ELECTROLYTIC CAPACITORS 2008

ELECTROLYTIC CAPACITORS 2008

ELECTROLYTIC CAPACITORS 2008

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

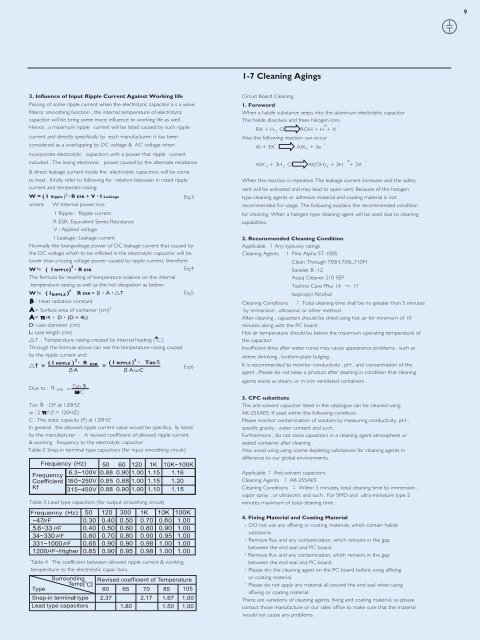

1-7 Cleaning Agings3. Influence of Input Ripple Current Against Working lifePassing of some ripple current when the electrolytic capacitor a s a wavefilteror smoothing function , the internal temperature of electrolyticcapacitor will be bring some more influence to working life as well .Hence , a maximum ripple current will be listed caused by such ripplecurrent and directly specifically by each manufacturer; it has beenconsidered as a overlapping by DC voltage & AC voltage whenincorporate electrolytic capacitors with a power that ripple currentincluded . The losing electronic power caused by the alternate resistance& direct leakage current inside the electrolytic capacitors will be cometo heat . Kindly refer to following for relation between in rated ripplecurrent and temperate raising:W = ( I Ripple ) 2whereR ESR + V I LeakageW: Internal power lossI Ripple : Ripple currentR ESR: Equivalent Series ResistanceV : Applied voltageI Leakage : Leakage currentEq.3Normally the losingvoltage power of DC leakage current that caused bythe DC voltage which to be inflicted in the electrolytic capacitor will belower than a losing voltage power caused by ripple current, therefore:W ( I RIPPLE) 2 R ESRThe formula for reaching of temperature balance on the internaltemperature raising as well as the hot dissipation as below:Eq.4Circuit Board Cleaning1. ForewordWhen a halide substance seeps into the aluminum electrolytic capacitorThe halide dissolves and frees halogen ions.RX + H 2 O ROH + H + + X -Also the following reaction can occurAl + 3X - AlX 3 + 3e -AlX 3 + 3H 2 O Al(OH) 3 + 3H + + 3X -When this reaction is repeated. The leakage current increases and the safetyvent will be activated and may lead to open vent. Because of this halogentype cleaning agents or adhesive material and coating material is notrecommended for usage. The following explains the recommended conditionfor cleaning. When a halogen type cleaning agent will be used due to cleaningcapabilities.2. Recommended Cleaning ConditionApplicable Any type.any ratingsCleaning Agents Pine Alpha ST-100SClean Through 750H,750L,710MSanelek B -12Aquq Cleaner 210 SEPCleaning Conditions Total cleaning time shall be no greater than 5 minutesTechno Care FRw 14 17W ( I RIPPLE ) 2 R ESR =Eq.5Isopropyl Alcohol: Heat radiation constant= Surface area of container (cm) 2 by immersion , ultrasonic or other method .= /4 D (D + 4L)After cleaning , capacitors should be dried using hot air for minimum of 10D: case diameter (cm)minutes along with the PC board .L: case length (cm)Hot air temperature should be below the maximum operating temperature ofT : Temperature raising created by internal heating ( C ).the capacitor .Through the formula above can see the temperature raising causedInsufficient dries after water runse may cause appearance problems , such asby the ripple current and:sleeve shrinking , bottom-plate bulging .T = ( I RIPPLE ) 2 R ESR = ( I RIPPLE )2 TanEq.6It is recommended to monitor conductivity , pH , and concentration of theCagent . Please do not keep a product after cleaning in condition that cleaningDue to : R ESR = Tan Cagents exists as steam, or in non ventilated containers .3. CFC substituteTan : DF at 120HZThe anti-solvent capacitor listed in the catalogue can be cleaned usingw : 2 f (f = 120HZ)AK-255AES. If used within the following condition.C : The static capacity (F) at 120HZPlease monitor contamination of solution by measuring conductivity, pH ,In general , the allowed ripple current value would be specifica lly listedspecific gravity , water content and such .by the manufacturer - A revised coefficient of allowed ripple currentFurthermore , do not store capacitors in a cleaning agent atmosphere or& working frequency to the electrolytic capacitor .Table-2 Snap-in terminal type capacitors (for input smoothing circuit)sealed container after cleaning .Also avoid using using ozone depleting substances for cleaning agents indifference to our global environments.Table-3 Lead type capacitors (for output smoothing circuit)Applicable Anti-solvent capacitorsCleaning Agents AK-255AESCleaning Conditions Within 5 minutes, total cleaning time by immersion ,vapor spray , or ultrasonic and such . For SMD and ultra-miniature type 2minutes maximum of total cleaning time .Table-4 The coefficient between allowed ripple current & workingtemperature to the electrolytic capac itors.4. Fixing Material and Coating MaterialDO not use any affixing or coating materials, which contain halidesubstance.Remove flux and any contamination, which remains in the gapbetween the end seal and PC board.Remove flux and any contamination, which remains in the gapbetween the end seal and PC board.Please dry the cleaning agent on the PC board before using affixingor coating material.Please do not apply any material all around the end seal when usingaffixing or coating material.There are variations of cleaning agents, fixing and coating material, so pleasecontact those manufacture or our sales office to make sure that the materialwould not cause any problems.