Technical Particulars For Drinking Water Coolers - csidc ...

Technical Particulars For Drinking Water Coolers - csidc ...

Technical Particulars For Drinking Water Coolers - csidc ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

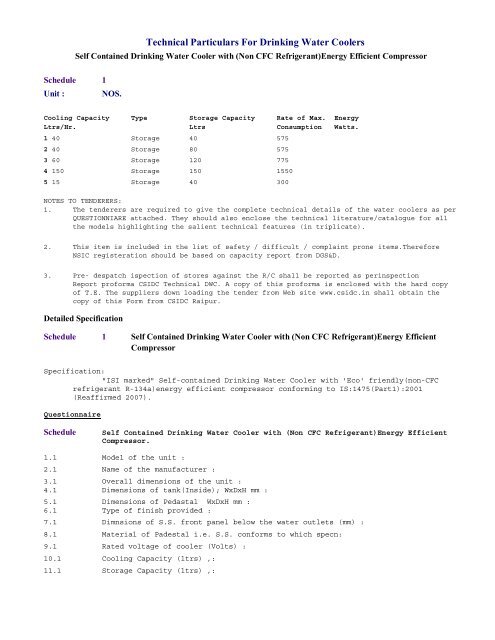

<strong>Technical</strong> <strong>Particulars</strong> <strong>For</strong> <strong>Drinking</strong> <strong>Water</strong> <strong>Coolers</strong>Self Contained <strong>Drinking</strong> <strong>Water</strong> Cooler with (Non CFC Refrigerant)Energy Efficient CompressorSchedule 1Unit :NOS.Cooling Capacity Type Storage Capacity Rate of Max. EnergyLtrs/Hr. Ltrs Consumption Watts.1 40 Storage 40 5752 40 Storage 80 5753 60 Storage 120 7754 150 Storage 150 15505 15 Storage 40 300NOTES TO TENDERERS:1. The tenderers are required to give the complete technical details of the water coolers as perQUESTIONNIARE attached. They should also enclose the technical literature/catalogue for allthe models highlighting the salient technical features (in triplicate).2. This item is included in the list of safety / difficult / complaint prone items.ThereforeNSIC registeration should be based on capacity report from DGS&D.3. Pre- despatch ispection of stores against the R/C shall be reported as perinspectionReport proforma CSIDC <strong>Technical</strong> DWC. A copy of this proforma is enclosed with the hard copyof T.E. The suppliers down loading the tender from Web site www.<strong>csidc</strong>.in shall obtain thecopy of this <strong>For</strong>m from CSIDC Raipur.Detailed SpecificationSchedule 1 Self Contained <strong>Drinking</strong> <strong>Water</strong> Cooler with (Non CFC Refrigerant)Energy EfficientCompressorSpecification:"ISI marked" Self-contained <strong>Drinking</strong> <strong>Water</strong> Cooler with 'Eco' friendly(non-CFCrefrigerant R-134a)energy efficient compressor conforming to IS:1475(Part1):2001(Reaffirmed 2007).QuestionnaireScheduleSelf Contained <strong>Drinking</strong> <strong>Water</strong> Cooler with (Non CFC Refrigerant)Energy EfficientCompressor.1.1 Model of the unit :2.1 Name of the manufacturer :3.1 Overall dimensions of the unit :4.1 Dimensions of tank(Inside); WxDxH mm :5.1 Dimensions of Pedastal WxDxH mm :6.1 Type of finish provided :7.1 Dimnsions of S.S. front panel below the water outlets (mm) :8.1 Material of Padestal i.e. S.S. conforms to which specn:9.1 Rated voltage of cooler (Volts) :10.1 Cooling Capacity (ltrs) ,:11.1 Storage Capacity (ltrs) ,:

12.1 <strong>Water</strong> supply pressure and size of water inlet (Kg/cm ,mm) :13.1 No of Faucets provided :14.1 Details of drains provided & material :15.1 Make & model of Compressor :16.1 Type of compressor :17.1 Starting method of compressor :18.1 Capacity of compressor (K.cal/hr):19.1 Max. output of compressor motor (Kw) :20.1 Rated current , speed, & voltage of compressor (Amps, rpm, volts) :21.1 Max. full load current of compressor :22.1 Warranty of compressor (In years) :23.1 Refrigerant used :24.1 Class of insulation of compressor motor :25.1 Pull down time for storage type water coolers as per Clause 7.8.2.1 :--a. Ambient temp (Deg.C)b. Initial water temp.(Deg.C)c. Final water temp.(Deg.C)d. Pull down time (Min)e. Voltage(Volts)f. Current(Amps)g. Power consumption(watts)26.1 a. Max. input of Fan motor (Amps/watts) :b. Type of fan motor to IS:996/79 with amdt. No.2 &3:27.1 Power factor of condensor fan motor :28.1 <strong>Particulars</strong> of Condenser Coil :--a. Face area(Sq.mtr):b. Tube material, OD, & wall thickness(mm):c. Number of rows :d. Number of holes per row(Nos):e. Fin material & thickness(mm):f. No. of fins per cm(Nos)29.1 <strong>Particulars</strong> of Insulating material :--a. Thickness (mm) :b. Material with trade name, if any. :30.1 Mention `Makes` of following items :--a. Electric Motor :b. Capacitor :c. Condenser / Evaporator :d. Thermostat with details of differential and its range:

General <strong>Technical</strong> requirement <strong>For</strong> TE :i) Firm shall have valid BIS License conforming to IS:1475(Part-1)2001(Reaffirmed2007).ii)iii)iv)The water <strong>Coolers</strong> shall be suitable for operation on 230 V +/-10 %,50 Hz,singlephase A.C.supply.The tenderers shall declare specn. details of non-CFC compressor.(a) During inspection production routine tests as mentioned in clause 7.2 ofIS1475(Part-1):2001(reaffirmed 2007) will be carried out as acceptance test on upto10% of the samples from the lot offered for inspection.(b) Complete testing facilities should be available as per IS: 1475(part-1) withthe firm with instruments accuracies as per clause 7.6 of the specification.v) Tank shall be fabricated from S.S Sheet of 0.8mm minimum thickness as per AISI 304and shall be made by electrically seam welded lap joints or alternatively from 0.63mmthickness Stainles steel sheet with PUF insulation. However tank fabricated by doubleseam jointing is also acceptable if the same is reinforced and sealed by lead-freesolder material. Use of lead soldering material for sealing the joints of water tankis not permitted. <strong>Water</strong> tank cover and lid bottom shall be made of 1.25mm aluminimumsheet duly anodised/eppoxy painted/high impact polystyrene (HIP) of1.5mm thickness.Positive locking of the lid is to be provided (lock with two keys). Adrain valve at the bottom of the storage tank to be provided to draw outwater while cleaning.vi)The cabinet of the water cooler shall be made of GS sheet of 1.0mm. The front panelbelow the water outlets in the storage type water coolers shall be made ofstainless steel of 0.8mm. The drain pan for storage type water coolers shall be made ofstainless steel sheet of 0.63mm upto size 40 ltrs/hr and beyond 40 ltrs/hr of 0.8mmthickness. The bottom pedestal shall be made of 2.65mm minimum thick stainless steelsheet. Pedestal shall have a minimum ground clearance of 100mm for ease ofcleaning.Pedestal shall be strong enough to withstand weight with storage tank fulland shall be reinforced to prevent askewing. The body shall be held securely with thepedestal with stainless steel nuts and bolts.The drain size should be 25mm or above.In case water outlets are provided on three sides then all the three lower panelsshould be made of aluminium sheet or stainless steel sheet.vii) The mild steel components used in the manufacture of the cabinet shall beindividually degreased, pickled, scrubbed and rinsed to remove grease, rust, scaleor/any other foreign elements. Immediately after pickling the M.S. parts shallbe given phosphating treatment. The components alongwith the front panels shall then begiven a primer coat with a finish coat of stove enamel paint. The finish shall be smoothand uniform with hard tough film of the enamel adhering to the surface. The finishshall be free from all the visible defects and shall not chip when tappedlightly with a dull pointed instrument. Alternative method of corrosion protection likeplastic powder coating, electrostatic painting shall be permitted.viii) Refrigeration coils to be fully soldered to the outside of the tank for good thermalcontact and not merely tack welded.ix)The tenderers are required to furnish wattage/litre for the model as actually obtainedin their product at rated conditions.x) There shall not be any gap between water tank cover (mask) and water tankto prevent rodent/inspect/dust entry.xi)xii)Condensor fan motor shall be capacitor start and capacitor run(CSR) or permanently splitcapacitor(PSC)or alternatively permanently lubricated motor may be provided.<strong>Water</strong> tank overflow should be adequately covered with strainer such as wire

meshetc. to avoid rodent/insect/dust entry.xiii) The power factor of water cooler shall not be less than 0.85 at capacity rating testconditions.xiv)xv)The thermostat shall conform to IS:11338-1985 (Reaffirmed 1999) The position of thethermostat shall be adjustable through a rotary switch mounted on the front or sidepanels. Minimum and maximum of the thermostat setting shall be from 10 deg C and 25deg.C which shall be marked.During inspection performance of thermostat shall also be checked at minimum and maximumpositions.SAMPLING:No of samples for acceptance test shall be 10% of the offered lot capacitywise subject tominimum of 1 number.Pre- despatch ispection of stores against the R/C shall be reported as perinspectionReport proforma CSIDC <strong>Technical</strong> DWC. A copy of this proforma is enclosed with the hard copyof T.E. The suppliers down loading the tender from Web site www.<strong>csidc</strong>.in shall obtain thecopy of this <strong>For</strong>m from CSIDC Raipur.