Technical Data Sheet - Total Refining & Chemicals

Technical Data Sheet - Total Refining & Chemicals

Technical Data Sheet - Total Refining & Chemicals

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

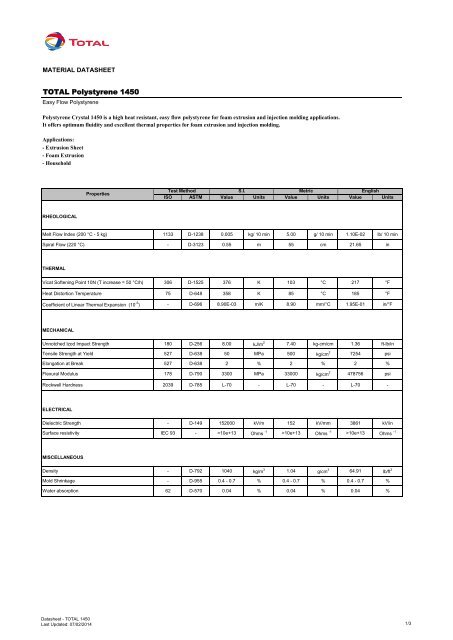

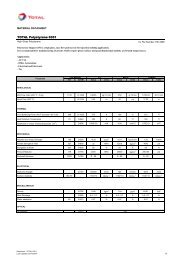

MATERIAL DATASHEETTOTAL Polystyrene 1450Easy Flow PolystyrenePolystyrene Crystal 1450 is a high heat resistant, easy flow polystyrene for foam extrusion and injection molding applications.It offers optimum fluidity and excellent thermal properties for foam extrusion and injection molding.Applications:- Extrusion <strong>Sheet</strong>- Foam Extrusion- HouseholdPropertiesTest Method S.I. Metric EnglishISO ASTM Value Units Value Units Value UnitsRHEOLOGICALMelt Flow Index (200 °C - 5 kg) 1133 D-1238 0.005 kg/ 10 min 5.00 g/ 10 min 1.10E-02 lb/ 10 minSpiral Flow (220 °C) - D-3123 0.55 m 55 cm 21.65 inTHERMALVicat Softening Point 10N (T increase = 50 °C/h) 306 D-1525 376 K 103 °C 217 °FHeat Distortion Temperature 75 D-648 358 K 85 °C 185 °FCoefficient of Linear Thermal Expansion (10 -5 ) - D-696 8.90E-03 m/K 8.90 mm/°C 1.95E-01 in/°FMECHANICALUnnotched Izod Impact Strength 180 D-256 8.00 kJ/m 2 7.40kg-cm/cm 1.36 ft-lb/inTensile Strength at Yield 527 D-638 50 MPa 500 kg/cm 27254 psiElongation at Break 527 D-638 2 % 2 % 2 %Flexural Modulus 178 D-790 3300 MPa 33000 kg/cm 2 478756 psiRockwell Hardness 2039 D-785 L-70 - L-70- L-70 -ELECTRICALDielectric Strength - D-149 152000 kV/m 152 kV/mm3861 kV/inSurface resistivity IEC 93 - >10e+13 Ohms -1 >10e+13 Ohms -1 >10e+13 Ohms -1MISCELLANEOUSDensity - D-792 1040 kg/m 3 1.04 g/cm 3 64.91 lb/ft 3Mold Shrinkage - D-955 0.4 - 0.7 % 0.4 - 0.7% 0.4 - 0.7 %Water absorption 62 D-570 0.04 % 0.04 %0.04 %<strong>Data</strong>sheet - TOTAL 1450Last Updated: 07/02/2014 1/3

RECOMMENDED INJECTION MOLDING PARAMETERSBarrel Temperature Value UnitsZone 1 170 - 180 °CZone 2 180 - 220 °CZone 3 210 - 240 °CZone 4 210 - 240 °CNozzle 210 - 240 °CGeneral Information :Standard Properties: All tests are carried out at 23 °C unless otherwise stated. Mechanical properties are measured on injection moulded test specimens.Bulk Density: Bulk Density of all Natural grades is approximately 0.6 g/cm 3 .TOTAL Polystyrene 1450 should be kept in a cool and dry place. Avoid direct exposure to sunlight.<strong>Total</strong> <strong>Refining</strong> & <strong>Chemicals</strong><strong>Total</strong> <strong>Refining</strong> & <strong>Chemicals</strong><strong>Total</strong> Petrochemicals Foshan Ltd<strong>Total</strong> Petrochemicals SEA Pte LtdNo.61, Jinben Industry Road, Sanshui District, 53 Tuas Crescent,Foshan, Guangdong (528132), P.R. China Singapore (638732)Tel: +86 757 8751 7888 Tel: +65 6862 1228Fax: +86 757 8751 8084 Fax: +65 6862 3735Information contained in this publication is true and accurate at the time of publication and to the best of our knowledge. The nominal values stated herein are obtained using laboratory test specimens.Before using one of the products mentioned herein, customers and other users should take all care in determining the suitability of such product for the intended use. Unless specifically indicated, theproducts mentioned herein are not suitable for applications in the pharmaceutical or medical sector. The companies within TOTAL REFINING & CHEMICALS do not accept any liability whatsoever arisingfrom the use of this information or the use, application or processing of any product described herein. No information contained in this publication can be considered as a suggestion to infringe patents. Thecompanies disclaim any liability that may be claimed for infringement or alleged infringement of patents.<strong>Data</strong>sheet - TOTAL 1450Last Updated: 07/02/2014 2/3

Safety and Material HandlingTOTAL REFINING & CHEMICALS offers acomprehensive range of TOTAL POLYSTYRENE(PS) specially formulated to suit different needs.This extensive line includes impact polymers, eithernatural or with additives, with equally wide-rangingproperties to fulfill all customer expectations interms of fire resistance, appearance, cost andprocessing. Its tremendous ease of processing andits low cost make it one of the most commonly usedpolymers in the food packaging, audio/video,household appliances and construction industries.TOTAL REFINING & CHEMICALS is committed toproviding information to assist our customers inreducing the risks of handling and using ourproducts. This bulletin sheet is intended to be aquick reference guide for TOTAL REFINING &CHEMICALS customers to store, handle and useour products safely and in an environmentally soundmanner. We aim to minimize the impact on mankindand the environment during production, storage,transportation, sale, use and disposal of ourproducts.Safety <strong>Data</strong> <strong>Sheet</strong>s are updated regularly, to reflectchanges and updates on information in an SDS.Before handling or using any product, pleaserequest and assess the most current Safety <strong>Data</strong><strong>Sheet</strong>s. The information provided below isappropriate only to TOTAL REFINING &CHEMICALS ’s products as delivered. In the courseof fabrication, many additives and ingredients maybe added before the finished product. These mustbe explored thoroughly for their respectively healthand safety considerations.precautions should be observed in the handling andfabrication of plastic materials.Noise is a common problem in the molding andcompounding process. If possible, no worker should beexposed to excessive noise (Leq8hours 85dBA). Properhearing protectors should be provided for workers,coupled with regular audiometric examinations.Air borne dusts often result from sawing, filing, andsanding of plastic parts in post-moulding operations.These may cause irritation to eyes and the upperrespiratory tract. Processing may also release fumes,which may contain irritating decomposition products.Adequate exhaust ventilation is recommended. Goodhousekeeping and controlling of dusts are necessary forsafe handling of product. Workers should use approvedrespirators. If vapours cause irritation to eyes, a full-facerespirator is recommended. Avoid accumulation of staticcharges during transfers in metallic systems.Workers should be protected from the possibility ofcontact with molten PS during fabrication. Molten materialmay causes burns. Wash affected areas abundantly andthoroughly with water. In case of adhesion, do not try toremove product. Treat the affected areas as burns.Proper manual handling practices should be observed inthe lifting and transportation of PS packages.Occurrences in back and arm injuries are common inerroneous lifting techniques.However, Polystyrene offers many possibilities forpost consumer recycling such as: (1) Energyrecycling using heat recovery systems for urbanand industrial heating systems, (2) Materialrecycling. Polystyrene should be recycledwhenever possible. Because of their high energycontent, plastics can help the entire waste mix burnhotter and more completely in a waste-to-energyincinerator.Care for the EnvironmentPS must not be discarded indiscriminately into thewaterways nor land.Heavy metals are not used in the manufacture ofTOTAL POLYSTYRENE. As such, disposal ofHIPS via convention methods would be safe for theenvironment. Incineration of HIPS would not emitheavy metals or deleterious dioxins into theenvironment. There would be no leaching of heavymetals into the earth when the incineration ash island filled.Customer NoticeTOTAL REFINING & CHEMICALS stresses theimportance of health and environmental protectionduring the entire lifetime of all TOTAL REFINING &CHEMICALS 's products, and calls for TOTALREFINING & CHEMICALS to cooperate closelywith its customers and partners. To help ensurethat TOTAL REFINING & CHEMICALS ’s productsare not used improperly, TOTAL REFINING &CHEMICALS’s personnel will assist customers indealing with product safety, health andenvironmental considerations.Product Stewardship ProgramThe aim of the product stewardship code of theresponsible care initiative, which makes health,safety and environmental protection an integralpart of designing, manufacturing, marketing,distributing, using, recycling and disposing ourproducts. Successful implementation of theseinitiatives is a shared responsibility that includes allwho come into contact with a product. TOTALREFINING & CHEMICALS will work withcustomers to help ensure that all who use andhandle our products follow safe andenvironmentally sound practices.General Safe Handling InformationTOTAL POLYSTYRENE are relatively inert andhave a very low degree of toxicity under normalconditions of use. TOTAL REFINING &CHEMICALS should be kept in cool and dry place.Avoid direct exposure to sunlight. Keep at roomtemperature. Nevertheless, safety and healthFlammability and CombustibilityThermal decomposition at 200 o C gives off flammable andharmful products such as styrene, ketones, toluenes andalcohol. There would be formation of toxic products, suchas carbon oxides through combustion.In fighting fire, wear a self-contained breathing apparatusand protective suit. Water or water fog are the preferredextinguishing media. Foam, alcohol resistant foam,carbon dioxide, or dry chemicals may also be used.Safe DisposalDisposal methods must be in compliance withinternational, national and local laws and regulations.Destroy the product by incineration at an approved wastedisposal site.This information is provided for GENERAL INFORMATION ONLY. TOTAL REFINING & CHEMICALS and its affiliates provide a Safety Dat a <strong>Sheet</strong> (SDS) for thisproduct, in the appropriate language, according to applicable laws and regulations.Anyone using this product should carefully review the SDS, as well as any other applicable precautions and instructions for u se. No liability whatsoever can beaccepted by TOTAL REFINING & CHEMICALS and its affiliates with regard to the handling, processing or use of the product or pr oducts concerned which must in allcases be used in accordance with all applicable laws and regulations.The information contained in this document is based on trials carried out by our Research Centers and data selected from the literature. To the best of our knowledgeand at the time of publication, this information is true and accurate. It shall, however, in no event be held to constitute o r imply any warranty, undertaking express orimplied commitment from our part. TOTAL REFINING & CHEMICALS and its affiliates disclaim any liability that may be claimed f or infringement or allegedinfringement of patents.<strong>Data</strong>sheet - TOTAL 1450Last Updated: 07/02/2014 3/3