Polyethylene for pipe systems - Total Refining & Chemicals

Polyethylene for pipe systems - Total Refining & Chemicals

Polyethylene for pipe systems - Total Refining & Chemicals

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Polyethylene</strong><strong>for</strong> <strong>pipe</strong> <strong>systems</strong>Hexene inside

<strong>Polyethylene</strong> compounds <strong>for</strong> <strong>pipe</strong> <strong>systems</strong>A Long Lasting commitment<strong>Total</strong> Petrochemicals sales of <strong>pipe</strong> compounds<strong>Total</strong> Petrochemicals is a major player in the <strong>pipe</strong> andfi ttings market and is a fully integrated company (fromcrude oil to polyethylene and polypropylene).It is <strong>Total</strong> Petrochemicals’ policy to build lasting andmutually benefi cial relations with its customers.Hexene insideAll <strong>Total</strong> Petrochemicals’ coloured <strong>Polyethylene</strong> <strong>pipe</strong>compounds are made exclusively with hexene ascomonomer, PE80 since 1974, PE100 since 1997.Compared to standard PE resins <strong>for</strong> <strong>pipe</strong>, the use ofhexene as comonomer is known to provide the followingbenefi ts:> better slow crack growth resistance> better resistance against rapid crack propagation> superior melt strength (low sag)1974 1980 1990 2000 2010More than 30 years of continuousgrowth and support to <strong>pipe</strong> <strong>systems</strong>customersCon<strong>for</strong>mity to ISO9001 since 1989 ensures productconsistency and quality of services.With more than 30 years presence on the <strong>pipe</strong> market,<strong>Total</strong> Petrochemicals’ PE <strong>pipe</strong> compounds are worldwidereferences to the plastic <strong>pipe</strong>s industry and itsend users.Your partnerResponding to the needs of our customers and thecreation of added value solutions <strong>for</strong> the industry arethe key objectives of <strong>Total</strong> Petrochemicals. A customerorientated organisation and an innovative productrange, offered through a dedicated and focused salesand technical team, make <strong>Total</strong> Petrochemicals yourideal partner.With our expertise based on a long-standing presenceand continuous investments in people and research,<strong>Total</strong> Petrochemicals is present and active in nationaland international standardisation groups, EU qualitymarks and associations.The local sales and support staff are located close toyou, backed up by a technical support team located inthe Research and Development Centre at Feluy(Belgium).

<strong>Polyethylene</strong> compounds <strong>for</strong> <strong>pipe</strong> <strong>systems</strong>worldwide used and approvedUnited States (PPI)Canada (PPI)France (LNE, Gaz de France)Belgium (Electrabel, Belgaqua)Hungary (several approvals)United Kingdom, Ireland (DWI, WRAS, NGT) Romania (several approvals)Netherlands (KIWA - Gastec)Bulgaria (several approvals)Denmark (Insta-Cert)Russian FederationNorway (Insta-Cert)(Gosgortekhnadzor)Sweden (Insta-Cert)Finland (Insta-Cert)China (several approvals)Germany (KRV, DVGW, DIBT)Poland (IGNIG, ...)JapanCzech Rep. / Slovakia (ITC)Switzerland (SVGW)Austria (OVGW)Slovenia(several approvals)Italy (IIP)Hong Kong(HK WSD, HKCG)India(several approvals)Argentina (IGA) Australia / New ZealandIran (NIGC)(PIPA)ChileEgypt (several approvals)IndonesiaBrazil (CEG, COMGAS, SABESP)Nigeria (several approvals)Turkey (several approvals)(several approvals)Singapore(PUB, Powergas)ColombiaTunisia (several approvals)MalaysiaPeruAlgeria (several approvals)(several approvals)EquatorMorocco (several approvals)VietnamSpain (AENOR, Gas Natural)(several approvals)Mexico (PPI, several approvals)Portugal (Gas de Portugal)

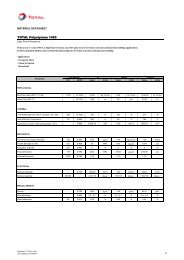

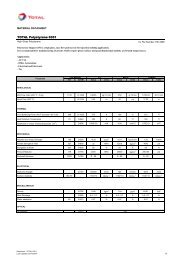

Medium and High Density <strong>Polyethylene</strong> (MDPE and HDPE) <strong>for</strong> pressure <strong>pipe</strong>s and fittingsGradeDensity*g/cm 3Melt fl ow rate5 kg - 190°Cg/10 minMinimumRequiredStrengthMPaFlexuralmodulusMPaMain propertiesTensile strength(50 mm/min),MPa at yieldTensile strength(50 mm/min),MPa at breakCompounddesignationISO 1183 ISO 1133/T ISO 9080 ISO 178 ISO 527 ISO 527 ISO 12162XRC 20 B 0.958 0.3 10.0 1050 25 35 PE 100 blackXSC 50 Blue 0.950 0.3 10.0 1050 25 35 PE 100 blueXSC 50 Orange 0.950 0.3 10.0 1050 25 35 PE 100 orangeXS 10 B 0.959 0.3 10.0 1100 26 35 PE 100 blackXS 10 Orange YCF 0.950 0.3 10.0 1100 26 35 PE 100 orange yellowXS 10 H 0.950 0.3 10.0 1100 26 35 PE 100 dark blueColourPE 100 RC <strong>for</strong>non-conventional<strong>pipe</strong> installation•••Typical applications(according to local standards)Gas••••Potable water••••Sewage••Industrialapplications••Thick wall <strong>pipe</strong>swww.enterprise-communication.be 03-2009 H7558XLS 12 B 0.959 0.2 10.0 1100 26 35 PE 100 black•3802 B 0.948 0.9 8.0 700 18 32 PE 80 black••3802 YCF 0.940 0.9 8.0 700 18 32 PE 80 yellow•* density of coloured compoundMedium and High Density <strong>Polyethylene</strong> (MDPE and HDPE) <strong>for</strong> stripe compoundsGrade Blue stripes Yellow stripes Orange stripes Brown stripesXS 10 B, XRC 20 B XS 10 H XS 10 YS XS 10 OS XS 10 BRS3802 B 3802 Blue LF 38 YS CF - -Medium and High Density <strong>Polyethylene</strong> (MDPE and HDPE) <strong>for</strong> PEX piping <strong>systems</strong>Grade Density Melt fl ow rate Application, processM 4040 0.940 4.0 (MI 2) PEX-b, silaneAll above mentioned grades comply with the regulations of most countries governing the contact of plastics with foodstuffs.Individual certificates can be obtained from <strong>Total</strong> Petrochemicals Research Feluy.In<strong>for</strong>mation contained in this publication is true and accurate at the time of publication and to the best of our knowledge. The nominal valuesstated herein are obtained using laboratory test specimens. Be<strong>for</strong>e using one of the products mentioned herein, customers and other usersshould take all care in determining the suitability of such product <strong>for</strong> the intended use. Unless specifically indicated, the products mentionedherein are not suitable <strong>for</strong> applications in the pharmaceutical or medical sector.The Companies within <strong>Total</strong> Petrochemicals do not accept any liability whatsoever arising from the use of this in<strong>for</strong>mation or the use, applicationor processing of any product described herein. No in<strong>for</strong>mation contained in this publication can be considered as a suggestion to infringe patents.The Companies disclaim any liability that may be claimed <strong>for</strong> infringement or alleged infringement of patents.

Medium and High Density <strong>Polyethylene</strong> (MDPE and HDPE) <strong>for</strong> non-pressure piping <strong>systems</strong>GradeDensity*g/cm 3Melt fl ow rate21.6 kg - 190°Cg/10 minMain propertiesFlexuralmodulusMPaISO 1183 ISO 1133/G ISO 1782008 SN 60 0.961 52 1400 naturalBM 593 0.959 26 1350 natural5802 0.957 22 1300 natural5503 0.954 27 1200 naturalHR 515 0.942 17,5 810 natural3802 0.938 18 700 naturalColourTypical applicationsTwin wall /corrugated /structured wall<strong>pipe</strong>••••Optical fi breconduit•••www.entercom.be 04-2009 H7579All above mentioned grades comply with the regulations of most countries governing the contact of plastics with foodstuffs.Individual certificates can be obtained from <strong>Total</strong> Petrochemicals Research Feluy.In<strong>for</strong>mation contained in this publication is true and accurate at the time of publication and to the best of our knowledge. The nominal valuesstated herein are obtained using laboratory test specimens. Be<strong>for</strong>e using one of the products mentioned herein, customers and other usersshould take all care in determining the suitability of such product <strong>for</strong> the intended use. Unless specifically indicated, the products mentionedherein are not suitable <strong>for</strong> applications in the pharmaceutical or medical sector.The Companies within <strong>Total</strong> Petrochemicals do not accept any liability whatsoever arising from the use of this in<strong>for</strong>mation or the use, applicationor processing of any product described herein. No in<strong>for</strong>mation contained in this publication can be considered as a suggestion to infringe patents.The Companies disclaim any liability that may be claimed <strong>for</strong> infringement or alleged infringement of patents.

Architecte: Samyn Partners & Co<strong>Total</strong> Petrochemicals Research FeluyBelgium

<strong>Polyethylene</strong> compounds <strong>for</strong> <strong>pipe</strong> <strong>systems</strong>Product range <strong>for</strong> <strong>pipe</strong>s and fittings> PE80 : yellow, black> PE100 : orange, blue, black> PE100 : compounds with extreme resistance against crack initiation and slow crack growth.> PE100 : black compound <strong>for</strong> thick wall pressure <strong>pipe</strong>s (low sag material).InnovationBecause innovation never comes alone, <strong>Total</strong>Petrochemicals always works alongside the importantplayers in the <strong>pipe</strong> industry.<strong>Total</strong> Petrochemicals’ research centers, with theirexpertise in the development of catalysts, polymersand processes, offer innovative, practical and costeffectivesolutions.Some of the key milestones achieved together with ourcustomers, are :1974, fi rst to offer hexene based MDPE PE80.1989, fi rst to offer Cadmium-free yellow compound.1997, fi rst to offer hexene based PE100.2001, fi rst to offer PE100 Super Slow Crack Growthresistant <strong>pipe</strong> compounds.2006, production of best-of-class low sag PE100,specifi cally developed <strong>for</strong> very large diameter<strong>pipe</strong>s.

<strong>Total</strong> Petrochemicalsa Petrochemicals World MajorThe world’s fi fth largest petrochemicals producer, <strong>Total</strong> Petrochemicals consolidatesthe petrochemicals activities of the <strong>Total</strong> Group : base chemicals and their relatedpolymers (polyethylene, polypropylene and polystyrene).With over 7,000 employees, <strong>Total</strong> Petrochemicals conducts its operations in Europe,the United States, the Middle East and Asia. Its products serve a vast number ofconsumer and industrial markets, including packaging, construction and automotive.As part of the <strong>Total</strong> Group, <strong>Total</strong> Petrochemicals draws on strong synergies with itsrefi ning activity, particularly in Europe and the United States, as well as with its explorationand production activity, in particular in the Middle East where the Companyis now a major ethylene producer using ethane feedstock.Marketing and SalesTOTAL PETROCHEMICALSa division of sa PetroFina nvrue de l’Industrie, 52, NijverheidsstraatB-1040 Brussels - BelgiumPhone : +32 (0) 2 288 94 53Fax : +32 (0) 2 288 35 36Research and DevelopmentTOTAL PETROCHEMICALS RESEARCH FELUY saZone Industrielle CB-7181 Feluy - BelgiumPhone : +32 (0) 2 288 40 05Fax : +32 (0) 2 288 46 60Technical AssistanceTOTAL PETROCHEMICALS RESEARCH FELUY saZone Industrielle CB-7181 Feluy - BelgiumPhone : +32 (0) 2 288 40 05Fax : +32 (0) 2 288 46 60) : polyethylene@total.com: : www.totalpetrochemicals.comwww.enterprise-communication.be : 10-2007 H7066 Photo Collection <strong>Total</strong> Petrochemicals/Paul Coerten/Enterprise Communication