Technical Particulars For EVAPORATIVE AIR COOLER - csidc ...

Technical Particulars For EVAPORATIVE AIR COOLER - csidc ...

Technical Particulars For EVAPORATIVE AIR COOLER - csidc ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

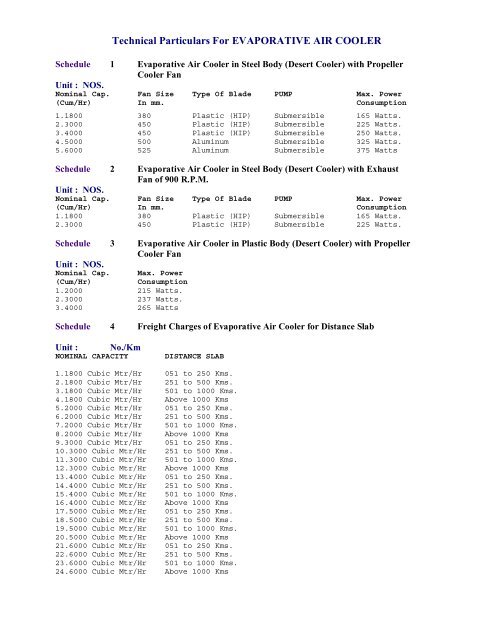

<strong>Technical</strong> <strong>Particulars</strong> <strong>For</strong> <strong>EVAPORATIVE</strong> <strong>AIR</strong> <strong>COOLER</strong>Schedule 1 Evaporative Air Cooler in Steel Body (Desert Cooler) with PropellerCooler FanUnit : NOS.Nominal Cap. Fan Size Type Of Blade PUMP Max. Power(Cum/Hr) In mm. Consumption1.1800 380 Plastic (HIP) Submersible 165 Watts.2.3000 450 Plastic (HIP) Submersible 225 Watts.3.4000 450 Plastic (HIP) Submersible 250 Watts.4.5000 500 Aluminum Submersible 325 Watts.5.6000 525 Aluminum Submersible 375 WattsSchedule 2 Evaporative Air Cooler in Steel Body (Desert Cooler) with ExhaustFan of 900 R.P.M.Unit : NOS.Nominal Cap. Fan Size Type Of Blade PUMP Max. Power(Cum/Hr) In mm. Consumption1.1800 380 Plastic (HIP) Submersible 165 Watts.2.3000 450 Plastic (HIP) Submersible 225 Watts.Schedule 3 Evaporative Air Cooler in Plastic Body (Desert Cooler) with PropellerCooler FanUnit : NOS.Nominal Cap. Max. Power(Cum/Hr)Consumption1.2000 215 Watts.2.3000 237 Watts.3.4000 265 WattsSchedule 4 Freight Charges of Evaporative Air Cooler for Distance SlabUnit : No./KmNOMINAL CAPACITYDISTANCE SLAB1.1800 Cubic Mtr/Hr 051 to 250 Kms.2.1800 Cubic Mtr/Hr 251 to 500 Kms.3.1800 Cubic Mtr/Hr 501 to 1000 Kms.4.1800 Cubic Mtr/Hr Above 1000 Kms5.2000 Cubic Mtr/Hr 051 to 250 Kms.6.2000 Cubic Mtr/Hr 251 to 500 Kms.7.2000 Cubic Mtr/Hr 501 to 1000 Kms.8.2000 Cubic Mtr/Hr Above 1000 Kms9.3000 Cubic Mtr/Hr 051 to 250 Kms.10.3000 Cubic Mtr/Hr 251 to 500 Kms.11.3000 Cubic Mtr/Hr 501 to 1000 Kms.12.3000 Cubic Mtr/Hr Above 1000 Kms13.4000 Cubic Mtr/Hr 051 to 250 Kms.14.4000 Cubic Mtr/Hr 251 to 500 Kms.15.4000 Cubic Mtr/Hr 501 to 1000 Kms.16.4000 Cubic Mtr/Hr Above 1000 Kms17.5000 Cubic Mtr/Hr 051 to 250 Kms.18.5000 Cubic Mtr/Hr 251 to 500 Kms.19.5000 Cubic Mtr/Hr 501 to 1000 Kms.20.5000 Cubic Mtr/Hr Above 1000 Kms21.6000 Cubic Mtr/Hr 051 to 250 Kms.22.6000 Cubic Mtr/Hr 251 to 500 Kms.23.6000 Cubic Mtr/Hr 501 to 1000 Kms.24.6000 Cubic Mtr/Hr Above 1000 Kms

Schedule 1 Evaporative Air Cooler in Steel Body (Desert Cooler) with Propeller Cooler FanSpecification :-Evaporative Air Coolers complete with Propeller type fan 1400 rpm (4poles) motor,conforming to IS 3315:1994 (Reaffirmed 2004)Edition 3.2 incorporatingAmendt.Nos.1&2 (except for galvanized steel sheet which shall have zinc coating notless than 100gms/sq.mtr.) & other specifications as per General <strong>Technical</strong>requirements.Schedule 2 Evaporative Air Cooler in Steel Body (Desert Cooler) with Exhaust Fan of 900R.P.M.Specification :-Evaporative Air Coolers complete with Exhaust type fan 900 rpm (6 poles)motor,conforming to IS 3315:1994 (Reaffirmed 2004)Edition 3.2 incorporatingAmendt.Nos.1&2(except for galvanized steel sheet which shall have zinc coating notless than 100gms/sq.mtr.) & other specifications as per General <strong>Technical</strong>requirements.Schedule 3 Evaporative Air Cooler in Plastic Body (Desert Cooler) with Propeller CoolerFanSpecification :-Evaporative Air Cooler (Desert Cooler), Plastic Body complete with Fan, filterpads,water pump etc. conforming to IS 3315:1994 (Reaffirmed 2004)Edition 3.2incorporating Amendt.Nos.1&2.1. coolers shall be suitable for 230 Volts +/-10%, single phase, 50 Hz.AC supply.2. Fan motor shall be 4-pole having 1400 RPM with three speeds.3. Tenderers shall submit type test report from CIPET conducted by them on theirproducts with reference to suitability of plastic components certifying thatair cooler components have been satisfactorily evaluated for their design andend use performance requirements as per relevant specification.4. Switches shall be rotary type with Propeller fan and pump with separatecontrol. The switch shall have marking: off-low-Medium and High.Alternatively Rotary/Piano switch conforming to IS 3854:1997 (Reaffirmed2007) amdt.1 to 5 may be used.5. Submersible Pump Shall be make of Crompton Greaves, Bajaj, Khaitan, Usha andshall be tested as per the requirement of IS:11951:1987 with amdt. No.1 to4(Reaffirmed 2007)for the performence of the pump.(Incase of submersible pump the firm shall furnish the manufacturer testcertificate for each rating along with manufacturer authorised dealer invoice andproduct catalogue etc. at the time of Ist inspection of the rate contract.)OrType test report for the submersible pump from any government approved laboratoryshall be furnish by the firm at the time of Ist inspection of the rate contract.6. Suitable motorized vertical louvers shall be provided in the grill of thecooler.7. The filter pads shall contain wood wool or suitable material capable ofholding moisture in a nylon mesh bag/ mesh with spikes and so fixed to bespread uniformly over the panel so as to avoid sagging of the pad. The padshall completely cover the grill panel. Grill panels may have enclosure toprevent sagging of filter pads.8. Electric motor and pump shall be ISI marked or approved make byDGS&D.Propeller Fan Motor shall conform to IS 996:1979 (Reaffirmed2005).Power factor of fan /blower motor shall not be less than 0.9.9. Provision shall be made for fixing high pressure ball valves (horizontalplunger type) including float valve 15mm size conforming to

IS:1703:2000(Reaffirmed 2005) or polyethylene float conforming to IS9762:1994(Reaffirmed 2004).10. The drain plug of suitable non-corrosive material shall be fitted in such away as to completely drain the water from the tank.11. The inside wiring connection shall be through suitable non-ferrous thimblesand the live contacts of rotary switch shall be protected by suitableenclosure of insulating material and electrical cords of the motor and thepump shall be sheathed type.12. Manufacturer,s type test certificate/BIS Liecense of the pump set, Propellerfan motor duly ISI Marked shall be submitted to the concerned Director of QAat the time of first inspection.Schedule 4 Freight Charges of Evaporative Air Cooler for Distance SlabSpecification :-Freight charges for road dispatches to consignee destination shall be quotedby the tenderers for each distance slab in No./Kms.subject to free delivry up to 50Kms.

QuestionnaireSchedule Evaporative Air Cooler in Steel Body (Desert Cooler) with Propeller CoolerFan1.0 Overall dimensions of the cooler:a. Width in mm (When measured Front side):b. Height in mm (When measured Front side):c. Depth in mm.:d. Overall Dimensions of the front Grill panel :e. Size of the Watertank (W x D x H):f. Weight in Kgs:1.1 a. Inside dimensions of Air grill in mm/Net area in Sq. mtrs.:b. Out side dimensions Air grill in mm/Gross area in Sq. mtrs:c. Stepped face to suit smaller window(H X W XD):d. Material use in bush for Louver of grill provided for it movement:1.2 a. Velocity of Air grill (mtrs/min) :b. Area of filter pads in Sq. mtrs:c. Material of filter pads:d. Galvanized wire guard of 2mm dia. net size 100 mm insquare/rectangular:1.3 a. Sizes of propeller fan:b. Material of fan ( Hub & Blade):c. Anti corrosive treatment for fan blade / motor shaft:d. Make of the motor:e. Three speed motor(L, M, H ):f. Type of enclosure of the fan motor:g. Efficiency of the fan motor:1.4 a. Are the coolers bearing ISI mark? :b. Are the motor bearing ISI mark? :c. Are the pumpset bearing ISI mark? :d. Are the switch of coolers bearing ISI mark? :e. Rotary type/Paino Type (L, M, H & Pumpset):f. Rating of the switch & its Make:1.5 (Submersible type):a. Out put (Head):b. Out put (Delivery):c. Maximum Power Consumption:d. Horse Power (for individual size of cooler to be indicatedseparately::e. RPM of Pump:f. Type of enclosure of Pump Motor:g. Make & Model:

QuestionnaireSchedule Evaporative Air Cooler in Steel Body (Desert Cooler) with Exhaust Fanof 900 R.P.M.1.0 Overall dimensions of the cooler:a. Width in mm (When measured Front side):b. Height in mm (When measured Front side):c. Depth in mm.:d. Overall Dimensions of the front Grill panel :e. Size of the Watertank (W x D x H):f. Weight in Kgs:1.1 a. Inside dimensions of Air grill in mm/Net area in Sq. mtrs.:b. Out side dimensions Air grill in mm/Gross area in Sq. mtrs:c. Stepped face to suit smaller window(H X W XD):d. Material use in bush for Louver of grill provided for it movement:1.2 a. Velocity of Air grill (mtrs/min) :b. Area of filter pads in Sq. mtrs:c. Material of filter pads:d. Galvanized wire guard of 2mm dia. net size 100 mm insquare/rectangular:1.3 a. Sizes of propeller fan:b. Material of fan ( Hub & Blade):c. Anti corrosive treatment for fan blade / motor shaft:d. Make of the motor:e. Three speed motor(L, M, H ):f. Type of enclosure of the fan motor:g. Efficiency of the fan motor:1.4 a. Are the coolers bearing ISI mark? :b. Are the motor bearing ISI mark? :c. Are the pumpset bearing ISI mark? :d. Are the switch of coolers bearing ISI mark? :e. Rotary type/Paino Type (L, M, H & Pumpset):f. Rating of the switch & its Make:1.5 (Submersible type):a. Out put (Head):b. Out put (Delivery):c. Maximum Power Consumption:d. Horse Power (for individual size of cooler to be indicatedseparately::e. RPM of Pump:f. Type of enclosure of Pump Motor:g. Make & Model:

QuestionnaireScheduleEvaporative Air Cooler in Plastic Body (Desert Cooler) with PropellerCooler Fan1.0 a. Make & Model No. :b. Capacity of Cooler :c. Width (Measured alongwith discharge grill side:d. Height of cooler :e. Depth of cooler :f. Size of Sump tank:g. Capacity of Sump Tank :h. Weight of cooler:1.1 a. Thickness of Top cover (mm) :b. Thickness of Bottom Tank (mm):c. Thickness of Side Panels (mm):Air Grill with manually adjustable Louvers :i) Inside Dimensions (mm):ii) Outside dimensions (mm) :iii) Gross area of the grill (Sq. mtr):1.2 a. Velocity of Air at grill (Mtr. per Minute):b. Material used for grills and moving arrangement:Filter Pads :a) Dimensions(mm):b) Material of filter Pads :1.3 a. Actual power consumption (Watt) of air cooler with load at ratedvoltage at zero static pressure conditions:b. Actual air delivery (CuM/hr) at zero static pressure conditions:c. Service value expressed as a ratio of actual air deilivery:1.4 a. Make /Model of Fan :b. Size of Fan :c. Dia of Fan (mm) :d. RPM of Fan :e. Air delivery of Fan :f. Horse power (<strong>For</strong> individual size of cooler to be indicatedseparately):g. Details of anti-corrosive treatment given to fan :1.5 a. Type of enclosure of fan motor & Rating:b. Power factor of fan motor :c. Efficiency of fan motor :d. RPM of the fan motor:e. Max. full load current of fan motor (Value to be indicatedseparately for individual size of cooler :1.6 (Submersible type):a. Out put (Head):b. Out put (Delivery):c. Maximum Power Consumption:d. Horse Power (for individual size of cooler to be indicatedseparately::e. RPM of Pump:f. Type of enclosure of Pump Motor:g. Make & Model:1.7 a. Make & Brand of Switches:b. Rating of Switches:c. Type of switch:d. Governing specification & in absence of IS Specn. maanufactuirer'sself-containedcomplete specification to be furished :

1.8 1.Confirmation whether the air cooler offered complies with additionalrequirements:2. Whether full testing facilities as per specn. are available at themanufacturer's works.3. Deviations/deficiencies from IS: 3315:94(Reaffirmed2004)with amdt1&2:1.9 a. Material of Bottom Tank:b. Material of Top Cover:c. Material of side grill piller:d.Material of Front Grill louvers (Movable type) :e. Extent of fire retardant used:Inspection Report PerformaDrawing/Proforma/Annexure Attached [Click on following to view/print]

General <strong>Technical</strong> requirement <strong>For</strong> TE :1. a) Propeller type Fan shall be complete with motor and fan motor shall be ISImarked to IS:996:1979 with amdt. No.-1,2&3 (Reaffirmed 2007 ).b) Exhaust fan shall be complete with motor and ISI marked to IS: 2312:1967with amendt.No.1 to 8(Reaffirmed 2005).c) Submersible Pump Shall be make of Crompton Greaves, Bajaj, Khaitan, Ushaand shall be tested as per the requirement of IS:11951:1987 with amdt. No.1to 4(Reaffirmed 2007) for the performence of the pump.(Incase of submersible pump the firm shall furnish the manufacturer testcertificate for each rating along with manufacturer authorised dealer invoice andproduct catalogue etc. at the time of Ist inspection of the rate contract.)OrType test report for the submersible pump from any government approvedlaboratory shall be furnish by the firm at the time of Ist inspection of the ratecontract.2. The Evaporative Air Coller, Pumpset Electric motorWith propeller Type/ExhaustFan shall be suitable for operation on 230 volts +/-10% ,single phase ,50 HzAC supply .3. The coolers shall be complete with fan, motor, filter pads, water pump etc.ADDITIONAL TECHNICAL REQUIREMENTS:-1. Schedule-1 & 3 Propeller fan motor will be of 1400 r.p.m.(4 pole)and shallhave three speeds.Schedule-2 Exhaust Fan shall be of 900 r.p.m (6pole motor) and shall havesingle speed.(The material used for Propeller fan shall be virgin HIPS and shall haveimpact resistance <strong>For</strong> impact test. The unit shall be dropped from 1 Mtrs. heightand shall not show any damage.)2. Filter panel, front, grill and top of the cooler body shall be made of 0.8 mmgalvanized steel sheet. The sump tank and rest of the body shall be made of1.0 mm thick galvanized steel sheet. The galvanised steel sheet shall be ISImarked and shall have zinc coating not less than 100 gms/ sq. metre and shallconform to IS: 277-2003(Reaffirmed 2007 ).2a. All internal surfaces including inside of the tank, fan blades, motorbody,pump, pump body and frame shall be painted with water resistant paintconforming to IS: 9862-1981 with amdt. No.1(Reaffirmed 2004).2b. The outer surface of the cooler shall be painted with enamel paint toIS:2932/2003.3. The cooler shall be provided rotary/piano type On-Off and speed selectionswitch for three speed cooler fan motor. Tenderers should indicate type ofswitch offered.4. Suitable nylon bushes shall be provided in the grill for easy and smoothmovement of louveres.5. The filter pads shall contain wood wool. The filter pads shall be fixed overthe panel and secured by clamping guard of galvanized wire of 2mm dia.approx. and net size 100 mm approx. square/rectangular. The wire guard shallbe fixed in the clamps to avoid any sagging.6. Punched hole of 15 mm size shall be provided to fix the float valve whererequired.7. The drain plug of brass/SS shall be fitted in such a way so as to be able tocompletely drain the water from the tank.8. The inside wiring connection shall be through suitable non-ferrous thimblesand the live contacts of rotary switch shall be protected by suitableenclosure of insulating material.The electrical cords of the motor and the pump shall be sheathed type.

9. a) 2 Nos. Coolers of each rating shall be type tested at the time of firstinspection against the Rate Contract.b) The contractor shall also submit Mahufacturer Type Test Certificates/BISLicense for the Pump set, Exhaust/ Fan Motor at the time of first inspection.The air coolers shall be offered duly preinspected by the firm. The aircoolers offered for inspection shall be tested for acceptance tests as perfollowing sampling plan. However sampling plan can be modified depending onthe level of quality control adopted by the firm at the discretion of theinspecting officer.Lot sizeNo. of samplesUp to 15 - 516 to 50 - 851 to 100 - 1310. Max. power consumption under zero static condition shall not exceed thefigures mentioned against the items.11. All the production routine tests shall be carried out as acceptance tests.Air delivery and power consumption of one evaporative air cooler for every100 Nos. air coolers would be checked at zero static pressure testconditions.12. The air cooler shall be provided with front filling arrangement and withconnecting cord of 2.5 mtrs. Length fitted with 3-pin moulded plug top of 5/6Amp.Rating.13. Capacity rating testing as well as type testing shall be carried out at zerostatic pressure, testing facilities for which shall be provided by you eitherat your works or with your sister concern preferably within 1 km. distance.Performance condition for carrying out testing shall be acceptable at anyambient conditions with RH higher than standard (40 +/-1.5 C.DB:24+/- 1.5 C.WB).14. Power consumption test: Each unit of a given lot shall be tested for powerconsumption test at free air flow condition .This power consumption figurewould not xceed the value arrived at by subtracting differential `D` from themax. Permissible ower consumption at zero static pressure test conditions asgiven in ISS.Differential `D` would be the difference between the actual power consumptionobserved t zero static pressure test conditions of an air cooler selected atrandom from the iven lot and the actual power consumption of the same ,aircooler at free air flowconditions. If more than one air cooler are tested at static conditions, thenmax.observed differential would be subtracted from the max. Permissible wattageat zero tatic pressure test conditions for arriving at acceptable value ofpower input for ll air cooler free air flow conditions.15. enderers shall declare the max. Noise level and the scale on which it ismeasured. They shall provide test facilities for the same.16. echnical Data for each capacity shall be furnished by the tenderers as per

QUESTION<strong>AIR</strong>ES attached.17. TESTING AND QUALITY CONTROL REQUIREMENT:1) he firm shall submit the test certificate for the following:-a) anufacturer test certificate in respect of grade for the plastic raw materialo be used indicating batch /lot number and quantity along with certified copyof nvoice,supporting challan. The test certificate shall contain details asper chedule.b) They shall declare the moulding plan indicating address and telephone numberof moulder to the inspectorate concerned, well in advance, so that they mayhave a random check on the offered grade, lot no./batch no. of material beingutilized in the moulding. In case, inspecting officer is unable to visit thefirm, the firm shall intimate the concerned Directorate of QA the quantitymoulded by them and may undertake the assembly of coolers.c) The concerned Dir of QA shall draw samples from moulded components either atmoulder's premises or at the firm's premises for testing of the plasticcomponents at CIPET for periodic type testing, at least once during thecurrency of R/c as per.Samples, one each at least, from each type of component material from one ofthe major moulded component pertaining to that category shall be drawn by theinspectorate for the test as per detailed of testing.d) The firm shall offer assembled coolers for inspection to the inspectingofficer for all tests as per IS: 3315:1994(Reaffirmed 2004) with amdt.No-1&2and R/C specns.and if found satisfactory shall allow the firm to dispatch and release theinspection documents pending receipt of the test report on plastic componentsfrom outside laboratory subject to the following conditions:-(i)On a certification from the firm that they have used the same grade/batch ofraw material in the moulding components offered for inspection.(ii) That they have submitted the samples drawn by the inspecting officer from theplastic moulded components to the testing laboratory and paid the requisitefees. Insupport of this they shall submit a copy of the supporting documentsof laboratory.(iii) that the firm shall abide by the decision of Director of QA (DGS&D) incase the test report issued by testing laboratory subsequent to the releaseof stores are found deviating from the specn. Requirement.18. The tenderers shall submit Test certificate for material containingFollowing parameters:--Parameter--------------------UnitDensity----------------------gms/ccMelt flow index--------------gms/10minMould shrinkage--------------in%Tensile strength at yield----kg/cmElongation at break----------in%Flexural strength------------kg/cmRockwell hardness------------R - scaleIzod impact strengtha) Notched-------------------kg/cmb) Unnotched-----------------Kg/cmFlammability-----------------UL.94-HBHeat deflection temperature(at 18.5 kg/cm 2)---Deg.C(fibre stress)Moisture absorption----------in%Abrasion resistance ------- mgs/1000cycles(at500gmload/1000 cycles using CS-10 wheel)Filler content---------------in%

19. PROCEDURE FOR THE TESTING OF FINISHED MOULDED COMPONENTS OF <strong>AIR</strong> <strong>COOLER</strong>S:TESTS----------------------LEVEL OF CONTROLS--------------REMARKS---------i) VISUAL INSPECTION-----------10%-------------Defect(such as sharpedges/cracks,unevenness or any processing defects shall not be allowed.ii)DIMENSION------------------1%--------------All samples should pass as perassembly requirements.iii) RESISTANCE TO CHEMICALS---1 No.-----------Samples should pass all the testsas per CIPET type test report(a) change in dimension(%)(b) change in weight(%)(c) Change in flexural modules(%) and stickness.iv)FILLER CONTENTS(%) ------1 No.-------------Samples should pass all the testsas per CIPET type test report.v) DROP TEST---------------- 1 No.-------------No crack, no permanentdeformation shall develop in any of the samples.vi) DIMENSIONAL STABILITY-----1 No.------------ Samples should meet therequirements.vii) WEATHERABILITY----------1 No.------------ Acceptance test shall be carriedout on the sample. <strong>For</strong> the type test firm shall furnish manufacturers typetest certificate.viii) FLAMMABILITY-----------1 No.------------ Sample should pass all the testsas per CIPET type test report.20. Pre-dispatch inspection of stores shall be reported as per Inspection Reportform No. DQAQ/MECH/275 enclosed. Tenderers while down loading the T.P. fromWeb site can down load the Inspection Report Performa from Web site itself.

fujh{k.k izfrosnu------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------nwjHkk’k ua- % -------------------------------------- QSDl ua- % --------------------------------Øa-@-------------------------------------------------------------------------------- fnukad --------------------lkexzh fujh{k.k izfrosnu dk Øekad ------------------------------------------------------------------------------1- Øsrk foHkkx dk uke % ------------------------------------------------------------------------------2- vuqcaf/kr bdkbZ dk uke o irk % ------------------------------------------------------------------------------% ------------------------------------------------------------------------------% ------------------------------------------------------------------------------3- vuqcaf/kr bdkbZ dk jsV dkUVªsDV % ------------------------------------------------------------------------------Øaekd ,oa fnukad % ------------------------------------------------------------------------------4- fujh{k.k fnukad -------------------- % fujh{k.k LFky ----------------------------------------------------Ø- Øsrk foHkkx dk Ø;kns”kØ-@fnukadlkexzh dk fooj.kvknsf”krek=klkexzh fujh{k.k fooj.kizLrqr Lohd`rek=k ek=kvLohd`rek=kfujh{k.kVhi& eSa izekf.kr djrk gwa fd mijksDr lkexzh eSus vius Kku ,oa foosd ds vuqlkj lh,lvkbZMhlh}kjk fu’ikfnr nj vuqca/k ds fu/kkZfjr rduhdh ekin.M ds vuqlkj fujh{k.k fd;k gSA& ;g fujh{k.k izfrosnu fuEufyf[kr fu;e ,oa “krksZ ds varxZr tkjh fd;k x;k gS %&1- Øsrk foHkkx fujh{k.k fnukad ls ,d ekg i”pkr lqiqnZxh ugha ysaxsA

iqoZ i`’B ls %&2- Øsrk foHkkx dks lkexzh dh xq.koRrk ,oa rduhdh ekin.Mksa ds laca/k esa dksbZ f”kdk;r gksrks bls lqiqnZxh ysus ds 7 fnolksa esa leLr fooj.k lfgr lh,lvkbZMhlh dks lwfpr djukvfuok;Z gksxkA3- Øsrk foHkkx lkexzh izkIr djus ds iwoZ] lqfuf”pr djs fd lkexzh dh xq.koRrk larks’ktudgSA4- Øsrk foHkkx lkexzh dh lqiqnZxh ysus ls iwoZ ;g lqfuf”pr dj ysa fd izR;sd lkexzh ijbdkbZ ds uke dk LVhdj@eksuks yxk gqvk gSA ;g vadu ;FkklaHko esVsfyd LVhdjvFkok LVsfUly vFkok isij LVhdj vFkok fujh{k.k ,tsUlh }kjk vuqeksfnr fd;k vU;rjhds ls gks ldrk gSA5- fujhf{kr lkexzh@Lohdkj dh xbZ lkexzh ij fujh{k.kdrkZ ,tsalh dk eksuks ,oa LVhdj e;uke@irk lfgr yxk;k x;k gSAfujhf{kreksuks @eksgjfnukad -----------------------------¼fujh{k.kdrkZ ,tsalh ds izfrfu/kh dk uke½Øa-@-------------------------------------------------------------------------------- fnukad --------------------izfrfyih %1- Øsrk foHkkx ¼uke ,oa irk lfgr½2- iznk;drkZ bdkbZ ¼nj vuqca/k /kkjd bdkbZ dk uke ,oa irk½3- izHkkjh foi.ku&I lh,lvkbZMhlh fyfe- ,yvkbZlh O;kolkf;d ifjlj] fo/kku lHkk jksM+]iaMjh]jk;iqj N-x-4- dk;kZy;hu izfr¼fujh{k.kdrkZ ,tsalh ds izfrfu/kh dk uke½