Technical Particulars For HDPE Tarpaulins TSC 04-01-2013 - csidc ...

Technical Particulars For HDPE Tarpaulins TSC 04-01-2013 - csidc ...

Technical Particulars For HDPE Tarpaulins TSC 04-01-2013 - csidc ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

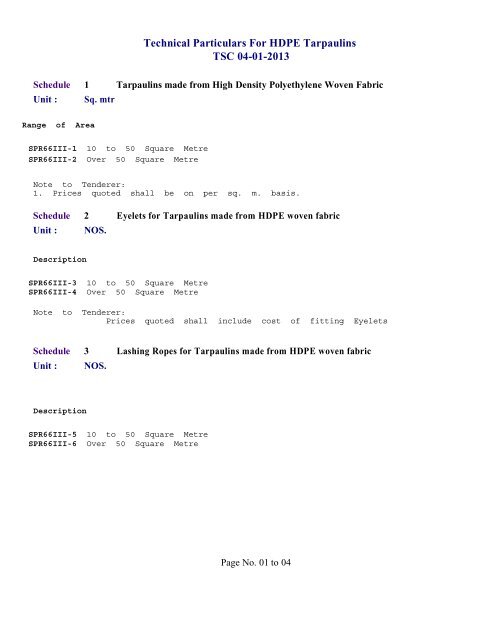

<strong>Technical</strong> <strong>Particulars</strong> <strong>For</strong> <strong>HDPE</strong> <strong>Tarpaulins</strong><strong>TSC</strong> <strong>04</strong>-<strong>01</strong>-2<strong>01</strong>3Schedule 1 <strong>Tarpaulins</strong> made from High Density Polyethylene Woven FabricUnit :Sq. mtrRange of AreaSPR66III-1 10 to 50 Square MetreSPR66III-2 Over 50 Square MetreNote to Tenderer:1. Prices quoted shall be on per sq. m. basis.Schedule 2 Eyelets for <strong>Tarpaulins</strong> made from <strong>HDPE</strong> woven fabricUnit :NOS.DescriptionSPR66III-3 10 to 50 Square MetreSPR66III-4 Over 50 Square MetreNote to Tenderer:Prices quoted shall include cost of fitting EyeletsSchedule 3 Lashing Ropes for <strong>Tarpaulins</strong> made from <strong>HDPE</strong> woven fabricUnit :NOS.DescriptionSPR66III-5 10 to 50 Square MetreSPR66III-6 Over 50 Square MetrePage No. <strong>01</strong> to <strong>04</strong>

Note to Tenderer:1)Prices quoted shall include cost of fitting Lashing Ropes.2)Tenderers shall purchase the raw material i.e. <strong>HDPE</strong> granules fromauthorized dealer and copy of manufacturers test certificate foreach batch and submit the purchase invoice along with manufacturerstest certificate to concern Director (QA) beforecommencement of inspection.Tenderer shall also furnish raw materialconsumption statement to the concerned DQA at the time of inspectionNOTE TO INDENTOR :The number of eyelets and lashing ropes as required for eachtarpaulin shall be ordered seprately from schedule-2 & 3.Detailed SpecificationSchedule1<strong>Tarpaulins</strong> made from High Density Polyethylene Woven FabricSpecification :Tarpaulin made from <strong>HDPE</strong> woven fabric complete with eyelets & lashing ropes toSpecification No.IS:7903:2005 & as per details given in general technical requirments.Schedule 2 Eyelets for <strong>Tarpaulins</strong> made from <strong>HDPE</strong> woven fabricSpecification :Eyelets as per details given in general technical requirements.Schedule3Lashing Ropes for <strong>Tarpaulins</strong> made from <strong>HDPE</strong> woven fabricSpecification :Lashing Ropes as per details given in general technical requirements.General <strong>Technical</strong> requirement <strong>For</strong> TE :1)Quality Assurance officer shall collect copy of the documents, (like purchaseand manufacturers test certificate for <strong>HDPE</strong> granules etc) and verify withoriginaldocuments before commencement of inspection.QA officer shall also collect rawmaterial consumption statement at the time of inspection.2) <strong>Tarpaulins</strong> Made from <strong>HDPE</strong> Woven Fabric-Following requirements shall beapplicable for this item.i)Size varying from 3.7 m. X 3.0 m. to 12.2 m. X 12.2 m. as required bythe Indentor.ii) Basic <strong>HDPE</strong> woven fabric used for lamination shall conform toIS:7903/2005 with Amdt No.1 of sept.2006.iii)Tarpaulin shall be manufactured from two layers of <strong>HDPE</strong> woven fabric.iv)Lashing ropes shall be of 12 mm Dia. & 1.5 m. length as perIS:4572:1992, Amds-1(Third Rev.)Page No. 02 to <strong>04</strong>

v)Metallic eyelets shall be as per specification no. IS:4084-1978,Amdt-1 & 2( First Revision). Eyelets shall be fixed at an interval of about 150 cms on allsides. Only one eyelet shall be used at corner and shall be fitted in a row withthe other eyelets. <strong>For</strong> tarpaulins of above 15.0 m.sq. in size re-inforcementtriangular pieces shall be provided for the eyelets. The triangular piece shallbe made of 20x20 cms piece folded along one diagonal. Each of these triangularpieces shall be inserted under each eyelet under the double turning, the foldededge of the strengthening piece being in line with the outer edge of the hem whenfinished. The centre of the eyelet shall be at a distance of 3 cms from outeredge of the hem.vi) The panels shall be flat (lap) joint. The ends & sides of thetarpaulin shall be hammed by lock type double stitch.vii) Sewing thread shall be <strong>HDPE</strong> tape/yarn similar material of lineardensity 66.6 tex to specification no. IS:6192:1994.3)Marking : Each tarpaulin shall be legible marked with the following informationat one corner on one side by printing on it with the ink.a) Name of manufacturer/Trade Markb) Size of tarpaulin & Sl. No.c) Year of manufacture.4)Packing : Each tarpaulin shall be suitably folded and packed with layer of hessianabout 225 gsm followed by an intermediate layer of polyethylene film of 0.038 mmthickness followed by an outer layer of hessian approx 340 gsm confirming to type 1of IS:2818 - 1964. The four corners of the packing shall be tied to keep at least15 cm ears for easy handling.5)SAMPLE CLAUSE:-APPROVED SAMPLES:-In case where Supply Order (S/O) stipulates samples to be approved by theindentor before bulk manufacture the supplier shall submit within 15 days ofreceiptof S/O three (03) identical sets of samples as per contract specificationsfor indentor's approval through inspecting officer. Each set shall contain threenumbers of samples each of items depicting indeterminable paramters such as,shade/tone (light, medium, dark) size make-up , feel, finish and workmanship.On the receipt of samples the inspecting officer shall examine the sample forsize/diension ) and mass (duly conditioned) to verify if they are as per requiredspecification and if found satisfactory shall forward the same to the indentor forhis approval in respect of indeterminable parameters.In case these parameters meet the requirement of indentor he shall label andseal the samples with remarks as "Approved" or "Not approved". Indentor shall retainone set of sample with him, forward one set to inspecting officer concerned and thebalance one set to the supplier for his guidance. Since approve of single sample willnot adequate indication of variation in shade etc. approval of just one sample in aset will not be acceptable. It is, therefore, necessary that at least two of thethree samples meet the approval of indentor. to depict the acceptable variationindeterminable parameters.Samples approved as above shall be known as "Approved Samples".In the event of indentor having repeat order under current R/C on the samesupplier the samples approved in the earlier S/O can be adopted against subsequentS/Os.Failure to submit samples by the stipulated date or in event of sample beingrejected by Inspecting Authority or by indentor, the S/O shall be liable to becancelled. at the risk and expense of contractor without any further reference tothe supplier. The purchaser shall also be entitled to take contractual/administativeand other remedial measure including short-closure of the rate contract.Page No. 03 to <strong>04</strong>

During manufacture/inspection of stores before despatch it shall be ensuredthat none of the offered/accepted lot is lighter or darker when compared with theapproved sample of light and dark shade respectively.REPRESENTATIVE SAMPLES:-During the course of inspection, samples will be drawn for detailed examinatinand tst as laid down in the specificatins. The inspecting offifcer shallsimultaneously draw additional two samples, similar to the samples drawn for detailedtests, to be sent to each of the consginees alongwith accepted lot. All these samplesshould conform to the approved samples in respect of the indeterminable paramterssuch as shade/tone (i.e. light, medium, dark), size, make-up, feel, finish andworkmanship.These samples shall be known as "Reprresentative Samples".The representative samples shall be lebelled and sealed by inspecting officerand forwarded to consignee with the lot. The bale/packing in which these samples arekept, shall be clearly indicated in the inspection note for each consignee.Theconsignees will be guided by these samples to determine whether the same lot as hasbeen inspected and accepted by the inspecting officer has been despatched by thesupplier.Approved by <strong>Technical</strong> Specification Committee Dated <strong>04</strong>-<strong>01</strong>-2<strong>01</strong>3Page No. <strong>04</strong> to <strong>04</strong>