Polyethylene for pipe systems - Total Refining & Chemicals

Polyethylene for pipe systems - Total Refining & Chemicals

Polyethylene for pipe systems - Total Refining & Chemicals

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

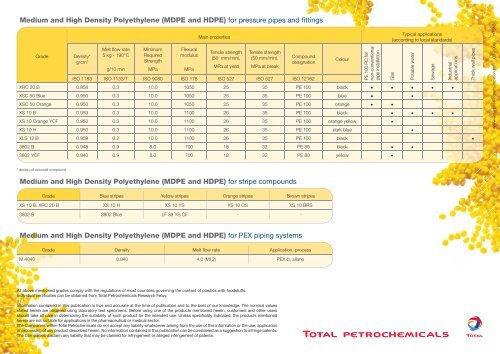

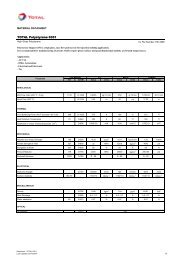

Medium and High Density <strong>Polyethylene</strong> (MDPE and HDPE) <strong>for</strong> pressure <strong>pipe</strong>s and fittingsGradeDensity*g/cm 3Melt fl ow rate5 kg - 190°Cg/10 minMinimumRequiredStrengthMPaFlexuralmodulusMPaMain propertiesTensile strength(50 mm/min),MPa at yieldTensile strength(50 mm/min),MPa at breakCompounddesignationISO 1183 ISO 1133/T ISO 9080 ISO 178 ISO 527 ISO 527 ISO 12162XRC 20 B 0.958 0.3 10.0 1050 25 35 PE 100 blackXSC 50 Blue 0.950 0.3 10.0 1050 25 35 PE 100 blueXSC 50 Orange 0.950 0.3 10.0 1050 25 35 PE 100 orangeXS 10 B 0.959 0.3 10.0 1100 26 35 PE 100 blackXS 10 Orange YCF 0.950 0.3 10.0 1100 26 35 PE 100 orange yellowXS 10 H 0.950 0.3 10.0 1100 26 35 PE 100 dark blueColourPE 100 RC <strong>for</strong>non-conventional<strong>pipe</strong> installation•••Typical applications(according to local standards)Gas••••Potable water••••Sewage••Industrialapplications••Thick wall <strong>pipe</strong>swww.enterprise-communication.be 03-2009 H7558XLS 12 B 0.959 0.2 10.0 1100 26 35 PE 100 black•3802 B 0.948 0.9 8.0 700 18 32 PE 80 black••3802 YCF 0.940 0.9 8.0 700 18 32 PE 80 yellow•* density of coloured compoundMedium and High Density <strong>Polyethylene</strong> (MDPE and HDPE) <strong>for</strong> stripe compoundsGrade Blue stripes Yellow stripes Orange stripes Brown stripesXS 10 B, XRC 20 B XS 10 H XS 10 YS XS 10 OS XS 10 BRS3802 B 3802 Blue LF 38 YS CF - -Medium and High Density <strong>Polyethylene</strong> (MDPE and HDPE) <strong>for</strong> PEX piping <strong>systems</strong>Grade Density Melt fl ow rate Application, processM 4040 0.940 4.0 (MI 2) PEX-b, silaneAll above mentioned grades comply with the regulations of most countries governing the contact of plastics with foodstuffs.Individual certificates can be obtained from <strong>Total</strong> Petrochemicals Research Feluy.In<strong>for</strong>mation contained in this publication is true and accurate at the time of publication and to the best of our knowledge. The nominal valuesstated herein are obtained using laboratory test specimens. Be<strong>for</strong>e using one of the products mentioned herein, customers and other usersshould take all care in determining the suitability of such product <strong>for</strong> the intended use. Unless specifically indicated, the products mentionedherein are not suitable <strong>for</strong> applications in the pharmaceutical or medical sector.The Companies within <strong>Total</strong> Petrochemicals do not accept any liability whatsoever arising from the use of this in<strong>for</strong>mation or the use, applicationor processing of any product described herein. No in<strong>for</strong>mation contained in this publication can be considered as a suggestion to infringe patents.The Companies disclaim any liability that may be claimed <strong>for</strong> infringement or alleged infringement of patents.