bridgethat would create approximately threequartersof an acre of green spacewith 25-ft-wide sidewalks to match thesidewalks at the ends of the bridge, aswell as planters, benches, decorativelighting, and a trellis to serve as ashaded area for the campus trolley stop.<strong>The</strong> walls and planters would be wideenough and high enough to obstructthe view of the interstate below thebridge. In addition, the original plancalled for removal of the existing bridgeand completion of the traffic lanes andsidewalks of the new bridge, withoutinterruption to vehicular or pedestriantraffic, by the beginning of the 2006football season. <strong>The</strong> total bridge width,including roadway, bicycle lanes,sidewalks, lawns, and planters, wouldbe 250 ft 3 in. However, the FederalHighway Administration required thatthe proposed structure provide forfuture high-occupancy vehicle expansionof the downtown connector. <strong>The</strong>refore,A wide sidewalk and trellis were used onthe south side of the plaza.Photo: ARCADIS U.S. Inc.it was necessary to increase the bridgelength to 256 ft 6 in. and reduce thebridge width to 223 ft 3 in.GDOT decided that the best way tomeet the requirements of all partiesinvolved was to award the project as adesign-build project with an acceleratedschedule. Ten design-build teamssubmitted Statements of Qualificationsin November 2003, and a shortlist offive teams was released in February2004. <strong>The</strong> project was advertised inApril 2004 and awarded to the winningteam of Sunbelt Structures Inc. (Sunbelt)and ARCADIS in June 2004. <strong>The</strong>entire process was greatly accelerated,especially in the planning stages. Onaverage, a GDOT project of this sizeand nature takes approximately 10 yearsfrom the initial concept to the lettingphase, whereas <strong>Fifth</strong> <strong>Street</strong> took just 10months. Notice to Proceed was issuedJuly 22, 2004.ARCADIS served as the project designerand performed all roadway, drainage,electrical, and structural design, withthe exception of the abutment at theeast end of the bridge. Hayward BakerInc. designed this abutment as a tiebackPlanters were used on the north side ofthe bridge to hide the interstate.Photo: ARCADIS U.S. Inc.wall abutment due to the presence ofan existing tieback wall that complicatedthe design and construction. <strong>The</strong>contractor, Sunbelt, was responsible forconstruction of the entire project.<strong>The</strong> new <strong>Fifth</strong> <strong>Street</strong> <strong>Bridge</strong> is a twospanbridge with span lengths of 137ft and 119 ft 6 in. Precast, prestressedconcrete beams were selected by thedesign-build team during the prebidphase as the most economical solutionfor the new structure. <strong>The</strong> final designused twenty-eight 74-in.-deep modifiedAASHTO bulb-tee beams in span 1. <strong>The</strong>modifications consisted of increasingthe depth of the bottom flange andwidth of the beam by 2 in. over theentire height of the beam to fit anadditional strand per row in the bottomflange and web. Span 2 used twenty-six74-in.-deep bulb-tee beams without theadditional 2 in. width. <strong>The</strong> large deadloads associated with the landscaping,planters, and sidewalks necessitated theuse of the deep beam and modifiedsection. In addition, the beams weredesigned and constructed using highperformance concrete with a 28‐dayspecified compressive strength of10,000 psi and 0.6‐in.-diameter strands.Structural steel diaphragms made up of6 x 6-in. angles were used instead ofGDOT’s typical CIP concrete diaphragms.<strong>The</strong>se were installed more quickly andprovided lateral support to the beamsalmost as soon as they were erected.Precast, prestressed concrete / Georgia Department of Transportation and Georgia Institute ofTechnology, Atlanta, Ga., OwnerPrecast Specialty Engineer (MSE walls): Reinforced Earth Co., Norcross, Ga.Precast Specialty Engineer (planter walls): Wolverton & Associates, Duluth, Ga.<strong>Bridge</strong> Description: Two-span bridge with precast, prestressed concrete beams and cast-in-place concrete deck supporting unusual loadsincluding planting areas up to 9-ft highStructural Components: 74-in.-deep bulb tees, modified 74-in.-deep bulb tees, planter walls on bridge, mechanically stabilized earth wallpanels, and cast-in-place concrete deck<strong>Bridge</strong> Cost: $10.12 millionASPIRE, Winter 2008 | 23

<strong>The</strong> walls and plantings are the most importantaesthetic feature of the new structure.<strong>The</strong> planter walls also had to beconsidered in the design of thebeams because of their effect on thedistribution of the sustained dead loadof the landscaping on the bridge. <strong>The</strong>density of normal landscape fill forplantings ranges from 110 pcf to 120pcf. GDOT decided to use a speciallightweight organic soil with a densityof 90 pcf to help reduce weight, but theloading was still significant. ARCADISwas concerned that the effect of thedeep wall sections would be to distributea greater percentage of the dead loadto the beams under the landscaping,particularly under the walls, instead ofbeing evenly distributed to all of thebeams in the cross section. This typeof loading was not addressed by theproject specifications, so ARCADISverified the actual load distributionusing a finite element model. <strong>The</strong> modelused plate elements for the deck andbeam elements modeled at the centerof gravity of each precast girder. <strong>The</strong>steel diaphragms were also included.<strong>The</strong> girders were then analyzedTrellis on the south side of the bridgeprovides shade. Photo: ARCADIS U.S. Inc.using conventional methods (Leap’sCONSPAN software) and verified withGDOT’s in-house prestressed concretebeam design program. <strong>The</strong> results ofthe model confirmed that the planterloads would be distributed to thegirders under the landscaping. Had thisanalysis not been performed, the girdersimmediately adjacent to the plantersmay have been under-designed.A pile bent and mechanically stabilizedearth (MSE) wall system comprise thewest end bent, while a tieback wallabutment supports the east end bent.<strong>The</strong> center wall pier of the existingbridge was widened, and the existingcap was modified to accommodatethe new concrete beams. <strong>The</strong> designand construction of the east abutmentwere complicated by the presence of anexisting tieback retaining wall and anexisting CIP retaining wall just in frontof the new wall. <strong>The</strong> abutment wasconstructed using secant-drilled shafts,supported by deep-tension micropiles.<strong>The</strong> shafts and tension micropiles werefounded on bedrock. However, wherethe old foundation of the existing CIPwall interfered with shaft construction,the drilled shafts were founded on topof the old footing, and compressionmicropiles were drilled through thefooting and founded in bedrock tosupport the shafts.<strong>The</strong> final and, perhaps, most significantchallenge was to complete the projectwithout disrupting traffic on either the<strong>Fifth</strong> <strong>Street</strong> <strong>Bridge</strong> or the interstate overthe entire two-year construction period.Lane shifts and closures were permittedon I-75/I-85 but were subject to time<strong>The</strong> exterior beams under the walls andlandscaping had to be spaced closertogether due to the effect the walls hadon the dead load distribution.Photo: Sunbelt Structures Inc.limits, as well as liquidated damages.Work-hour limitations were also in effectfor special events in the area, such assporting events, concerts, and festivals.Traffic on the <strong>Fifth</strong> <strong>Street</strong> <strong>Bridge</strong> itselfwas maintained by reducing the numberof lanes to one in each direction. Usingthe staged construction scheme, thewidened part of the structure was builtfirst, and then traffic was shifted to thenewly constructed portion of the bridgeso the remainder of the bridge could beconstructed.<strong>The</strong> structure was completed andopened to traffic in December 2006,just 29 months after Notice to Proceedwas issued.__________________Jim Aitken is the Structures DepartmentManager for ARCADIS’ Atlanta office,Mike Clements is a Design Group Leaderin the Office of <strong>Bridge</strong> Design at theGeorgia Department of Transportation,and Tim Schmitz, formerly with ARCADIS,was the structural designer for the project.For more information on this or otherprojects, visit www.aspirebridge.org.Providing a <strong>Pedestrian</strong>-Friendly Environment<strong>The</strong> new bridge provides a roadway that is48 ft wide, the same width as the originalstructure. However, it carries only twolanes of vehicular traffic; the remainingwidth is dedicated to bicycle and turninglanes. Each side of the roadway has a24-ft-wide sidewalk. While the total bridgewidth is 223 ft 3 in., more than 125 ft arelandscaped areas, with 75 ft on the northside and more than 50 ft on the south side.Benches for seating are provided on eachside of the bridge. On the south side of theroadway, a trellis provides a bench withshade. On the north side, sloped walkwaysgive pedestrians access to an area oflawn. Decorative lighting illuminates thesidewalks and landscaping on both sides ofthe bridge. Precast concrete walls separateeach of the lawn and landscaped areasfrom the pedestrian and roadway areas.<strong>The</strong> planting plan included multi-tieredplanting areas that range in height from 1ft 6 in. to 9 ft. <strong>The</strong> walls and plantings arethe most important aesthetic feature of thenew structure and define the character andnature of the new space on <strong>Fifth</strong> <strong>Street</strong>.<strong>The</strong> design called for the walls to be CIP,but Sunbelt decided to precast the walls onsite. Special counterforts were designed toreplace the CIP system to support the walls.24 | ASPIRE, Winter 2008

PROJECTFIFTH <strong>Street</strong> PEDESTRIAN PLAZA <strong>Bridge</strong> / ATLANTA, GEORGIA<strong>The</strong> beams inSpan 2 have not yetdeflected into theirfinal position.A bulb-teecross section wasmodified to allowan extra line ofstrands in the web.Web | ASPIRE, Winter 2008

FIFTH <strong>Street</strong> PEDESTRIAN PLAZA <strong>Bridge</strong> / ATLANTA, GEORGIAPROJECTA new tiebackretaining wall wasneeded at one end.Photo: Hayward BakerASPIRE, Winter 2008 | Web

PROJECTFIFTH <strong>Street</strong> PEDESTRIAN PLAZA <strong>Bridge</strong> / ATLANTA, GEORGIASpeciallydesignedcounterfortswere used tosupport the9-ft-high precastplanter walls.Main Photo:GDOTInset Photo: Planter walls and trellis on the southside of the bridge. Photo: ARCADOS U.S. Inc.Steel diaphragms wereused to provide quickinstallation and lateralsupport to the beams.Web | ASPIRE, Winter 2008