Portable Foam Inductor - Hawkes Fire

Portable Foam Inductor - Hawkes Fire

Portable Foam Inductor - Hawkes Fire

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

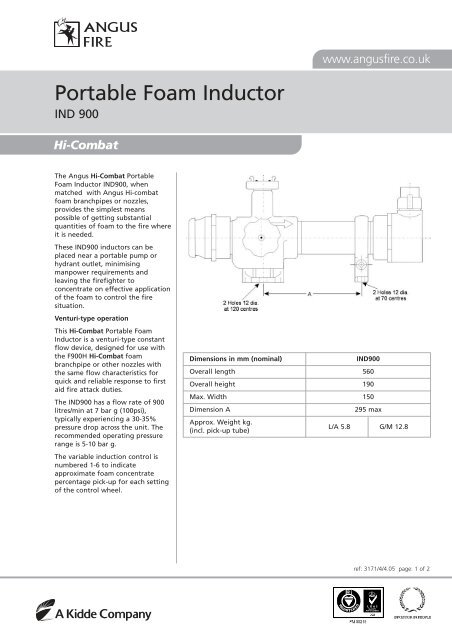

www.angusfire.co.uk<strong>Portable</strong> <strong>Foam</strong> <strong>Inductor</strong>IND 900Hi-CombatThe Angus Hi-Combat <strong>Portable</strong><strong>Foam</strong> <strong>Inductor</strong> IND900, whenmatched with Angus Hi-combatfoam branchpipes or nozzles,provides the simplest meanspossible of getting substantialquantities of foam to the fire whereit is needed.These IND900 inductors can beplaced near a portable pump orhydrant outlet, minimisingmanpower requirements andleaving the firefighter toconcentrate on effective applicationof the foam to control the firesituation.Venturi-type operationThis Hi-Combat <strong>Portable</strong> <strong>Foam</strong><strong>Inductor</strong> is a venturi-type constantflow device, designed for use withthe F900H Hi-Combat foambranchpipe or other nozzles withthe same flow characteristics forquick and reliable response to firstaid fire attack duties.The IND900 has a flow rate of 900litres/min at 7 bar g (100psi),typically experiencing a 30-35%pressure drop across the unit. Therecommended operating pressurerange is 5-10 bar g.The variable induction control isnumbered 1-6 to indicateapproximate foam concentratepercentage pick-up for each settingof the control wheel.Dimensions in mm (nominal)IND900Overall length 560Overall height 190Max. Width 150Dimension A295 maxApprox. Weight kg.(incl. pick-up tube)L/A 5.8 G/M 12.8ref: 3171/4/4.05 page: 1 of 2

Hi-CombatCOLOUR CODEDAngus Hi-Combat <strong>Portable</strong> inductors have been designed to match the characteristics of Angus Hi-Combat foambranchpipes. Correct matching is essential if optimum performance is to be obtained.For fast action and minimised risk of branchpipe mismatching the IND900 is colour codedIND900 and F900HBlue colour band450 equipment Red colour band225 equipment No colour bandNormally supplied with 2 1 /2“ BS.336 Instantaneous couplings or BSP male threaded connections, but many otherconnections are available from the “Armourite” range. For further details of the Angus F900H Hi-Combat foambranchpipe see data sheet 3042. For smaller flow inductors (nominal 225 or 450 litres/min) see the Hi-CombatUniductor Data Sheet 5300.USING A HI-COMBAT PORTABLE INDUCTORIf the flow rating of the branchpipe is greater than that of the inductor, throw from the branchpipe will be reduced.If the flow rating of the branchpipe is less than that of the inductor, induction may cease.The standard unit is available in corrosion resistant light alloy, although a gunmetal version is available where saltwaterapplications are anticipated. A tough, chip-resistant yellow thermoplastic finish is provided as standard onboth versions.Normally one or two lengths of Duraline fire hose can be used between each portable inductor and Hi-Combatbranchpipe but it is recommended that a hose with 64mm (2 1 /2“) diameter is chosen for the IND900 to minimisepressure losses. Longer lengths can be used if care is taken to keep the hose as straight and level as possible betweeninductor and branchpipe.It is recommended that Hi-Combat branchpipes are operated no more than 6 metres vertically above the Hi-Combat<strong>Portable</strong> <strong>Inductor</strong> to avoid back pressure problems occurring, and achieve maximum performance at the nozzle.Each portable inductor is fitted with a non-return valve and 1metre long pick-up tube, to allow use with 25 litrefoam drums or temporary reservoirs. This also avoids the potential risk of water diluting the foam supply, which canbe caused by high back pressures occurring due to poor hose configurations, operating up steep slopes, ormismatching of equipment.FIXED INSTALLATIONSFor use in fixed installations, the separate range of Angus “FI” IN-LINE INDUCTORS provide a cost-effective, simpleand reliable method of proportioning foam concentrate where constant flow conditions prevail.There are six models in the range with performance extending from 65 to 4,000 litres/min at inlet pressures ofbetween 4 and 16 bar g. Within these limits, the induction rate can be accurately set between 1% and 6%. Eachinductor is accurately calibrated at the factory to match the specific requirements of the system into which it is to beinstalled.For further details of the Angus FIXED IN-LINE INDUCTORS range see Data Sheet 5032 and Section 2 of the Angus<strong>Foam</strong> Systems Engineering Manual.© Angus <strong>Fire</strong>. Angus <strong>Fire</strong> reserves the right to modify any specification without prior notice.ref: 3171/4/4.05 page: 2 of 2THAME PARK ROAD, THAME, OXFORDSHIRE, OX9 3RT, ENGLANDTel: +44 (0)1844 265000 Fax: +44 (0)1844 265156e-mail: general.enquiries@kiddeuk.co.uk